TiC-modified CNTs as reinforcing fillers for isotropic graphite produced from mesocarbon microbeads

-

摘要: 采用无压放电等离子烧结技术,用纳米TiC改性多壁碳纳米管(MWCNTs),将纳米TiC改性后的碳纳米管(T-CNTs)掺杂到中间相炭微球(MCMB)中以制备高性能的各向同性石墨材料。利用X射线衍射(XRD)、扫描电子显微镜(SEM)、透射电子显微(TEM)等对T-CNTs和制备的石墨材料结构进行表征;并采用万能试验机、激光导热仪和热膨胀系数仪测试了制备石墨材料的力学性能和热学性能。结果表明,纳米TiC成功的附着在CNTs的表面。与未添加T-CNTs的各向同性石墨相比,T-CNTs/MCMB各向同性石墨材料其力学强度有显著的提高,材料的抗折强度提高了70%,石墨化度提高10%,热学性能也有不同程度的提高。

-

关键词:

- 放电等离子烧结 /

- TiC改性多壁碳纳米管 /

- 中间相炭微球 /

- 各向同性石墨

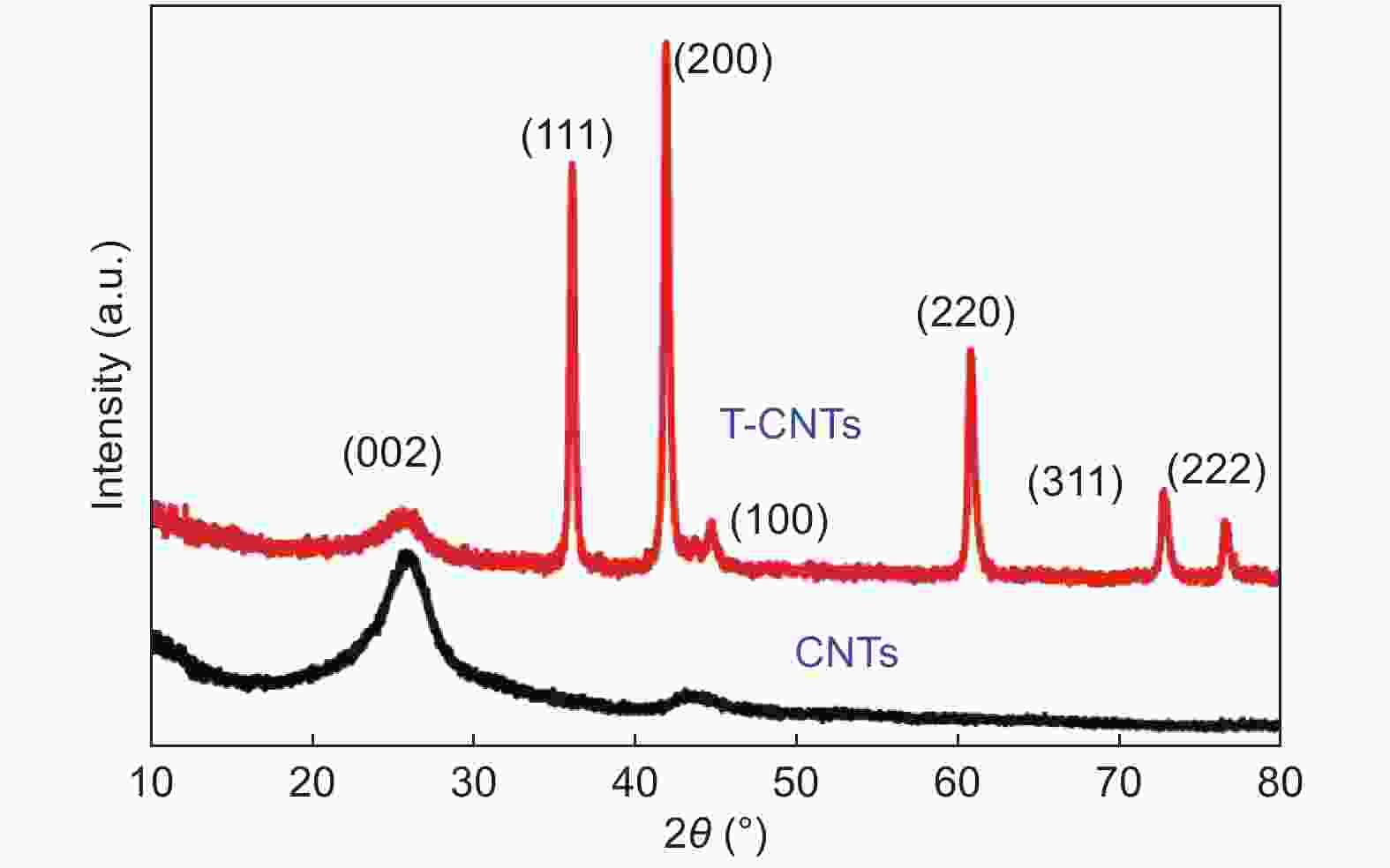

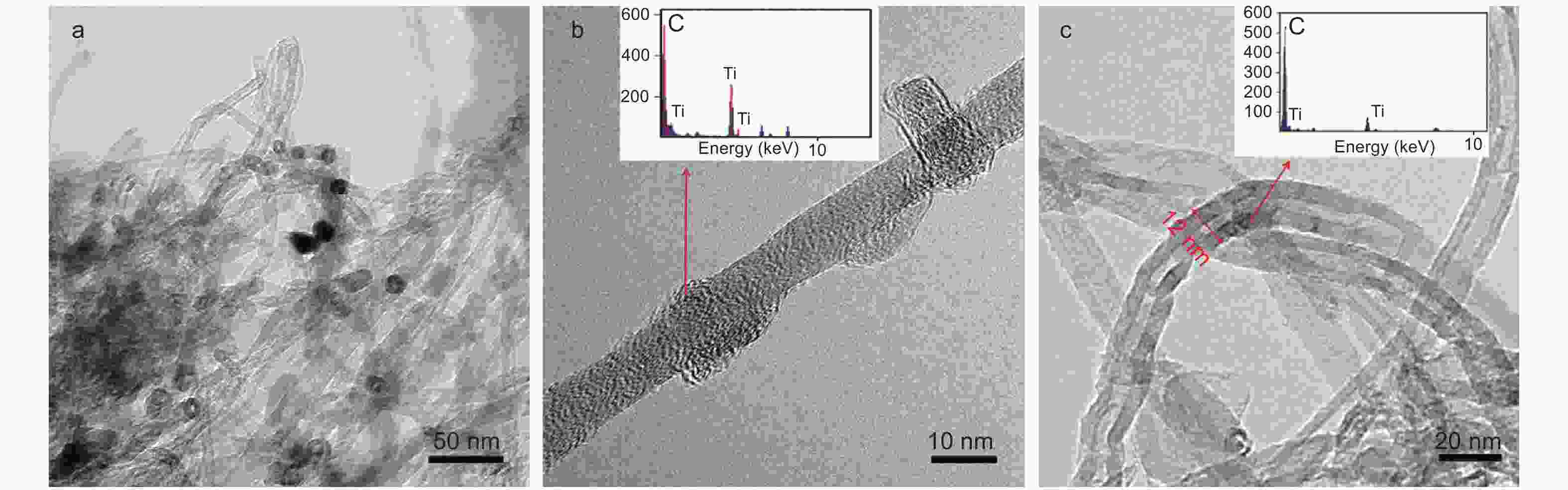

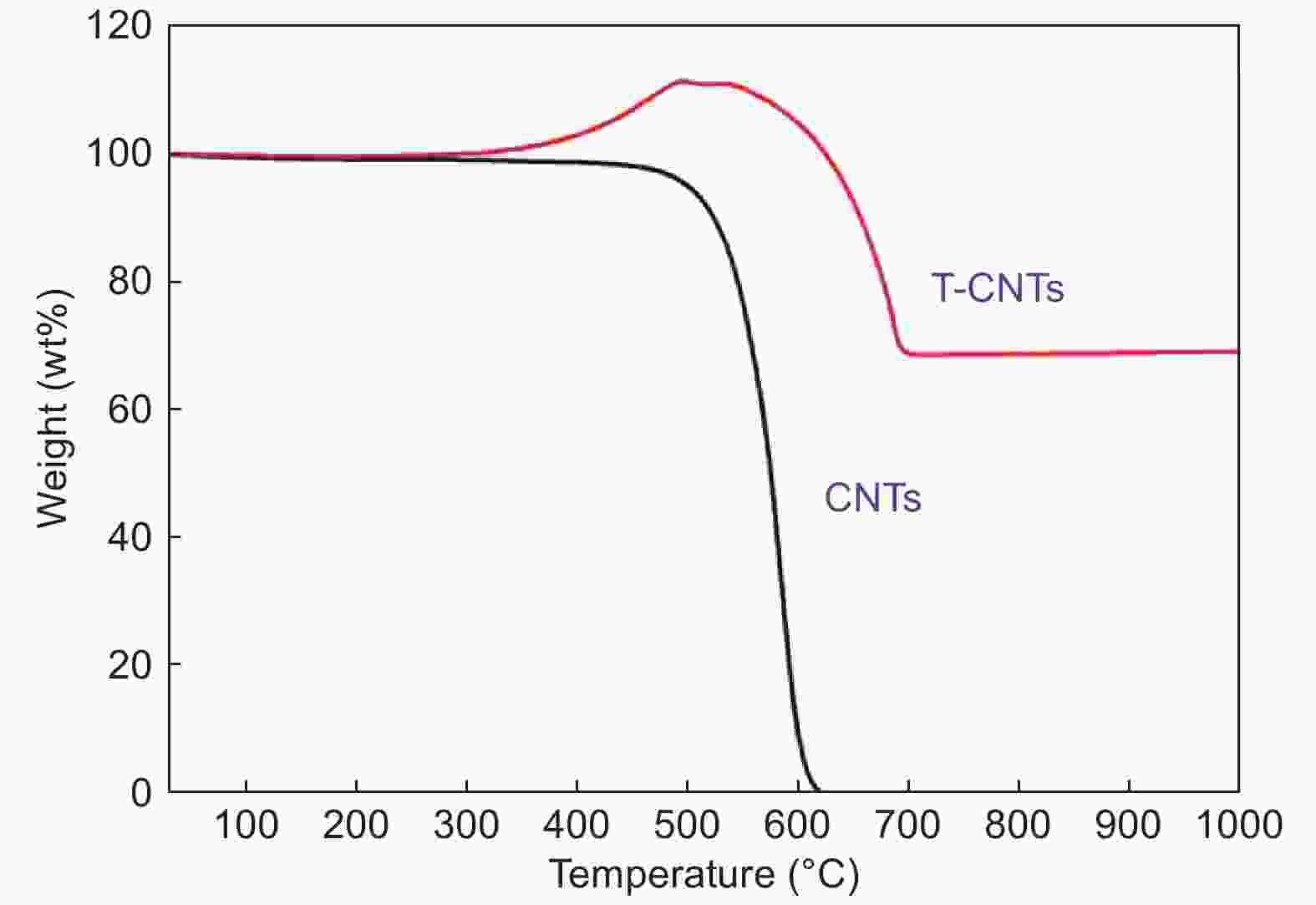

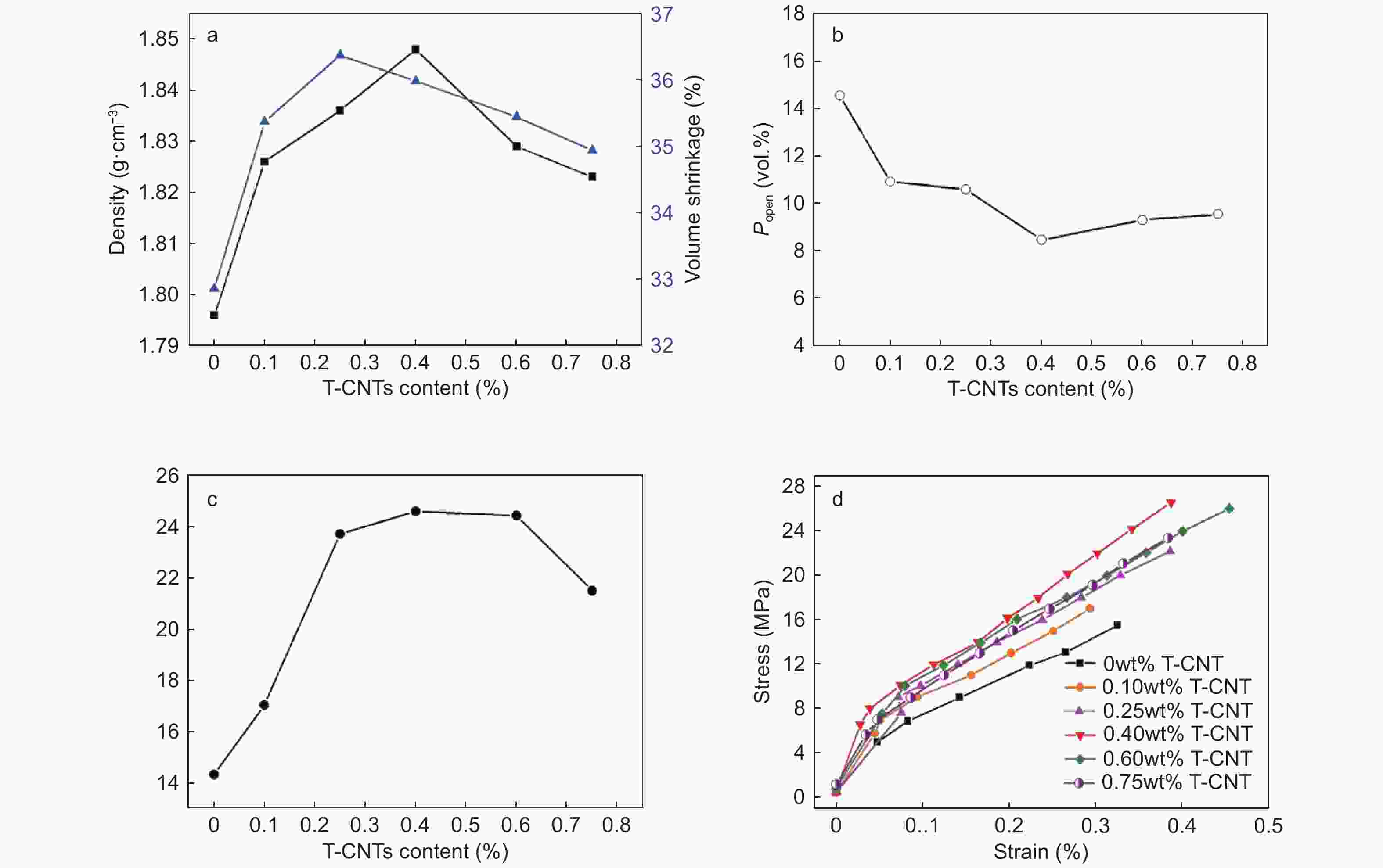

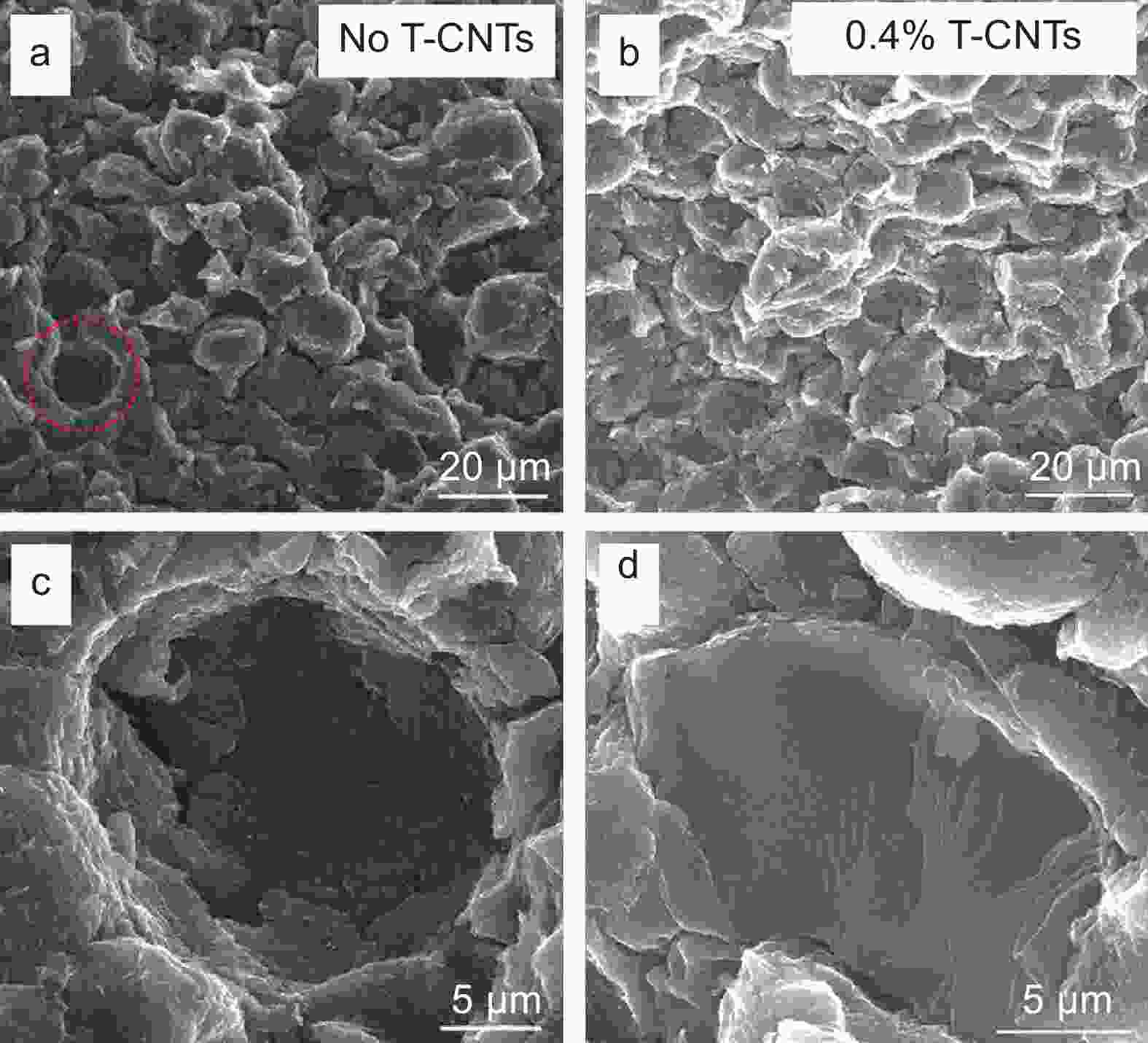

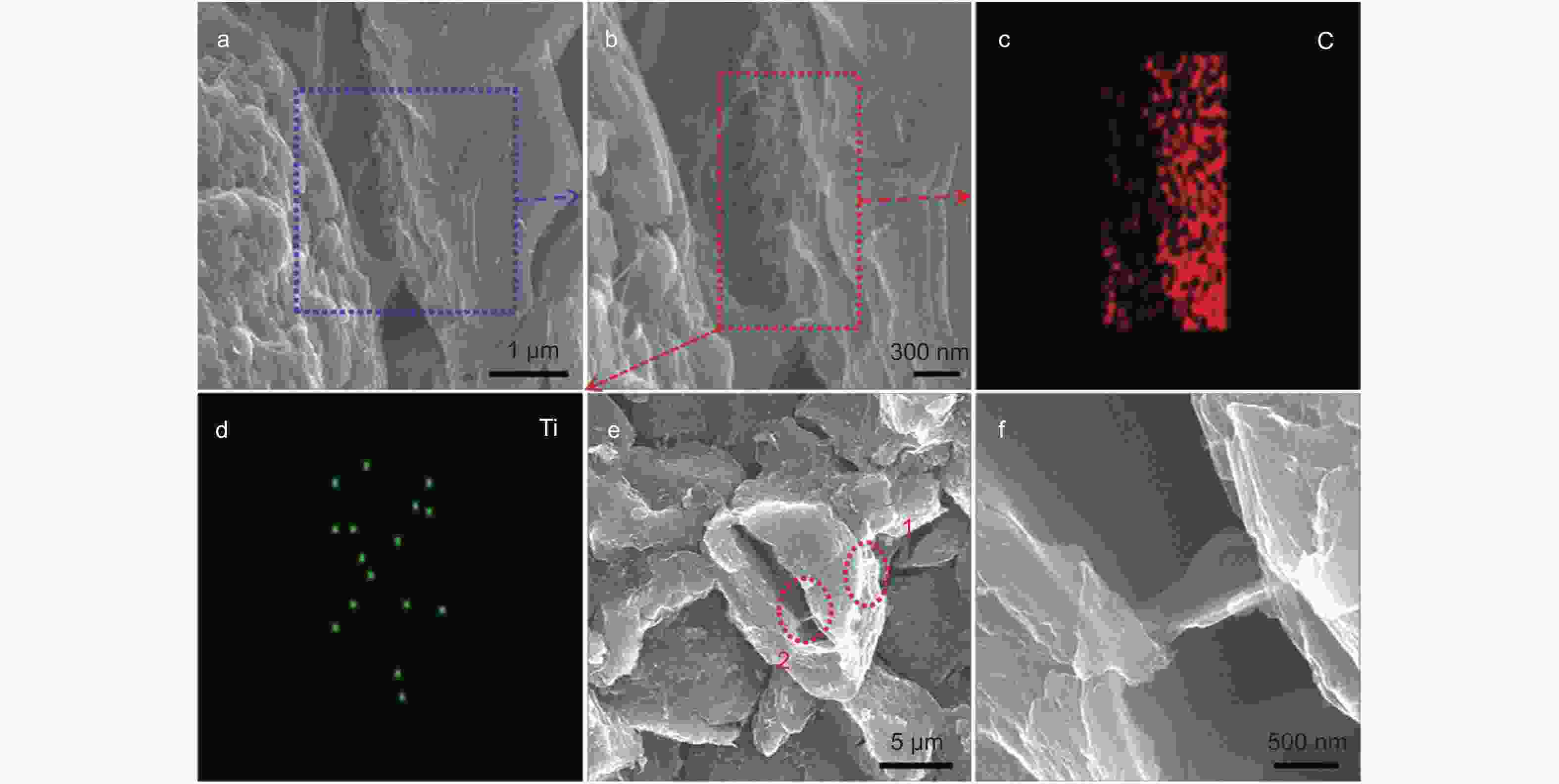

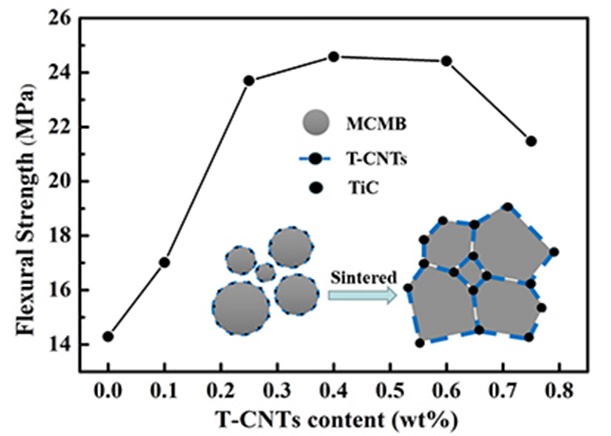

Abstract: Multi-wall carbon nanotubes (CNTs) were modified by nano-TiC using a pressureless spark plasma sintering technology. The TiC-modified CNTs (T-CNTs) were added to mesocarbon microbeads (MCMBs) to prepare high performance isostatically pressed graphite materials. The structures of the T-CNTs and the prepared isotropic graphite materials were characterized by XRD, SEM and TEM. The mechanical and thermal properties of isotropic graphite reinforced by T-CNTs were measured by a micro-controlled electronic universal testing machine, laser thermal conductivity meter and thermal expansion coefficient meter. Results showed that the nano-TiC was successfully grown on the surface of CNTs. Compared with the isotropic graphite prepared from MCMBs without T-CNTs, the isotropic graphite with T-CNTs has a significant improvement in physical properties (density, open porosity and volume shrinkage). Its flexural strength and degree of graphitization increased by 70% and 10%, respectively, and the thermal properties were also improved to some degree. -

Table 1. Physical parameters of MCMBs.

D50(µm) TI(wt%) QI(wt%) Volatiles(wt%) Ash(wt%) 12 99.20 96.30 7.68 0.25 Note: *TI: Toluene insolubles. *QI: Quinoline insolubles. Table 2. Element composition of T-CNTs.

Element C O Ti Atomic (%) 91.12 6.34 2.54 Table 3. The combination properties of different samples.

Sample Density

(g·cm−3)Volume

shrinkage (%)Open

porosity (%)Flexural

strength (MPa)MCMB 1.796 32.86 14.56 14.29 MCMB with

0.40% CNTs1.827 34.39 11.59 19.46 MCMB with

0.40% T-CNTs1.848 35.98 8.48 24.58 Table 4. CTE and isotropic ratios of graphite samples with different T-CNTs contents.

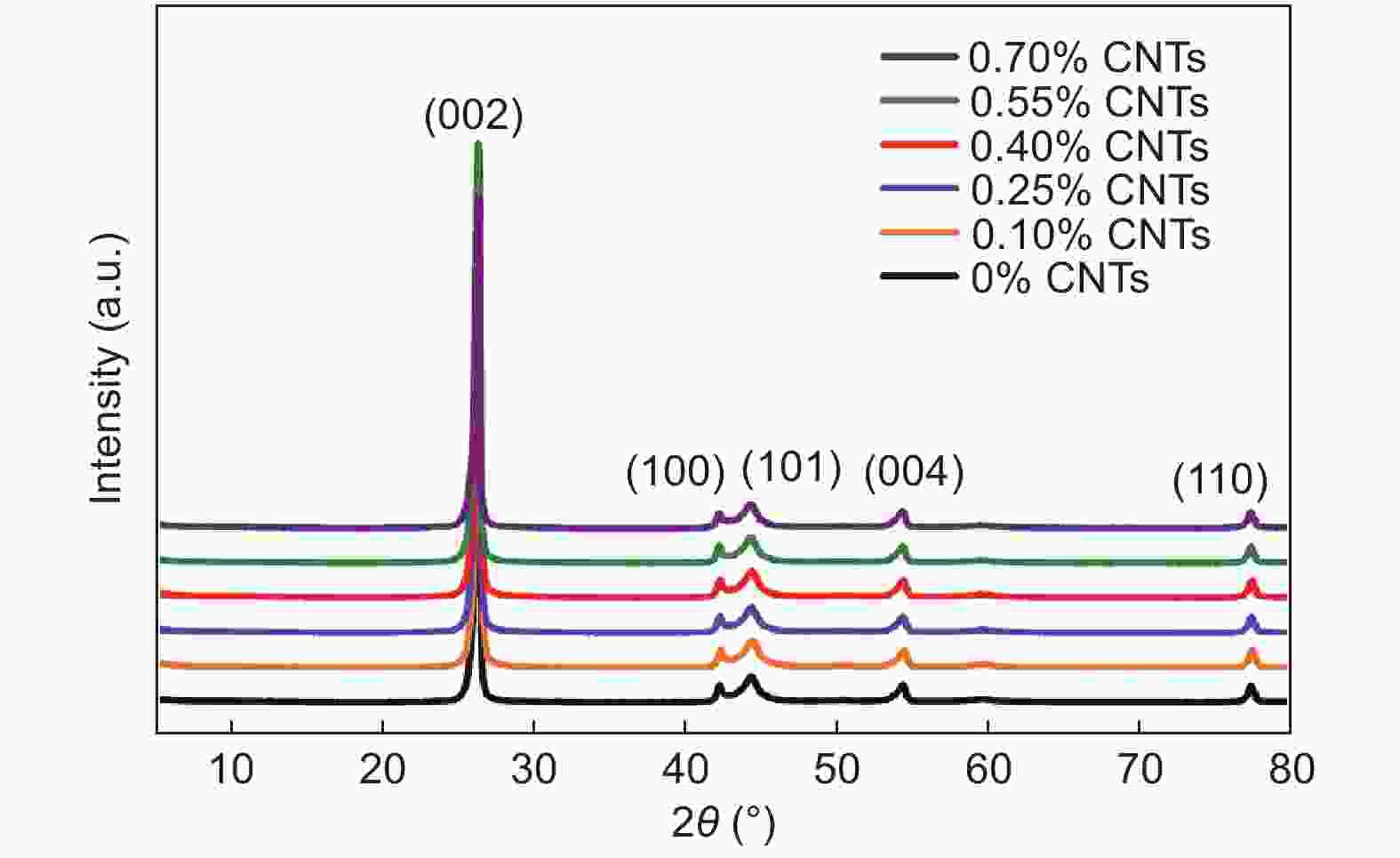

Sample CTE (10−6/K) Isotropy ratio Axial Radial MCMB 5.48 5.13 1.07 MCMB with 0.25% T-CNTs 5.08 4.93 1.03 MCMB with 0.40% T-CNTs 5.15 5.05 1.02 Table 5. Degree of graphitization of CNT/MCMB graphite samples calculated by XRD results.

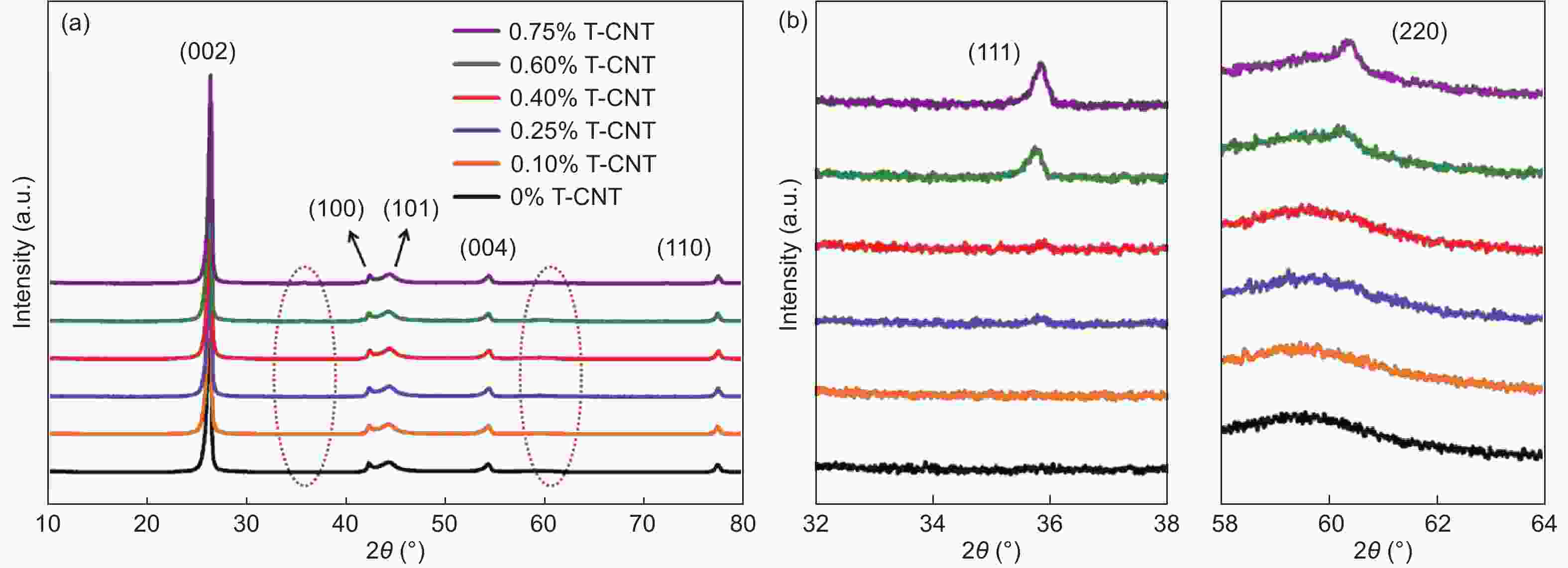

Sample 2θ (°) d002 (nm) Graphitization degree (%) MCMB 26.30 0.3385 64.0 MCMB with 0.25% CNTs 26.33 0.3382 67.4 MCMB with 0.40% CNTs 26.35 0.3379 70.9 MCMB with 0.70% CNTs 26.30 0.3385 64.0 Table 6. Degree of graphitization of T-CNT/MCMB graphite samples calculated by XRD results.

Sample 2θ(°) d002(nm) Graphitization degree(%) MCMB 26.30 0.3385 64.0 MCMB with 0.10% T-CNTs 26.30 03385 64.0 MCMB with 0.25% T-CNTs 26.34 0.3380 69.8 MCMB with 0.40% T-CNTs 26.36 0.3377 73.3 MCMB with 0.75% T-CNTs 26.38 0.3375 75.6 -

[1] Yang X, Gu X H, Wang Y H. Application and research of isostatic pressing isotropic graphite[J]. Carbon,2012,149(1):24-25. [2] B T Kelly. Physics of Graphite[M]. London: Applied Science Publisher, 1981. [3] Liu M, Zhang W T, Song J L, et al. Irradiation resistance study of binderless nanopore-isotropic graphite for use in molten salt nuclear reactors[J]. Nucl Eng Des,2018,335:231-240. doi: 10.1016/j.nucengdes.2018.05.027 [4] März B, Jolley K, Marrow T J, et al. Mesoscopic structure features in synthetic graphite[J]. Mater Des,2018,142:268-278. doi: 10.1016/j.matdes.2018.01.038 [5] Yamada T, Matsushima Y, Kuroda M, et al. Evaluation of fracture toughness of fine-grained isotropic graphites for HTGR[J]. Nucl Eng Des,2014,271:323-326. doi: 10.1016/j.nucengdes.2013.11.055 [6] Wang Y G, Y Korai, I Mochida. Carbon disc of high density and strength prepared from synthetic pitch-derived mesocarbon microbeads[J]. Carbon,1999,37(7):1049-1057. doi: 10.1016/S0008-6223(98)00298-X [7] Shen K, Huang Z H, Kang F Y, et al. Advantages of natural microcrystalline graphite filler over petroleum coke in isotropic graphite preparation[J]. Carbon,2015,90:197-206. doi: 10.1016/j.carbon.2015.03.068 [8] Hoffmann W R, Huttinger K J. Sintering of powders of polyaromatic mesophase to high-strength isotropic carbons—I. Influence of the raw material and sintering conditions on the properties of the carbon materials[J]. Carbon,1994,32(6):1087-1103. doi: 10.1016/0008-6223(94)90218-6 [9] Norfolk C, Mukasyan A, Hayes D, et al. Processing of mesocarbon microbeads to high-performance materials: Part I. Studies towards the sintering mechanism[J]. Carbon,2004,42(1):11-19. doi: 10.1016/j.carbon.2003.09.020 [10] Wen K Y, Marrow T J, Marsden B J. The microstructure of nuclear graphite binders[J]. Carbon,2008,46(1):62-71. doi: 10.1016/j.carbon.2007.10.025 [11] Jones A N, Hall G N, Joyce M, et al. Microstructural characterisation of nuclear grade graphite[J]. J Nucl Mater,2008,381(1-2): 152-157. doi: 10.1016/j.jnucmat.2008.07.038 [12] Kane J, Karthik C, Butt D P, et al. Microstructural characterization and pore structure analysis of nuclear graphite[J]. J Nucl Mater,2011,415(2):189-197. doi: 10.1016/j.jnucmat.2011.05.053 [13] Karthik C, Kane J, Butt D P, et al. Microstructural Characterization of Next Generation Nuclear Graphites[J]. Microsc Microanal,2012,18(2):272-278. doi: 10.1017/S1431927611012360 [14] Xie W J, Liu H B, Liu J P, et al. Effect of raw material types on properties of isostatic graphite[J]. Carbon technology,2013,4:27-31. [15] Lu X R, Wang C Y, Fan Q M. The influence of characteristics of ultra fine MCMB powders and molding conditions on the properties of sintered bodies[J]. New Carbon Mater,2004,19(2):109-113. [16] Zhong Q, Xie G, Yu X H, et al. Research on High Purity Graphite Production Technology[J]. Carbon technology,2012,4:13-16. [17] Liu H B, Qin D J, Chen H, et al. Preparation of High Density and High Strength Graphite by Coal Pitch Modified Mesophase Carbon Microspheres[J]. Journal of Hunan University,2018,6:40-44. [18] Hou D D, Chen H, Ding L, et al. Structure and Properties of Graphite Materials Prepared by Medium Temperature Pitch Modified MCMB[J]. Carbon technology,2017,5:35-39. [19] Ding L, Chen H, Hou D D, et al. Effect of carbonization temperature on properties of mesophase carbon microspheres for preparation of high density and high strength carbon materials[J]. Carbon technology,2018,37(3):45-55. [20] Cheng Y L, Li T H, Fang C Q, et al. In situ preparation and mechanical properties of CNTs/MCMBs composites[J]. Composites, Part B,2013,47:290-297. doi: 10.1016/j.compositesb.2012.11.009 [21] Shen K, Zhang Q, Huang Z H, et al. Interface enhancement of carbon nanotube/mesocarbon microbead isotropic composites[J]. Composites, Part A,2014,56:44-50. doi: 10.1016/j.compositesa.2013.09.008 [22] García-Rosales C, López-Galilea I, Ordás N, et al. Ti-doped isotropic graphite: A promising armour material for plasma-facing components[J]. J Nucl Mater,2009,386-388:801-804. doi: 10.1016/j.jnucmat.2008.12.224 [23] López-Galilea I, Ordás N, García- Rosales C, et al. Improvement of thermal shock resistance of isotropic graphite by Ti-doping[J]. J Nucl Mater,S2009,386-388:805-808. doi: 10.1016/j.jnucmat.2008.12.227 [24] Saba F, Sajjadi S A, Sabzevar M H, et al. Formation mechanism of nano titanium carbide on multi-walled carbon nanotube and influence of the nanocarbides on the load-bearing contribution of the nanotubes inner-walls in aluminum-matrix composites[J]. Carbon,2017,115:720-729. doi: 10.1016/j.carbon.2017.01.062 [25] Saba F, Sabzevar M H, Sajjadi S A, et al. The effect of TiC: CNT mixing ratio and CNT content on the mechanical and tribological behaviors of TiC modified CNT-reinforced Al-matrix nanocomposites[J]. Powder Technol,2018,331:107-120. doi: 10.1016/j.powtec.2018.03.023 [26] Saba F, Zhang F M, Sajjadi S A, et al. Pulsed current field assisted surface modification of carbon nanotubes with nanocrystalline titanium carbide[J]. Carbon,2016,101:261-271. doi: 10.1016/j.carbon.2016.02.012 [27] Saba F, Sajjadi S A, Sabzevar M H, et al. TiC-modified carbon nanotubes, TiC nanotubes and TiC nanorods: Synthesis and characterization[J]. Ceram Int,2018,44:7949-7954. doi: 10.1016/j.ceramint.2018.01.233 [28] Taguchi T, Yamamoto H, Shamoto S. Synthesis and characterization of single-phase TiC nanotubes, TiC nanowires, and carbon nanotubes equipped with TiC nanoparticles[J]. J Phys Chem C,2007,111(51):18888-18891. doi: 10.1021/jp0756909 [29] Zhu X K, Zhao K Y, Cheng B C, et al. Synthesis of nanocrystalline TiC powder by mechanical alloying[J]. Mater Sci Eng, C,2001,16:103-105. doi: 10.1016/S0928-4931(01)00283-1 [30] Li C Y, Chou T W. Elastic moduli of multi-walled carbon nanotubes and the effect of van der Waals forces[J]. Compos Sci Technol,2003,63:1517-1524. doi: 10.1016/S0266-3538(03)00072-1 [31] Gherrab M, Garnier V, Gavarini S, et al. Oxidation behavior of nano-scaled and micron-scaled TiC powders under air[J]. Int J Refract Met Hard Mater,2013,41:590-596. doi: 10.1016/j.ijrmhm.2013.07.012 [32] Deng C F, Wang D Z, Zhang X X, et al. Processing and properties of carbon nanotubes reinforced aluminum composites[J]. Mater Sci Eng, A,2007,444(1-2):138-145. doi: 10.1016/j.msea.2006.08.057 [33] Ray H Baughman, Anvar A Zakhidov, Walt A de Heer. Carbon nanotubes—the route toward applications[J]. Science,2002,297:787-792. doi: 10.1126/science.1060928 [34] Zhang F Q, Huang Q Z, Huang B Y, et al. Relationship between thermal conductivity and graphitization degree of a chopped carbon fiber/resin-derived carbon composite[J]. Materials Engineering,2003,9:18-21. [35] Ōya A, Ōtani S. Catalytic graphitization of carbons by various metals[J]. Carbon,1979,17:131-137. doi: 10.1016/0008-6223(79)90020-4 -

下载:

下载: