Research progress on the effect of graphene oxide on the properties of cement-based composites

-

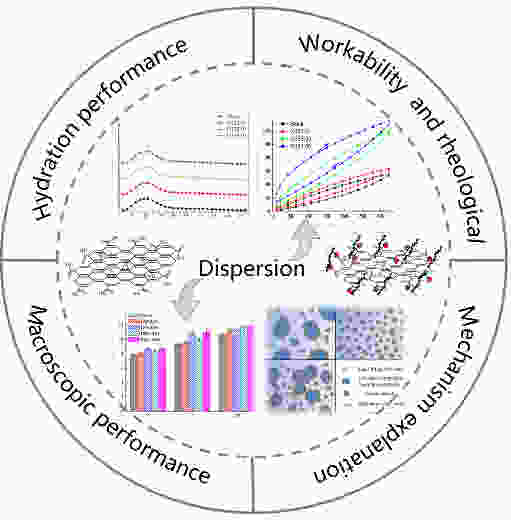

摘要: 氧化石墨烯(GO)是一种极具潜力的纳米增强材料,对水泥基复合材料具有显著的增强和增韧作用。但现有研究中仍存在一些盲点和有争议的领域,需通过进一步的研究加以阐明。本文综述了GO增强水泥基复合材料的最新研究进展,介绍了GO对水泥基复合材料性能的影响及其作用机制,重点阐述了GO在水泥环境中的分散性,GO对水化性能、工作性和流变性能和宏观性能(机械性能和耐久性能)的影响以及可能的增强和增韧机制。基于现有研究中存在的问题,提出了未来的研究重点,为GO在实际工程中的应用奠定了坚实的基础。Abstract: Graphene oxide (GO) has significant strengthening and toughening effects on cement-based composites as a nano-reinforcement filler, and research progress on these materials is presented. The effects of GO on the properties of cementitious composites are summarized, including the dispersion stability of GO in a cement environment, the hydration properties, workability, rheological properties, mechanical properties and durability. Reinforcement and toughening mechanisms are proposed. Prospective research trends are discussed based on the problems already encountered

-

Key words:

- Graphene oxide /

- Cement /

- Dispersion /

- Hydration /

- Toughening and strengthening mechanism

-

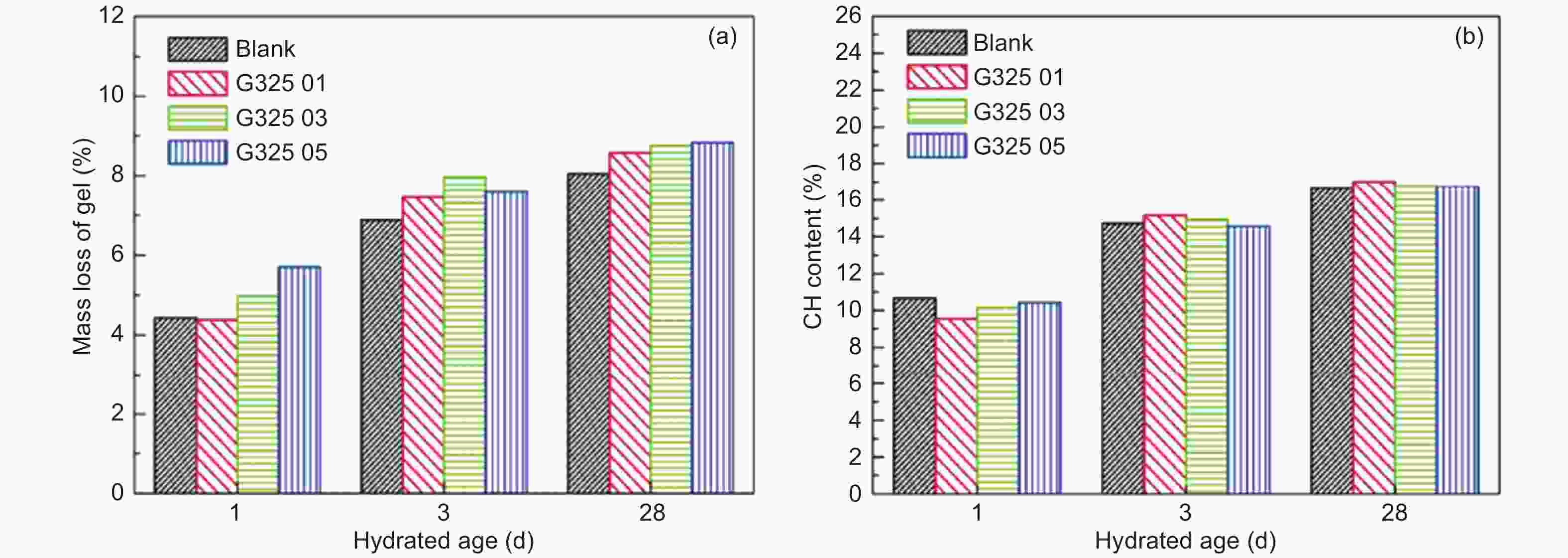

Figure 2. The influence of GO content on the cement hydration product content at different hydration ages: (a) cement gel and (b) CH[53].

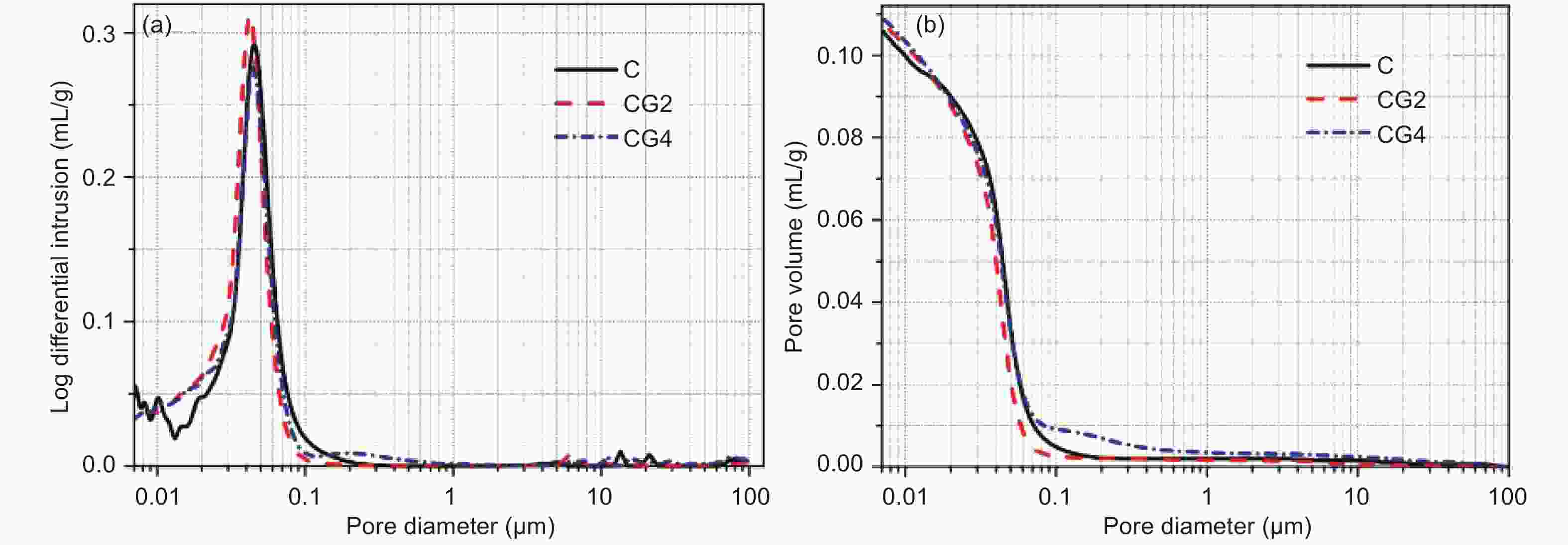

Figure 3. (a) Differential and (b) cumulative pore size distributions of GO-Cement[48].

Figure 4. Intrusion pore volume of mercury at different pore size ranges for all cement mixes[68].

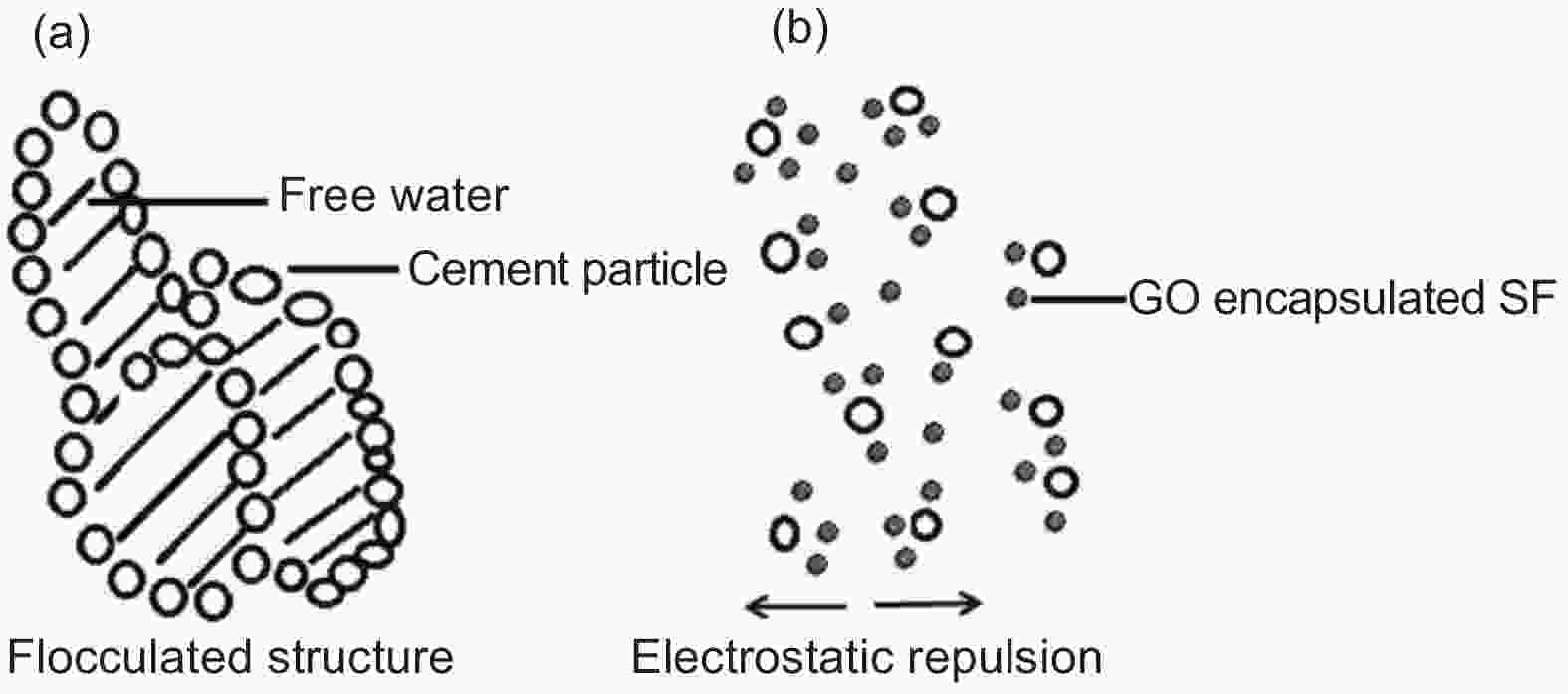

Figure 5. Schematic illustration of (a) the formation of flocculated structure and (b) the influence mechanism of GOSF[19].

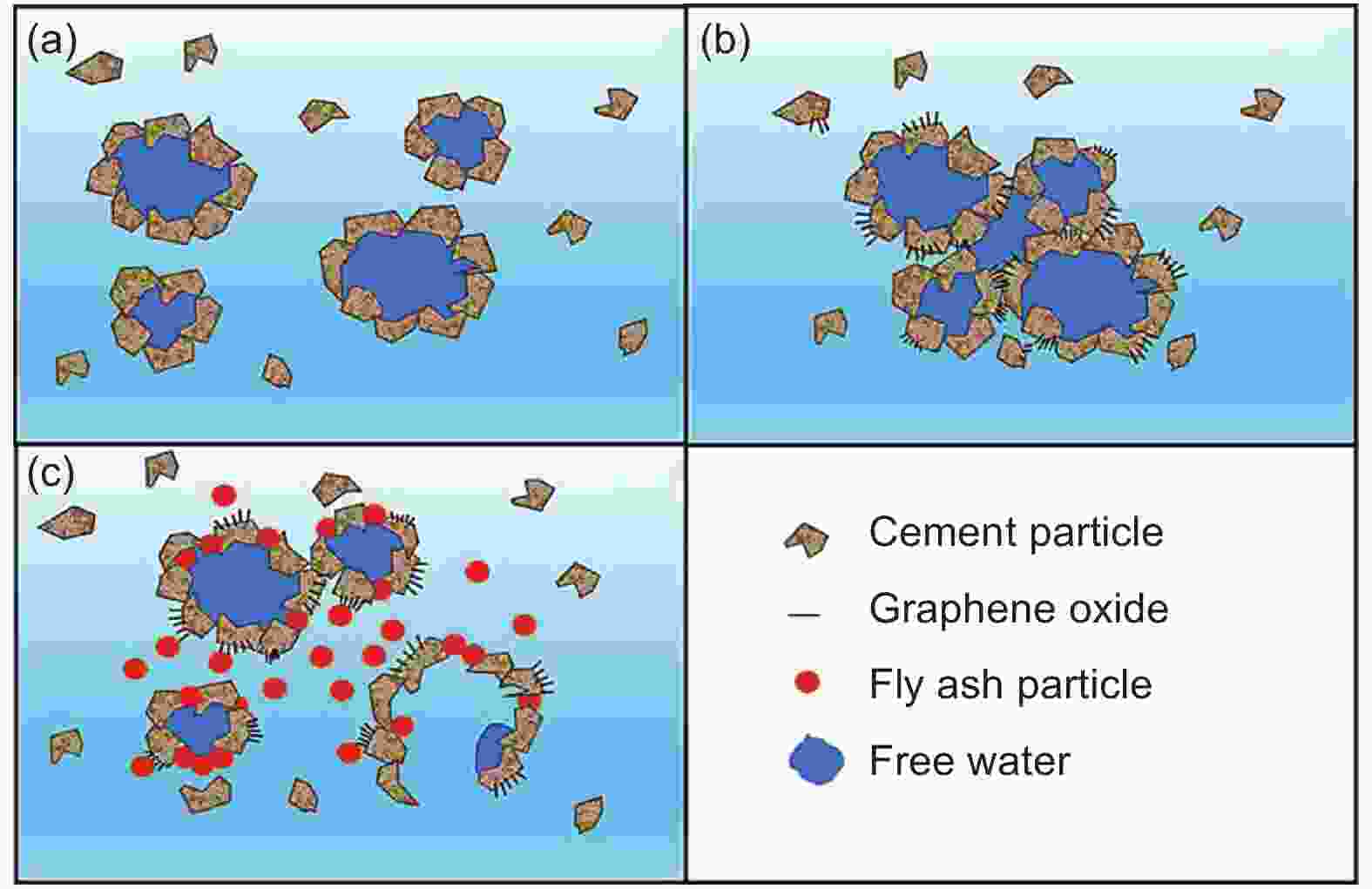

Figure 6. Effect of fly ash and GO on the formation of flocculation structure[40].

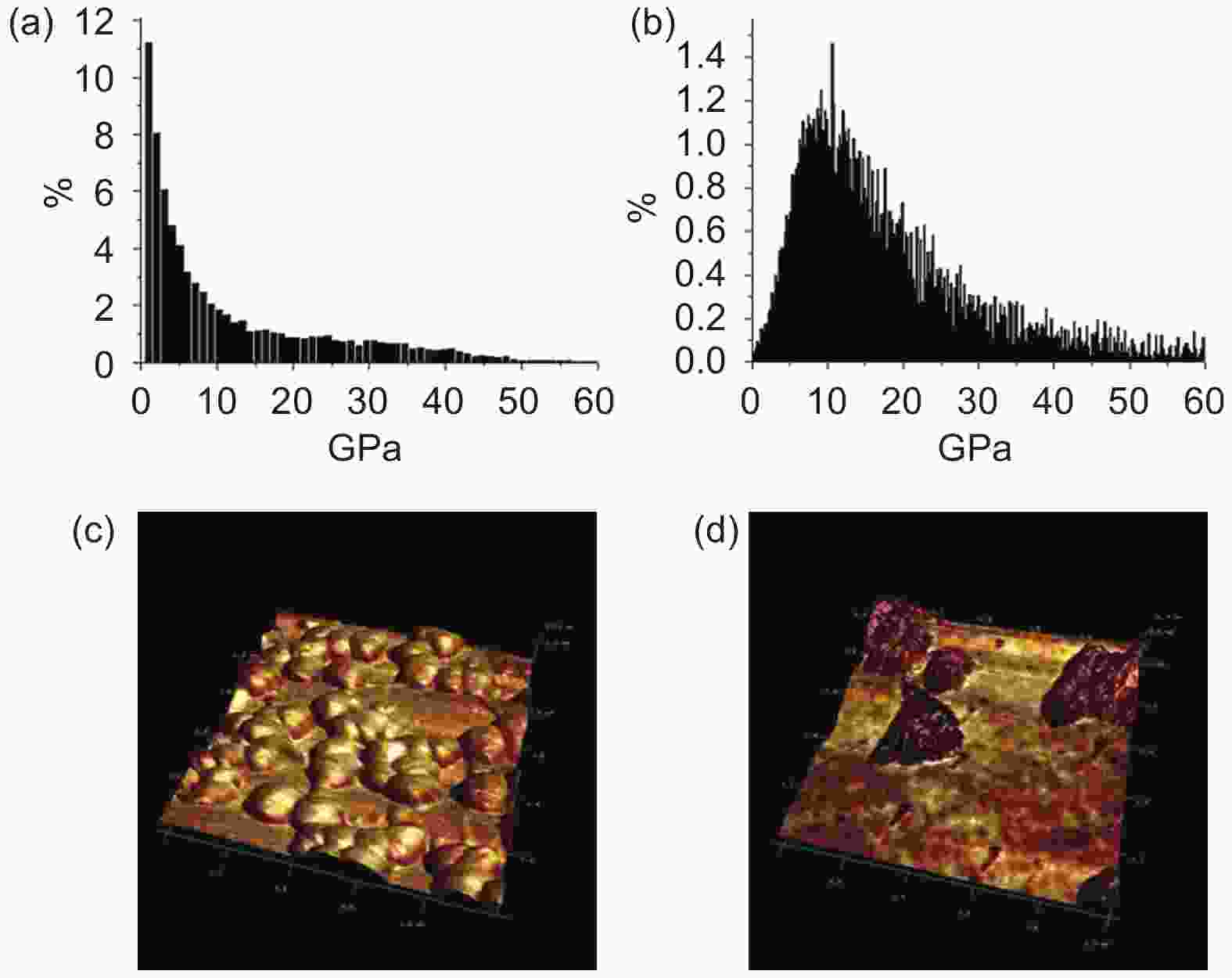

Figure 7. (a) Young’s modulus values of the reference sample, (b) nanocomposite, (c) topography of the reference sample, (d) nanocomposite estimated by AFM[62].

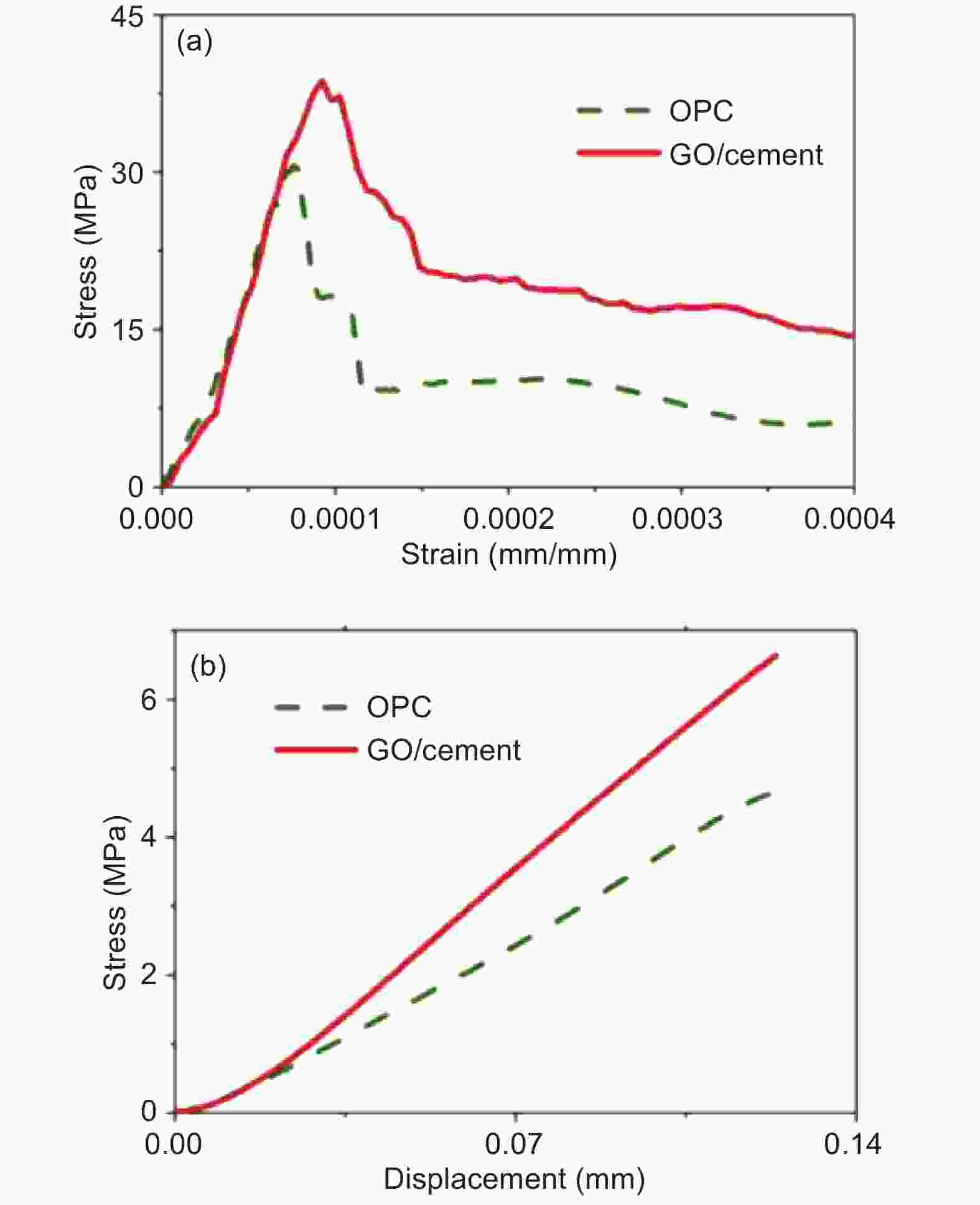

Figure 8. GO-cement loading curve. (a) Stress-strain curve (compressive load) and (b) Load-displacement curve (flexural load). OPC: ordinary Portland cement[8].

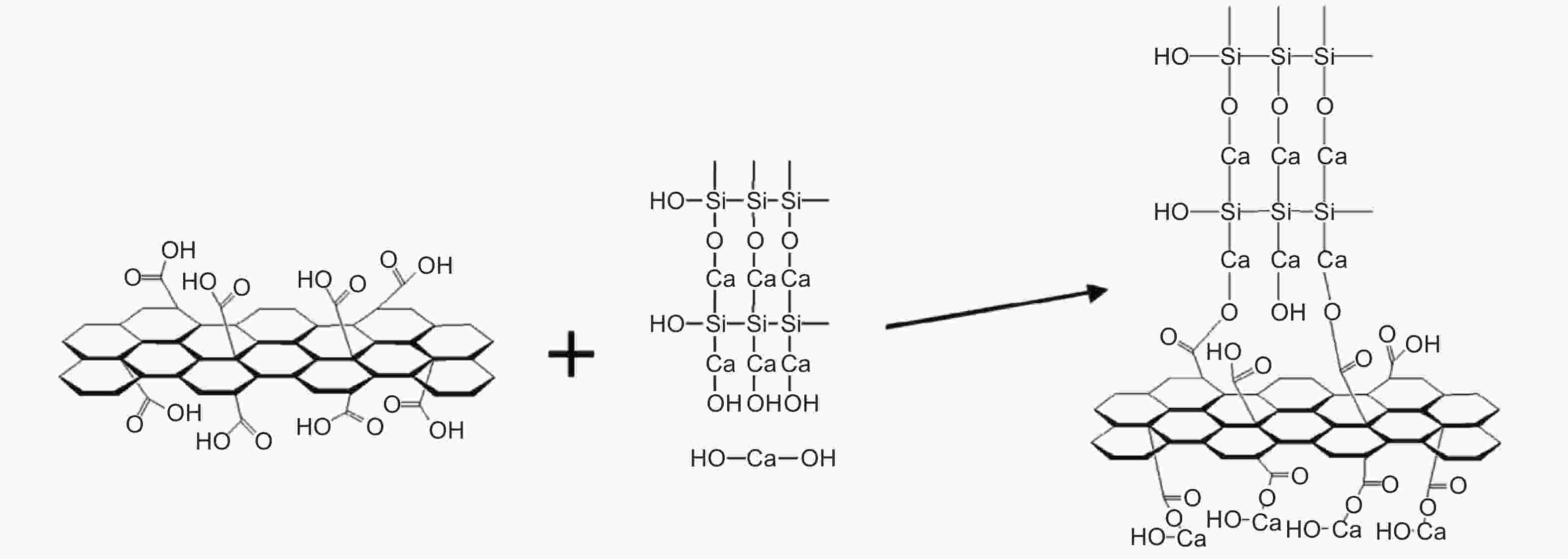

Figure 9. Schematic reaction between carboxylic acid groups and hydration productions of cement[8].

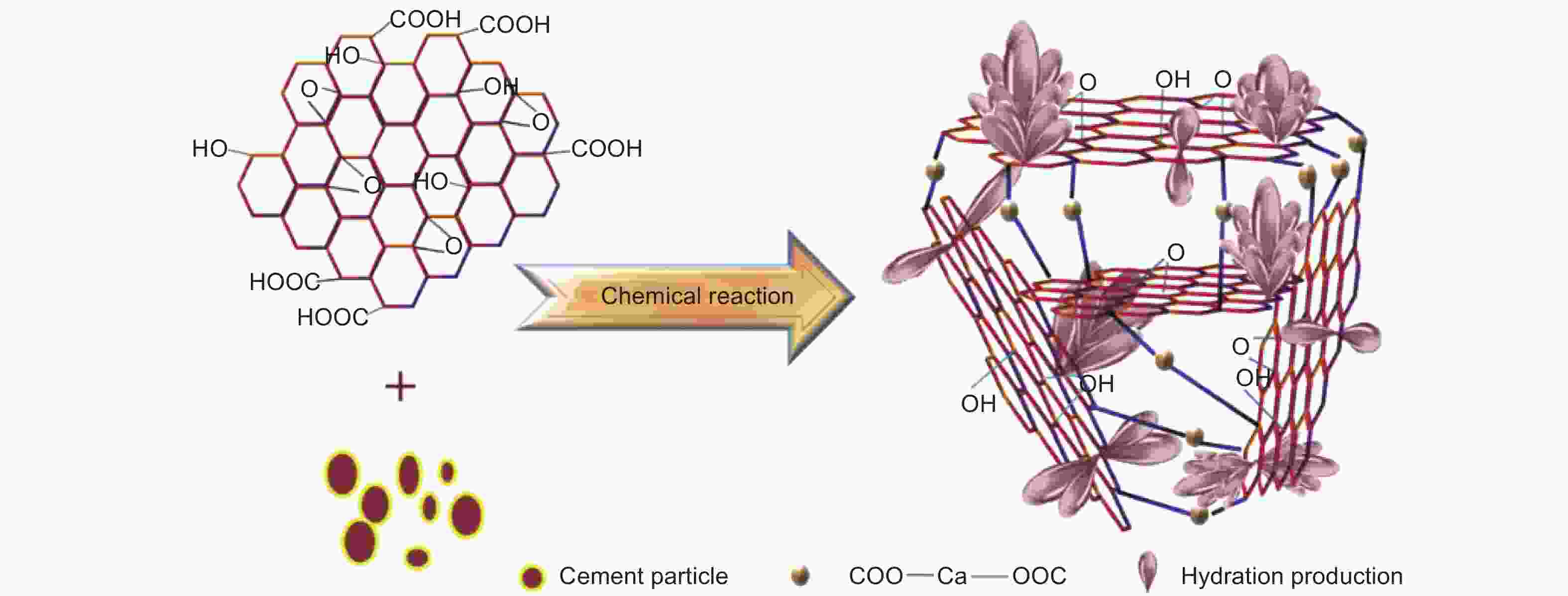

Figure 10. The model of GO nanosheets modified cement[95].

Table 1. The improvement of GO dispersion processes.

Research system GO concentration

(mg/ml)GO

contenta (wt.%)w/cb Dispersion process Dispersant Refs. SPSd 4 0.02 0.4 (1) Add dispersant to GO solution.

(2) Add the dispersant to the simulated cement pore solution, and then add the GO solution (only for ADVA210)ADVA 210,

Sika Viscocrete 6, Gum Arabic,

Micro Air 905[33] CPSd 6 0.05 0.5 Mix the GO solution and the dispersant with electromagnetic stirring, and then sonicate for 30 min LS, PNS, PCEc [34] CP, APd 1, 2 0.04, 0.08 0.4 Add dispersant to GO solution and then mix with powder PCEc [36] CPd - 0.01–0.05 0.33 Chemically functionalized graphene oxide (GOM) was synthesized by the chemical reaction polyether amine [41] CPd - 0.01–0.05 0.29 Copolymerization of graphene oxide nanosheets (GONs) and PCE's monomers of methacrylic acid, sodium allyl sulfonate and methacrylate polyoxyethylene ether. PCEc [42] CPd - 0.01, 0.03 0.35 React GO with vinyltrimethoxysilane, then copolymerise with acrylic acid and isobutylene alcohol ethoxylates Vinyltrimethoxysilane [1] SPS, CPd 4 0.02 0.4 Add SF to the GO solution and stir for 30 s at 4000 r/min Silica fume [39] CPd 4 0.01, 0.03 0.3 Add GO solution to FA-cement system and stir Fly ash [40] Note: a: by weight of cement. b: water to cement ratio.

c: sodium lignosulfonate(LS), polycondensate of b-naphthalene sulfonate formaldehyde (PNS), polycarboxylate superplasticizer (PCE).

d: simulated pore solution (SPS), cement pore solution (CPS), cement paste (CP), alite paste (AP).Table 2. The impact of GO on the hydration process.

w/ca Optimal dosage

(GO)dAdmixture Research

systemIn induction period minimum Peak heat

flow time (h)Peak heat

flow (mW. g−1)48 h total

heat (J. g−1)Refs. time (h) heat flow (mW. g−1) 0.4 0.04% - cement 1.40 (1.39)b 0.664 (0.622)b 7.705 (7.98121)b 3.79 (3.65)b - [48] 0.4 0.08% - cement - - 6.072 (6.447) 2.50 (2.35) 180.2 [49] 0.35 0.08% - cement - - 6.884 (7.392) 2.48 (2.32) 201.3 [47] 0.5 0.08% - alite - - 11.501 (11.883) 2.053 (1.773) - [52] 0.5 0.05% PCEc cement - - 14.089 (15.022) 6.004 (4.862) - [54] 0.4 0.04% PCE alite - - 22.003 (29.942) 2.492 (2.204) 155.6 [36] 0.5 0.05% PCE cement 2.50

(2.00)0.677 (0.702) 12.198 (12.499) 6.11 (5.203) - [26] Note: a: water to cement ratio. b: values in parentheses are blank groups. c: polycarboxylate superplasticizer (PCE). d: by the weight of cement or alite. Table 3. The influence of GO on the mechanical properties of cement-based composites.

Research system w/ca Optimal dosage (GO)b Age (d) PCE dosageb Compressive strength growth Flexural strength growth Refs. Cement paste 0.38 0.032% - 0.20% 17.800% 12.00% [77] Cement mortar 0.38 0.032% - 0.20% 23.20% 18.30% [77] Cement paste 0.44 0.03% 28 - 17.20% 7.80% [80] Cement paste 0.3 0.03% 28 - 8.50% 32.20% [40] Cement mortar 0.37 0.03% 28 0.20% 15.67% 20% [78] Cement paste 0.4 0.04% 28 - 15.10% - [19] Cement paste 0.4 0.04% 7 - 6.10% - [48] Cement paste 0.4 0.04% 28 - 14.00% - [48] Cement paste 0.5 0.03% 28 - 31.75% - [59] Cement paste 0.4 0.06% 28 - 46.60% 14.20% [49] Cement paste 0.5 0.10% 28 0.26% 16.98% 26% [75] Cement paste 0.4 0.20% 3 0.20% 42.30% - [20] Cement paste 0.4 0.20% 28 0.20% 11.20% - [20] Cement paste 0.29 0.05% 3 0.50% 52.40% 86.10% [69] Cement paste 0.29 0.05% 28 0.50% 40.40% 90.50% [69] Cement mortar 0.37 0.05% 3 0.50% 43.20% 69.40% [69] Cement mortar 0.37 0.05% 28 0.50% 24.40% 70.50% [69] Cement paste 0.4 0.03% 28 - - 26.55% [33] Cement paste 0.5 0.05% 7 - 19.58% 32.86% [8] Note: a: water to cement ratio. b: PCE and GO are by the weight of cement. -

[1] Wang Q, Li S, Pan S, et al. Synthesis and properties of a silane and copolymer-modified graphene oxide for use as a water-reducing agent in cement pastes[J]. New Carbon Materials,2018,33(2):131-139. doi: 10.1016/S1872-5805(18)60330-0 [2] Hanif A, Lu Z, Sun M, et al. Green lightweight ferrocement incorporating fly ash cenosphere based fibrous mortar matrix[J]. Journal of Cleaner Production,2017,159:326-335. doi: 10.1016/j.jclepro.2017.05.079 [3] Ma H, Li Z. Microstructures and mechanical properties of polymer modified mortars under distinct mechanisms[J]. Construction and Building Materials,2013,47:579-587. doi: 10.1016/j.conbuildmat.2013.05.048 [4] Hanif A, Lu Z, Diao S, et al. Properties investigation of fiber reinforced cement-based composites incorporating cenosphere fillers[J]. Construction and Building Materials,2017,140:139-149. doi: 10.1016/j.conbuildmat.2017.02.093 [5] Lu Z, Zhang J, Sun G, et al. Effects of the form-stable expanded perlite/paraffin composite on cement manufactured by extrusion technique[J]. Energy,2015,82:43-53. doi: 10.1016/j.energy.2014.12.043 [6] Zhang P, Wang K, Li Q, et al. Fabrication and engineering properties of concretes based on geopolymers/alkali-activated binders - A review[J]. Journal of Cleaner Production,2020,258:120896. doi: 10.1016/j.jclepro.2020.120896 [7] Yuanxun Z, Peng Z, Yingchun C, et al. Cracking resistance and mechanical properties of basalt fibers reinforced cement-stabilized macadam[J]. Composites Part B,2019,165:312-334. doi: 10.1016/j.compositesb.2018.11.115 [8] Pan Z, He L, Qiu L, et al. Mechanical properties and microstructure of a graphene oxide–cement composite[J]. Cement and Concrete Composites,2015,58:140-147. doi: 10.1016/j.cemconcomp.2015.02.001 [9] Zhang P, Wang K, Wang J, et al. Mechanical properties and prediction of fracture parameters of geopolymer/alkali-activated mortar modified with PVA fiber and nano-SiO2[J]. Ceramics International,2020,46(12):20027-20037. doi: 10.1016/j.ceramint.2020.05.074 [10] Zhang P, Wan J, Wang K, et al. Influence of nano-SiO2 on properties of fresh and hardened high performance concrete: A state-of-the-art review[J]. Construction and Building Materials,2017,148:648-658. doi: 10.1016/j.conbuildmat.2017.05.059 [11] Cwirzen A, Habermehl-Cwirzen K, Nasibulin A G, et al. SEM/AFM studies of cementitious binder modified by MWCNT and nano-sized Fe needles[J]. Materials Characterization,2009,60(7):735-740. doi: 10.1016/j.matchar.2008.11.001 [12] Novoselov K S, Geim A K, Morozov S V, et al. Electric field effect in atomically thin carbon films[J]. Science,2004,306(5696):666-669. doi: 10.1126/science.1102896 [13] Zhu Y, Murali S, Cai W, et al. Graphene and graphene oxide: Synthesis, properties, and applications[J]. Advanced Materials,2010,22(35):3906-3924. doi: 10.1002/adma.201001068 [14] Korayem A H, Tourani N, Zakertabrizi M, et al. A review of dispersion of nanoparticles in cementitious matrices: Nanoparticle geometry perspective[J]. Construction and Building Materials,2017,153:346-357. doi: 10.1016/j.conbuildmat.2017.06.164 [15] Cao J, Chung D D L. Colloidal graphite as an admixture in cement and as a coating on cement for electromagnetic interference shielding[J]. Cement and Concrete Research,2003,33(11):1737-1740. doi: 10.1016/S0008-8846(03)00152-2 [16] Peyvandi A, Soroushian P, Abdol N, et al. Surface-modified graphite nanomaterials for improved reinforcement efficiency in cementitious paste[J]. Carbon (New York),2013,63:175-186. [17] Suk J W, Piner R D, An J, et al. Mechanical properties of monolayer graphene oxide[J]. ACS Nano,2010,4(11):6557-6564. doi: 10.1021/nn101781v [18] Robinson J T, Zalalutdinov M, Baldwin J W, et al. Wafer-scale reduced graphene oxide films for nanomechanical devices[J]. Nano Letters,2008,8(10):3441-3445. doi: 10.1021/nl8023092 [19] Shang Y, Zhang D, Yang C, et al. Effect of graphene oxide on the rheological properties of cement pastes[J]. Construction and Building Materials,2015,96:20-28. doi: 10.1016/j.conbuildmat.2015.07.181 [20] Yang H, Monasterio M, Cui H, et al. Experimental study of the effects of graphene oxide on microstructure and properties of cement paste composite[J]. Composites Part A: Applied Science and Manufacturing,2017,102:263-272. doi: 10.1016/j.compositesa.2017.07.022 [21] Zhu X H, Kang X J, Yang K, et al. Effect of graphene oxide on the mechanical properties and the formation of layered double hydroxides (LDHs) in alkali-activated slag cement[J]. Construction and Building Materials,2017,132:290-295. doi: 10.1016/j.conbuildmat.2016.11.059 [22] Lu Z, Hou D, Ma H, et al. Effects of graphene oxide on the properties and microstructures of the magnesium potassium phosphate cement paste[J]. Construction and Building Materials,2016,119:107-112. doi: 10.1016/j.conbuildmat.2016.05.060 [23] Shao G, Lu Y, Wu F, et al. Graphene oxide: The mechanisms of oxidation and exfoliation[J]. Journal of Materials Science,2012,47(10):4400-4409. doi: 10.1007/s10853-012-6294-5 [24] Stephens C, Brown L, Sanchez F. Quantification of the re-agglomeration of carbon nanofiber aqueous dispersion in cement pastes and effect on the early age flexural response[J]. Carbon,2016,107:482-500. doi: 10.1016/j.carbon.2016.05.076 [25] Wu L, Liu L, Gao B, et al. Aggregation kinetics of graphene oxides in aqueous solutions: Experiments, mechanisms, and modeling[J]. Langmuir,2013,29(49):15174-15181. doi: 10.1021/la404134x [26] Zhao L, Zhu S, Wu H, et al. Deep research about the mechanisms of graphene oxide (GO) aggregation in alkaline cement pore solution[J]. Construction and Building Materials,2020,247:118446. doi: 10.1016/j.conbuildmat.2020.118446 [27] Babak F, Abolfazl H, Alimorad R, et al. Preparation and mechanical properties of graphene oxide: Cement nanocomposites[J]. The Scientific World Journal,2014,2014:1-10. [28] Chuah S, Pan Z, Sanjayan J G, et al. Nano reinforced cement and concrete composites and new perspective from graphene oxide[J]. Construction and Building Materials,2014,73:113-124. doi: 10.1016/j.conbuildmat.2014.09.040 [29] Wang B, Han Y, Liu S. Effect of highly dispersed carbon nanotubes on the flexural toughness of cement-based composites[J]. Construction and Building Materials,2013,46:8-12. doi: 10.1016/j.conbuildmat.2013.04.014 [30] Sobolkina A, Mechtcherine V, Khavrus V, et al. Dispersion of carbon nanotubes and its influence on the mechanical properties of the cement matrix[J]. Cement and Concrete Composites,2012,34(10):1104-1113. doi: 10.1016/j.cemconcomp.2012.07.008 [31] Collins F, Lambert J, Duan W H. The influences of admixtures on the dispersion, workability, and strength of carbon nanotube–OPC paste mixtures[J]. Cement and Concrete Composites,2012,34(2):201-207. doi: 10.1016/j.cemconcomp.2011.09.013 [32] Liebscher M, Lange A, Schröfl C, et al. Impact of the molecular architecture of polycarboxylate superplasticizers on the dispersion of multi-walled carbon nanotubes in aqueous phase[J]. Journal of Materials Science,2017,52(4):2296-2307. doi: 10.1007/s10853-016-0522-3 [33] Chuah S, Li W, Chen S J, et al. Investigation on dispersion of graphene oxide in cement composite using different surfactant treatments[J]. Construction and Building Materials,2018,161:519-527. doi: 10.1016/j.conbuildmat.2017.11.154 [34] Zhao L, Guo X, Liu Y, et al. Investigation of dispersion behavior of GO modified by different water reducing agents in cement pore solution[J]. Carbon (New York),2018,127:255-269. [35] Jiang L, Gao L, Sun J. Production of aqueous colloidal dispersions of carbon nanotubes[J]. Journal of Colloid and Interface Science,2003,260(1):89-94. doi: 10.1016/S0021-9797(02)00176-5 [36] Ghazizadeh S, Duffour P, Skipper N T, et al. Understanding the behaviour of graphene oxide in Portland cement paste[J]. Cement and Concrete Research,2018,111:169-182. doi: 10.1016/j.cemconres.2018.05.016 [37] Zhang Y, Kong X. Correlations of the dispersing capability of NSF and PCE types of superplasticizer and their impacts on cement hydration with the adsorption in fresh cement pastes[J]. Cement and Concrete Research,2015,69:1-9. doi: 10.1016/j.cemconres.2014.11.009 [38] Qin W, Guodong Q, Dafu Z, et al. Influence of the molecular structure of a polycarboxylate superplasticiser on the dispersion of graphene oxide in cement pore solutions and cement-based composites[J]. Construction and Building Materials,2021,272:121969. doi: 10.1016/j.conbuildmat.2020.121969 [39] Li X, Korayem A H, Li C, et al. Incorporation of graphene oxide and silica fume into cement paste: A study of dispersion and compressive strength[J]. Construction and Building Materials,2016,123:327-335. doi: 10.1016/j.conbuildmat.2016.07.022 [40] Wang Q, Cui X, Wang J, et al. Effect of fly ash on rheological properties of graphene oxide cement paste[J]. Construction and Building Materials,2017,138:35-44. doi: 10.1016/j.conbuildmat.2017.01.126 [41] Wang M, Yao H, Wang R, et al. Chemically functionalized graphene oxide as the additive for cement–matrix composite with enhanced fluidity and toughness[J]. Construction and Building Materials,2017,150:150-156. doi: 10.1016/j.conbuildmat.2017.05.217 [42] Lu S H, Deng L J, Yang W Q, et al. Fabrication of polycarboxylate/graphene oxide nanosheet composites by copolymerization for reinforcing and toughening cement composites[J]. Cement and Concrete Composites,2016,66:1-9. doi: 10.1016/j.cemconcomp.2015.11.007 [43] Yang H, Cui H, Tang W, et al. A critical review on research progress of graphene/cement based composites[J]. Composites Part A: Applied Science and Manufacturing,2017,102:273-296. doi: 10.1016/j.compositesa.2017.07.019 [44] Lu L, Zhao P, Lu Z. A short discussion on how to effectively use graphene oxide to reinforce cementitious composites[J]. Construction and Building Materials,2018,189:33-41. doi: 10.1016/j.conbuildmat.2018.08.170 [45] Hou Y F. Cementing Material[M]. Beijing: China Electric Power Press, 2012. [46] Wang M, Wang R, Yao H, et al. Adsorption characteristics of graphene oxide nanosheets on cement[J]. RSC advances,2016,6(68):63365-63372. doi: 10.1039/C6RA10902K [47] Lu Z, Li X, Hanif A, et al. Early-age interaction mechanism between the graphene oxide and cement hydrates[J]. Construction and Building Materials,2017,152:232-239. doi: 10.1016/j.conbuildmat.2017.06.176 [48] Li X, Liu Y M, Li W G, et al. Effects of graphene oxide agglomerates on workability, hydration, microstructure and compressive strength of cement paste[J]. Construction and Building Materials,2017,145:402-410. doi: 10.1016/j.conbuildmat.2017.04.058 [49] Li W, Li X, Chen S J, et al. Effects of graphene oxide on early-age hydration and electrical resistivity of Portland cement paste[J]. Construction and Building Materials,2017,136:506-514. doi: 10.1016/j.conbuildmat.2017.01.066 [50] Land G, Stephan D. The influence of nano-silica on the hydration of ordinary Portland cement[J]. Journal of Materials Science,2012,47(2):1011-1017. doi: 10.1007/s10853-011-5881-1 [51] Jansen D, Neubauer J, Goetz-Neunhoeffer F, et al. Change in reaction kinetics of a Portland cement caused by a superplasticizer — Calculation of heat flow curves from XRD data[J]. Cement and Concrete Research,2012,42(2):327-332. doi: 10.1016/j.cemconres.2011.10.005 [52] Ghazizadeh S, Duffour P, Skipper N T, et al. An investigation into the colloidal stability of graphene oxide nano-layers in alite paste[J]. Cement and Concrete Research,2017,99:116-128. doi: 10.1016/j.cemconres.2017.05.011 [53] Wang Q, Li S Y, Wang J, et al. Effect of graphene oxide on the hydration process of cement and its main hydration products[J]. Journal of the Chinese Ceramic Society,2018,46(02):163-172. [54] Zhao L, Guo X, Liu Y, et al. Hydration kinetics, pore structure, 3D network calcium silicate hydrate, and mechanical behavior of graphene oxide reinforced cement composites[J]. Construction and Building Materials,2018,190:150-163. doi: 10.1016/j.conbuildmat.2018.09.105 [55] Sanchez F, Sobolev K. Nanotechnology in concrete – A review[J]. Construction and Building Materials,2010,24(11):2060-2071. doi: 10.1016/j.conbuildmat.2010.03.014 [56] Shi C J, Yuan Q. Analytical Methods for Testing Cement-based Materials[M]. Beijing: China Architecture & Building Press, 2018. [57] Escalante-Garcia J I. Nonevaporable water from neat OPC and replacement materials in composite cements hydrated at different temperatures[J]. Cement and Concrete Research,2003,33(11):1883-1888. doi: 10.1016/S0008-8846(03)00208-4 [58] Mounanga P, Khelidj A, Loukili A, et al. Predicting Ca(OH)2 content and chemical shrinkage of hydrating cement pastes using analytical approach[J]. Cement and Concrete Research,2004,34(2):255-265. doi: 10.1016/j.cemconres.2003.07.006 [59] Gong K, Pan Z, Korayem A H, et al. Reinforcing effects of graphene oxide on portland cement paste[J]. Journal of Materials in Civil Engineering,2015,27(2):A4014010. [60] Li X, Lu Z, Chuah S, et al. Effects of graphene oxide aggregates on hydration degree, sorptivity, and tensile splitting strength of cement paste[J]. Composites Part A: Applied Science and Manufacturing,2017,100:1-8. doi: 10.1016/j.compositesa.2017.05.002 [61] Sharma S, Kothiyal N C. Influence of graphene oxide as dispersed phase in cement mortar matrix in defining the crystal patterns of cement hydrates and its effect on mechanical, microstructural and crystallization properties[J]. RSC Advances,2015,5(65):52642-52657. doi: 10.1039/C5RA08078A [62] Horszczaruk E, Mijowska E, Kalenczuk R J, et al. Nanocomposite of cement/graphene oxide – Impact on hydration kinetics and Young’s modulus[J]. Construction and Building Materials,2015,78:234-242. doi: 10.1016/j.conbuildmat.2014.12.009 [63] Qin H, Wei W, Hang Hu Y. Synergistic effect of graphene-oxide-doping and microwave-curing on mechanical strength of cement[J]. Journal of Physics and Chemistry of Solids,2017,103:67-72. doi: 10.1016/j.jpcs.2016.12.009 [64] Shi H S, Guo X L, Kan L L. Cement-based Materials Science[M]. Beijing: China Building Materials Press, 2011. [65] Tong T, Fan Z, Liu Q, et al. Investigation of the effects of graphene and graphene oxide nanoplatelets on the micro- and macro-properties of cementitious materials[J]. Construction and Building Materials,2016,106:102-114. doi: 10.1016/j.conbuildmat.2015.12.092 [66] Zhao L, Guo X, Song L, et al. An intensive review on the role of graphene oxide in cement-based materials[J]. Construction and Building Materials,2020,241:117939. doi: 10.1016/j.conbuildmat.2019.117939 [67] Kumar R, Bhattacharjee B. Study on some factors affecting the results in the use of MIP method in concrete research[J]. Cement and Concrete Research,2003,33(3):417-424. doi: 10.1016/S0008-8846(02)00974-2 [68] Mohammed A, Sanjayan J G, Duan W H, et al. Incorporating graphene oxide in cement composites: A study of transport properties[J]. Construction and Building Materials,2015,84:341-347. doi: 10.1016/j.conbuildmat.2015.01.083 [69] Wang Q, Wang J, Lu C, et al. Influence of graphene oxide additions on the microstructure and mechanical strength of cement[J]. New Carbon Materials,2015,30(4):349-356. doi: 10.1016/S1872-5805(15)60194-9 [70] Song S M, Sun L. Civil Engineering Materials[M]. Wuhan: Wuhan University of Technology Press, 2011. [71] Secrieru E, Cotardo D, Mechtcherine V, et al. Changes in concrete properties during pumping and formation of lubricating material under pressure[J]. Cement and Concrete Research,2018,108:129-139. doi: 10.1016/j.cemconres.2018.03.018 [72] Wang Q, Wang J, Lv C, et al. Rheological behavior of fresh cement pastes with a graphene oxide additive[J]. New Carbon Materials,2016,31(6):574-584. doi: 10.1016/S1872-5805(16)60033-1 [73] Ran Q, Somasundaran P, Miao C, et al. Adsorption mechanism of comb polymer dispersants at the cement/water interface[J]. Journal of Dispersion Science and Technology,2010,31(6):790-798. doi: 10.1080/01932690903333580 [74] Birenboim M, Nadiv R, Alatawna A, et al. Reinforcement and workability aspects of graphene-oxide-reinforced cement nanocomposites[J]. Composites Part B: Engineering,2019,161:68-76. doi: 10.1016/j.compositesb.2018.10.030 [75] Long W, Wei J, Xing F, et al. Enhanced dynamic mechanical properties of cement paste modified with graphene oxide nanosheets and its reinforcing mechanism[J]. Cement and Concrete Composites,2018,93:127-139. doi: 10.1016/j.cemconcomp.2018.07.001 [76] Long W, Gu Y, Xiao B, et al. Micro-mechanical properties and multi-scaled pore structure of graphene oxide cement paste: Synergistic application of nanoindentation, X-ray computed tomography, and SEM-EDS analysis[J]. Construction and Building Materials,2018,179:661-674. doi: 10.1016/j.conbuildmat.2018.05.229 [77] Lu Z, Chen B, Leung C Y, et al. Aggregation size effect of graphene oxide on its reinforcing efficiency to cement-based materials[J]. Cement and Concrete Composites,2019,100:85-91. doi: 10.1016/j.cemconcomp.2019.04.005 [78] Lu S, Ma Y, Qiu C, et al. Effect of graphene oxide nanosheets of microstructure and mechanical properties of cement composites[J]. Construction and Building Materials,2013,49:121-127. doi: 10.1016/j.conbuildmat.2013.08.022 [79] Long W J, Li H D, Fang C L, et al. Uniformly dispersed and re-agglomerated graphene oxide-based cement pastes: A comparison of rheological properties, mechanical properties and microstructure[J]. Nanomaterials,2018,8(1):31. doi: 10.3390/nano8010031 [80] Hu M, Guo J, Fan J, et al. Dispersion of triethanolamine-functionalized graphene oxide (TEA-GO) in pore solution and its influence on hydration, mechanical behavior of cement composite[J]. Construction and Building Materials,2019,216:128-136. doi: 10.1016/j.conbuildmat.2019.04.180 [81] Lu S, Ma Y, Qiu C, et al. Regulation of GO on cement hydration crystals and its toughening effect[J]. Magazine of Concrete Research,2013,65(20):1246-1254. doi: 10.1680/macr.13.00190 [82] Lu S, Liu J, Sun T, et al. Effect of GO nanosheets on shapes of cement hydration crystals and their formation process[J]. Construction and Building Materials,2014,64:231-239. doi: 10.1016/j.conbuildmat.2014.04.061 [83] Chen G, Dai Z, Sun L, et al. Synergistic effects of platinum–cerium carbonate hydroxides–reduced graphene oxide on enhanced durability for methanol electro-oxidation[J]. Journal of Materials Chemistry A,2019,7(11):6562-6571. doi: 10.1039/C9TA00226J [84] Mohammed A, Sanjayan J G, Duan W H, et al. Graphene oxide impact on hardened cement expressed in enhanced freeze–thaw resistance[J]. Journal of Materials in Civil Engineering,2016,28(9):04016072. doi: 10.1061/(ASCE)MT.1943-5533.0001586 [85] Lu S, Zhang J, Zhu L, et al. Preparation of cement composites with ordered microstructures via doping with graphene oxide nanosheets and an investigation of their strength and durability[J]. Materials,2016,9(11):924. doi: 10.3390/ma9110924 [86] Korayem A H, Ghoddousi P, Javid A A S, et al. Graphene oxide for surface treatment of concrete: A novel method to protect concrete[J]. Construction and Building Materials,2020,243:118229. doi: 10.1016/j.conbuildmat.2020.118229 [87] Zheng W, Chen W G, Feng T, et al. Enhancing chloride ion penetration resistance into concrete by using graphene oxide reinforced waterborne epoxy coating[J]. Progress in Organic Coatings,2020,138:105389. doi: 10.1016/j.porgcoat.2019.105389 [88] Lu Z, Hou D, Meng L, et al. Mechanism of cement paste reinforced by graphene oxide/carbon nanotubes composites with enhanced mechanical properties[J]. RSC advances,2015,5(122):1165-1598. [89] Li X, Wei W, Qin H, et al. Co-effects of graphene oxide sheets and single wall carbon nanotubes on mechanical properties of cement[J]. Journal of Physics and Chemistry of Solids,2015,85:39-43. doi: 10.1016/j.jpcs.2015.04.018 [90] Hosseini E, Zakertabrizi M, Habibnejad Korayem A, et al. Tunable, multifunctional ceramic composites via intercalation of fused graphene boron nitride nanosheets[J]. ACS applied materials & interfaces,2019,11(8):8635-8644. [91] Alkhateb H, Al-Ostaz A, Cheng A H D, et al. Materials genome for graphene-cement nanocomposites[J]. Journal of Nanomechanics and Micromechanics,2013,3(3):67-77. doi: 10.1061/(ASCE)NM.2153-5477.0000055 [92] Sharma S, Kothiyal N C. Comparative effects of pristine and ball-milled graphene oxide on physico-chemical characteristics of cement mortar nanocomposites[J]. Construction and Building Materials,2016,115:256-268. doi: 10.1016/j.conbuildmat.2016.04.019 [93] Lv S, Ting S, Liu J, et al. Use of graphene oxide nanosheets to regulate the microstructure of hardened cement paste to increase its strength and toughness[J]. CrystEngComm,2014,16(36):8508-8516. doi: 10.1039/C4CE00684D [94] Kang D, Seo K S, Lee H, et al. Experimental study on mechanical strength of GO-cement composites[J]. Construction and Building Materials,2017,131:303-308. doi: 10.1016/j.conbuildmat.2016.11.083 [95] Wang M, Wang R, Yao H, et al. Study on the three dimensional mechanism of graphene oxide nanosheets modified cement[J]. Construction and Building Materials,2016,126:730-739. doi: 10.1016/j.conbuildmat.2016.09.092 [96] Hou D, Lu Z, Li X, et al. Reactive molecular dynamics and experimental study of graphene-cement composites: Structure, dynamics and reinforcement mechanisms[J]. Carbon,2017,115:188-208. doi: 10.1016/j.carbon.2017.01.013 [97] Cui H, Yan X, Tang L, et al. Possible pitfall in sample preparation for SEM analysis - A discussion of the paper “Fabrication of polycarboxylate/graphene oxide nanosheet composites by copolymerization for reinforcing and toughening cement composites” by Lv et al.[J]. Cement and Concrete Composites,2017,77:81-85. doi: 10.1016/j.cemconcomp.2016.12.007 [98] Sanchez F, Zhang L. Molecular dynamics modeling of the interface between surface functionalized graphitic structures and calcium–silicate–hydrate: Interaction energies, structure, and dynamics[J]. Journal of Colloid and Interface Science,2008,323(2):349-358. doi: 10.1016/j.jcis.2008.04.023 [99] Fan X, Peng W, Li Y, et al. Deoxygenation of exfoliated graphite oxide under alkaline conditions: A green route to graphene preparation[J]. Advanced Materials,2008,20(23):4490-4493. doi: 10.1002/adma.200801306 [100] Perera S D, Mariano R G, Nijem N, et al. Alkaline deoxygenated graphene oxide for supercapacitor applications: An effective green alternative for chemically reduced graphene[J]. Journal of Power Sources,2012,215:1-10. doi: 10.1016/j.jpowsour.2012.04.059 -

下载:

下载: