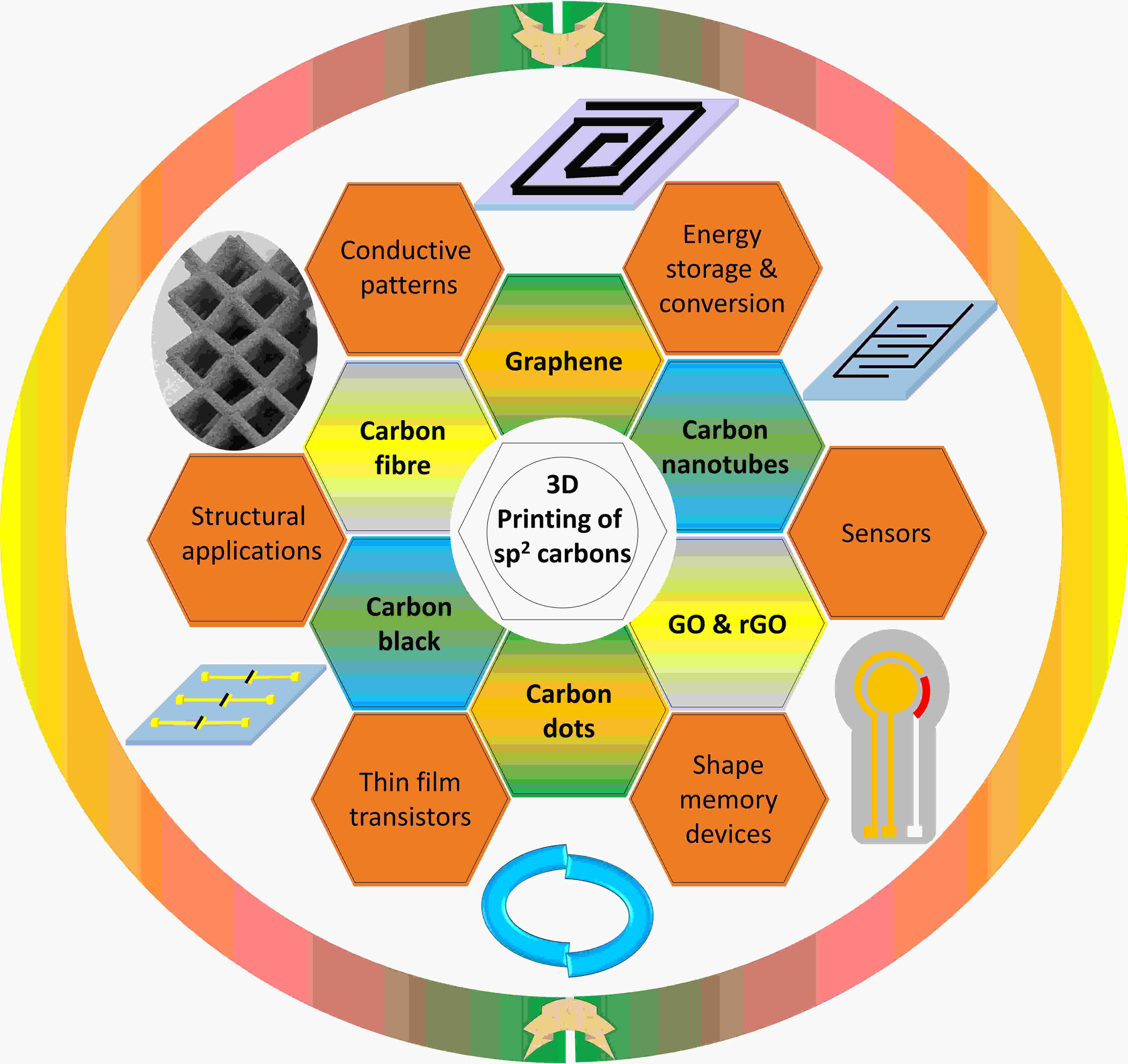

A comprehensive review of the 3D printing of sp2 carbons: Materials, properties and applications

-

摘要:

3D打印可以改变现有的生产方法,是第四次工程革命中的一项现代技术。它从成型原理上提出了分层制造、逐层叠加成型的新颖生产方法,从根本上简化了制造工艺,实现了大规模定制生产。然而,这一新技术仍存在许多问题。除了纯石墨烯外,sp2碳具有好的亲水性,3D打印难度较小。sp2碳还可在3D打印中的各种阶段应用。纯石墨烯的疏水性使其难以在水系介质中打印和加工。毛细管油墨的发展使得纯石墨烯的3D打印成为可能。本文综述了sp2碳的3D打印技术的最新进展。首先简要概述了3D打印技术,随后概述了sp2碳的3D打印及其在各种方面的应用。最后,讨论了这一新领域的发展前景和机遇。

Abstract:Three dimensional (3D) printing is a modern technology that has the possibility to transform existing production methods. It offers a novel production method of layered manufacturing and layer-by-layer stacking, which radically simplifies the manufacturing process and enables large-scale customizable production. However, there are still numerous problems with this new technology. Except for pure graphene, sp2 carbons can be 3D printed with little difficulty because of their hydrophilicity. The hydrophobic nature of pure graphene makes it difficult to print and process in water-based media, but advances in capillary inks allow for the 3D printing of pure graphene. This review focuses on the most recent developments in the 3D printing of sp2 carbons. A concise overview of 3D printing technologies is presented, followed by a summary of 3D printed sp2 carbons and their diverse applications. Finally, prospects and opportunities for this new field are discussed.

-

Key words:

- 3D printing technologies /

- sp2 carbons /

- Carbon-based composites /

- Applications

-

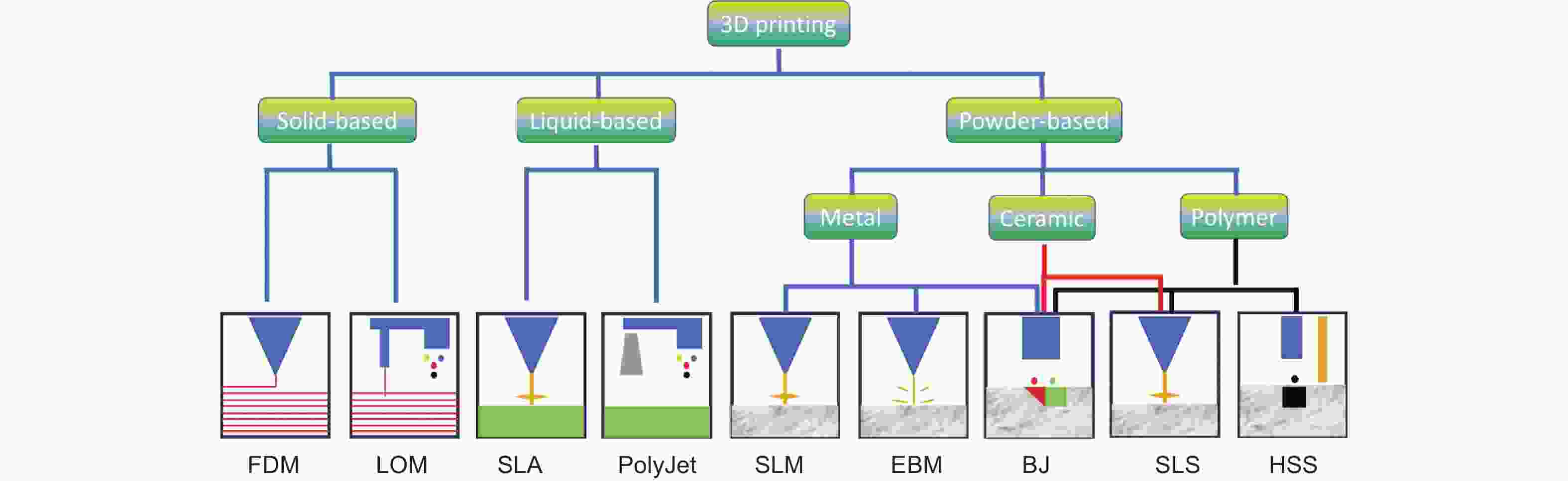

Figure 2. Technical classification of 3D printing techniques. PolyJet: photopolymer jetting, SLM: selective laser melting, HSS: high-speed sintering, BJ: binder jetting, EBM: electron beam melting. Adopted from Ref.[45] with little modifications

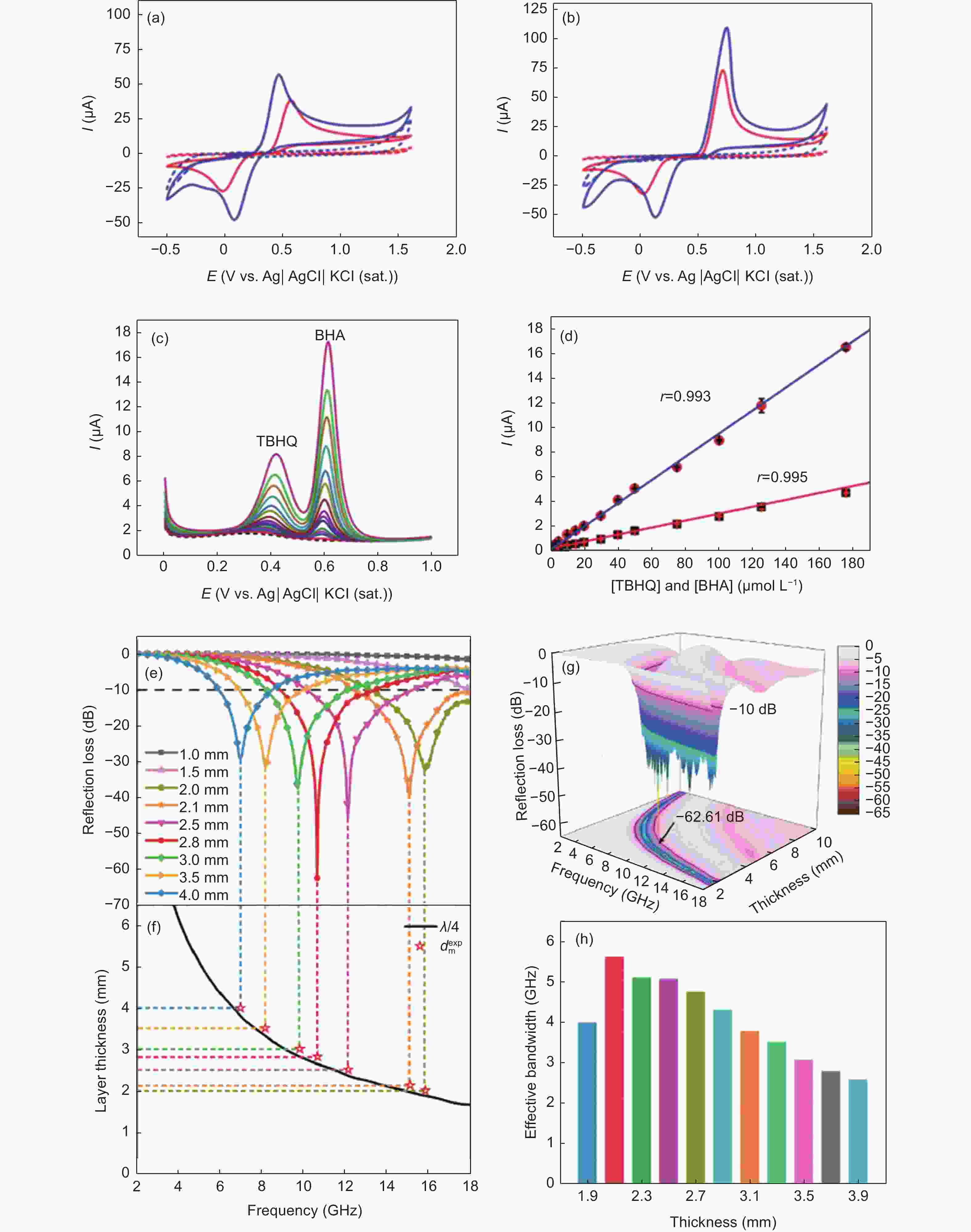

Figure 3. Cyclic voltammetric (CV) of (a) TBHQ, (b) BHA, (c) differential pulse voltammetry responses of TBHQ and BHA, and (d) corresponding calibration curves. Reproduced from Ref.[59] with permission from Springer. (e) Calculated reflection loss curves, (g) corresponding 3D plot, (f) layer thickness matching , and (h) effective absorption bandwidth. Reproduced from Ref.[57] with permission from the Elsevier

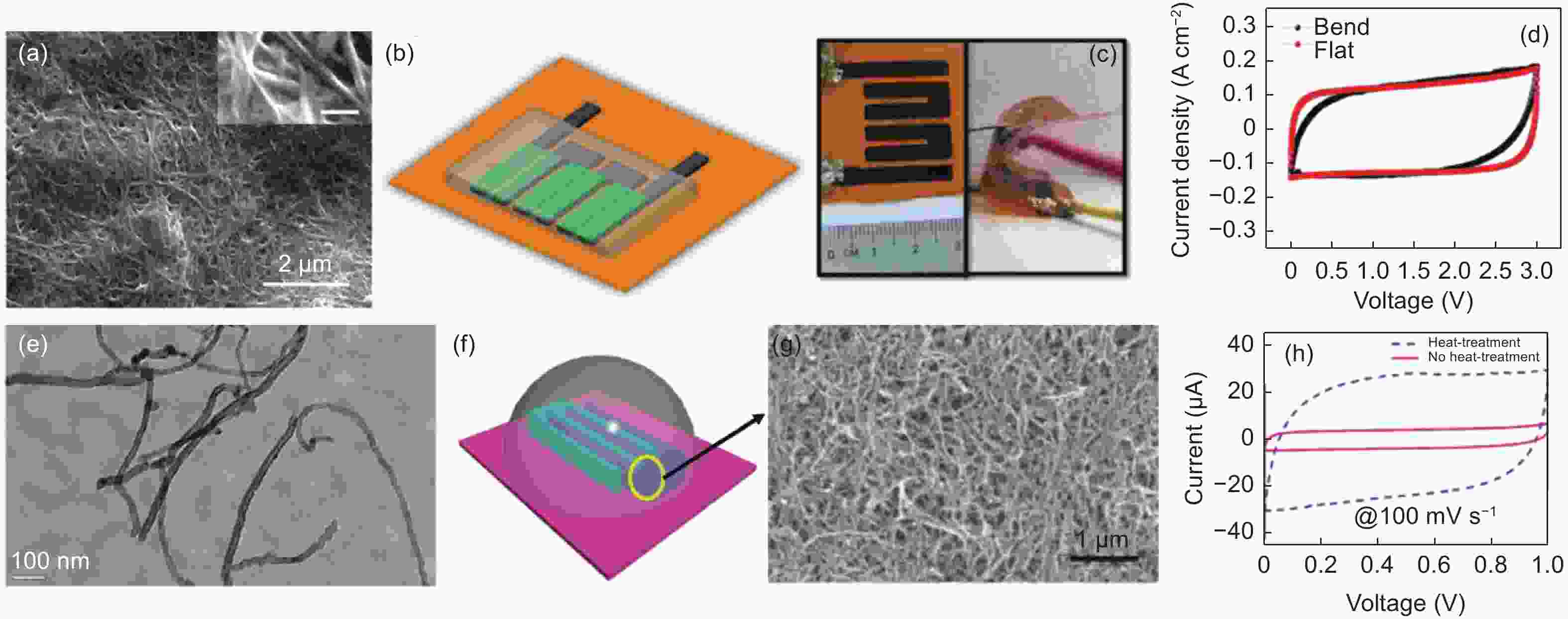

Figure 4. (a) SEM image of 3D printed CNTs. (b) Schematic of fabricated device. (c) Real-time digital image of the device. (d) CV profile of 3D printed CNT device. Reproduced from Ref.[72] with permission from the American Chemical Society. (e) TEM image of CNTs. (f) Schematic of the device in which polymer gel electrolyte is cast. (g) SEM image of the electrode material. (h) CV profile of packaged device. Reproduced from Ref.[73] with permission from the American Chemical Society

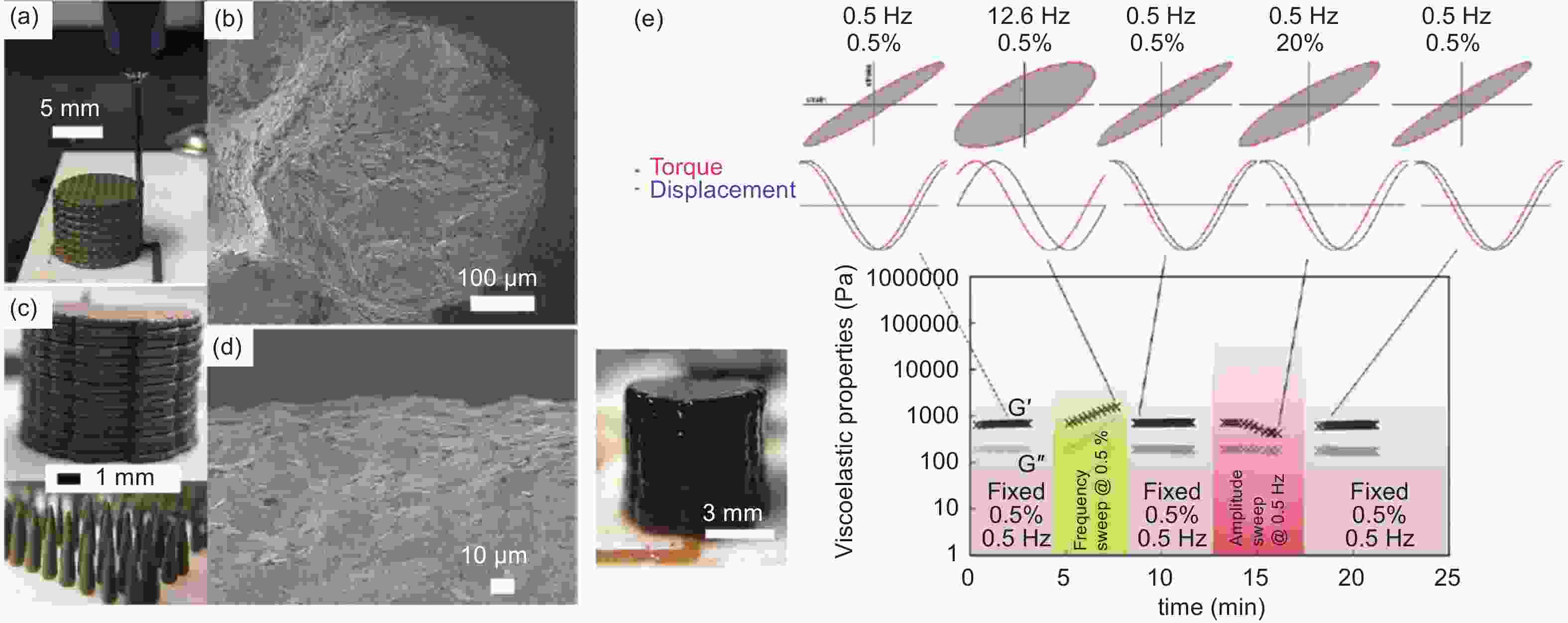

Figure 5. (a) and (c) Printed structures. (b) and (d) FESEM images. (e) Viscoelastic fingerprints of 3D printed PVA-GO ink with 0.3% GO loading. Reproduced from Ref. [99] with permission from the American Chemical Society

Figure 6. (a) Graphical representation of printing process and different structures printed with GO/geopolymer nanocomposite. (b) Printability of GG/GO bio-inks. Digital images of (c) the printed matrix pentagram, (d) gradient spacing grids and ( e, f, g) printing fidelity for GO bio-inks. Reproduced from Ref.[102] and [92] with permission from the Elsevier

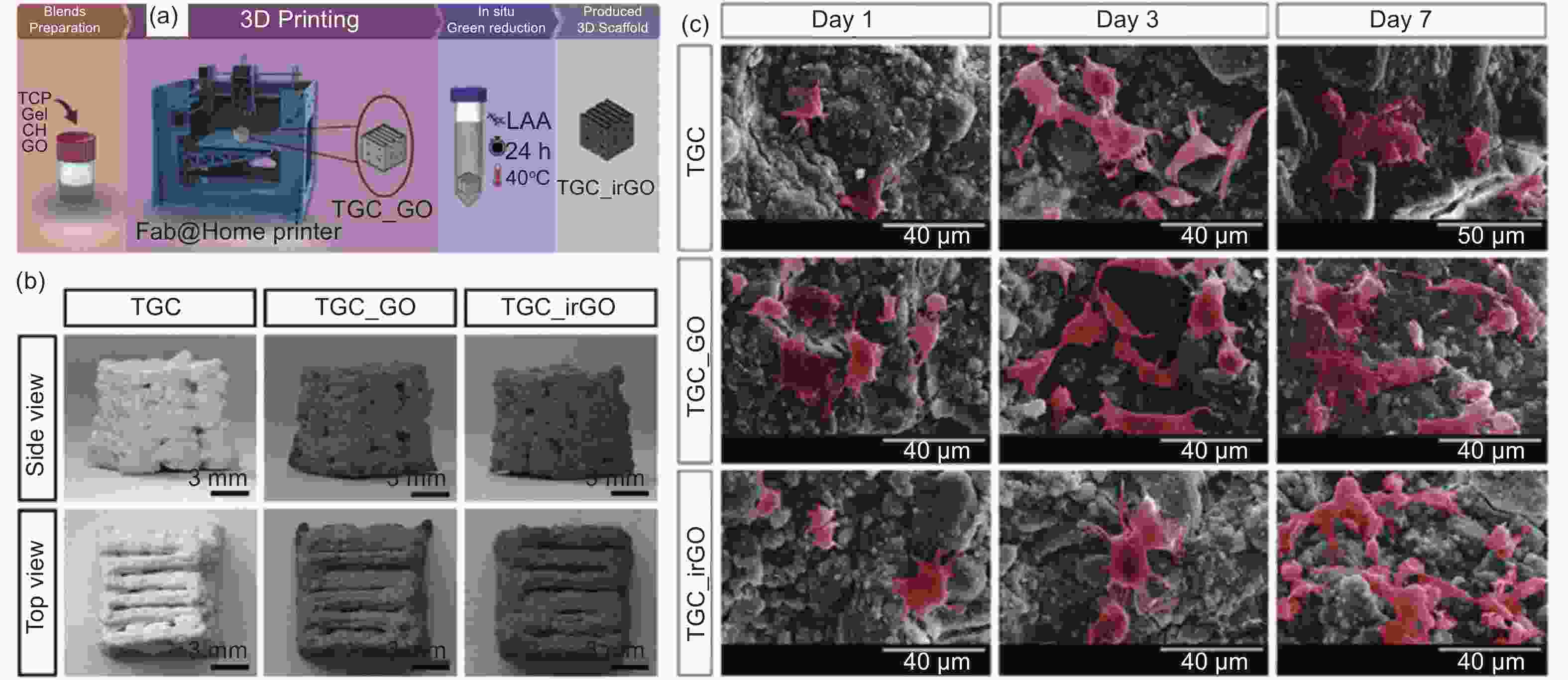

Figure 7. (a) Schematic of 3D rGO scaffold preparation. (b) Macroscopic images of prepared scaffolds (side and top views). (c) Biological properties. Reproduced from Ref.[100] with permission from the Elsevier

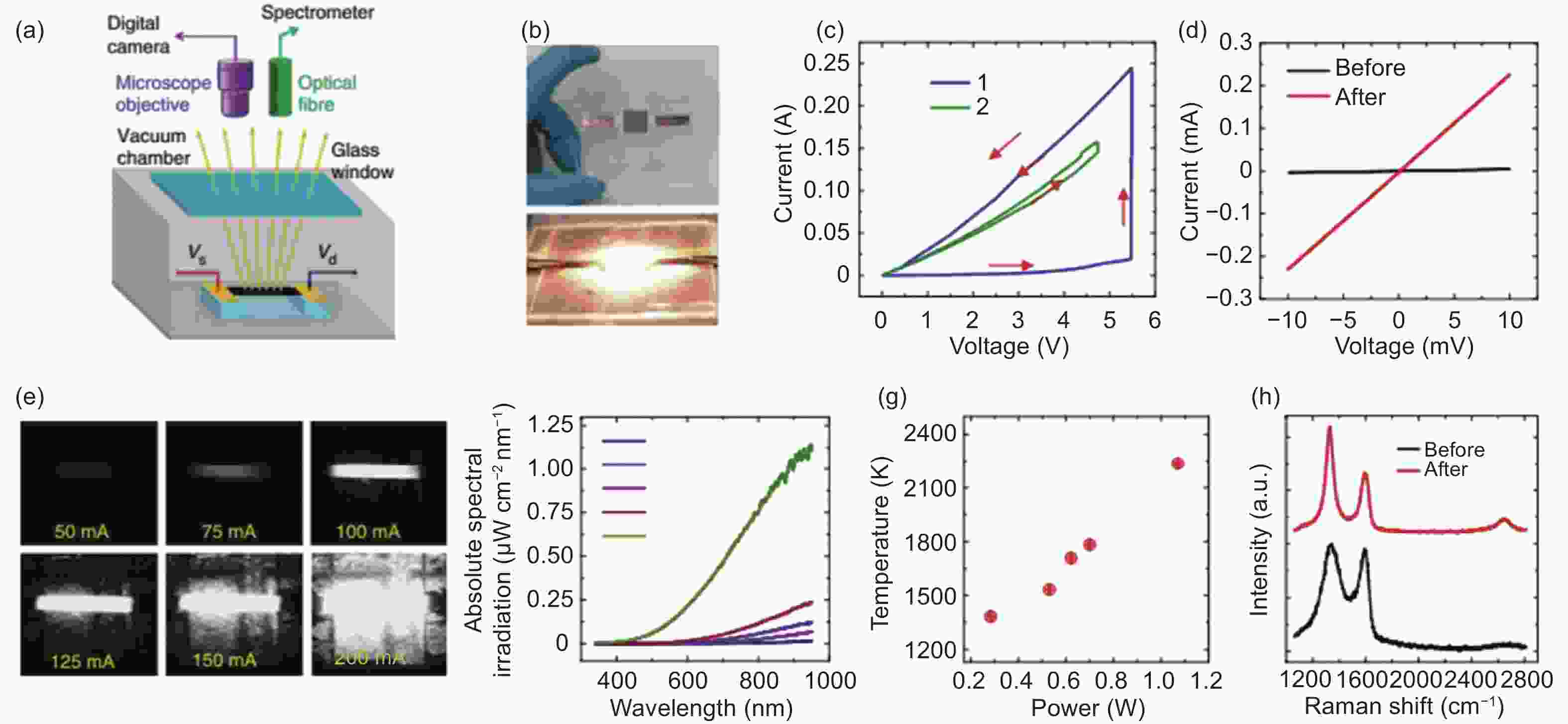

Figure 8. (a) Schematic of temperature treatment setup for rGO. (b) Digital image of Al-rGO thin film. I vs V profile of Al-rGO film (c) before and (d) after heat treatment. (e) Al-rGO thin film under Joule heating. (f) Emission spectra of thin-film. (g) Temperature monitored at different powers. (h) Raman spectra with and without heat treatment. Reproduced from Ref.[101] with permission from Nature

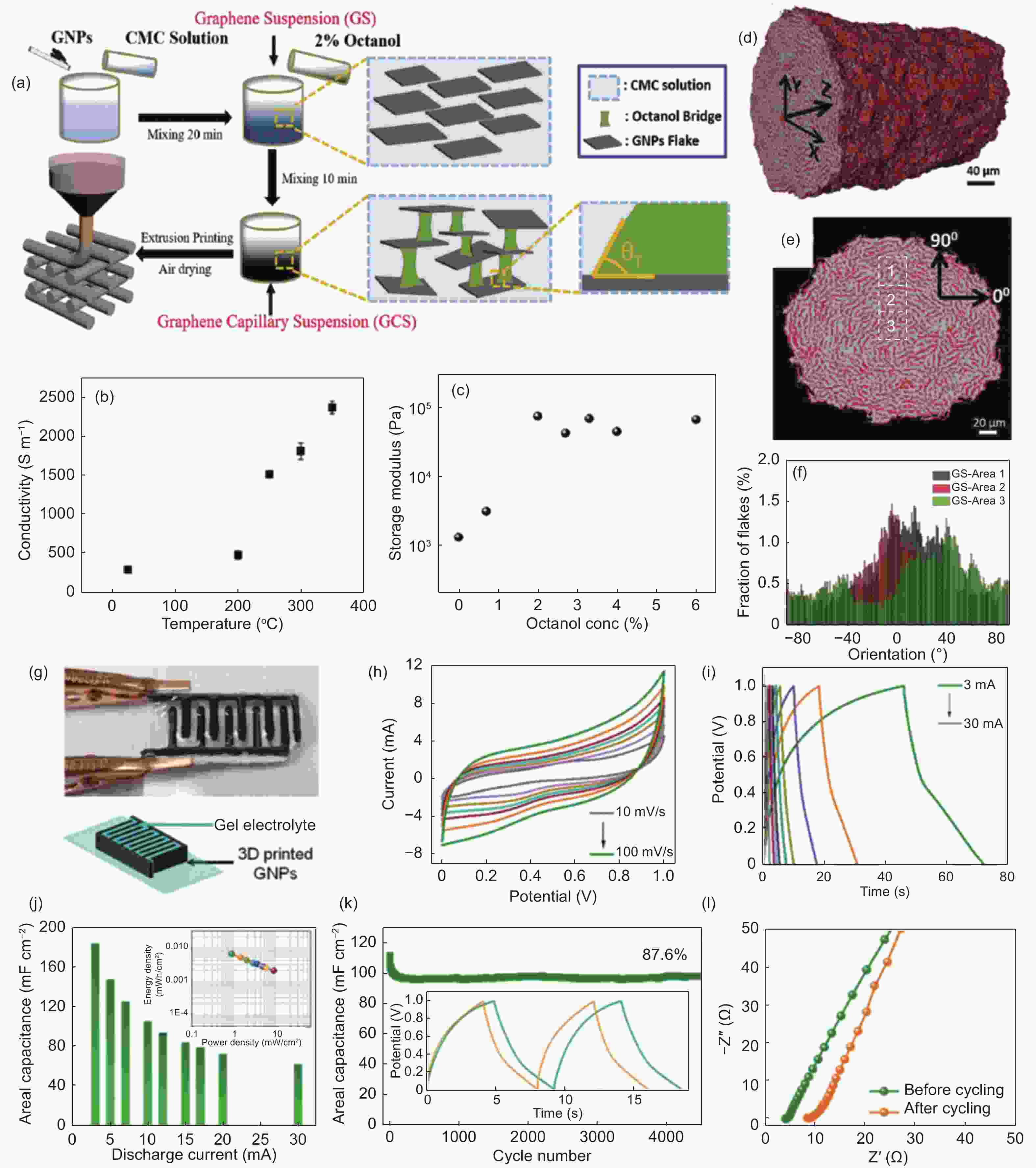

Figure 9. (a) Graphical representation of ink formulation and printing. (b) Conductivity of 3D printed aqueous graphene ink. (c) Storage modulus vs octanol amount. X-ray tomography analysis: (d) 3D image, (e) cross-section view and (f) histogram of graphene flake orientation. Reproduced from Ref.[117] with permission from the Royal Society of Chemistry. (g) Digital image and schematic of 3D printed device. (h) CV profile, (i) GCD profile, (j) histogram of areal capacitance, (k) cycle test profile and (l) Nyquist plot ofthe 3D printed flexible supercapacitor. Reproduced from Ref.[118] with permission from the American Chemical Society

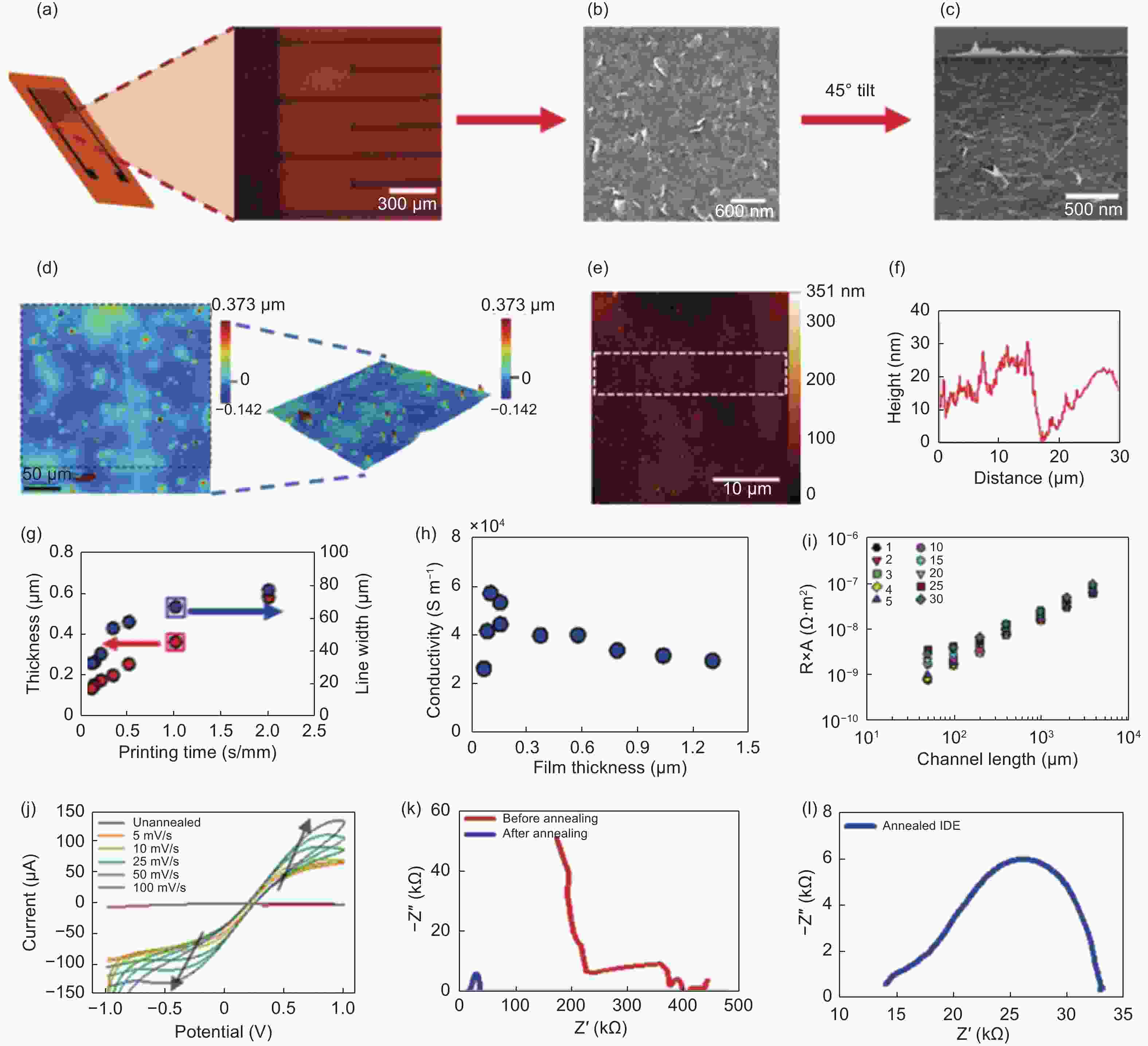

Figure 10. (a) Schematic and optical micrographs of the graphene electrode. (b) and (c) The morphology of printed graphene electrode. (d) 2D and 3D images for surface roughness study. (e) and (f) AFM image and height profile of the electrode. (g) The electrode thickness vs printing speed. (h) Conductivity vs electrode thickness. (i) Resistance vs electrode length. (j) CV profile, (k) Nyquist plot and (l) magnified Nyquist plot for the annealed electrode. Reproduced from Ref.[120] with permission from the American Chemical Society

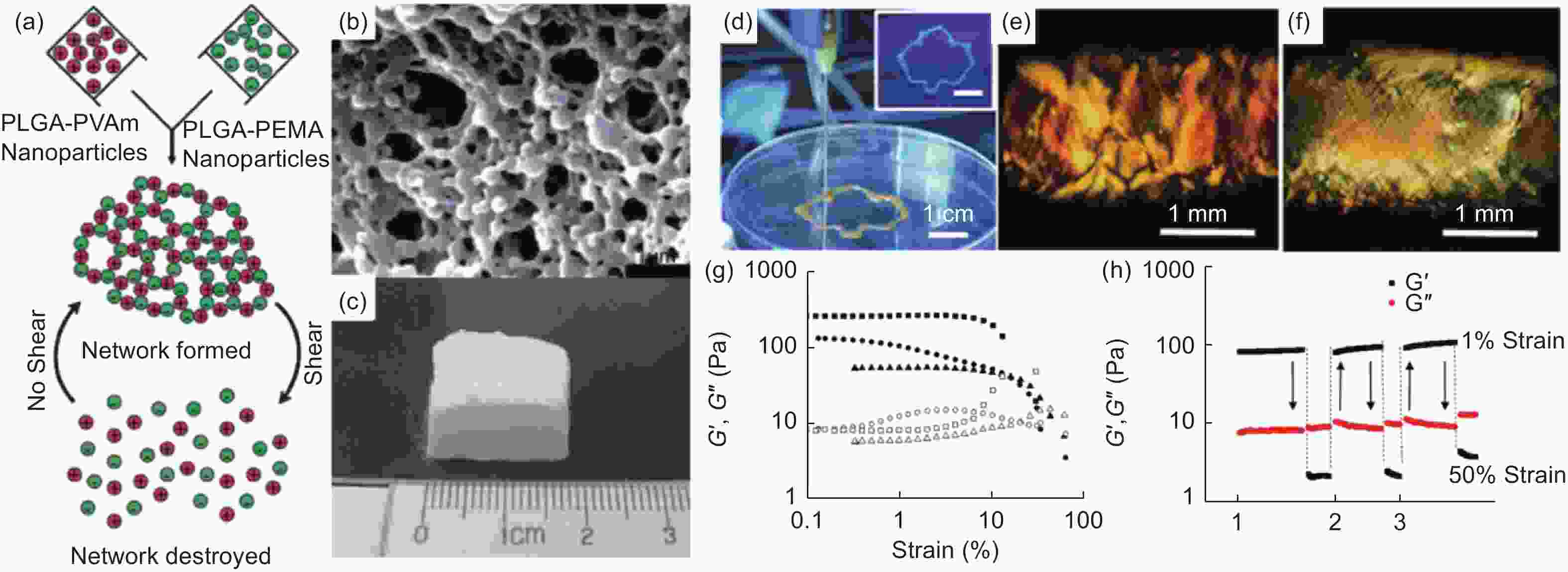

Figure 11. (a) Schematic mechanism of self-healing and shear-thinning behavior of colloidal gel. (b) SEM and (c) digital image of a colloidal gel. Reproduced from Ref.[122] with permission from the Royal Society of Chemistry. (d) 3D printed GQDs structure. (e) and (f) Fluorescence images at 365 nm excitation. (g) Storage (solid) and loss (empty) modulus curves of GQD-hydrogel. (h) Effect of cycling on storage and loss modulus. Reproduced from Ref.[127] with permission from the American Chemical Society

Table 1. 3D printed CNT-polymer structures

Table 2. 3D printed sp2 carbons and their applications

Materials Applications Ref. Graphene-CMC Electrical properties [117] Graphene-aerogel Energy storage [141] Graphene/Li0.35Zn0.3Fe2.35O4 Microwave absorption [142] Graphene/Carbonyl Iron/PMMA Microwave absorption [143] Graphene-polyamide Electric motor [144] GO-LFP and GO-LTO Energy storage [145] Functionalized-GO Biosensors [146] GO-PLA Bone tissue engineering [147] rGO-polycaprolactone Regenerative engineering [148] rGO/magnesium nanohybrid Bone tissue engineering [149] rGO-polycaprolactone Antibacterial and Tissue Engineering [150] rGO-gold composite Electrochemical detection [151] rGO-MXene Electromagnetic interference shielding [152] rGO-MnO2 Energy storage [153] GO-elastomer resin composite Strain sensors [154] CNT yarn-Ultem Structural applications [155] Multiwall CNTs-PLA Conductive patterns [156] CNTs-PLA Welding [157] CNTs-Polycaprolactone Cardiac Tissue Engineering [158] Multiwall CNTs-PEGDA bioink Nerve regeneration [159] CNTs-TPU Multiaxial force sensors [160] Multiwall CNTs-PDMS Strain sensors [161] Orange CDs-sodium polyacrylate Optical properties [133] CDs-hydrogels Optical properties [162] Red CDs-2-HCA Gas sensors [163] -

[1] Shahrubudin N, Lee T C, Ramlan R. An overview on 3D printing technology: Technological, materials, and applications[J]. Procedia Manufacturing,2019,35:1286-1296. doi: 10.1016/j.promfg.2019.06.089 [2] Ligon S C, Liska R, Stampfl J, et al. Polymers for 3D printing and customized additive manufacturing[J]. Chemical Reviews,2017,117:10212-10290. doi: 10.1021/acs.chemrev.7b00074 [3] Huang S H, Liu P, Mokasdar A, et al. Additive manufacturing and its societal impact: A literature review[J]. The International Journal of Advanced Manufacturing Technology,2013,67:1191-1203. doi: 10.1007/s00170-012-4558-5 [4] Bozkurt Y, Karayel E. 3D printing technology; methods, biomedical applications, future opportunities and trends[J]. Journal of Materials Research and Technology,2021,14:1430-1450. doi: 10.1016/j.jmrt.2021.07.050 [5] Huang Y, Leu M C, Mazumder J, et al. Additive manufacturing: Current state, future potential, gaps and needs, and recommendations[J]. Journal of Manufacturing Science and Engineering, Transactions of the ASME,2015,137:1-11. [6] Khosravani M R, Reinicke T. On the environmental impacts of 3D printing technology[J]. Applied Materials Today,2020,20:100689. doi: 10.1016/j.apmt.2020.100689 [7] Afif A, Rahman S M, Tasfiah Azad A, et al. Advanced materials and technologies for hybrid supercapacitors for energy storage – A review[J]. Journal of Energy Storage,2019,25:100852. doi: 10.1016/j.est.2019.100852 [8] Smith A T, LaChance A M, Zeng S, et al. Synthesis, properties, and applications of graphene oxide/reduced graphene oxide and their nanocomposites[J]. Nano Materials Science,2019,1:31-47. doi: 10.1016/j.nanoms.2019.02.004 [9] Akinwande D, Brennan C J, Bunch J S, et al. A review on mechanics and mechanical properties of 2D materials – graphene and beyond[J]. Extreme Mechanics Letters,2016,13:42-47. [10] Wang Z, Zhang Q, Long S, et al. Three-dimensional printing of polyaniline/reduced graphene oxide composite for high-performance planar supercapacitor[J]. ACS Applied Materials & Interfaces,2018,10:10437-10444. [11] Pandey S, Kumar A, Karakoti M, et al. 3D graphene nanosheets from plastic waste for highly efficient HTM free perovskite solar cells[J]. Nanoscale Advances,2021,3:4726-4738. doi: 10.1039/D1NA00183C [12] Jandyal A, Chaturvedi I, Wazir I, et al. 3D printing – A review of processes, materials and applications in industry 4. 0[J]. Sustainable Operations and Computers,2022,3:33-42. doi: 10.1016/j.susoc.2021.09.004 [13] Zhang D, Chi B, Li B, et al. Fabrication of highly conductive graphene flexible circuits by 3D printing[J]. Synthetic Metals,2016,217:79-86. doi: 10.1016/j.synthmet.2016.03.014 [14] Wei X, Li D, Jiang W, et al. 3D Printable graphene composite[J]. Scientific Report,2015,5:1-7. [15] Kamat A M, Pei Y, Jayawardhana B, et al. Biomimetic soft polymer microstructures and piezoresistive graphene MEMS sensors using sacrificial metal 3D printing[J]. ACS Applied Materials & Interfaces,2021,13:1094-1104. [16] Wang D, Huang X, Li J, et al. 3D printing of graphene-doped target for “matrix-free” laser desorption/ionization mass spectrometry[J]. Chemical Communications,2018,54:2723-2726. doi: 10.1039/C7CC09649F [17] Wang X, Zhi L, Mullen K. Transparent, conductive graphene electrodes for dye-sensitized solar cells[J]. Nano Letters,2008,8:323-327. doi: 10.1021/nl072838r [18] Al-bahrani M R, Ahmad W, Mehnane H F, et al. Enhanced electrocatalytic activity by RGO/MWCNTs/NiO counter electrode for dye-sensitized Solar Cells[J]. Nano-Micro Letters,2015,7:298-306. doi: 10.1007/s40820-015-0043-7 [19] López-Naranjo E J, González-Ortiz L J, Apátiga L M, et al. Transparent electrodes: A review of the use of carbon-based nanomaterials[J]. Journal of Nanomaterials,2016,2016:4928365. [20] Lee K T, Park D H, Baac H W, et al. Graphene- and carbon-nanotube-based transparent electrodes for semitransparent solar cells[J]. Materials,2018,11:1503. doi: 10.3390/ma11091503 [21] Tiwari S K, Sahoo S, Wang N, et al. Graphene research and their outputs: Status and prospect[J]. Journal of Science:Advanced Materials and Devices,2020,5:10-29. doi: 10.1016/j.jsamd.2020.01.006 [22] Guo B, Ji X, Wang W, et al. Highly flexible, thermally stable, and static dissipative nanocomposite with reduced functionalized graphene oxide processed through 3D printing[J]. Composites Part B:Engineering,2021,208:108598. doi: 10.1016/j.compositesb.2020.108598 [23] Jakus A E, Secor E B, Rutz A L, et al. Three-dimensional printing of high-content graphene scaffolds for electronic and biomedical applications[J]. ACS Nano,2015,9:4636-4648. doi: 10.1021/acsnano.5b01179 [24] Lei C W, Hsieh M L, Liu W R. A facile approach to synthesize carbon quantum dots with pH-dependent properties[J]. Dyes and Pigments,2019,169:73-80. doi: 10.1016/j.dyepig.2019.05.014 [25] Mansuriya B D, Altintas Z. Applications of graphene quantum dots in biomedical sensors[J]. Sensors,2020,20:1-71. doi: 10.1109/JSEN.2020.3014328 [26] Guo H, Zhao H, Niu H, et al. Highly thermally conductive 3D printed graphene filled polymer composites for scalable thermal management applications[J]. ACS Nano,2021,15:6917-6928. doi: 10.1021/acsnano.0c10768 [27] Carvalho Fernandes D C, Lynch D, Berry V. 3D-printed graphene/polymer structures for electron-tunneling based devices[J]. Scientific Report,2020,10:1-8. doi: 10.1038/s41598-019-56847-4 [28] Zhu L, Guo X, Chen Y, et al. Graphene oxide composite membranes for water purification[J]. ACS Applied Nano Materials,2022,5:3643-3653. doi: 10.1021/acsanm.1c04322 [29] Hegab H M, Zou L. Graphene oxide-assisted membranes: Fabrication and potential applications in desalination and water purification[J]. Journal of Membrane Science,2015,484:95-106. doi: 10.1016/j.memsci.2015.03.011 [30] Zhang L, Mohamed H H, Dillert R. et al. Kinetics and mechanisms of charge transfer processes in photocatalytic systems: A review[J]. Journal of Photochemistry and Photobiology C,2012,13:263-276. doi: 10.1016/j.jphotochemrev.2012.07.002 [31] Yousefi N, Lu X, Elimelech M, et al. Environmental performance of graphene-based 3D macrostructures[J]. Nature Nanotechnology,2019,14:107-119. doi: 10.1038/s41565-018-0325-6 [32] Chandrasekaran S, Feaster J, Ynzunza J, et al. Three-dimensional printed MoS2/graphene aerogel electrodes for hydrogen evolution reactions[J]. ACS Materials Au. (2022). https://doi.org/10.1021/acsmaterialsau.2c00014. [33] Qiao Y, Liu Y, Chen C, et al. 3D-Printed graphene oxide framework with thermal shock synthesized nanoparticles for Li-CO2 batteries[J]. Advanced Functional Materials,2018,28:1805899. doi: 10.1002/adfm.201805899 [34] Ren Y, Meng F, Zhang S, et al. CNT@MnO2 composite ink toward a flexible 3D printed micro-zinc-ion battery[J]. Carbon Energy,2022,4:446-457. doi: 10.1002/cey2.177 [35] Ma J, Shen W, Li C, et al. Light reharvesting and enhanced efficiency of dye-sensitized solar cells based 3D-CNT/graphene counter electrodes[J]. Journal of Materials Chemistry A,2015,3:12307-12313. doi: 10.1039/C5TA02214B [36] Xiang D, Zhang X, Han Z, et al. 3D printed high-performance flexible strain sensors based on carbon nanotube and graphene nanoplatelet filled polymer composites[J]. Journal of Materials Science,2020,55:15769-15786. doi: 10.1007/s10853-020-05137-w [37] Saxena A, Kamran M. A comprehensive study on 3D printing technology[J]. MIT international journal of mechanical engineering,2016,6:63-69. [38] Jasveer S, Jianbin X. Comparison of different types of 3D printing technologies[J]. International Journal of Scientific and Research Publications,2018,8:1-9. [39] Ngo T D, Kashani A, Imbalzano G, et al. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges[J]. Composites Part B:Engineering,2018,143:172-196. doi: 10.1016/j.compositesb.2018.02.012 [40] Tofail S A M, Koumoulos E P, Bandyopadhyay A, et al. Additive manufacturing: scientific and technological challenges, market uptake and opportunities[J]. Materials Today,2018,21:22-37. doi: 10.1016/j.mattod.2017.07.001 [41] Penumakala P K, Santo J, Thomas A. A critical review on the fused deposition modeling of thermoplastic polymer composites[J]. Composites Part B:Engineering,2020,201:108336. doi: 10.1016/j.compositesb.2020.108336 [42] Tagliaferri S, Panagiotopoulos A, Mattevi C. Direct ink writing of energy materials[J]. Materials Advances,2021,2:540-563. doi: 10.1039/D0MA00753F [43] Shinde V V, Celestine A D, Beckingham L E, et al. Stereolithography 3D printing of microcapsule catalyst-based self-healing composites[J]. ACS Applied Polymer Materials,2020,2:5048-5057. doi: 10.1021/acsapm.0c00872 [44] Lahtinen E, Kukkonen E, Jokivartio J, et al. Preparation of highly porous carbonous electrodes by selective laser sintering[J]. ACS Applied Energy Materials,2019,2:1314-1318. doi: 10.1021/acsaem.8b01881 [45] Wang Y, Xu Z, Wu D, et al. Current status and prospects of polymer powder 3D printing technologies[J]. Materials,2020,13:2406. doi: 10.3390/ma13102406 [46] Chan H K, Griffin J, Lim J J, et al. The impact of 3D printing technology on the supply chain: Manufacturing and legal perspectives[J]. International Journal of Production Economics,2018,205:156-162. doi: 10.1016/j.ijpe.2018.09.009 [47] Javaid M, Haleem A, Singh R P, et al. Role of additive manufacturing applications towards environmental sustainability[J]. Advanced Industrial and Engineering Polymer Research,2021,4:312-322. doi: 10.1016/j.aiepr.2021.07.005 [48] Rayna T, Striukova L. From rapid prototyping to home fabrication: How 3D printing is changing business model innovation[J]. Technological Forecasting and Social Change,2016,102:214-224. doi: 10.1016/j.techfore.2015.07.023 [49] Blyweert P, Nicolas V, Fierro V, et al. 3D printing of carbon-based materials: A review[J]. Carbon,2021,183:449-485. doi: 10.1016/j.carbon.2021.07.036 [50] Fu K, Yao Y, Dai J, et al. Progress in 3D printing of carbon materials for energy-related applications[J]. Advanced Materials,2017,29:1-20. [51] Park S H, Goodall G, Kim W S. Perspective on 3D-designed micro-supercapacitors[J]. Materials & Design,2020,193:108797. [52] Mondal S, Khastgir D. Elastomer reinforcement by graphene nanoplatelets and synergistic improvements of electrical and mechanical properties of composites by hybrid nano fillers of graphene-carbon black & graphene-MWCNT[J]. Composites Part A: Applied Science and Manufacturing,2017,102:154-165. doi: 10.1016/j.compositesa.2017.08.003 [53] Dungani R, Sumardi I, Alamsyah E M, et al. A study on fracture toughness of nano-structured carbon black-filled epoxy composites[J]. Polymer Bulletin,2021,78:6867-6885. doi: 10.1007/s00289-020-03444-5 [54] Mezzi A, Kaciulis S. Surface investigation of carbon films: From diamond to graphite[J]. Surface and Interface Analysis,2010,42:1082-1084. doi: 10.1002/sia.3348 [55] Osswald S, Yushin G, Mochalin V, et al. Control of sp2/sp3 carbon ratio and surface chemistry of nanodiamond powders by selective oxidation in air[J]. Journal of the American Chemical Society,2006,128:11635-11642. doi: 10.1021/ja063303n [56] Vidakis N, Petousis M, Velidakis E, et al. Fused filament fabrication three-dimensional printing multi-functional of polylactic acid/carbon black nanocomposites[J]. Journal of Carbon Research,2021,7:52. doi: 10.3390/c7030052 [57] Lei L, Yao Z, Zhou J, et al. 3D printing of carbon black/polypropylene composites with excellent microwave absorption performance[J]. Composites Science and Technology,2020,200:108479. doi: 10.1016/j.compscitech.2020.108479 [58] Callanan C J, Hsu L, McGee A. Formulation and evaluation of carbon black 3D printing materials[J]. Ocean 2018 MTS/IEEE Charleston,2018:1-7. [59] Inoque N I G, João A F, de Faria L V, et al. Electrochemical determination of several biofuel antioxidants in biodiesel and biokerosene using polylactic acid loaded with carbon black within 3D-printed devices[J]. Microchimica Acta,2022,189:1-11. doi: 10.1007/s00604-021-05112-5 [60] Sathies T, Senthil P, Prakash C. Application of 3D printed PLA-carbon black conductive polymer composite in solvent sensing[J]. Materials Research Express,2019,6:115349. doi: 10.1088/2053-1591/ab5040 [61] Espera A H, Valino A D, Palaganas J O, et al. 3D printing of a robust polyamide-12-Carbon black composite via selective laser sintering: Thermal and electrical conductivity[J]. Macromolecular Materials and Engineering,2019,304:1-8. [62] Tseng T L, Garcia Rosales C A, Garcia Duarte M F, et al. 3D printing of shape memory polymer (SMP)/carbon black (CB) nanocomposites with electro-responsive toughness enhancement[J]. Materials Research Express,2018,5:065704. doi: 10.1088/2053-1591/aacd53 [63] Anzar N, Hasan R, Tyagi M, et al. Carbon nanotube - A review on synthesis, properties and plethora of applications in the field of biomedical science[J]. Sensors International,2020,1:100003. doi: 10.1016/j.sintl.2020.100003 [64] Ali E, Hadis D, Hamzeh K, et al. Carbon nanotubes: properties, synthesis, purification, and medical applications[J]. Nanoscale Research Letters,2014,9:393. doi: 10.1186/1556-276X-9-393 [65] Smart S K, Cassady A I, Lu G Q, et al. The biocompatibility of carbon nanotubes[J]. Carbon,2006,44:1034-1047. doi: 10.1016/j.carbon.2005.10.011 [66] Roy S, David-Pur M, Hanein Y. Carbon nanotube-based ion selective sensors for wearable applications[J]. ACS Applied Materials & Interfaces,2017,9:35169-35177. [67] Pang J, Bachmatiuk A, Yang F, et al. Applications of carbon nanotubes in the Internet of things era[J]. Nano-Micro Letters,2021,13:1-15. doi: 10.1007/s40820-020-00525-y [68] Fukuda T, Arai F, Dong L. Assembly of nanodevices with carbon nanotubes through nanorobotic manipulations[J]. Proceedings of the IEEE,2003,91:1803-1818. [69] Jariwala D, Sangwan V K, Lauhon L J, et al. Carbon nanomaterials for electronics, optoelectronics, photovoltaics, and sensing[J]. Chemical Society Reviews,2013,42:2824-2860. doi: 10.1039/C2CS35335K [70] Jiang B, Huang H, Gong W, et al. Wood-Inspired binder enabled vertical 3D printing of g-C3N4/CNT arrays for highly efficient photoelectrochemical hydrogen evolution[J]. Advanced Functional Materials,2021,31:1-12. [71] Goh G L, Agarwala S, Yeong W Y. Directed and on-demand alignment of carbon nanotube: A review toward 3D printing of electronics[J]. Advanced Materials Interfaces,2019,6:1801318. doi: 10.1002/admi.201801318 [72] Chen B, Jiang Y, Tang X, et al. Fully packaged carbon nanotube supercapacitors by direct ink writing on flexible substrates[J]. ACS Applied Materials & Interfaces,2017,9:28433-28440. [73] Yu W, Zhou H, Li B Q, et al. 3D printing of carbon nanotubes-based microsupercapacitors[J]. ACS Applied Materials & Interfaces,2017,9:4597-4604. [74] Goh G L, Agarwala S, Yeong W Y. Aerosol-jet-printed preferentially aligned carbon nanotube twin-lines for printed electronics[J]. ACS Applied Materials & Interfaces,2019,11:43719-43730. [75] Lu S, Zheng J, Cardenas J A, et al. Uniform and stable aerosol jet printing of carbon nanotube thin-film transistors by ink temperature Control[J]. ACS Applied Materials & Interfaces,2020,12:43083-43089. [76] Shi S, Chen Y, Jing J, et al. Preparation and 3D-printing of highly conductive polylactic acid/carbon nanotube nanocomposites: Via local enrichment strategy[J]. RSC Advances,2019,9:29980-29986. doi: 10.1039/C9RA05684J [77] Mora A, Verma P, Kumar S. Electrical conductivity of CNT/polymer composites: 3D printing, measurements and modeling[J]. Composites Part B: Engineering,2020,183:107600. doi: 10.1016/j.compositesb.2019.107600 [78] Yan J, Zhi G, Kong D, et al. 3D printed rGO/CNT microlattice aerogel for a dendrite-free sodium metal anode[J]. Journal of Materials Chemistry A,2020,8:19843-19854. doi: 10.1039/D0TA05817C [79] McLean C, Tiller B, Mansour R, et al. Characterising the response of novel 3D printed CNT electrodes to the virulence factor pyocyanin[J]. Journal of Electroanalytical Chemistry,2022,909:116149. doi: 10.1016/j.jelechem.2022.116149 [80] Llinas J P, Hekmaty M A, Talin A A, et al. Origami terahertz detectors realized by inkjet printing of carbon nanotube inks[J]. ACS Applied Nano Materials,2020,3:2920-2927. [81] Gnanasekaran K, Heijmans T, van Bennekom S, et al. 3D printing of CNT- and graphene-based conductive polymer nanocomposites by fused deposition modeling[J]. Applied Materials Today,2017,9:21-28. doi: 10.1016/j.apmt.2017.04.003 [82] Mustonen T, Kordás K, Saukko S, et al. Inkjet printing of transparent and conductive patterns of single-walled carbon nanotubes and PEDOT-PSS composites[J]. Physica Status Solidi (B):Basic Research,2007,244:4336-4340. doi: 10.1002/pssb.200776186 [83] Gonzalez G, Chiappone A, Roppolo I, et al. Development of 3D printable formulations containing CNT with enhanced electrical properties[J]. Polymer,2017,109:246-253. doi: 10.1016/j.polymer.2016.12.051 [84] Christ J F, Aliheidari N, Ameli A, et al. 3D printed highly elastic strain sensors of multiwalled carbon nanotube/thermoplastic polyurethane nanocomposites[J]. Materials & Design,2017,131:394-401. [85] Kordás K, Mustonen T, Tóth G, et al. Inkjet printing of electrically conductive patterns of carbon nanotubes[J]. Small,2006,2:1021-1025. doi: 10.1002/smll.200600061 [86] Harussani M M, Sapuan S M, Nadeem G, et al. Recent applications of carbon-based composites in defence industry: A review[J]. Defence Technology,2022,18:1281-1300. doi: 10.1016/j.dt.2022.03.006 [87] Jovanović V, Samaržija-Jovanović S, Budinski-Simendić J, et al. Composites based on carbon black reinforced NBR/EPDM rubber blends[J]. Composites Part B:Engineering,2013,45:333-340. doi: 10.1016/j.compositesb.2012.05.020 [88] Nanni F, Ruscito G, Puglia D, et al. Effect of carbon black nanoparticle intrinsic properties on the self-monitoring performance of glass fibre reinforced composite rods[J]. Composites Science and Technology,2011,71:1-8. doi: 10.1016/j.compscitech.2010.08.015 [89] Sogancioglu M, Yel E, Ahmetli G. Behaviour of waste polypropylene pyrolysis char-based epoxy composite materials[J]. Environmental Science and Pollution Research,2020,27:3871-3884. doi: 10.1007/s11356-019-07028-3 [90] Pervaiz S, Qureshi T A, Kashwani G, et al. 3D printing of fiber-reinforced plastic composites using fused deposition modeling: A status review[J]. Materials,2021,14:4520. doi: 10.3390/ma14164520 [91] Hu Q, Duan Y, Zhang H, et al. Manufacturing and 3D printing of continuous carbon fiber prepreg filament[J]. Journal of Materials Science,2018,53:1887-1898. doi: 10.1007/s10853-017-1624-2 [92] Nakagawa Y, ichiro Mori K, Maeno T. 3D printing of carbon fibre-reinforced plastic parts[J]. The International Journal of Advanced Manufacturing Technology,2017,91:2811-2817. doi: 10.1007/s00170-016-9891-7 [93] Calignano F, Lorusso M, Roppolo I, et al. Investigation of the mechanical properties of a carbon fibre-reinforced nylon filament for 3d printing[J]. Machines,2020,8:1-13. [94] Silva M, Pinho I S, Covas J A, et al. 3D printing of graphene-based polymeric nanocomposites for biomedical applications[J]. Functional Composite Materials 2, 2021. https://doi.org/10.1186/s42252-021-00020-6. [95] Liang Z, Yao Y, Jiang B, et al. 3D printed graphene-based 3000 K probe[J]. Advanced Functional Materials,2021,31:1-9. [96] Qian Y, Li C, Qi Y, et al. 3D printing of graphene oxide composites with well controlled alignment[J]. Carbon,2021,171:777-784. doi: 10.1016/j.carbon.2020.08.077 [97] Jiang Y, Xu Z, Huang T, et al. Direct 3D printing of ultralight graphene oxide aerogel microlattices[J]. Advanced Functional Materials,2018,28:1-8. [98] Zhang Q, Zhang F, Medarametla S P, et al. 3D printing of graphene aerogels[J]. Small,2016,12:1702-1708. doi: 10.1002/smll.201503524 [99] Tunon E G, Feilden E, Zheng H, et al. Graphene oxide: An all-in-one processing additive for 3D printing[J]. ACS Applied Materials & Interfaces,2017,9:32977-32989. [100] Lacey S D, Kirsch D J, Li Y, et al. Extrusion-based 3D printing of hierarchically porous advanced battery electrodes[J]. Advanced Materials,2018,30:1705651. doi: 10.1002/adma.201705651 [101] Ling S, Kang W, Tao S, et al. Highly concentrated graphene oxide ink for facile 3D printing of supercapacitors[J]. Nano Materials Science,2019,1:142-148. doi: 10.1016/j.nanoms.2019.05.003 [102] Zhong J, Zhou G, He P, et al. 3D printing strong and conductive geo-polymer nanocomposite structures modified by graphene oxide[J]. Carbon,2017,117:421-426. doi: 10.1016/j.carbon.2017.02.102 [103] Zhu S, Yao L, Pan C, et al. 3D printed gellan gum/graphene oxide scaffold for tumor therapy and bone reconstruction[J]. Composites Science and Technology,2021,208:108763. doi: 10.1016/j.compscitech.2021.108763 [104] Zhang S, Wang L, Luo Y, et al. A novel UV-curable molecular-modified graphene oxide for high-resolution printed electronics[J]. Carbon,2021,176:470-479. doi: 10.1016/j.carbon.2021.01.150 [105] Guo B, Liang G, Yu S, et al. 3D printing of reduced graphene oxide aerogels for energy storage devices: A paradigm from materials and technologies to applications[J]. Energy Storage Materials,2021,39:146-165. doi: 10.1016/j.ensm.2021.04.021 [106] Tung D T, Tam L T T, Dung H T, et al. Freeze gelation 3D printing of rGO-CuCo2S4 nanocomposite for high-performance supercapacitor electrodes[J]. Electrochimica Acta,2021,392:138992. doi: 10.1016/j.electacta.2021.138992 [107] Kim J H, Chang W S, Kim D, et al. 3D printing of reduced graphene oxide nanowires[J]. Advanced Materials,2015,27:157-161. doi: 10.1002/adma.201404380 [108] Zhang W, Bi E, Li M, et al. Synthesis of Ag/rGO composite as effective conductive ink filler for flexible inkjet printing electronics[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects,2016,490:232-240. [109] da Silvaa Vinicius A O P, Fernandes-Junior Wilson S, Rocha Diego P, et al. 3D-printed reduced graphene oxide/polylactic acid electrodes: A new prototyped platform for sensing and biosensing applications[J]. Biosensors and Bioelectronics,2020,170:112684. doi: 10.1016/j.bios.2020.112684 [110] Vijayavenkataraman S, Thaharah S, Zhang S, et al. 3D-Printed PCL/rGO conductive scaffolds for peripheral nerve injury repair[J], 2019, 45: 515-523. [111] Cabral C S D, Miguel S P, de Melo-Diogo D, et al. Green reduced graphene oxide functionalized 3D printed scaffolds for bone tissue regeneration[J]. Carbon,2019,146:513-523. doi: 10.1016/j.carbon.2019.01.100 [112] Chen Y, Egan G C, Wan J, et al. Ultra-fast self-assembly and stabilization of reactive nanoparticles in reduced graphene oxide films[J]. Nature Communications,2016,7:12332. doi: 10.1038/ncomms12332 [113] Li L, Secor E B, Chen K S, et al. High-performance solid-state supercapacitors and microsupercapacitors derived from printable graphene inks[J]. Advanced Energy Materials,2016,6:1-8. [114] Ambrosi A, Chua C K, Bonanni A, et al. Electrochemistry of graphene and related materials, Chemical Reviews, 2014, 114: 7150–7188. [115] Bitsch B, Gallasch T, Schroeder M, et al. Capillary suspensions as beneficial formulation concept for high energy density Li-ion battery electrodes[J]. Journal of Power Sources,2016,328:114-123. doi: 10.1016/j.jpowsour.2016.07.102 [116] Koos E, Kannowade W, Willenbacher N. Restructuring and aging in a capillary suspension[J]. Rheologica Acta,2014,53:947-957. doi: 10.1007/s00397-014-0805-z [117] Ding H, Barg S, Derby B. Direct 3D printing of graphene using capillary suspensions[J]. Nanoscale,2020,12:11440-11447. doi: 10.1039/C9NR10831A [118] Tagliaferri S, Nagaraju G, Panagiotopoulos A, et al. Aqueous inks of pristine graphene for 3D printed microsupercapacitors with high capacitance[J]. ACS Nano,2021,15:15342-15353. doi: 10.1021/acsnano.1c06535 [119] Kumar S, Goswami M, Singh N, et al. Pristine graphene-ink for 3D-printed flexible solid-state supercapacitor[J]. Carbon Letters,2022,32:979-985. doi: 10.1007/s42823-022-00331-z [120] Parate K, Rangnekar S V, Jing D, et al. Aerosol-jet-printed graphene immunosensor for label-free cytokine monitoring in serum[J]. ACS Applied Materials & Interfaces,2020,12:8592-8603. [121] Sha J, Li Y, Salvatierra R V, et al. Three-dimensional printed graphene foams[J]. ACS Nano, 2017, 11: 6860–6867. [122] Schroeder K L, Goreham R V, Nann T. Graphene quantum dots for theranostics and bioimaging[J]. Pharmaceutical Research,2016,33:2337-2357. doi: 10.1007/s11095-016-1937-x [123] Zhang Z, Zhang J, Chen N, et al. Graphene quantum dots: An emerging material for energy-related applications and beyond[J]. Energy & Environmental Science,2012,5:8869-8890. [124] Li L, Wu G, Yang G, et al. Focusing on luminescent graphene quantum dots: Current status and future perspectives[J]. Nanoscale,2013,5:4015-4039. doi: 10.1039/c3nr33849e [125] Ni J, Huang X, Bai Y, et al. Resistance to aggregation-caused quenching: chitosan-based solid carbon dots for white light-emitting diode and 3D printing[J]. Advanced Composites and Hybrid Materials. (2022).https://doi.org/10.1007/s42114-022-00483-6. [126] Kumar S, Goswami M, Singh N, et al. Exploring carbon quantum dots as an aqueous electrolyte for energy storage devices[J]. Journal of Energy Storage,2022,55:105522. doi: 10.1016/j.est.2022.105522 [127] Khabibullin A, Alizadehgiashi M, Khuu N, et al. Injectable shear-thinning fluorescent hydrogel formed by cellulose nanocrystals and graphene quantum dots[J]. Langmuir,2017,33:12344-12350. doi: 10.1021/acs.langmuir.7b02906 [128] Kondiah P J, Choonara Y E, Kondiah P P D, et al. A review of injectable polymeric hydrogel systems for application in bone tissue engineering[J]. Molecules,2016,21:1580. doi: 10.3390/molecules21111580 [129] Guvendiren M, Lu H D, Burdick J A. Shear-thinning hydrogels for biomedical applications[J]. Soft Matter,2012,8:260-272. doi: 10.1039/C1SM06513K [130] Kirchmajer D M, Gorkin R, Panhuis M H. An overview of the suitability of hydrogel-forming polymers for extrusion-based 3D-printing[J]. Journal of Materials Chemistry B,2015,3:4105-4117. doi: 10.1039/C5TB00393H [131] Liu Z, Yao P. Injectable shear-thinning xanthan gum hydrogel reinforced by mussel-inspired secondary crosslinking[J]. RSC Advances,2015,5:103292-103301. doi: 10.1039/C5RA17246B [132] Saranti A, Tiron-Stathopoulos A, Papaioannou L, et al. 3D-printed bioactive scaffolds for bone regeneration bearing carbon dots for bioimaging purposes[J]. Smart Materials in Medicine,2022,3:12-19. doi: 10.1016/j.smaim.2021.11.002 [133] Zhou Y, Mintz K J, Oztan C Y, et al. Embedding carbon dots in superabsorbent polymers for additive manufacturing[J]. Polymers,2018,10:1-12. [134] Ge Y, Zhang T, Zhou B, et al. Nanostructured resorcinol-formaldehyde ink for 3D direct writing[J]. Journal of Materials Research and Technology,2018,33:2052-2061. doi: 10.1557/jmr.2018.104 [135] Steldinger H, Esposito A, Brunnengräber K, et al. Activated carbon in the third dimension-3D printing of a tuned porous carbon[J]. Advanced Science,2019,6:1901340. doi: 10.1002/advs.201901340 [136] Bian B, Shi D, Cai X, et al. 3D printed porous carbon anode for enhanced power generation in microbial fuel cell[J]. Nano Energy,2018,44:174-180. doi: 10.1016/j.nanoen.2017.11.070 [137] Shao Y, Guizani C, Grosseau P, et al. Use of lignocellulosic materials and 3D printing for the development of structured monolithic carbon materials[J]. Composites Part B:Engineering,2018,149:206-215. doi: 10.1016/j.compositesb.2018.05.035 [138] Chen X, Zhao G, Wu Y, et al. Cellular carbon microstructures developed by using stereolithography[J]. Carbon,2017,123:34-44. doi: 10.1016/j.carbon.2017.07.043 [139] Rezaei B, Pan J Y, Gundlach C, et al. Highly structured 3D pyrolytic carbon electrodes derived from additive manufacturing technology[J]. Materials & Design,2020,193:108834. [140] Cao Q, Shin M, Lavrik N V, et al. 3D-Printed carbon nanoelectrodes for in vivo neurotransmitter sensing[J]. Nano Letters,2020,20:6831-6836. doi: 10.1021/acs.nanolett.0c02844 [141] Tang X, Zhou H, Cai Z, et al. Generalized 3D printing of graphene-based mixed-dimensional hybrid aerogels[J]. ACS Nano,2018,12:3502-3511. doi: 10.1021/acsnano.8b00304 [142] Zuo Y, Su X, Li X, et al. Multimaterial 3D-printing of graphene/Li0. 35Zn0. 3Fe2. 35O4 and graphene/carbonyl iron composites with superior microwave absorption properties and adjustable bandwidth[J]. Carbon,2020,167:62-74. doi: 10.1016/j.carbon.2020.05.071 [143] Zuo Y, Yao Z, Lin H, et al. Digital light processing 3D printing of graphene/carbonyl iron/polymethyl methacrylate nanocomposites for efficient microwave absorption[J]. Composites Part B:Engineering,2019,179:107533. doi: 10.1016/j.compositesb.2019.107533 [144] De Leon A C, Rodier B J, Bajamundi C, et al. Plastic metal-free electric motor by 3d printing of graphene-polyamide powder[J]. ACS Applied Energy Materials,2018,1:1726-1733. doi: 10.1021/acsaem.8b00240 [145] Fu K, Wang Y, Yan C, et al. Graphene oxide-based electrode inks for 3D-printed lithium-ion batteries[J]. Advanced Materials,2016,28:2587-2594. doi: 10.1002/adma.201505391 [146] Gosai A, Khondakar K R, Ma X, et al. Application of functionalized graphene oxide based biosensors for health monitoring: Simple graphene derivatives to 3D printed platforms[J]. Biosensors,2021,11:384. doi: 10.3390/bios11100384 [147] Belaid H, Nagarajan S, Teyssier C, et al. Development of new biocompatible 3D printed graphene oxide-based scaffolds[J]. Materials Science and Engineering:C,2020,110:110595. doi: 10.1016/j.msec.2019.110595 [148] Seyedsalehi A, Daneshmandi L, Barajaa M, et al. Fabrication and characterization of mechanically competent 3D printed polycaprolactone-reduced graphene oxide scaffolds[J]. Scientific Reports,2020,10:1-14. doi: 10.1038/s41598-020-78977-w [149] Golzar H, Mohammadrezaei D, Yadegari A, et al. Incorporation of functionalized reduced graphene oxide/magnesium nanohybrid to enhance the osteoinductivity capability of 3D printed calcium phosphate-based scaffolds[J]. Composites Part B:Engineering,2020,185:107749. doi: 10.1016/j.compositesb.2020.107749 [150] Angulo-Pineda C, Srirussamee K, Palma P, et al. Electroactive 3D printed scaffolds based on percolated composites of polycaprolactone with thermally reduced graphene oxide for antibacterial and tissue engineering applications[J]. Nanomaterials,2020,10:9-13. [151] Gugoasa L A, Stefan-van Staden R I, van Staden J F, et al. Electrochemical determination of bisphenol a in saliva by a novel three-dimensional (3D) printed gold-reduced graphene oxide (rGO) composite paste electrode[J]. Analytical Letters,2019,52:2583-2606. doi: 10.1080/00032719.2019.1620262 [152] Dai Y, Wu X, Li L, et al. 3D printing of resilient, lightweight and conductive MXene/reduced graphene oxide architectures for broadband electromagnetic interference shielding[J]. Journal of Materials Chemistry A,2022,10:11375-11385. doi: 10.1039/D2TA01388F [153] Zhao X, Liu B, Pan P, et al. Fabrication of reduced graphene oxide/manganese oxide ink for 3D-printing technology on the application of high-performance supercapacitors[J]. Journal of Materials Science,2021,56:8102-8114. doi: 10.1007/s10853-020-05761-6 [154] Qian C, Xiao T, Chen Y, et al. 3D printed reduced graphene oxide/elastomer resin composite with structural modulated sensitivity for flexible strain sensor[J]. Advanced Engineering Materials,2022,24:1-9. [155] Gardner J M, Sauti G, Kim J W, et al. 3-D printing of multifunctional carbon nanotube yarn reinforced components[J]. Additive Manufacturing,2016,12:38-44. doi: 10.1016/j.addma.2016.06.008 [156] Postiglione G, Natale G, Griffini G, et al. Conductive 3D microstructures by direct 3D printing of polymer/carbon nanotube nanocomposites via liquid deposition modeling[J]. Composites Part A:Applied Science and Manufacturing,2015,76:110-114. doi: 10.1016/j.compositesa.2015.05.014 [157] Sweeney C B, Lackey B A, Pospisil M J, et al. Welding of 3D-printed carbon nanotube–polymer composites by locally induced microwave heating[J]. Science Advances,2017,3:1-7. [158] Ho C M B, Mishra A, Lin P T P, et al. 3D printed polycaprolactone carbon nanotube composite scaffolds for cardiac tissue engineering[J]. Macromolecular Bioscience,2017,17:1-9. [159] Lee S J, Zhu W, Nowicki M, et al. 3D printing nano conductive multi-walled carbon nanotube scaffolds for nerve regeneration[J]. Journal of Neural Engineering,2018,15:016018. doi: 10.1088/1741-2552/aa95a5 [160] Kim K, Park J, hoon Suh J, et al. 3D printing of multiaxial force sensors using carbon nanotube (CNT)/thermoplastic polyurethane (TPU) filaments[J]. Sensors and Actuators A:Physical,2017,263:493-500. doi: 10.1016/j.sna.2017.07.020 [161] Abshirini M, Charara M, Liu Y, et al. 3D printing of highly stretchable strain sensors based on carbon nanotube nanocomposites[J]. Advanced Engineering Materials,2018,20:1-9. [162] Tomal W, Świergosz T, Pilch M, et al. New horizons for carbon dots: Quantum nano-photoinitiating catalysts for cationic photopolymerization and three-dimensional (3D) printing under visible light[J]. Polymer Chemistry,2021,12:3661-3676. doi: 10.1039/D1PY00228G [163] Yang F, Yang L, Xu L, et al. 3D-printed smartphone-based device for fluorimetric diagnosis of ketosis by acetone-responsive dye marker and red emissive carbon dots[J]. Microchimica Acta,2021,188:306. doi: 10.1007/s00604-021-04965-0 -

下载:

下载: