Algae-based carbons: Design, preparation and recent advances in their use in energy storage, catalysis and adsorption

-

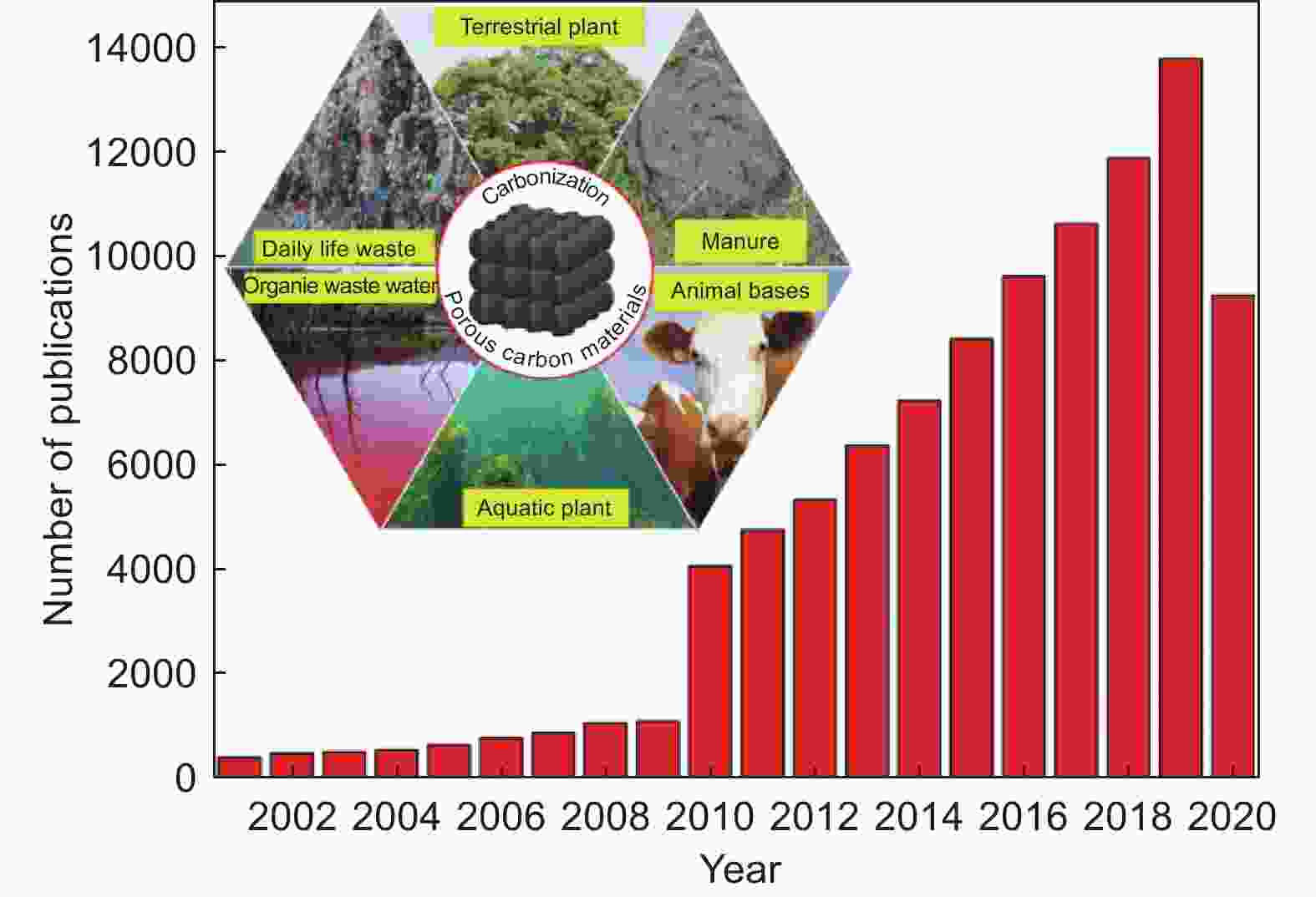

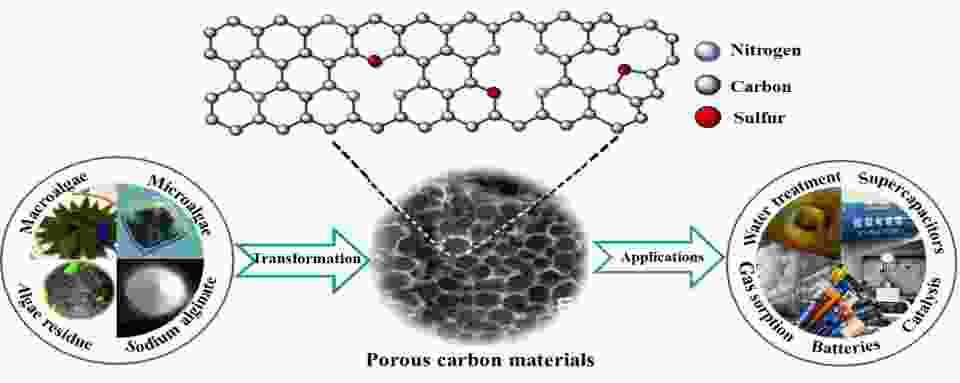

摘要: 能源危机和环境恶化是人类社会面临的两大难题。多孔炭材料因孔隙发达、结构易调和化学性质稳定等特点在能源存储和生态环境治理等领域具有重要作用,其应用性能高度依赖碳源的选择及其合成方法和条件优化。生物质富含有机碳元素且具有成本低、可再生等优点,以生物质为碳源构建多孔炭材料符合绿色化学理念、具备实现大规模工业化应用前景,特别是藻类生物质因富含杂原子纤维组分被认为是构建杂原子掺杂多孔炭材料的优良前驱体。通过有效调控合成方法和工艺过程,设计具有孔径结构和表面化学性质可控的藻类生物炭材料并在能源存储和生态环境治理等应用领域表现出优异性能,有效实现能源资源与生态环境和谐共存,特别是有研究报道海带基多孔炭的比表面积高达4000 m2/g。本文系统评述了藻类生物炭材料的制备方法及其孔径结构形成机理,并着重介绍这类多孔炭材料在电化学储能和吸附等方面的研究进展及其性能调控策略。提出藻类生物质衍生多孔炭材料面临的新趋势与挑战,并对未来开发低成本、高效率的高性能生物质基多孔炭材料的探索方向进行了展望。Abstract: Porous carbons with well-developed pores, tunable microstructures and stable chemistry play a significant role in energy storage and environmental pollution control. Biomass is a carbon precursor that is abundant, low cost, sustainable and carbon neutral, and is promising for the large-scale production of porous carbons. Among the various types of biomass, algae usually contain abundant cellulose and heteroatoms, which are suitable precursors for heteroatom-doped carbons. Recent advances in synthesis methods for algae-based porous carbons are reviewed and their pore formation mechanisms discussed. Their potential applications in adsorption, catalysis and energy storage are highlighted, and strategies for improving their performance are proposed. Future research trends and challenges for algae-based carbons are discussed, especially as they relate to their low-cost production and performance improvement.

-

Key words:

- Algae biomass /

- Porous carbons /

- Green chemistry /

- Energy storage /

- Adsorption

-

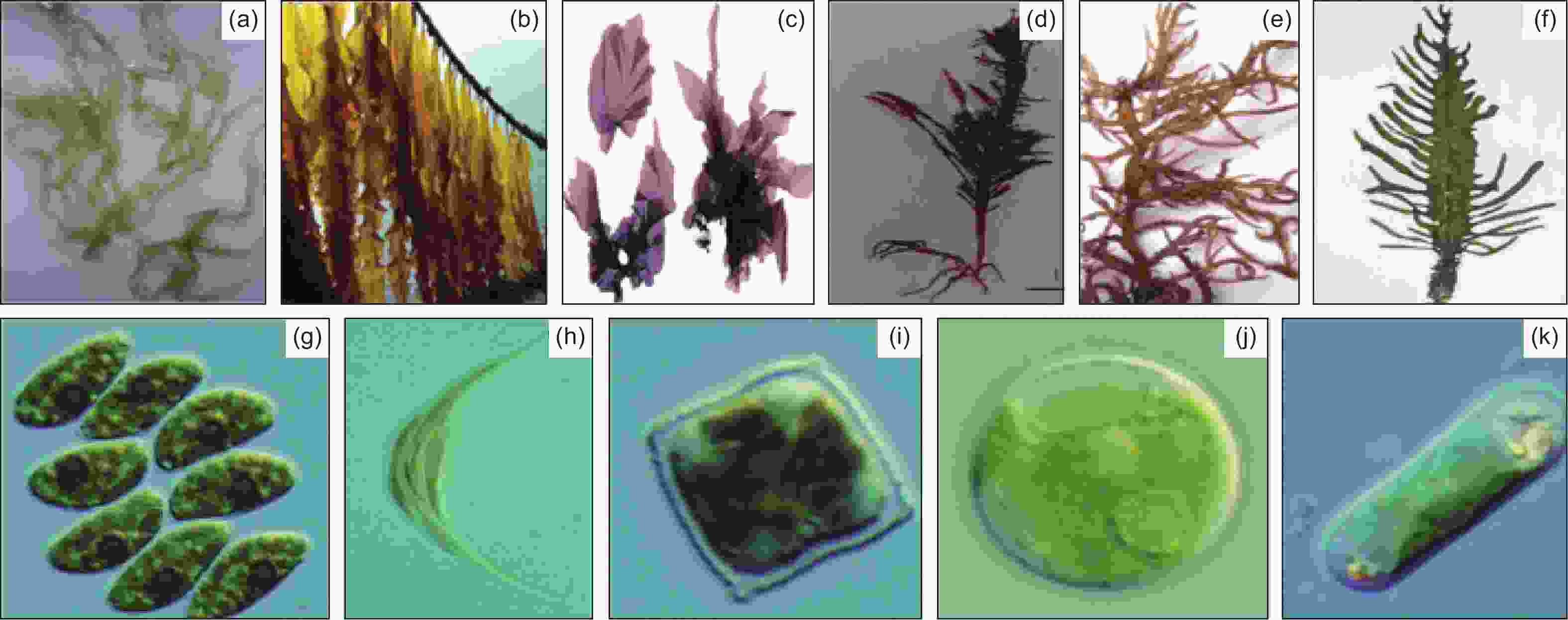

Figure 2. Top represents photos for typical macroalgae (a, prolifera; b, kelp; c, laver; d, gelidium; e, hypnea; and f, undaria), and Bottom represents micrographs of several types of microalgae (g, scenedesmus obliquus; h, ankistrodesmus sp.; i, tetraedron sp.; j, chlorella sp.; and k, mesotaenium sp.)

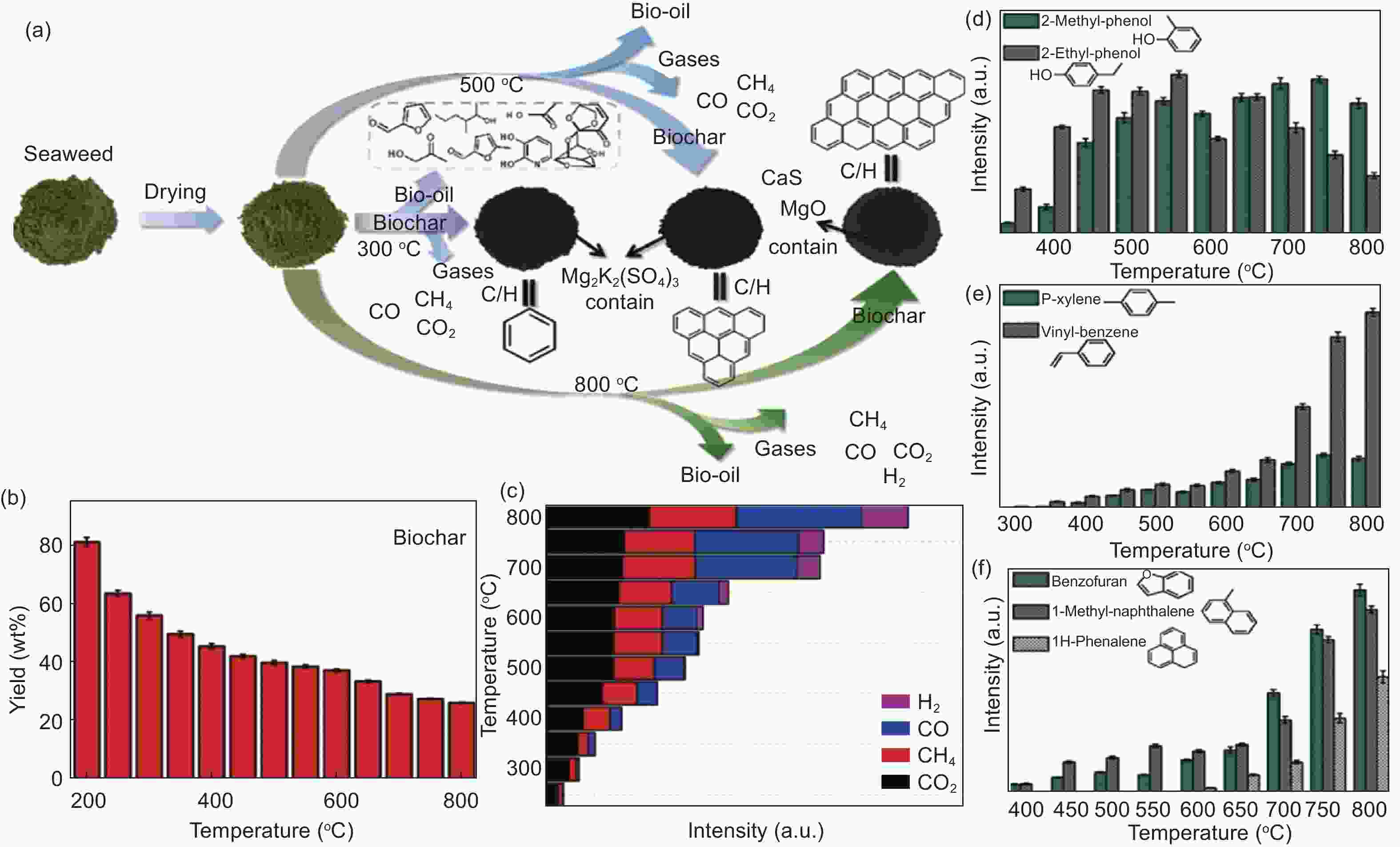

Figure 3. (a) Thermal decomposition of seaweeds to produce carbons, (b) yields of biochar, (c) gas compositions under different temperatures and (d-f) the normalized distribution of typical phenolics and N-containing organics in bio-oil produced from carbonization of seaweeds. Reproduced with permission from ref.[54]. Copyright 2020 Elsevier.

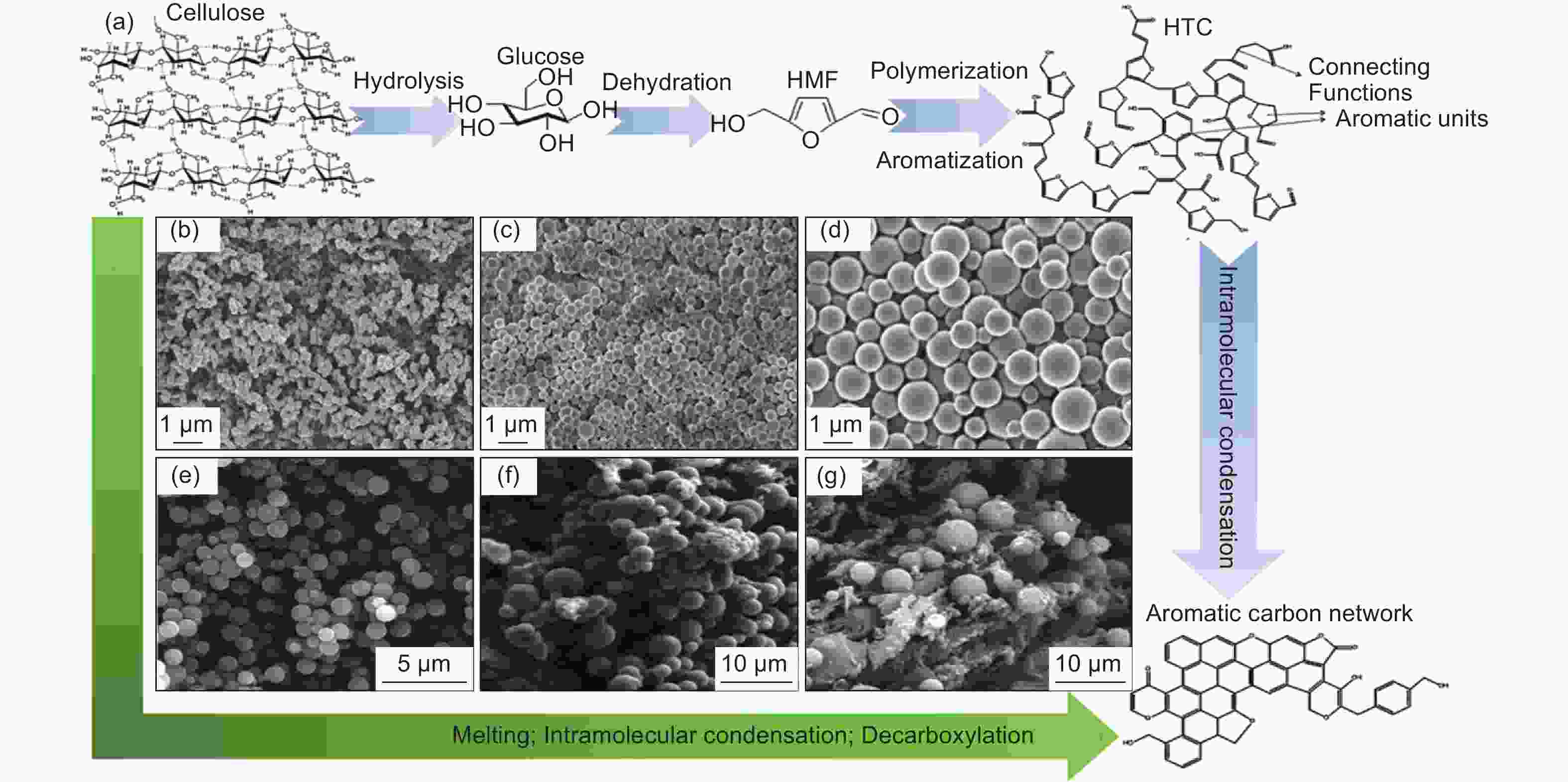

Figure 4. (a) Possible mechanism for HTC fromation from cellulose, SEM images of HTCs from (b) fructose, (c) xylose, and (d) furfural (Reproduced with permission from ref.[58]. Copyright 2012 RSC), and SEM images of HTCs from (e) starch, (f) cellulose and (g) sawdust.Reproduced with permission from ref.[61]. Copyright 2011 RSC.

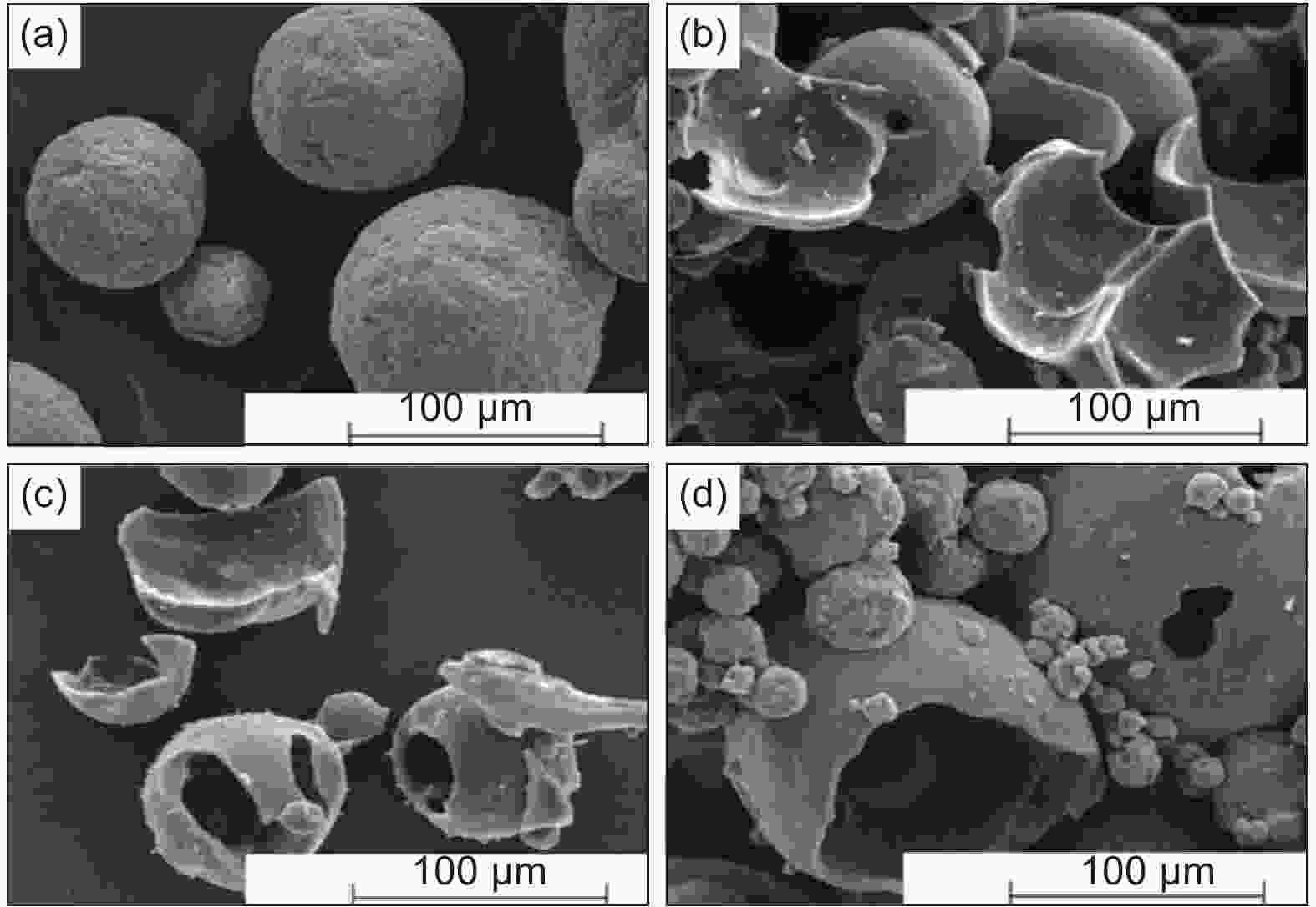

Figure 5. (a) SEM images of AR material and carbons from carbonization and CO2 etching with increasing holding time: (b) 20, (c) 40, and (d) 60 min. Reproduced with permission from ref.[70]. Copyright 2015 Elsevier.

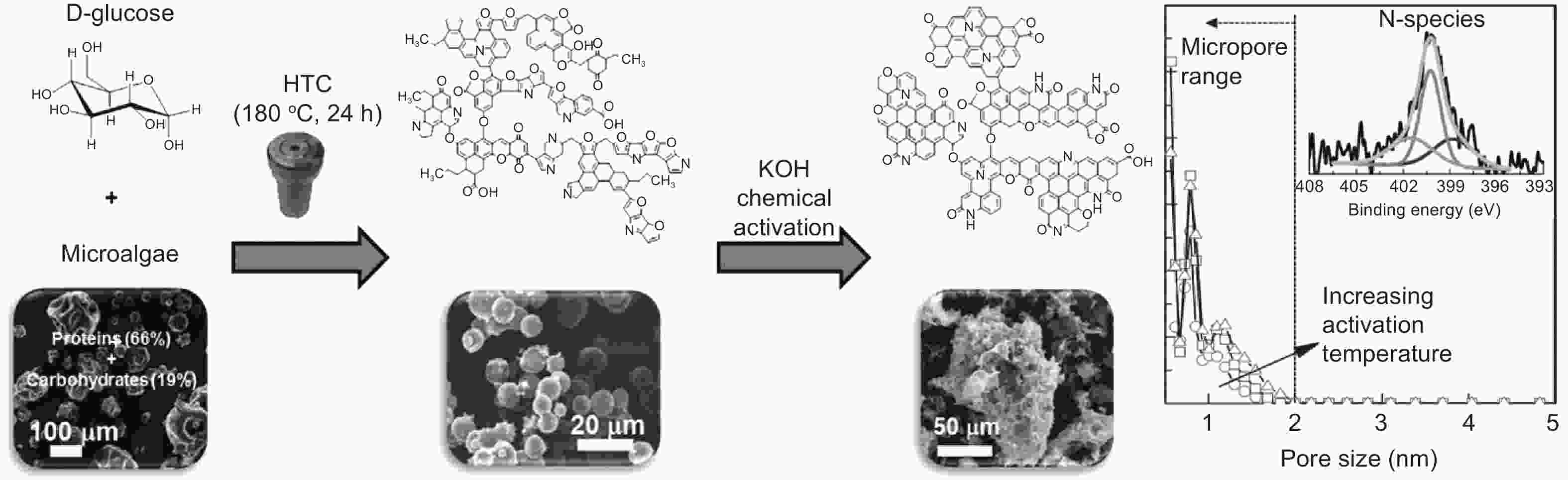

Figure 6. Schematic of N-doped carbon production from a mixture of microalgae and glucose, XPS results of N-species, and pore size distributions (PSDs) of carbons with various activation temperatures. Reproduced with permission from ref.[77]. Copyright 2014 Elsevier.

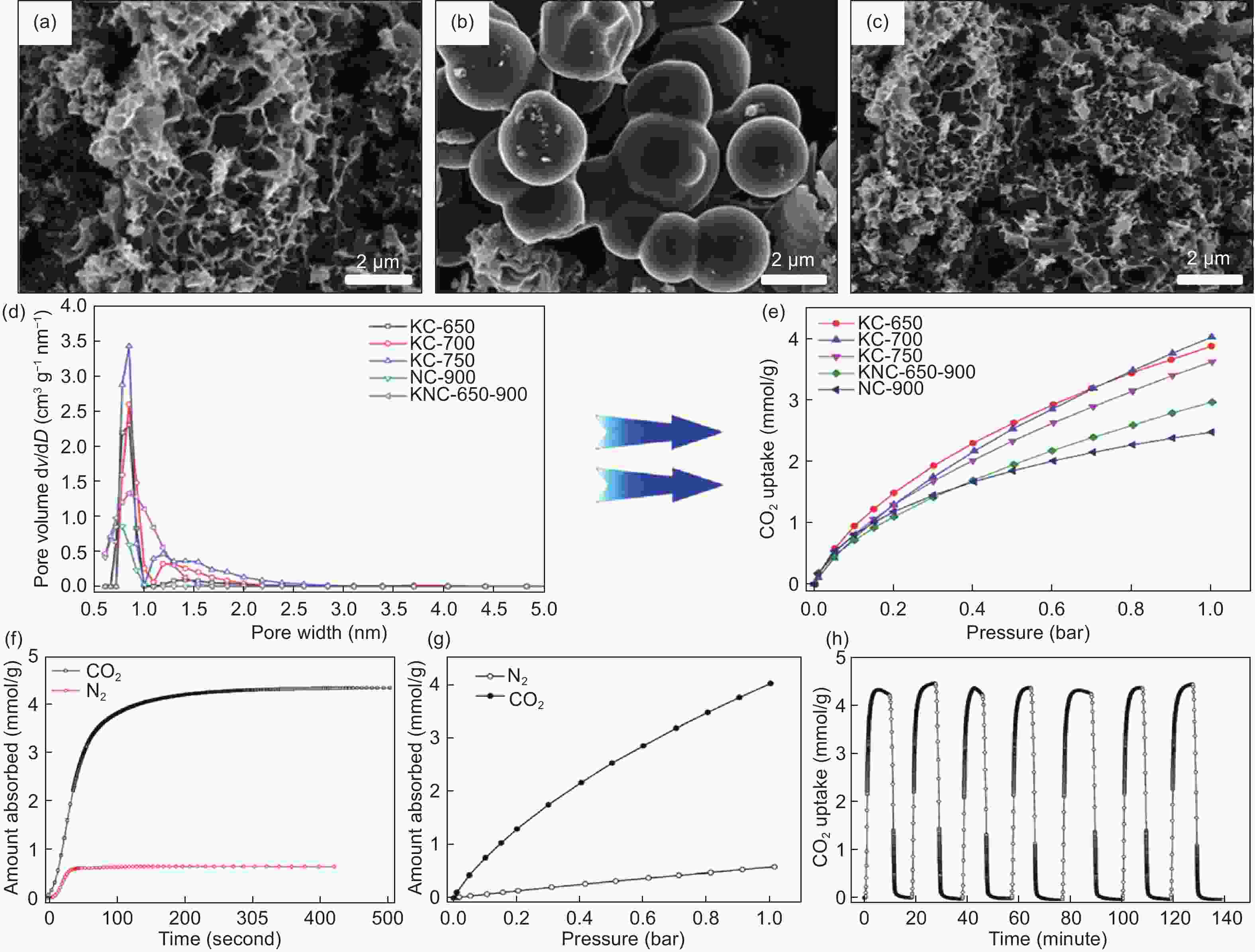

Figure 7. SEM images of carbons: (a) KC-700, (b) NC-900, and (c) KNC-650-900 using Chlorococcum sp. as a precursor, (d) PSDs of carbons, (e) CO2 uptake at 25 °C and 1 bar, (f) kinetics and (g) isotherms of CO2 and N2 for KC-700 at 25 °C up to 1 bar and (h) CO2 adsorption/desorption cycles for KC-700. Reproduced with permission from ref.[83]. Copyright 2016 RSC.

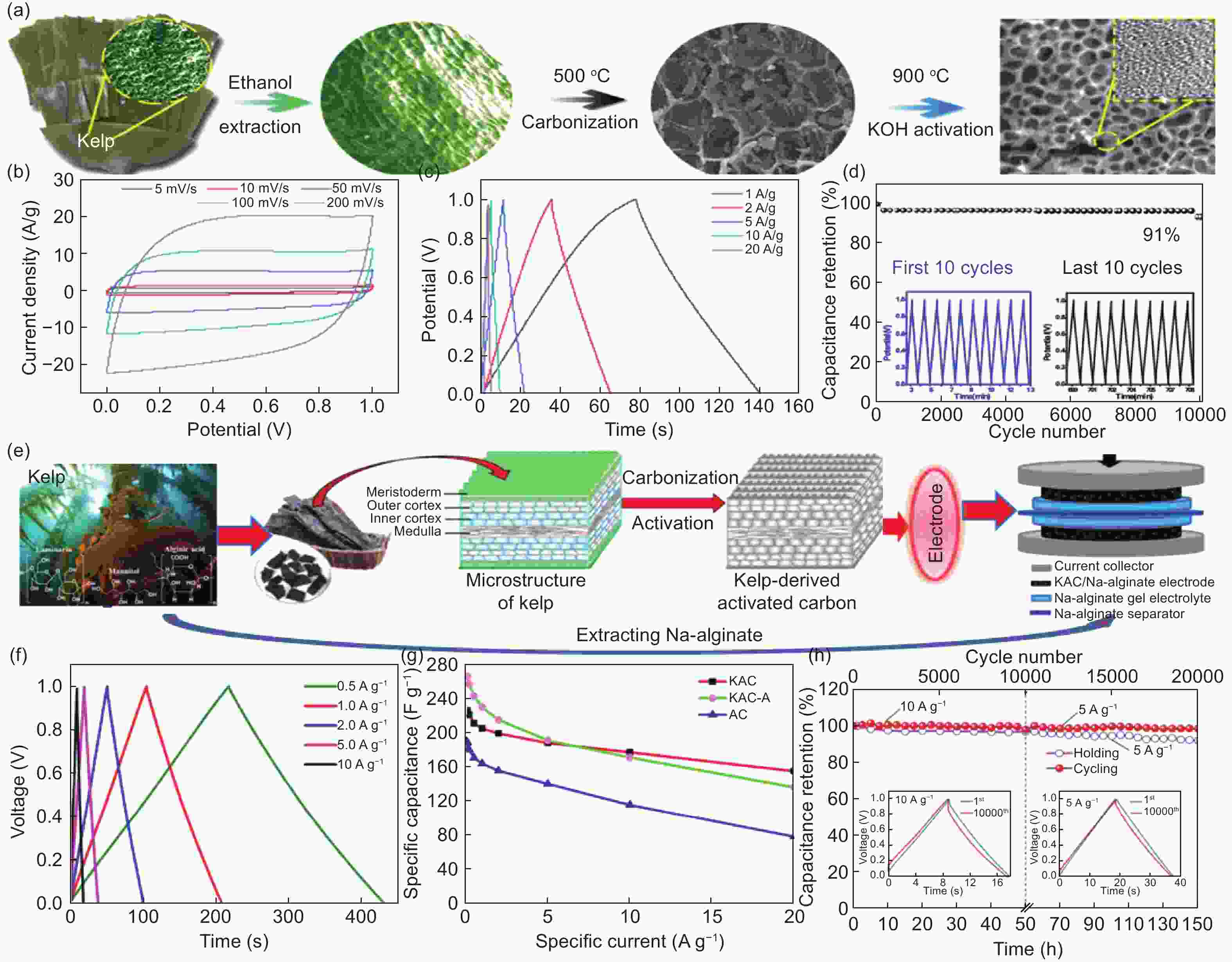

Figure 8. (a) Scheme for kelp carbons, (b-d) CV and GCD curves, and cycling of a symmetric cell in 6 mol L−1KOH (Reproduced with permission from ref.[98]. Copyright 2019 ACS), (e) scheme for a ‘all-kelp’ solid-state cell, (f) GCD curves, (g) capacitance variation, and (h) cycling and constant voltage hold test. Inset was GCD curve of the first and 10 000th cycles. The performance in 1 mol L−1 H2SO4 (KAC-A) was also tested. Reproduced with permission from ref.[101]. Copyright 2017 RSC.

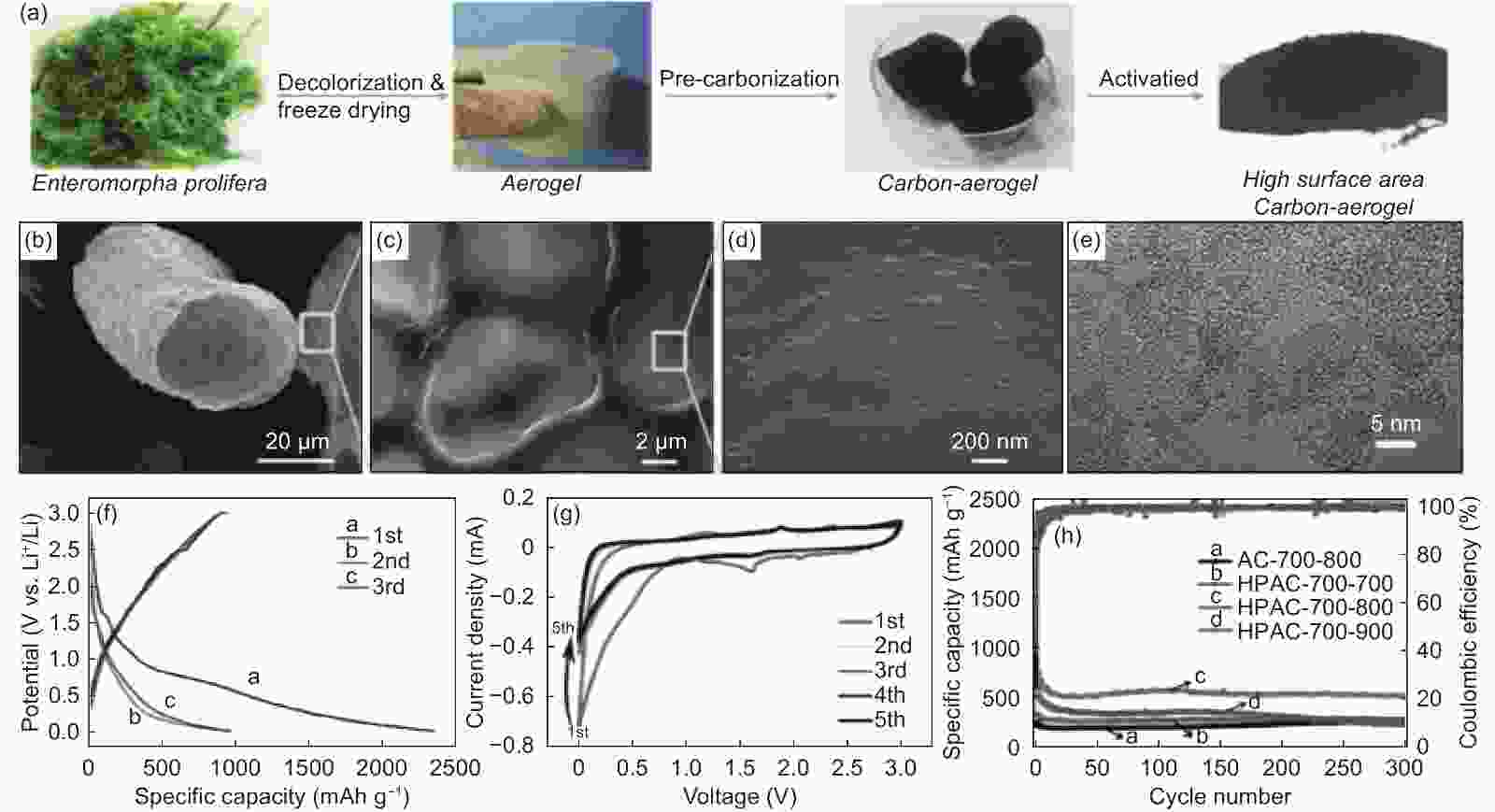

Figure 9. (a) Scheme for carbon aerogels, (b-e) SEM and TEM images of HPCA-700-800, (f) GCD curves at 0.1 A g−1 up to 3.0 V (vs. Li+/Li), (g) CV curves at 0.1 mV/s and (h) stability and Coulombic efficiency of carbons at 0.5 A g−1. Reproduced with permission from ref.[95]. Copyright 2016 WILEY-VCH Verlag GmbH & Co. KGaA.

Figure 10. (a) Scheme for S-doped carbons, (b) N2 isotherms, (c-e) SEM images and EDS mapping for C, O and S, (f) CV curves of S/HPSCA-400 at 0.1 mV s−1 between 1.7−2.8 V (vs. Li+/Li), (g) GCD profiles and (h) cycling performance and Coulombic efficiency at 1 C rate, (1 C=1675 mAh g−1). Reproduced with permission from ref.[73]. Copyright 2019 Elsevier.

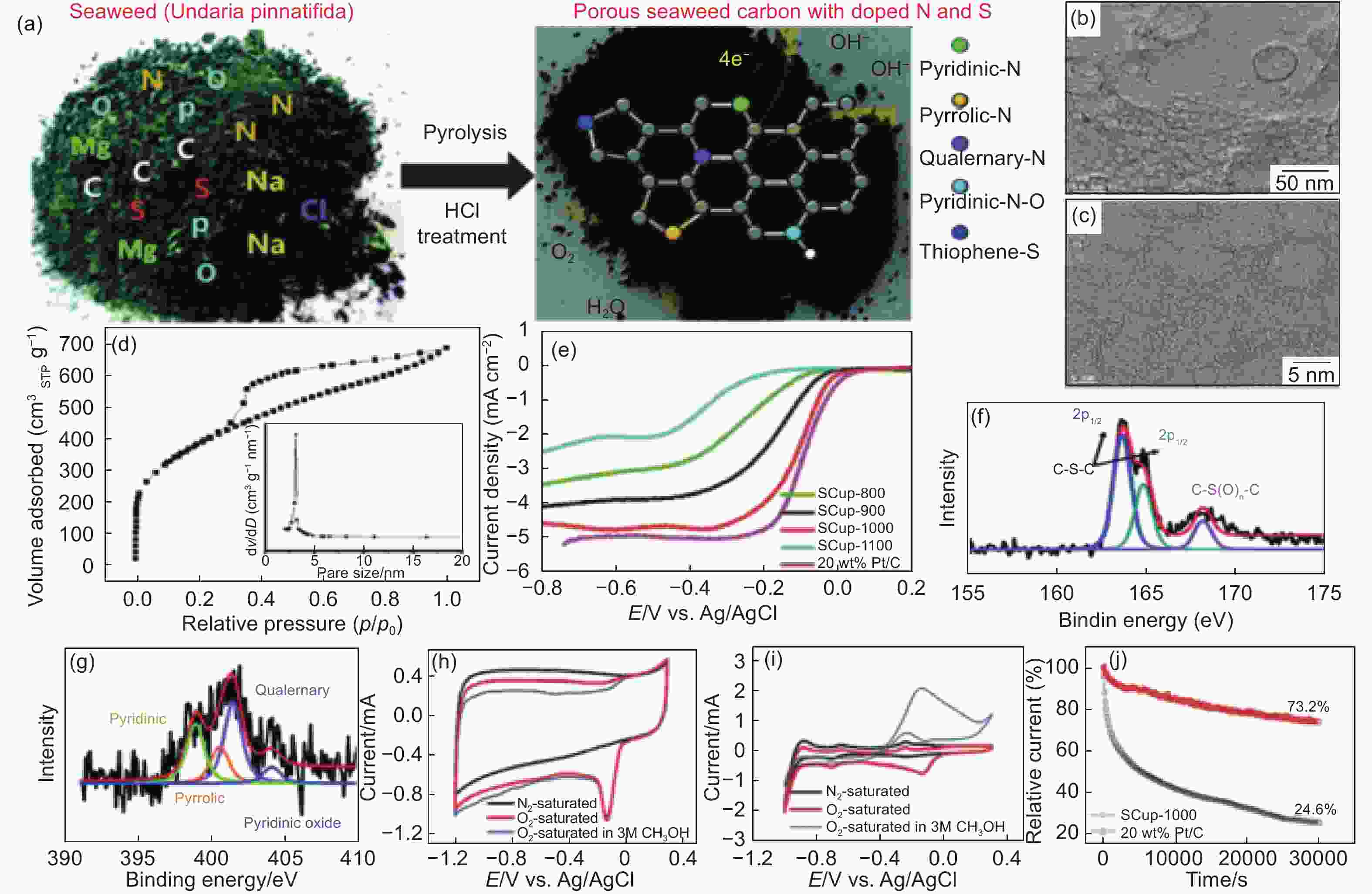

Figure 11. (a) Scheme for a N, S-doped carbon from Undaria pinnatifida, (b, c) TEM images for the carbon carbonized at 1000 °C, (d) N2 isotherms, (e) LSV curves at 1600 r min−1 and 10 mV s−1, (f, g) XPS for S, N-species, (h, i) CV curves at 50 mV s−1 in 0.1 mol L−1 KOH and (j) durability performance at ORR peak potential in the O2-saturated 0.1 mol L−1 KOH at 1600 r min−1. Reproduced with permission from ref.[50]. Copyright 2014 Wiley-VCH Verlag GmbH & Co. KGaA.

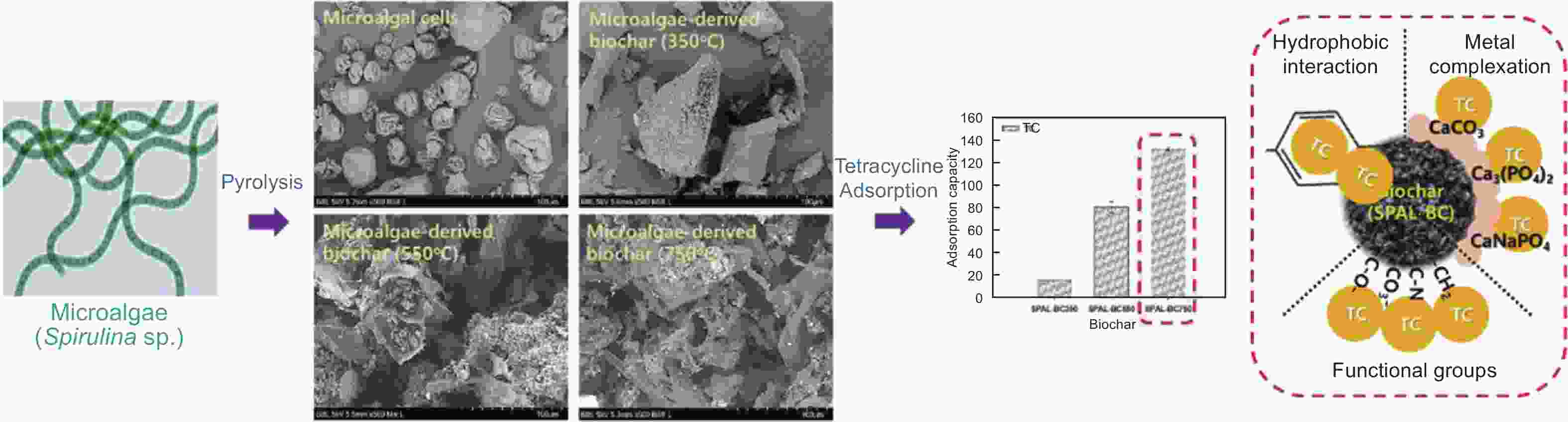

Figure 12. Scheme of carbons from direct carbonization of Spirulina sp.and SEM images for carbons obtained at various temperatures and possible mechanism for tetracycline removal. Reproduced with permission from ref.[119]. Copyright 2020 Elsevier.

Table 1. Different conditions for the carbonization of biomass and their effects on the yield of solid carbons. Reproduced with permission from ref.[4] Copyright 2020 Elsevier.

Types of carbonization Temperature (°C) Heating rate

(°C min−1)Yields of solid carbons (%) Slow 300−800 <10 ~30−35 Fast 400−600 >10 ~10−12 Flash <650 ~1000 ~10 Gasification 700-1500 ~1000 ~10 -

[1] Alatalo S M, Pileidis F, Mäkilä E, et al. Versatile cellulose-based carbon aerogel for the removal of both cationic and anionic metal contaminants from water[J]. ACS Applied Materials & Interfaces,2015,7(46):25875-25883. [2] Seo D K, Lee S K, Kang M W, et al. Gasification reactivity of biomass chars with CO2[J]. Biomass and Bioenergy,2010,34(12):1946-1953. doi: 10.1016/j.biombioe.2010.08.008 [3] Yan M, Hantoko D, Susanto H, et al. Hydrothermal treatment of empty fruit bunch and its pyrolysis characteristics[J]. Biomass Conversion and Biorefinery,2019,9(4):709-717. doi: 10.1007/s13399-019-00382-9 [4] Li Z J, Guo D F, Liu Y Y, et al. Recent advances and challenges in biomass-derived porous carbon nanomaterials for supercapacitors[J]. Chemical Engineering Journal,2020,397:125418. doi: 10.1016/j.cej.2020.125418 [5] Huang G G, Wang Y, Zhang T Y, et al. High-performance hierarchical N-doped porous carbons from hydrothermally carbonized bamboo shoot shells for symmetric supercapacitors[J]. Journal of the Taiwan Institute of Chemical Engineers,2019,96:672-680. doi: 10.1016/j.jtice.2018.12.024 [6] Wang Y X, Tian W, Wang L H, et al. A tunable molten-salt route for scalable synthesis of ultrathin amorphous carbon nanosheets as high-performance anode materials for lithium-ion batteries[J]. ACS Applied Materials & Interfaces,2018,10(6):5577-5585. [7] Zhao C, Li Y H, He Z X, et al. KHCO3 activated carbon microsphere as excellent electrocatalyst for VO2+/VO2+ redox couple for vanadium redox flow battery[J]. Journal of Energy Chemistry,2019,29:103-110. doi: 10.1016/j.jechem.2018.02.006 [8] Guo C Z, Hu R, Liao W L, et al. Protein-enriched fish “biowaste” converted to three-dimensional porous carbon nano-network for advanced oxygen reduction electrocatalysis[J]. Electrochimica Acta,2017,236:228-238. doi: 10.1016/j.electacta.2017.03.169 [9] Escobar B, Pérez-Salcedo K Y, Alonso-Lemus I L, et al. N-doped porous carbon from Sargassum spp. as metal-free electrocatalysts for oxygen reduction reaction in alkaline media[J]. International Journal of Hydrogen Energy,2017,42(51):30274-30283. doi: 10.1016/j.ijhydene.2017.06.240 [10] Wang J, Wang Y L, Hu H B, et al. From metal-organic frameworks to porous carbon materials: Recent progress and prospects from energy and environmental perspectives[J]. Nanoscale,2020,12(7):4238-4268. doi: 10.1039/C9NR09697C [11] D'Alessandro D M, Smit B, Long J R. Carbon dioxide capture: Prospects for new materials[J]. Angewandte Chemie International Edition,2010,49(35):6058-6082. doi: 10.1002/anie.201000431 [12] Deng J, Li M M, Wang Y. Biomass-derived carbon: Synthesis and applications in energy storage and conversion[J]. Green Chemistry,2016,18(18):4824-4854. doi: 10.1039/C6GC01172A [13] Li L C, Zou D S, Xiao Z H, et al. Biochar as a sorbent for emerging contaminants enables improvements in waste management and sustainable resource use[J]. Journal of Cleaner Production,2019,210:1324-1342. doi: 10.1016/j.jclepro.2018.11.087 [14] Huang G G, Liu Y F, Wu X X, et al. Activated carbons prepared by the KOH activation of a hydrochar from garlic peel and their CO2 adsorption performance[J]. New Carbon Materials,2019,34(3):247-257. doi: 10.1016/S1872-5805(19)60014-4 [15] Huang G G, Wu X X, Hou Y R, et al. Sustainable porous carbons from garlic peel biowaste and KOH activation with an excellent CO2 adsorption performance[J]. Biomass Conversion and Biorefinery,2020,10(2):267-276. doi: 10.1007/s13399-019-00412-6 [16] Lin L, Zhai S R, Xiao Z Y, et al. Dye adsorption of mesoporous activated carbons produced from NaOH-pretreated rice husks[J]. Bioresource Technology,2013,136:437-443. doi: 10.1016/j.biortech.2013.03.048 [17] Wu Z C, Tian K, Huang T, et al. Hierarchically porous carbons derived from biomasses with excellent microwave absorption performance[J]. ACS Applied Materials & Interfaces,2018,10(13):11108-11115. [18] Karnan M, Subramani K, Sudhan N, et al. Aloe vera derived activated high-surface-area carbon for flexible and high-energy supercapacitors[J]. ACS Applied Materials & Interfaces,2016,8(51):35191-35202. [19] Li B, Dai F, Xiao Q F, et al. Nitrogen-doped activated carbon for a high energy hybrid supercapacitor[J]. Energy & Environmental Science,2016,9(1):102-106. [20] Zhang C Y, Zhu X H, Cao M, et al. Hierarchical porous carbon materials derived from sheep manure for high-capacity supercapacitors[J]. ChemSusChem,2016,9(9):932-937. doi: 10.1002/cssc.201501624 [21] Wu X X, Zhang C Y, Tian Z W, et al. Large-surface-area carbons derived from lotus stem waste for efficient CO2 capture[J]. New Carbon Materials,2018,33(3):252-261. doi: 10.1016/S1872-5805(18)60338-5 [22] Singh S, Kumar V, Dhanjal D S, et al. A sustainable paradigm of sewage sludge biochar: Valorization, opportunities, challenges and future prospects[J]. Journal of Cleaner Production,2020,269:122259. doi: 10.1016/j.jclepro.2020.122259 [23] Luo H Y, Chen M X, Cao J H, et al. Cocoon silk-derived, hierarchically porous carbon as anode for highly robust potassium-ion hybrid capacitors[J]. Nano-Micro Letters,2020,12(1):113. doi: 10.1007/s40820-020-00454-w [24] Li Y Y, Wang L, Gao B, et al. Hierarchical porous carbon materials derived from self-template bamboo leaves for lithium-sulfur batteries[J]. Electrochimica Acta,2017,229:352-360. doi: 10.1016/j.electacta.2017.01.166 [25] Zhang Y, Liu S S, Zheng X Y, et al. Biomass organs control the porosity of their pyrolyzed carbon[J]. Advanced Functional Materials,2017,27(3):1604687. doi: 10.1002/adfm.201604687 [26] Hou Y R, Yan S N, Huang G G, et al. Fabrication of N-doped carbons from waste bamboo shoot shell with high removal efficiency of organic dyes from water[J]. Bioresource Technology,2020,303:122939. doi: 10.1016/j.biortech.2020.122939 [27] Hou Y R, Huang G G, Li J H, et al. Hydrothermal conversion of bamboo shoot shell to biochar: Preliminary studies of adsorption equilibrium and kinetics for rhodamine B removal[J]. Journal of Analytical and Applied Pyrolysis,2019,143:104694. doi: 10.1016/j.jaap.2019.104694 [28] Lu L, Yu W T, Wang Y F, et al. Application of biochar-based materials in environmental remediation: From multi-level structures to specific devices[J]. Biochar,2020,2(1):1-31. doi: 10.1007/s42773-020-00041-7 [29] Amiri R, Ahmadi M. Treatment of wastewater in sewer by Spirogyra sp. green algae: Effects of light and carbon sources[J]. Water and Environment Journal,2020,34(3):311-321. doi: 10.1111/wej.12463 [30] Suganya T, Varman M, Masjuki H H, et al. Macroalgae and microalgae as a potential source for commercial applications along with biofuels production: A biorefinery approach[J]. Renewable and Sustainable Energy Reviews,2016,55:909-941. doi: 10.1016/j.rser.2015.11.026 [31] Raymundo-Piñero E, Leroux F, Béguin F. A high-performance carbon for supercapacitors obtained by carbonization of a seaweed biopolymer[J]. Advanced Materials,2006,18(14):1877-1882. doi: 10.1002/adma.200501905 [32] Wei Q L, Chen Z M, Wang X F, et al. A two-step method for the preparation of high performance corncob-based activated carbons as supercapacitor electrodes using ammonium chloride as a pore forming additive[J]. New Carbon Materials,2018,33(5):402-408. doi: 10.1016/S1872-5805(18)60348-8 [33] Jin H L, Feng X, Li J, et al. Heteroatom-doped porous carbon materials with unprecedented high volumetric capacitive performance[J]. Angewandte Chemie International Edition,2019,58(8):2397-2401. doi: 10.1002/anie.201813686 [34] Ren X M, Li H, Chen J, et al. N-doped porous carbons with exceptionally high CO2 selectivity for CO2 capture[J]. Carbon,2017,114:473-481. doi: 10.1016/j.carbon.2016.12.056 [35] Pandey D, Daverey A, Arunachalam K. Biochar: Production, properties and emerging role as a support for enzyme immobilization[J]. Journal of Cleaner Production,2020,255:120267. doi: 10.1016/j.jclepro.2020.120267 [36] Yang H, Ye S W, Zhou J M, et al. Biomass-derived porous carbon materials for supercapacitor[J]. Frontiers in Chemistry,2019,7(274):1-17. [37] Chen Q, Tan X F, Liu Y G, et al. Biomass-derived porous graphitic carbon materials for energy and environmental applications[J]. Journal of Materials Chemistry A,2020,8(12):5773-5811. doi: 10.1039/C9TA11618D [38] Chen Y D, Liu F Y, Ren N Q, et al. Revolutions in algal biochar for different applications: State-of-the-art techniques and future scenarios[J]. Chinese Chemical Letters,2020,30(10):2591-2602. [39] Chen C Y, Yeh K L, Aisyah R, et al. Cultivation, photobioreactor design and harvesting of microalgae for biodiesel production: A critical review[J]. Bioresource Technology,2011,102(1):71-81. doi: 10.1016/j.biortech.2010.06.159 [40] Ullah K, Ahmad M, Sofia, et al. Assessing the potential of algal biomass opportunities for bioenergy industry: A review[J]. Fuel,2015,143:414-423. doi: 10.1016/j.fuel.2014.10.064 [41] Brennan L, Owende P. Biofuels from microalgae-A review of technologies for production, processing, and extractions of biofuels and co-products[J]. Renewable and Sustainable Energy Reviews,2010,14(2):557-577. doi: 10.1016/j.rser.2009.10.009 [42] Bharathiraja B, Chakravarthy M, Ranjith Kumar R, et al. Aquatic biomass (algae) as a future feed stock for bio-refineries: A review on cultivation, processing and products[J]. Renewable and Sustainable Energy Reviews,2015,47:634-653. doi: 10.1016/j.rser.2015.03.047 [43] Vassilev S V, Vassileva C G. Composition, properties and challenges of algae biomass for biofuel application: An overview[J]. Fuel,2016,181:1-33. doi: 10.1016/j.fuel.2016.04.106 [44] Bird M I, Wurster C M, De Paula Silva P H, et al. Algal biochar-production and properties[J]. Bioresource Technology,2011,102(2):1886-1891. doi: 10.1016/j.biortech.2010.07.106 [45] Parmar A, Singh N K, Pandey A, et al. Cyanobacteria and microalgae: A positive prospect for biofuels[J]. Bioresource Technology,2011,102(22):10163-10172. doi: 10.1016/j.biortech.2011.08.030 [46] Christenson L, Sims R. Production and harvesting of microalgae for wastewater treatment, biofuels, and bioproducts[J]. Biotechnology Advances,2011,29(6):686-702. doi: 10.1016/j.biotechadv.2011.05.015 [47] Oncel S S. Microalgae for a macroenergy world[J]. Renewable and Sustainable Energy Reviews,2013,26:241-264. doi: 10.1016/j.rser.2013.05.059 [48] Yang C Y, Li R, Zhang B, et al. Pyrolysis of microalgae: A critical review[J]. Fuel Processing Technology,2019,186:53-72. doi: 10.1016/j.fuproc.2018.12.012 [49] Chaiwong K, Kiatsiriroat T, Vorayos N, et al. Study of bio-oil and bio-char production from algae by slow pyrolysis[J]. Biomass and Bioenergy,2013,56:600-606. doi: 10.1016/j.biombioe.2013.05.035 [50] Song M Y, Park H Y, Yang D S, et al. Seaweed-derived heteroatom-doped highly porous carbon as an electrocatalyst for the oxygen reduction reaction[J]. ChemSusChem,2014,7(6):1755-1763. doi: 10.1002/cssc.201400049 [51] Sevilla M, Ferrero G A, Fuertes A B. One-pot synthesis of biomass-based hierarchical porous carbons with a large porosity development[J]. Chemistry of Materials,2017,29(16):6900-6907. doi: 10.1021/acs.chemmater.7b02218 [52] Sri S S, Palanivelu K, Ramachandran A, et al. Biochar from biomass waste as a renewable carbon material for climate change mitigation in reducing greenhouse gas emissions-a review[J]. Biomass Conversion and Biorefinery,2020 doi: 10.1007/s13399-020-00604-5 [53] Ferrera-Lorenzo N, Fuente E, Bermúdez J M, et al. Conventional and microwave pyrolysis of a macroalgae waste from the agar-agar industry. Prospects for bio-fuel production[J]. Bioresource Technology,2014,151:199-206. doi: 10.1016/j.biortech.2013.10.047 [54] Zhang C T, Zhang L J, Gao J X, et al. Evolution of the functional groups/structures of biochar and heteroatoms during the pyrolysis of seaweed[J]. Algal Research,2020,48:101900. doi: 10.1016/j.algal.2020.101900 [55] Tian Z W, Qiu Y, Zhou J C, et al. The direct carbonization of algae biomass to hierarchical porous carbons and CO2 adsorption properties[J]. Materials Letters,2016,180:162-165. doi: 10.1016/j.matlet.2016.05.169 [56] Chen W H, Huang M Y, Chang J S, et al. Thermal decomposition dynamics and severity of microalgae residues in torrefaction[J]. Bioresource Technology,2014,169:258-264. doi: 10.1016/j.biortech.2014.06.086 [57] Ren M, Jia Z Y, Tian Z W, et al. High performance N-doped carbon electrodes obtained via hydrothermal carbonization of macroalgae for supercapacitor applications[J]. ChemElectroChem,2018,5(18):2686-2693. doi: 10.1002/celc.201800603 [58] Titirici M M, White R J, Falco C, et al. Black perspectives for a green future: hydrothermal carbons for environment protection and energy storage[J]. Energy & Environmental Science,2012,5(5):6796-6822. [59] Ibrahim A F M, Dandamudi K P R, Deng S G, et al. Pyrolysis of hydrothermal liquefaction algal biochar for hydrogen production in a membrane reactor[J]. Fuel,2020,265:116935. doi: 10.1016/j.fuel.2019.116935 [60] Zhu C Z, Zhai J F, Dong S J. Bifunctional fluorescent carbon nanodots: Green synthesis via soy milk and application as metal-free electrocatalysts for oxygen reduction[J]. Chemical Communications,2012,48(75):9367-9369. doi: 10.1039/c2cc33844k [61] Sevilla M, Fuertes A B. Sustainable porous carbons with a superior performance for CO2 capture[J]. Energy & Environmental Science,2011,4(5):1765-1771. [62] Sevilla M, Fuertes A B. The production of carbon materials by hydrothermal carbonization of cellulose[J]. Carbon,2009,47(9):2281-2289. doi: 10.1016/j.carbon.2009.04.026 [63] Sevilla M, Fuertes A B. Chemical and structural properties of carbonaceous products obtained by hydrothermal carbonization of saccharides[J]. Chemistry-A European Journal,2009,15(16):4195-4203. doi: 10.1002/chem.200802097 [64] Titirici M M, White R J, Brun N, et al. Sustainable carbon materials[J]. Chemical Society Reviews,2015,44(1):250-290. doi: 10.1039/C4CS00232F [65] Heilmann S M, Davis H T, Jader L R, et al. Hydrothermal carbonization of microalgae[J]. Biomass and Bioenergy,2010,34(6):875-882. doi: 10.1016/j.biombioe.2010.01.032 [66] Xu Q, Qian Q, Augustine Q, et al. Hydrothermal carbonization of macroalgae and the effects of experimental parameters on the properties of hydrochars[J]. ACS Sustainable Chemistry & Engineering,2013,1(9):1092-1101. [67] Baccile N, Laurent G, Babonneau F, et al. Structural characterization of hydrothermal carbon spheres by advanced solid-state MAS 13C NMR investigations[J]. The Journal of Physical Chemistry C,2009,113(22):9644-9654. doi: 10.1021/jp901582x [68] Falco C, Sevilla M, White R J, et al. Renewable nitrogen-doped hydrothermal carbons derived from microalgae[J]. ChemSusChem,2012,5(9):1834-1840. doi: 10.1002/cssc.201200022 [69] Chen X F, Zhang J Y, Zhang B, et al. A novel hierarchical porous nitrogen-doped carbon derived from bamboo shoot for high performance supercapacitor[J]. Scientific Reports,2017,7(1):7362. doi: 10.1038/s41598-017-06730-x [70] Chang Y M, Tsai W T, Li M H, et al. Preparation and characterization of porous carbon material from post-extracted algal residue by a thermogravimetric system[J]. Algal Research,2015,9:8-13. doi: 10.1016/j.algal.2015.02.011 [71] Li Y G, Zhou W, Wang H L, et al. An oxygen reduction electrocatalyst based on carbon nanotube-graphene complexes[J]. Nature Nanotechnology,2012,7(6):394-400. doi: 10.1038/nnano.2012.72 [72] Chen L, Ji T, Logan B, et al. Hierarchical porous and high surface area tubular carbon as dye adsorbent and capacitor electrode[J]. ACS Applied Materials & Interfaces,2015,7(22):12230-12237. [73] Li D H, Chang G J, Zong L, et al. From double-helix structured seaweed to s-doped carbon aerogel with ultra-high surface area for energy storage[J]. Energy Storage Materials,2019,17:22-30. doi: 10.1016/j.ensm.2018.08.004 [74] Liu S F, Yang P P, Wang L L, et al. Nitrogen-doped porous carbons from lotus leaf for CO2 capture and supercapacitor electrodes[J]. Energy & Fuels,2019,33(7):6568-6576. [75] Yang Z X, Zhang G J, Xu Y, et al. One step N-doping and activation of biomass carbon at low temperature through NaNH2: An effective approach to CO2 adsorbents[J]. Journal of CO2 Utilization,2019,33:320-329. doi: 10.1016/j.jcou.2019.06.021 [76] Cai J J, Qi J B, Yang C P, et al. Poly(vinylidene chloride)-based carbon with ultrahigh microporosity and outstanding performance for CH4 and H2 storage and CO2 capture[J]. ACS Applied Materials & Interfaces,2014,6(5):3703-3711. [77] Sevilla M, Gu W, Falco C, et al. Hydrothermal synthesis of microalgae-derived microporous carbons for electrochemical capacitors[J]. Journal of Power Sources,2014,267:26-32. doi: 10.1016/j.jpowsour.2014.05.046 [78] Singh G, Lakhi K S, Kim I Y, et al. Highly efficient method for the synthesis of activated mesoporous biocarbons with extremely high surface area for high-pressure CO2 adsorption[J]. ACS Applied Materials & Interfaces,2017,9(35):29782-29793. [79] Balahmar N, Al-Jumialy A S, Mokaya R. Biomass to porous carbon in one step: Directly activated biomass for high performance CO2 storage[J]. Journal of Materials Chemistry A,2017,5(24):12330-12339. doi: 10.1039/C7TA01722G [80] Wang J, Wang Y L, Liang Y, et al. Nitrogen-doped carbons from in-situ glucose-coated ZIF-8 as efficient adsorbents for Rhodamine B removal from wastewater[J]. Microporous and Mesoporous Materials,2021,310:110662. doi: 10.1016/j.micromeso.2020.110662 [81] Wu Y Q, Chen Z A, Liu Y N, et al. One step synthesis of N-doped activated carbons derived from sustainable microalgae-NaAlg composites for CO2 and CH4 adsorption[J]. Fuel,2018,233:574-581. doi: 10.1016/j.fuel.2018.06.094 [82] Zhang Z Q, Wang K, Atkinson J D, et al. Sustainable and hierarchical porous Enteromorpha prolifera based carbon for CO2 capture[J]. Journal of Hazardous Materials,2012,229-230:183-191. doi: 10.1016/j.jhazmat.2012.05.094 [83] Luo H, Zhu C C, Tan Z C, et al. Preparation of N-doped activated carbons with high CO2 capture performance from microalgae (Chlorococcum sp.)[J]. RSC Advances,2016,6(45):38724-38730. doi: 10.1039/C6RA04106J [84] Sevilla M, Falco C, Titirici M M, et al. High-performance CO2 sorbents from algae[J]. RSC Advances,2012,2(33):12792-12797. doi: 10.1039/c2ra22552b [85] Wu X X, Tian Z W, Hu L Q, et al. Macroalgae-derived nitrogen-doped hierarchical porous carbons with high performance for H2 storage and supercapacitors[J]. RSC Advances,2017,7(52):32795-32805. doi: 10.1039/C7RA05355J [86] Gao J, Xie J, Liu X Y, et al. Preparation and evaluation of modified cyanobacteria-derived activated carbon for H2 adsorption[J]. RSC Advances,2017,7(33):20412-20421. doi: 10.1039/C6RA28660G [87] Ferrera-Lorenzo N, Fuente E, Suárez-Ruiz I, et al. Sustainable activated carbons of macroalgae waste from the Agar-Agar industry. Prospects as adsorbent for gas storage at high pressures[J]. Chemical Engineering Journal,2014,250:128-136. doi: 10.1016/j.cej.2014.03.119 [88] Han X, Chen H, Liu Y X, et al. Study on removal of gaseous hydrogen sulfide based on macroalgae biochars[J]. Journal of Natural Gas Science and Engineering,2020,73:103068. doi: 10.1016/j.jngse.2019.103068 [89] Zhu B J, Liu B, Qu C, et al. Tailoring biomass-derived carbon for high-performance supercapacitors from controllably cultivated algae microspheres[J]. Journal of Materials Chemistry A,2018,6(4):1523-1530. doi: 10.1039/C7TA09608A [90] Wang J S, Qin F F, Guo Z G, et al. Oxygen- and nitrogen-enriched honeycomb-like porous carbon from laminaria japonica with excellent supercapacitor performance in aqueous solution[J]. ACS Sustainable Chemistry & Engineering,2019,7(13):11550-11563. [91] Tian Z W, Xiang M, Zhou J C, et al. Nitrogen and oxygen-doped hierarchical porous carbons from algae biomass: Direct carbonization and excellent electrochemical properties[J]. Electrochimica Acta,2016,211:225-233. doi: 10.1016/j.electacta.2016.06.053 [92] Gao X L, Xing W, Zhou J, et al. Superior capacitive performance of active carbons derived from enteromorpha prolifera[J]. Electrochimica Acta,2014,133:459-466. doi: 10.1016/j.electacta.2014.04.101 [93] Gao Y, Zhang W L, Yue Q Y, et al. Simple synthesis of hierarchical porous carbon from enteromorpha prolifera by a self-template method for supercapacitor electrodes[J]. Journal of Power Sources,2014,270:403-410. doi: 10.1016/j.jpowsour.2014.07.115 [94] Yu W H, Wang H L, Liu S, et al. N, O-codoped hierarchical porous carbons derived from algae for high-capacity supercapacitors and battery anodes[J]. Journal of Materials Chemistry A,2016,4:5973-5983. doi: 10.1039/C6TA01821A [95] Wu M B, Li P, Li Y, et al. Enteromorpha based porous carbons activated by zinc chloride for supercapacitors with high capacity retention[J]. RSC Advances,2015,5(21):16575-16581. doi: 10.1039/C4RA13428A [96] Cui J F, Xi Y L, Chen S, et al. Prolifera-green-tide as sustainable source for carbonaceous aerogels with hierarchical pore to achieve multiple energy storage[J]. Advanced Functional Materials,2016,26(46):8487-8495. doi: 10.1002/adfm.201603933 [97] Xie T, Wang J, Liu X H, et al. Hierarchical porous activated carbon derived from Enteromorpha prolifera for superior electrochemical capacitive behavior[J]. Ionics,2020,26(1):403-413. doi: 10.1007/s11581-019-03223-x [98] Li J, Liu K, Gao X, et al. Oxygen- and nitrogen-enriched 3D porous carbon for supercapacitors of high volumetric capacity[J]. ACS Applied Materials & Interfaces,2015,7(44):24622-24628. [99] Raymundo-Piñero E, Cadek M, Béguin F. Tuning carbon materials for supercapacitors by direct Pyrolysis of seaweeds[J]. Advanced Functional Materials,2009,19(7):1032-1039. doi: 10.1002/adfm.200801057 [100] Pourhosseini S E M, Norouzi O, Naderi H R. Study of micro/macro ordered porous carbon with olive-shaped structure derived from Cladophora glomerata macroalgae as efficient working electrodes of supercapacitors[J]. Biomass and Bioenergy,2017,107:287-298. doi: 10.1016/j.biombioe.2017.10.025 [101] Zeng J, Wei L, Guo X. Bio-inspired high-performance solid-state supercapacitors with the electrolyte, separator, binder and electrodes entirely from kelp[J]. Journal of Materials Chemistry A,2017,5(48):25282-25292. doi: 10.1039/C7TA08095F [102] Zhai Z Z, Ren B, Xu Y L, et al. Green and facile fabrication of Cu-doped carbon aerogels from sodium alginate for supercapacitors[J]. Organic Electronics,2019,70:246-251. doi: 10.1016/j.orgel.2019.04.028 [103] Zhang N, Yan X H, Li J, et al. Biosorption-directed integration of hierarchical CoO/C composite with nickel foam for high-performance supercapacitor[J]. Electrochimica Acta,2017,226:132-139. doi: 10.1016/j.electacta.2016.12.192 [104] Pourhosseini S E M, Norouzi O, Salimi P, et al. Synthesis of a novel interconnected 3D pore network algal biochar constituting iron nanoparticles derived from a harmful marinebiomass as high-performance asymmetric supercapacitor electrodes[J]. ACS Sustainable Chemistry & Engineering,2018,6(4):4746-4758. [105] Ru H H, Bai N B, Xiang K X, et al. Porous carbons derived from microalgae with enhanced electrochemical performance for lithium-ion batteries[J]. Electrochimica Acta,2016,194:10-16. doi: 10.1016/j.electacta.2016.02.083 [106] Salimi P, Norouzi O, Pourhoseini S E M, et al. Magnetic biochar obtained through catalytic pyrolysis of macroalgae: A promising anode material for Li-ion batteries[J]. Renewable Energy,2019,140:704-714. doi: 10.1016/j.renene.2019.03.077 [107] Ouyang H B, Gong Q Q, Li C Y, et al. Porphyra derived hierarchical porous carbon with high graphitization for ultra-stable lithium-ion batteries[J]. Materials Letters,2019,235:111-115. doi: 10.1016/j.matlet.2018.10.020 [108] Wu D L, Cheng J Y, Wang T, et al. A novel porous N- and S-self-doped carbon derived from Chinese rice wine lees as high-performance electrode materials in a supercapacitor[J]. ACS Sustainable Chemistry & Engineering,2019,7(14):12138-12147. [109] Seo J C, Umirov N, Park S B, et al. Microalgae-derived hollow carbon-MoS2 composite as anode for lithium-ion batteries[J]. Journal of Industrial and Engineering Chemistry,2019,79:106-114. doi: 10.1016/j.jiec.2019.05.046 [110] Ho S H, Chen Y D, Li R X, et al. N-doped graphitic biochars from C-phycocyanin extracted Spirulina residue for catalytic persulfate activation toward nonradical disinfection and organic oxidation[J]. Water Research,2019,159:77-86. doi: 10.1016/j.watres.2019.05.008 [111] Qi Y F, Ge B X, Zhang Y Q, et al. Three-dimensional porous graphene-like biochar derived from Enteromorpha as a persulfate activator for sulfamethoxazole degradation: Role of graphitic N and radicals transformation[J]. Journal of Hazardous Materials,2020,399:123039. doi: 10.1016/j.jhazmat.2020.123039 [112] Wang H, Wang H, Zhao H, et al. Adsorption and fenton-like removal of chelated nickel from Zn-Ni alloy electroplating wastewater using activated biochar composite derived from taihu blue algae[J]. Chemical Engineering Journal,2020,379:122372. doi: 10.1016/j.cej.2019.122372 [113] Chen C, Ma T F, Shang Y N, et al. In-situ pyrolysis of Enteromorpha as carbocatalyst for catalytic removal of organic contaminants: Considering the intrinsic N/Fe in Enteromorpha and non-radical reaction[J]. Applied Catalysis B: Environmental,2019,250:382-395. doi: 10.1016/j.apcatb.2019.03.048 [114] Kumar A, Kumar J, Bhaskar T. High surface area biochar from sargassum tenerrimum as potential catalyst support for selective phenol hydrogenation[J]. Environmental Research,2020,186:109533. doi: 10.1016/j.envres.2020.109533 [115] Su R D, Li Q, Chen Y S, et al. One-step synthesis of Cu2O@carbon nanocapsules composites using sodium alginate as template and characterization of their visible light photocatalytic properties[J]. Journal of Cleaner Production,2019,209:20-29. doi: 10.1016/j.jclepro.2018.10.234 [116] Aravindhan R, Raghava Rao J, Unni Nair B. Preparation and characterization of activated carbon from marine macro-algal biomass[J]. Journal of Hazardous Materials,2009,162(2):688-694. [117] Zheng H S, Guo W Q, Li S, et al. Adsorption of p-nitrophenols (PNP) on microalgal biochar: Analysis of high adsorption capacity and mechanism[J]. Bioresource Technology,2017,244:1456-1464. doi: 10.1016/j.biortech.2017.05.025 [118] Peng L, Ren Y Q, Gu J D, et al. Iron improving bio-char derived from microalgae on removal of tetracycline from aqueous system[J]. Environmental Science and Pollution Research,2014,21(12):7631-7640. doi: 10.1007/s11356-014-2677-2 [119] Choi Y K, Choi T R, Gurav R, et al. Adsorption behavior of tetracycline onto spirulina sp. (microalgae)-derived biochars produced at different temperatures[J]. Science of The Total Environment,2020,710:136282. doi: 10.1016/j.scitotenv.2019.136282 [120] Qiao K L, Tian W J, Bai J, et al. Preparation of biochar from enteromorpha prolifera and its use for the removal of polycyclic aromatic hydrocarbons (PAHs) from aqueous solution[J]. Ecotoxicology and Environmental Safety,2018,149:80-87. doi: 10.1016/j.ecoenv.2017.11.027 [121] Zhu X Z, Gao Y, Yue Q Y, et al. Preparation of green alga-based activated carbon with lower impregnation ratio and less activation time by potassium tartrate for adsorption of chloramphenicol[J]. Ecotoxicology and Environmental Safety,2017,145:289-294. doi: 10.1016/j.ecoenv.2017.07.053 [122] Cheng H, Ji R T, Bian Y R, et al. From macroalgae to porous graphitized nitrogen-doped biochars - Using aquatic biota to treat polycyclic aromatic hydrocarbons-contaminated water[J]. Bioresource Technology,2020,303:122947. doi: 10.1016/j.biortech.2020.122947 [123] Gao Y, Yue Q Y, Gao B Y, et al. Comparisons of porous, surface chemistry and adsorption properties of carbon derived from enteromorpha prolifera activated by H4P2O7 and KOH[J]. Chemical Engineering Journal,2013,232:582-590. doi: 10.1016/j.cej.2013.08.011 [124] Masoumi S, Dalai A K. Optimized production and characterization of highly porous activated carbon from algal-derived hydrochar[J]. Journal of Cleaner Production,2020,263:121427. doi: 10.1016/j.jclepro.2020.121427 [125] Tayibi S, Monlau F, Fayoud N E, et al. One-pot activation and pyrolysis of Moroccan Gelidium sesquipedale red macroalgae residue: Production of an efficient adsorbent biochar[J]. Biochar,2020,1:401-412. [126] Chen Y D, Lin Y C, Ho S H, et al. Highly efficient adsorption of dyes by biochar derived from pigments-extracted macroalgae pyrolyzed at different temperature[J]. Bioresource Technology,2018,259:104-110. doi: 10.1016/j.biortech.2018.02.094 [127] Li X Y, Han D, Xie J F, et al. Hierarchical porous activated biochar derived from marine macroalgae wastes (Enteromorpha prolifera): facile synthesis and its application on methylene blue removal[J]. RSC Advances,2018,8(51):29237-29247. doi: 10.1039/C8RA04929G [128] Parsa M, Nourani M, Baghdadi M, et al. Biochars derived from marine macroalgae as a mesoporous by-product of hydrothermal liquefaction process: Characterization and application in wastewater treatment[J]. Journal of Water Process Engineering,2019,32:100942. doi: 10.1016/j.jwpe.2019.100942 [129] Boakye P, Tran H N, Lee D S, et al. Effect of water washing pretreatment on property and adsorption capacity of macroalgae-derived biochar[J]. Journal of Environmental Management,2019,233:165-174. [130] Jung K W, Jeong T U, Kang H J, et al. Characteristics of biochar derived from marine macroalgae and fabrication of granular biochar by entrapment in calcium-alginate beads for phosphate removal from aqueous solution[J]. Bioresource Technology,2016,211:108-116. doi: 10.1016/j.biortech.2016.03.066 [131] Sewu D D, Lee D S, Tran H N, et al. Effect of bentonite-mineral co-pyrolysis with macroalgae on physicochemical property and dye uptake capacity of bentonite/biochar composite[J]. Journal of the Taiwan Institute of Chemical Engineers,2019,104:106-113. doi: 10.1016/j.jtice.2019.08.017 [132] Jung K W, Kim K, Jeong T U, et al. Influence of pyrolysis temperature on characteristics and phosphate adsorption capability of biochar derived from waste-marine macroalgae (Undaria pinnatifida roots)[J]. Bioresource Technology,2016,200:1024-1028. doi: 10.1016/j.biortech.2015.10.016 [133] Jung K W, Hwang M J, Jeong T U, et al. A novel approach for preparation of modified-biochar derived from marine macroalgae: Dual purpose electro-modification for improvement of surface area and metal impregnation[J]. Bioresource Technology,2015,191:342-345. doi: 10.1016/j.biortech.2015.05.052 [134] Jung K W, Ahn K H. Fabrication of porosity-enhanced MgO/biochar for removal of phosphate from aqueous solution: Application of a novel combined electrochemical modification method[J]. Bioresource Technology,2016,200:1029-1032. doi: 10.1016/j.biortech.2015.10.008 [135] Huang S W, Chen X, Wang D D, et al. Bio-reduction and synchronous removal of hexavalent chromium from aqueous solutions using novel microbial cell/algal-derived biochar particles: Turning an environmental problem into an opportunity[J]. Bioresource Technology,2020,309:123304. doi: 10.1016/j.biortech.2020.123304 [136] Park S H, Cho H J, Ryu C, et al. Removal of copper(II) in aqueous solution using pyrolytic biochars derived from red macroalga Porphyra tenera[J]. Journal of Industrial and Engineering Chemistry,2016,36:314-319. doi: 10.1016/j.jiec.2016.02.021 [137] Shen Y, Li H, Zhu W, et al. Microalgal-biochar immobilized complex: A novel efficient biosorbent for cadmium removal from aqueous solution[J]. Bioresource Technology,2017,244(1):1031-1038. [138] Bordoloi N, Goswami R, Kumar M, et al. Biosorption of Co (II) from aqueous solution using algal biochar: Kinetics and isotherm studies[J]. Bioresource Technology,2017,244(2):1465-1469. [139] Chen Y Y, Hui H X, Lu S, et al. Characteristics of enteromorpha prolifera biochars and their adsorption performance and mechanisms for Cr(VI)[J]. Environmental Science,2017,38(9):3953-3961. [140] Ge Y M, Zhu S S, Chang J S, et al. Immobilization of Hg(II) on high-salinity Spirulina residue-induced biochar from aqueous solutions: Sorption and transformation mechanisms by the dual-mode isotherms[J]. Environmental Pollution,2020,265:115087. doi: 10.1016/j.envpol.2020.115087 [141] Poo K M, Son E B, Chang J S, et al. Biochars derived from wasted marine macro-algae (Saccharina japonica and Sargassum fusiforme) and their potential for heavy metal removal in aqueous solution[J]. Journal of Environmental Management,2018,206:364-372. doi: 10.1016/j.jenvman.2017.10.056 [142] Son E B, Poo K M, Chang J S, et al. Heavy metal removal from aqueous solutions using engineered magnetic biochars derived from waste marine macro-algal biomass[J]. Science of the Total Environment,2018,615:161-168. doi: 10.1016/j.scitotenv.2017.09.171 [143] Son E B, Poo K M, Mohamed H O, et al. A novel approach to developing a reusable marine macro-algae adsorbent with chitosan and ferric oxide for simultaneous efficient heavy metal removal and easy magnetic separation[J]. Bioresource Technology,2018,259:381-387. doi: 10.1016/j.biortech.2018.03.077 [144] Chen Y Y, Wang B Y, Xin J, et al. Adsorption behavior and mechanism of Cr(VI) by modified biochar derived from Enteromorpha prolifera[J]. Ecotoxicology and Environmental Safety,2018,164:440-447. doi: 10.1016/j.ecoenv.2018.08.024 [145] Wang Y, Yang Q X, Chen J J, et al. Adsorption behavior of Cr(VI) by magnetically modified enteromorpha prolifera based biochar and the toxicity analysis[J]. Journal of Hazardous Materials,2020,395:122658. doi: 10.1016/j.jhazmat.2020.122658 [146] Wu J, Zheng H, Zhang F, et al. Iron-carbon composite from carbonization of iron-crosslinked sodium alginate for Cr(VI) removal[J]. Chemical Engineering Journal,2019,362:21-29. doi: 10.1016/j.cej.2019.01.009 [147] Zhang H, Tang Y, Cai D Q, et al. Hexavalent chromium removal from aqueous solution by algal bloom residue derived activated carbon: equilibrium and kinetic studies[J]. Journal of Hazardous Materials,2010,181(1-3):801-808. doi: 10.1016/j.jhazmat.2010.05.084 [148] Jin H M, Hanif M U, Capareda S, et al. Copper(II) removal potential from aqueous solution by pyrolysis biochar derived from anaerobically digested algae-dairy-manure and effect of KOH activation[J]. Journal of Environmental Chemical Engineering,2016,4(1):365-372. doi: 10.1016/j.jece.2015.11.022 -

下载:

下载: