High performance lithium-sulfur batteries using three-dimensional hierarchical porous carbons to host the sulfur

-

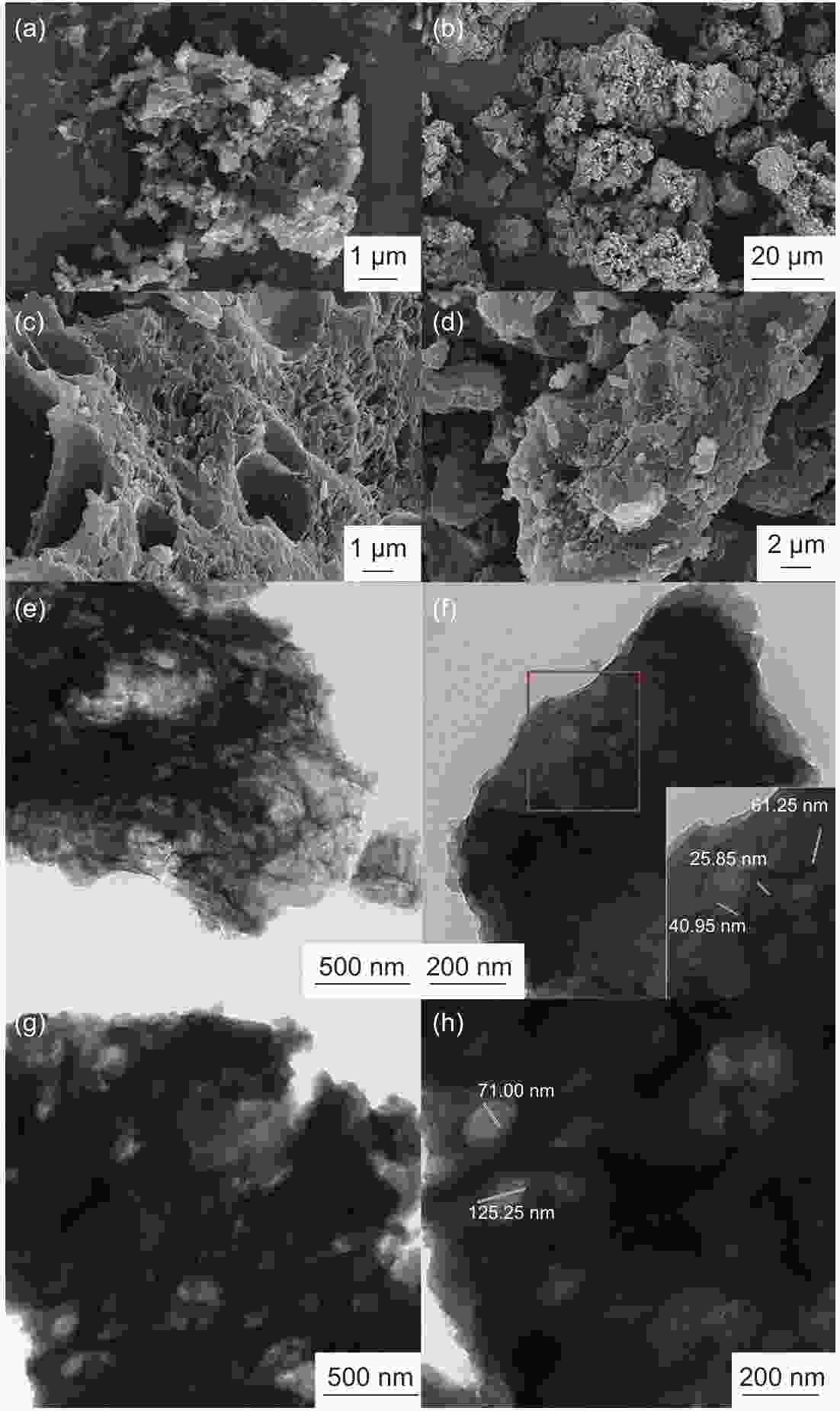

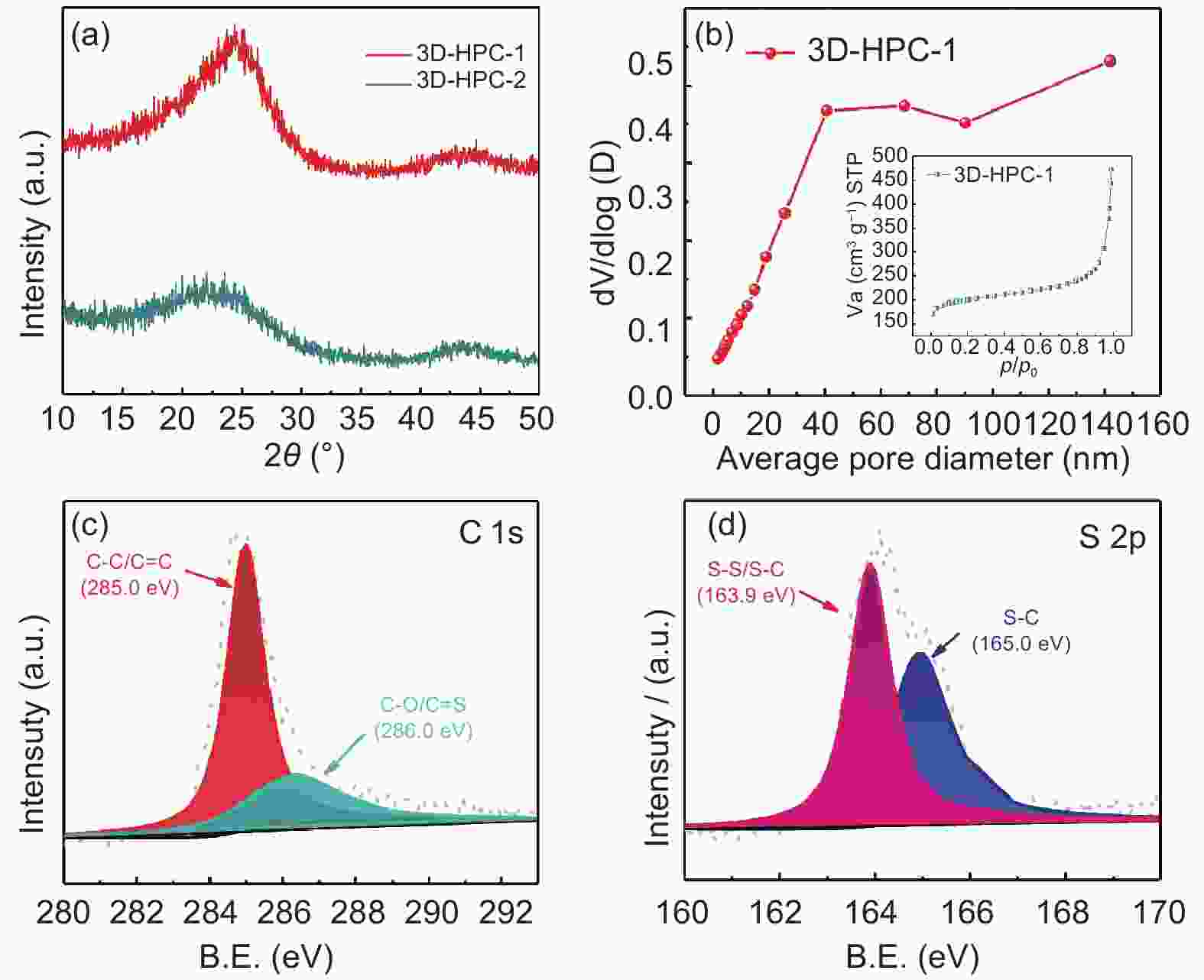

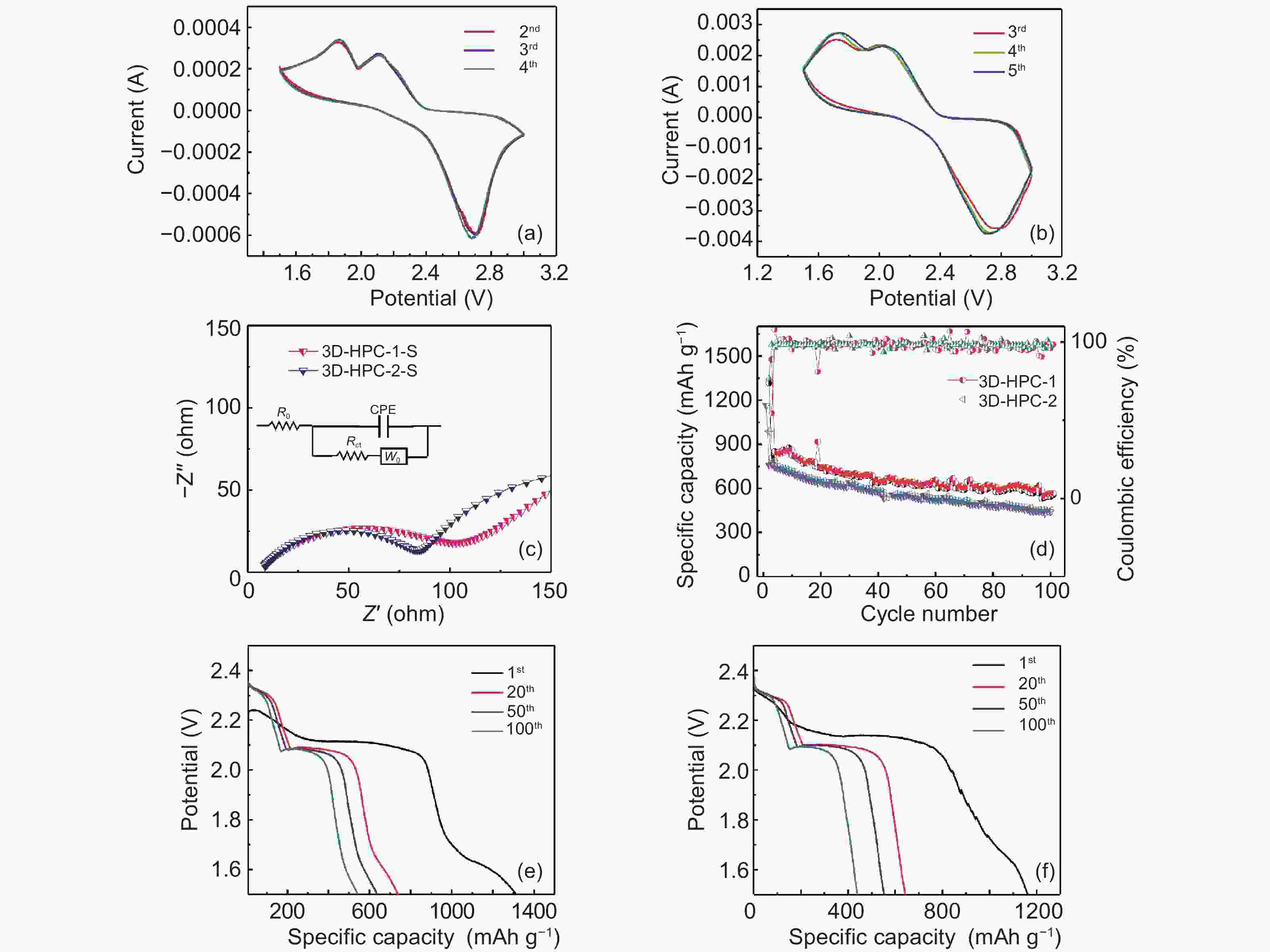

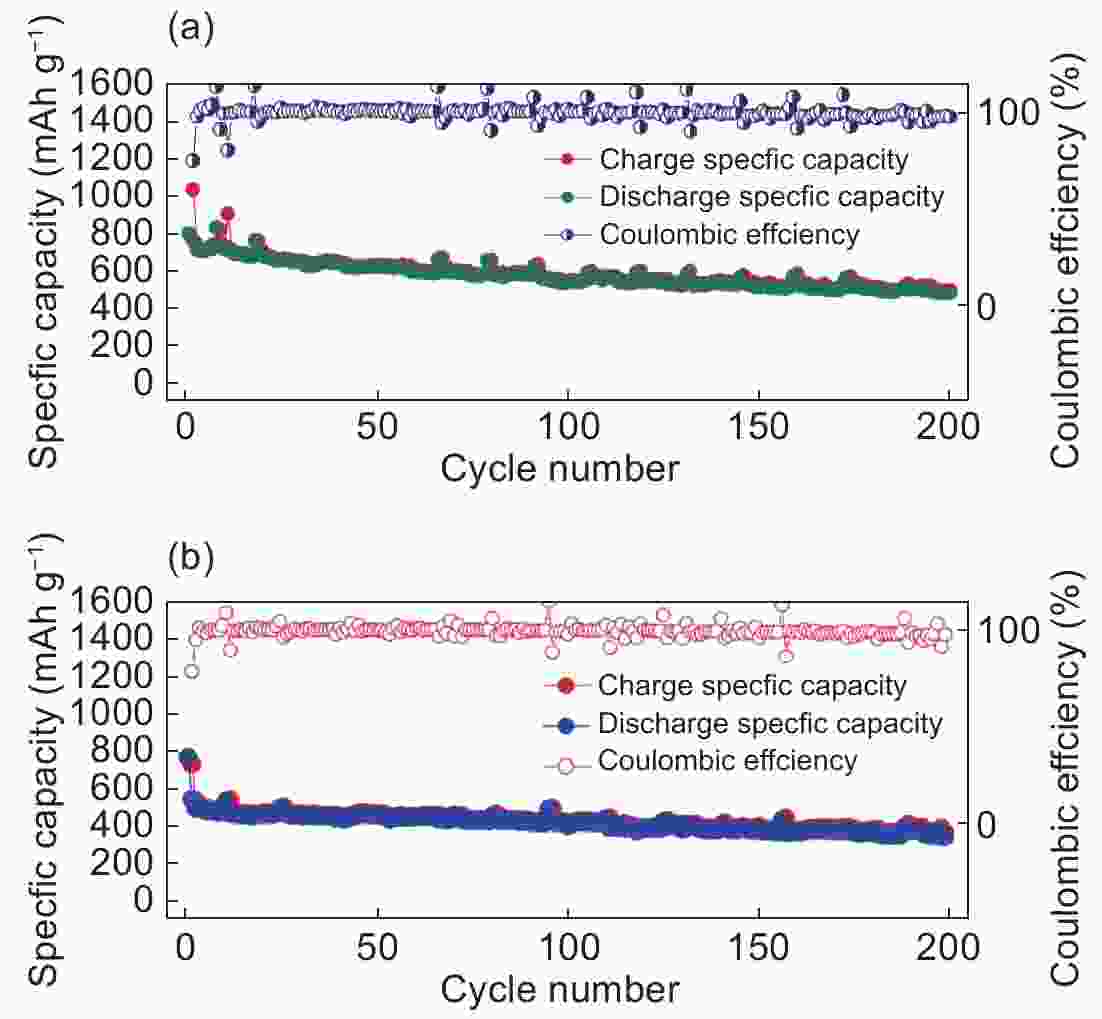

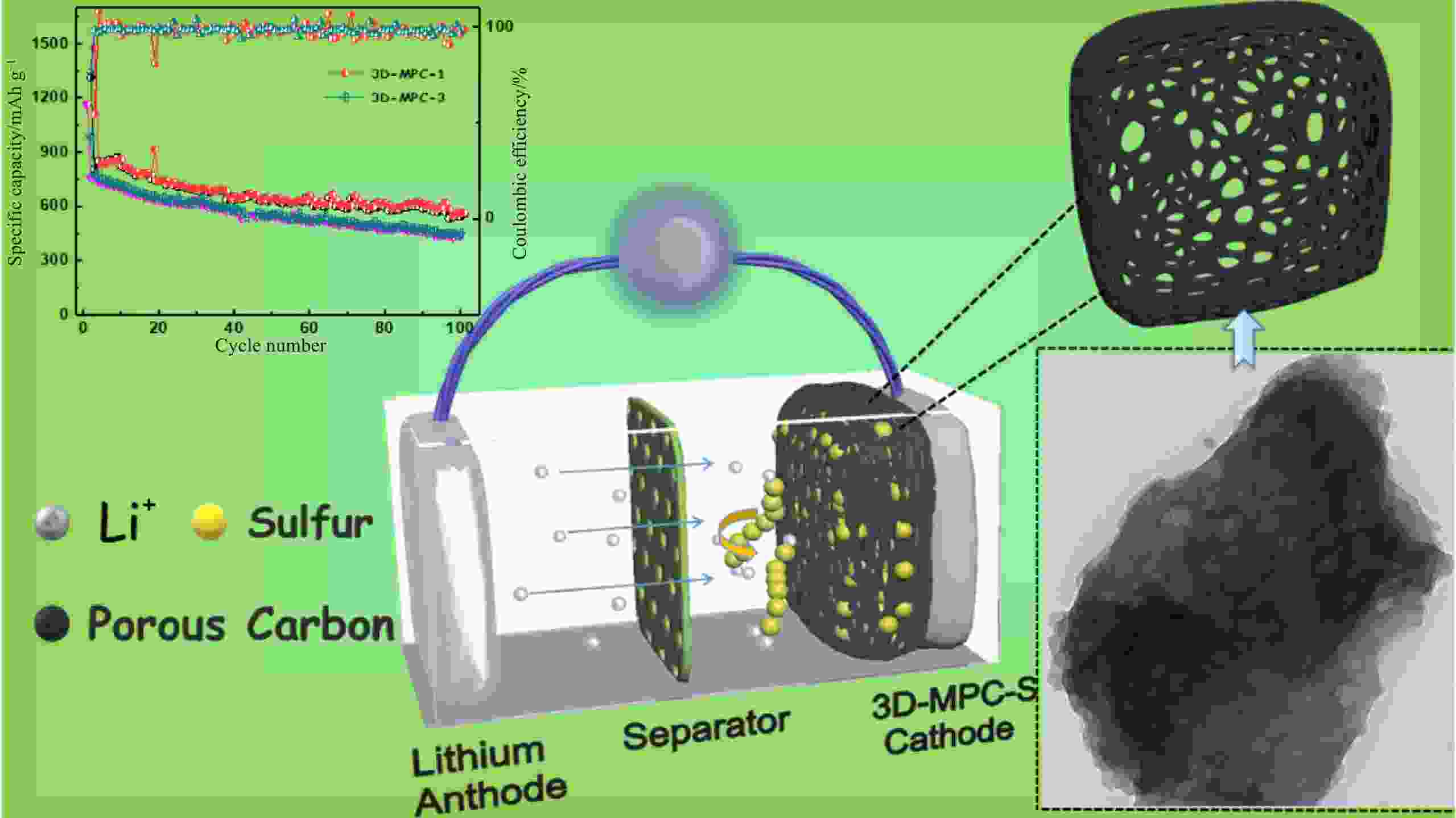

摘要: 锂硫电池由于其高能量密度和低廉的价格,将在未来的储能领域得到广泛应用。然而,它面临许多挑战,特别是在硫的负载和可溶性多硫化物的穿梭效应方面。为了解决这些问题,本文设计了一种三维多级孔炭材料(3D-HPC)作为锂硫电池中硫的载体。采用模板法,在去除模板剂聚甲基丙烯酸甲酯和氧化锌后得到了三维多孔结构。电镜和BET测试表明相互连通的大孔道与大量的大尺寸介孔协同构成了三维导电碳网络。三维网络有利于离子和电子的转移,同时通过较大尺寸的孔缓解阴极的体积膨胀,多级孔通过毛细凝结抑制了穿梭效应。电化学测试结果表明,3D-HPC-S阴极具有良好的电化学性能。在实际环境中的测试结果显示0.2倍率下3D-HPC-S首次放电比容量为1 314.6 mAh·g−1,经100次循环后,容量保持率为69.13%。在0.5倍率下循环200次容量保持率为59.02%,平均库伦效率为98.16%。3D-HPC-S阴极有望进一步促进锂硫电池的商业化发展。Abstract: Lithium-sulfur batteries are promising for future energy storage because of their high-energy density and low price. However, they have many problems, especially the large volume change during cycling and the shuttle effect of the soluble polysulfides. To solve these problems, a three-dimensional porous carbon (3D-HPC) was investigated as the sulfur host of a lithium-sulfur battery. The 3D-HPC was prepared by a template method using polymethyl methacrylate and zinc oxide as the templates to form mesopores and macropores, respectively. The results showed that the interconnected macroporous channels and abundant large mesopores formed a three-dimensional conductive carbon network which is beneficial for electron/ion transfer and relieves the cathode volume change by the physical limiting effect. The pores alleviate the shuttle effect by the capillary condensation. A 3D-HPC-S composite used as the cathode has excellent electrochemical properties. The first discharge specific capacity of the 3D-HPC-S is 1 314.6 mAh g−1 at 0.2 C with a sulfur loading of 70%. After 100 cycles, the capacity retention rate is 69.13%. At 0.5 C, the capacity retention rate after 200 cycles is 59.02% and the average coulombic efficiency is 98.16%.

-

Figure 4. CV of (a) 3D-HPC-1-S and (b) 3D-HPC-2-S cathodes between 3.0 V and 1.5 V with a scan rate of 1 mV s−1, (c) EIS spectra of the 3D-HPC-1-S and 3D-HPC-2-S cathodes before the cycle, (d) long-term cycling stabilities of the 3D-HPC-1-S cathode and 3D-HPC-2-S cathode over 100 cycles, charge-discharge profiles of (e) 3D-HPC-1 and (f) 3D-HPC-2 cathode at 0.5 C for 1st, 20th, 50th and 100th cycles.

-

[1] Xie J, Peng H, Huang J, et al. A Supramolecular capsule for reversible polysulfide storage/delivery in lithium–sulfur batteries[J]. Angewandte Chemie International Edition,2017,56(51):16223-16227. doi: 10.1002/anie.201710025 [2] Jia Y, Zhao Y, Yang X, Ren M, et al. Sulfur encapsulated in nitrogen-doped graphene aerogel as a cathode material for high performance lithium-sulfur batteries[J]. International Journal of Hydrogen Energy,2021,46(10):7642-7652. doi: 10.1016/j.ijhydene.2020.11.199 [3] Li M, Wahyudi W, Kumar P, et al. A scalable approach to construct free-standing and flexible carbon networks for lithium-sulfur battery[J]. ACS Applied Materials & Interfaces,2017,9(9):8047-8054. doi: 10.1021/acsami.6b12546 [4] Shan Y, Li L. An interlayer composed of porous carbon sheet embedded with TiO2 nanoparticles for stable and high rate lithium-sulfur batteries[J]. Chemical Communication,2021,57(75):9550-9553. doi: 10.1039/d1cc01520f [5] Jiang Y, Deng Y, Zhang B, et al. Recent progress on the design of hollow carbon spheres to host sulfur in room-temperature sodium-sulfur batteries[J]. Nanoscale,2020,12(23):12308-12316. doi: 10.1039/d0nr02607g [6] Yuan H, Peng H, Huang J, et al. Sulfur redox reactions at working interfaces in lithium–sulfur batteries: A perspective[J]. Advanced Materials Interfaces,2019,6(4):1802046. doi: 10.1002/admi.201802046 [7] Li L B, Shan Y H, Wang F R, et al. Improving fast and safe transfer of lithium ions in solid-state lithium batteries by porosity and channel structure of polymer electrolyte[J]. ACS Applied Materials & Interfaces,2021,13(41):48525-48535. doi: 10.1016/j.cej.2019.05.119 [8] Chu H, Noh H, Kim Y J, et al. Achieving three-dimensional lithium sulfide growth in lithium-sulfur batteries using high-donor-number anions[J]. Nature Communications,2019,10(1):188. doi: 10.1038/s41467-018-07975-4 [9] Lin S, Shafique M K, Cai Z, et al. Three-dimensional-ordered porous nanostructures for lithium-sulfur battery anodes and cathodes confer superior energy storage performance[J]. ACS Nano,2019,13(11):13037-13046. doi: 10.1021/acsnano.9b05718 [10] Yan M, Chen H, Yu Y, et al. 3D Ferroconcrete-like aminated carbon nanotubes network anchoring sulfur for advanced lithium-sulfur battery[J]. Advanced Energy Materials,2018,8(25):1801066. doi: 10.1002/aenm.201801066 [11] Chen X C, Li L B, Shan Y H, et al. Synergistic effect of cerium oxide with core-shell structure embedded in porous carbon for high-performance lithium-sulfur batteries[J]. Materials Today Communications,2021,27:102381. doi: 10.1016/j.mtcomm.2021.102381 [12] Lin H, Yang D D, Lou N, et al. Functionalized titanium nitride-based MXenes as promising host materials for lithium-sulfur batteries: A first principles study[J]. Ceramics International,2019,45(2):1588-1594. doi: 10.1016/j.ceramint.2018.10.033 [13] Pang Y, Wei J, Wang Y, et al. Synergetic protective effect of the ultralight MWCNTs/NCQDs modified separator for highly stable lithium-sulfur batteries[J]. Advanced Energy Materials,2018,8(10):1802288. [14] Li G, Wang S, Zhang Y, et al. Revisiting the role of polysulfides in lithium-sulfur batteries[J]. Advanced Materials,2018,30(22):1705590. doi: 10.1002/adma.201705590 [15] Yang Y, Yu Y, Ma G, et al. High-performance lithium?sulfur batteries fabricated from a three-dimensional porous reduced graphene oxide/La2O3microboards/sulfur aerogel[J]. Ceramics International,2019,45(7):9017-9024. doi: 10.1016/j.ceramint.2019.01.235 [16] Wang F, Zuo Z, Li L, et al. Graphdiyne nanostructure for high-performance lithium-sulfur batteries[J]. Nano Energy,2020,68:104307. doi: 10.1016/j.nanoen.2019.104307 [17] Patil S B, Kim H J, Lim H K, et al. Exfoliated 2D lepidocrocite titanium oxide nanosheets for high sulfur content cathodes with highly stable Li–S battery performance[J]. ACS Energy Letters,2018,3(2):409-412. [18] Sun W, Liu C, Li Y, et al. Rational construction of Fe2N@C yolk-shell nanoboxes as multifunctional hosts for ultralong lithium-sulfur batteries[J]. ACS Nano,2019,13(10):12137-12147. doi: 10.1021/acsnano.9b06629 [19] Ren Y X, Zeng L, Jiang H R, et al. Rational design of spontaneous reactions for protecting porous lithium electrodes in lithium-sulfur batteries[J]. Nature Communications,2019,10(1):3249. doi: 10.1038/s41467-019-11168-y [20] Shan Y H, Li L B, Yang X Y. Solid-state polymer electrolyte solves the transfer of lithium ions between the solid-solid interface of the electrode and the electrolyte in lithium-sulfur and lithium-ion batteries[J]. ACS Applied Energy Materials,2021, 4(5): 5101-5112 doi: 10.1021/acsaem.1c00658 [21] Zhou B, Hu X, Zeng G, et al. Bottom-up construction of porous organic frameworks with built-In TEMPO as a cathode for lithium-sulfur batteries[J]. ChemSusChem,2017,10(14):2955-2961. doi: 10.1002/cssc.201700749 [22] Long B, Qiao Z, Zhang J, et al. Polypyrrole-encapsulated amorphous Bi2S3 hollow sphere for long life sodium ion batteries and lithium–sulfur batteries[J]. Journal of Materials Chemistry A,2019,7(18):11370-11378. doi: 10.1039/C9TA01358J [23] Wu X, Yuan X, Yu J, et al. A high-capacity dual core-shell structured MWCNTs@S@PPy nanocomposite anode for advanced aqueous rechargeable lithium batteries[J]. Nanoscale,2017,9(31):11004-11011. doi: 10.1039/C7NR03602G [24] Fei L, Li X, Bi W, et al. Graphene/sulfur hybrid nanosheets from a space-confined "sauna" reaction for high-performance lithium-sulfur batteries[J]. Advanced Materials,2015,27(39):5936-5942. doi: 10.1002/adma.201502668 [25] Chen G, Li J, Liu N, et al. Synthesis of nitrogen-doped oxygen-deficient TiO2−x/reduced graphene oxide/sulfur microspheres via spray drying process for lithium-sulfur batteries[J]. Electrochimica Acta,2019,326:134968. doi: 10.1016/j.electacta.2019.134968 [26] Lu X, Zhang Q, Wang J, et al. High performance bimetal sulfides for lithium-sulfur batteries[J]. Chemical Engineering Journal,2019,358:955-961. doi: 10.1016/j.cej.2018.10.104 [27] Li L B, Shan Y H, Yang X Y. New insights for constructing solid polymer electrolytes with ideal lithium-ion transfer channels by using inorganic filler[J]. Materials Today Communications,2021,26:101910. doi: 10.1016/j.mtcomm.2020.101910 [28] Wei B, Shang C, Pan X, et al. Lotus root-like nitrogen-doped carbon nanofiber structure assembled with VN catalysts as a multifunctional host for superior lithium-sulfur batteries[J]. Nanomaterials-Basel,2019,9(12):1724. doi: 10.3390/nano9121724 [29] Deng N, Liu Y, Wang L, et al. Designing of a phosphorus, nitrogen, and sulfur three-flame retardant applied in a gel poly-m-phenyleneisophthalamide nanofiber membrane for advanced safety lithium-sulfur batteries[J]. ACS Applied Materials & Interfaces,2019,11(40):36705-36716. [30] Bian Z, Yuan T, Xu Y, et al. Boosting Li-S battery by rational design of freestanding cathode with enriched anchoring and catalytic N-sites carbonaceous host[J]. Carbon,2019,150:216-223. doi: 10.1016/j.carbon.2019.05.022 [31] Li P, Deng J, Li J, et al. Hollow graphene spheres coated separator as an efficient trap for soluble polysulfides in Li-S battery[J]. Ceramics International,2019,45(10):13219-13224. doi: 10.1016/j.ceramint.2019.04.006 [32] Park G D, Kang Y C. Aerosol-assisted synthesis of porous and hollow carbon-carbon nanotube composite microspheres as sulfur host materials for high-performance Li-S batteries[J]. Applied Surface Science,2019,495:143637. doi: 10.1016/j.apsusc.2019.143637 [33] Wang P, Li N, Zhang Z, et al. Synergetic enhancement of polysulfide chemisorption and electrocatalysis over bicontinuousMoN@N-rich carbon porous nano-octahedra for Li–S batteries[J]. Journal of Materials Chemistry A,2019,7(38):21934-21943. doi: 10.1039/C9TA05517G [34] Wang J, Liu Y, Cheng M, et al. Hierarchical porous carbon-graphene-based lithium–sulfur batteries[J]. Electrochimica Acta,2019,318:161-168. doi: 10.1016/j.electacta.2019.05.090 [35] Wang Y, Lu Y, Luo R, et al. Densely-stacked N-doped mesoporous TiO2 /carbon microsphere derived from outdated milk as high-performance electrode material for energy storages[J]. Ceramics International,2018,44(14):16265-16272. doi: 10.1016/j.ceramint.2018.06.020 [36] Yao Y, Xiao Z, Liu P, et al. Facile synthesis of 2D ultrathin and ultrahigh specific surface hierarchical porous carbon nanosheets for advanced energy storage[J]. Carbon,2019,155:674-685. doi: 10.1016/j.carbon.2019.09.010 [37] Niu S Z, Wu S D, Lu W, et al. A one-step hard-templating method for the preparation of a hierarchical microporous-mesoporous carbon for lithium-sulfur batteries[J]. New Carbon Materials,2017,32(4):289-296. doi: 10.1016/S1872-5805(17)60123-9 [38] He Y, Qiao Y, Chang Z, et al. Developing a "polysulfide-phobic" strategy to restrain shuttle effect in lithium-sulfur batteries[J]. Angewandte Chemie International,2019,58(34):11774-11780. doi: 10.1002/anie.201906055 [39] Gueon D, Hwang J T, Yang S B, et al. Spherical macroporous carbon nanotube particles with ultrahigh sulfur loading for lithium-sulfur battery cathodes[J]. ACS Nano,2018,12(1):226-233. doi: 10.1021/acsnano.7b05869 [40] Wang Q, Liu H, Li R, et al. Clustered-microcapsule-shaped microporous carbon-coated sulfur composite synthesized via in situ oxidation[J]. ACS Applied Materials Interfaces,2017,9(51):44512-44518. doi: 10.1021/acsami.7b14467 [41] Zhu F L, Yang, Z, Zhao, J P, et al. Microwave assisted preparation of expanded graphite/sulfur composites as cathodes for Li-S batteries[J]. New Carbon Materials,2016,31(2):199-204. doi: 10.1016/S1872-5805(16)60011-2 [42] Shi R, Han C, Li H, et al. NaCl-templated synthesis of hierarchical porous carbon with extremely large specific surface area and improved graphitization degree for high energy density lithium ion capacitors[J]. Journal of Materials Chemistry A,2018,6(35):17057-17066. doi: 10.1039/C8TA05853A [43] Jang J, Lim B, Choi M, et al. A simple synthesis of mesoporous carbons with tunable mesopores using a colloidal template-mediated vapor deposition polymerization[J]. Chemical. Communications,2005(33):4214-4216. doi: 10.1039/b506265a [44] Deng X, Li J, Ma L, et al. Three-dimensional porous carbon materials and their composites as electrodes for electrochemical energy storage systems[J]. Materials Chemistry Frontiers,2019,3(11):2221-2245. doi: 10.1039/C9QM00425D [45] Cheng D, Zhao Y, An T, et al. 3D interconnected crumpled porous carbon sheets modified with high-level nitrogen doping for high performance lithium sulfur batteries[J]. Carbon,2019,154:58-66. doi: 10.1016/j.carbon.2019.07.094 [46] Gu X, Li H, Wen H, et al. From agaric hydrogel to nitrogen-doped 3D porous carbon for high-performance Li-S batteries[J]. Journal of Materials Science,2019,55(3):1136-1147. [47] Wang L, Zhi W, Wan J, et al. 3D porous spherical sulfur/carbon cathode materials with in situ vapor-phase polymerized polypyrrole coating layer for high-performance lithium–sulfur batteries[J]. ACS Sustainable Chemistry Engineering,2019,7(3):3339-3348. doi: 10.1021/acssuschemeng.8b05489 [48] Xu H, Liu Y, Bai Q, et al. Discarded cigarette filter-derived hierarchically porous carbon@graphene composites for lithium-sulfur batteries[J]. Journal of Materials Chemistry A,2019,7(8):3558-3562. doi: 10.1039/C8TA11615F [49] Li Y, Cai, Q, Wang, L, et al. Mesoporous TiO2 nanocrystals/graphene as an efficient sulfur host material for high-performance lithium-sulfur batteries[J]. ACS Applied Materials International,2016,8(36):23784-23792. doi: 10.1021/acsami.6b09479 [50] Miao X, Sun D, Zhou X, et al. Designed formation of nitrogen and sulfur dual-doped hierarchically porous carbon for long-life lithium and sodium ion batteries[J]. Chemical Engineering Journal,2019,15(364):208-216. -

下载:

下载: