-

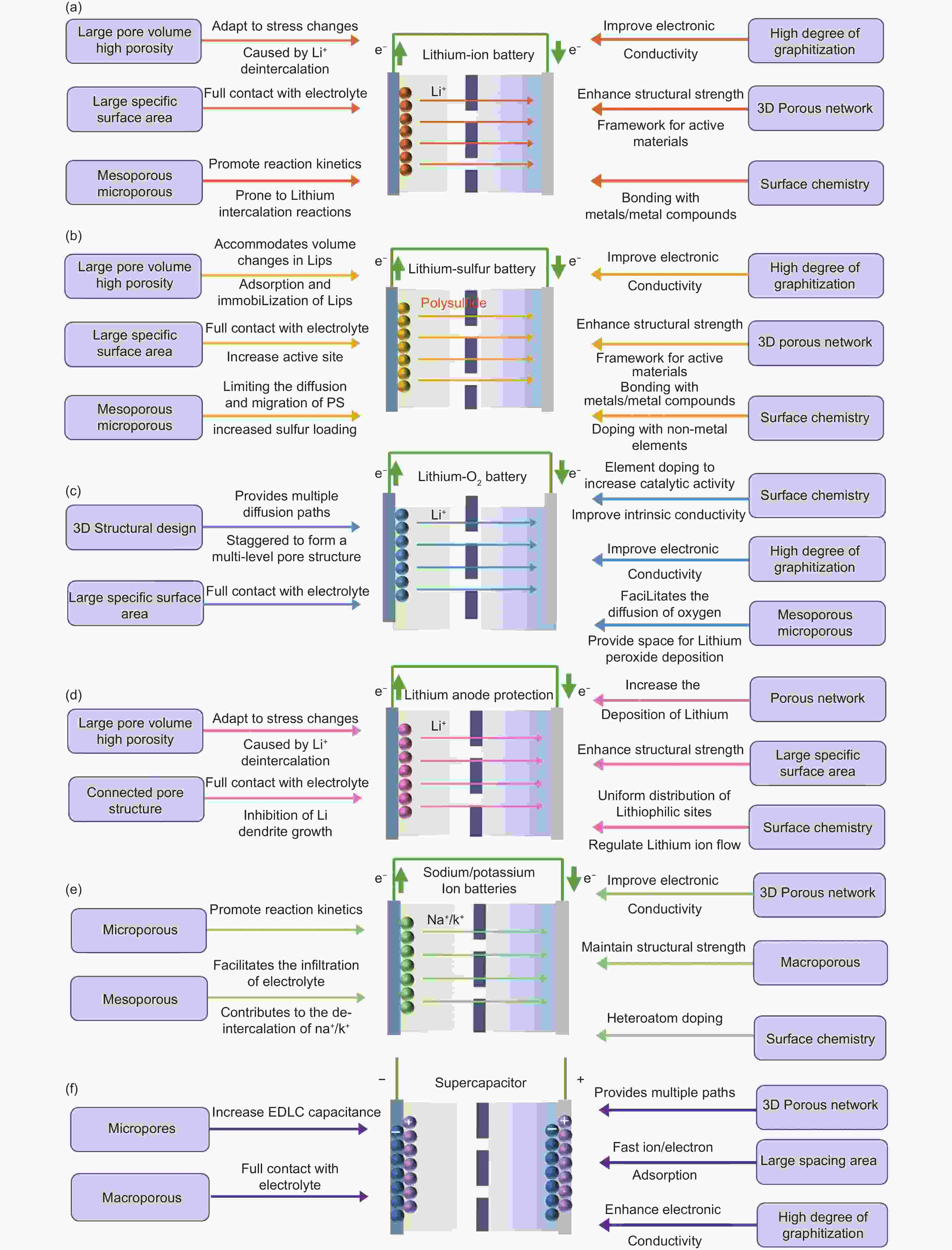

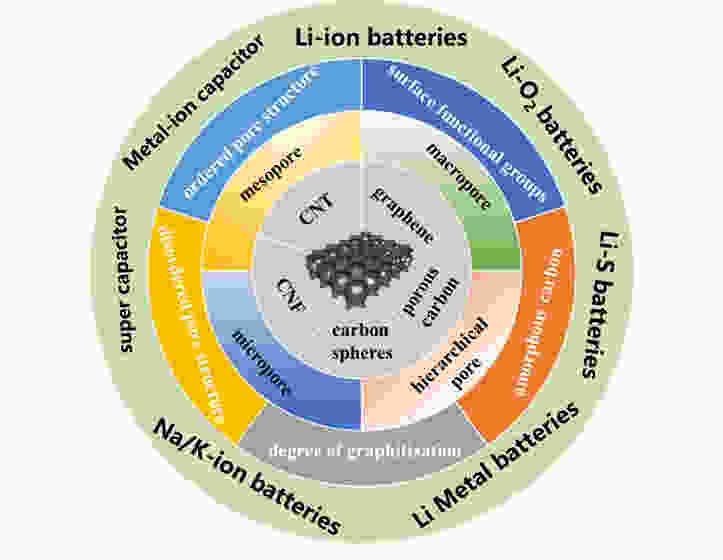

摘要: 多孔炭材料具有质量轻、比表面积大、导电性好和稳定性高的优点,在电化学储能领域得到了广泛的应用。近几十年来,多孔炭材料的结构构筑和功能化设计取得了较大的进步。本文以多孔炭在不同储能器件中的应用发展为导向,结合多孔炭结构设计和功能化发展,综述了其在锂离子电池、锂空气电池、锂硫电池、锂负极保护、钠离子电池、钾离子电池等电化学储能器件中的研究成果和进展,最后总结了多孔炭的结构控制和功能化的策略,并展望了多孔炭材料未来研究的方向和挑战。Abstract: Porous carbons are widely used in the field of electrochemical energy storage due to their light weight, large specific surface area, high electronic conductivity and structural stability. Over the past decades, the construction and functionalization of porous carbons have seen great progress. This review summarizes progress in the use of porous carbons in different energy storage devices, such as lithium-ion, lithium-oxygen, lithium-sulfur, and lithium-metal batteries for anode protection, sodium-ion and potassium-ion batteries, supercapacitors and metal ion capacitors. Methods for the synthesis and functionalization of porous carbons are discussed and the effects of their pore texture on the electrochemical performance of different energy storage systems are outlined. Strategies for their structural control are proposed, and the challenges and prospects for their use in energy storage devices are discussed.

-

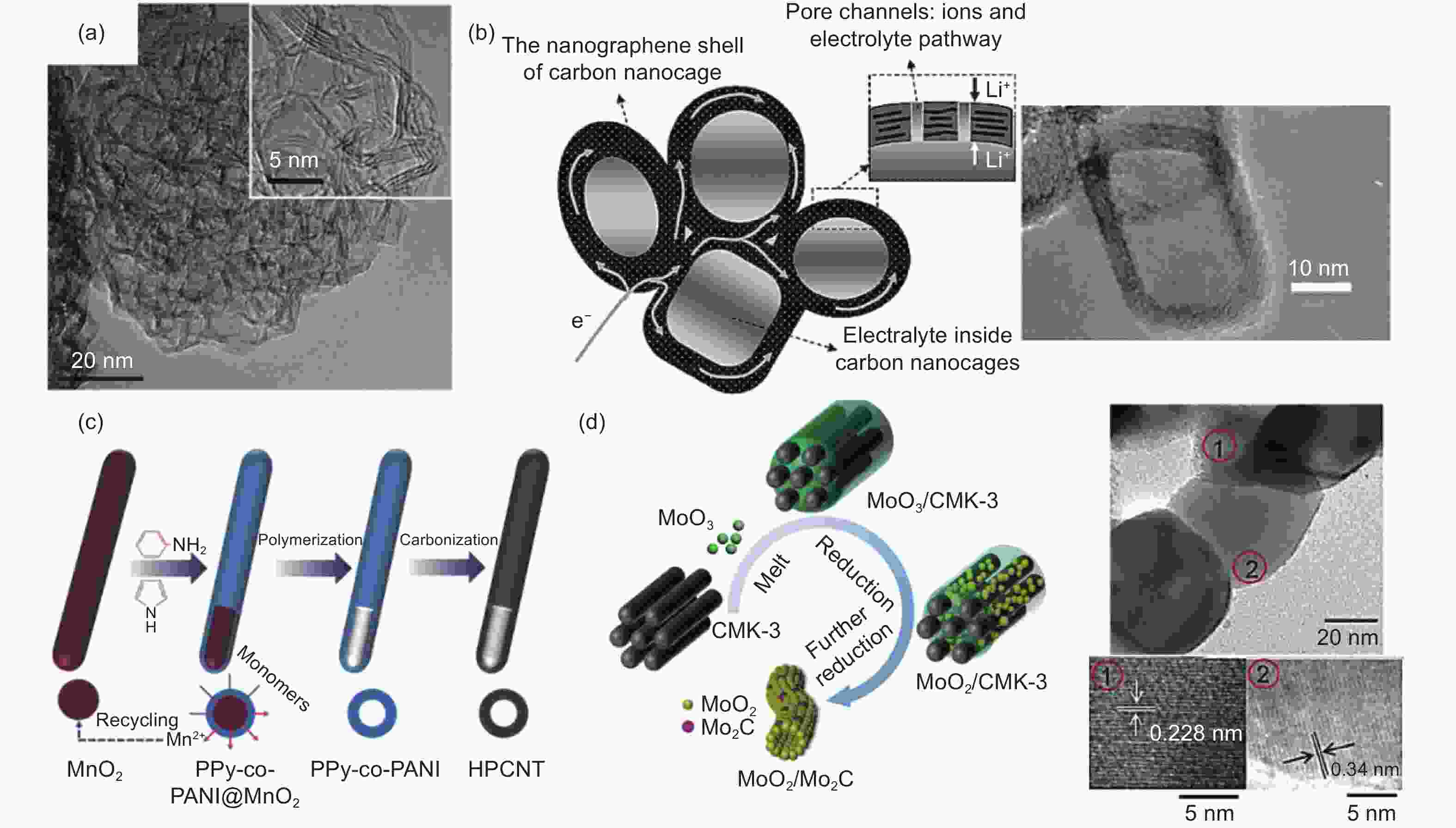

图 2 (a)多孔炭球TEM透射电镜图[11];(b)碳纳米笼的作用示意图和TEM透射电镜图[20];(c)分层多孔碳纳米管的设计和制造示意图[22];(d)二氧化钼/碳化钼纳米管的合成机理和TEM、HRTEM图[14]

Figure 2. (a) TEM images of porous carbon spheres[11]; Reprinted with permission by copyright 2022, Elsevier. (b) Schematic representations of electron transportation and Li ion diffusion in the carbonnanocages and TEM image of the carbonnanocages[20]; Reprinted with permission by Elsevier. (c) Schematic illustration of the preparation of hierarchically porous carbon nanotubes[22]; Reprinted with permission by John Wiley and Sons. (d) The schematic illustration of the preparation of MoO2/Mo2C Heteronanotubes and TEM images[14]. Reprinted with permission by John Wiley and Sons

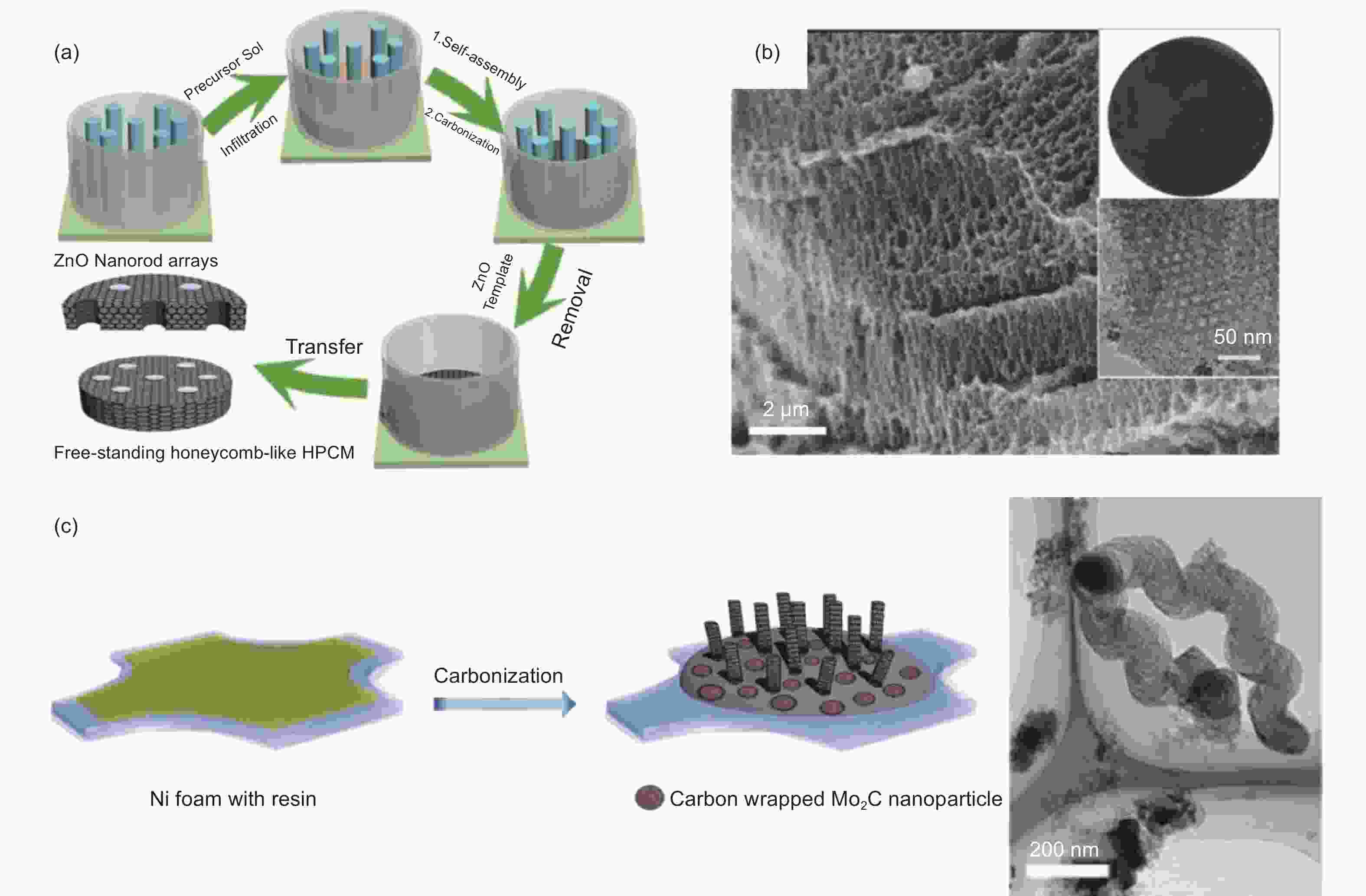

图 3 蜂窝煤状大孔炭膜的(a)合成示意图和(b)SEM图[71] ;(c)Mo2C@C/Ni复合材料的生成过程机理和TEM图[59]

Figure 3. (a) Schematic illustration of the preparation of the free-standing hierarchically porous carbon membrane and (b) SEM image of the membrane (top inset, optical photo and bottom inset, TEM image) [71]; Reprinted with permission by John Wiley and Sons. (c) Schematic process for the synthesis of Mo2C@C/Ni and SEM image [59] , Reprinted with permission by John Wiley and Sons

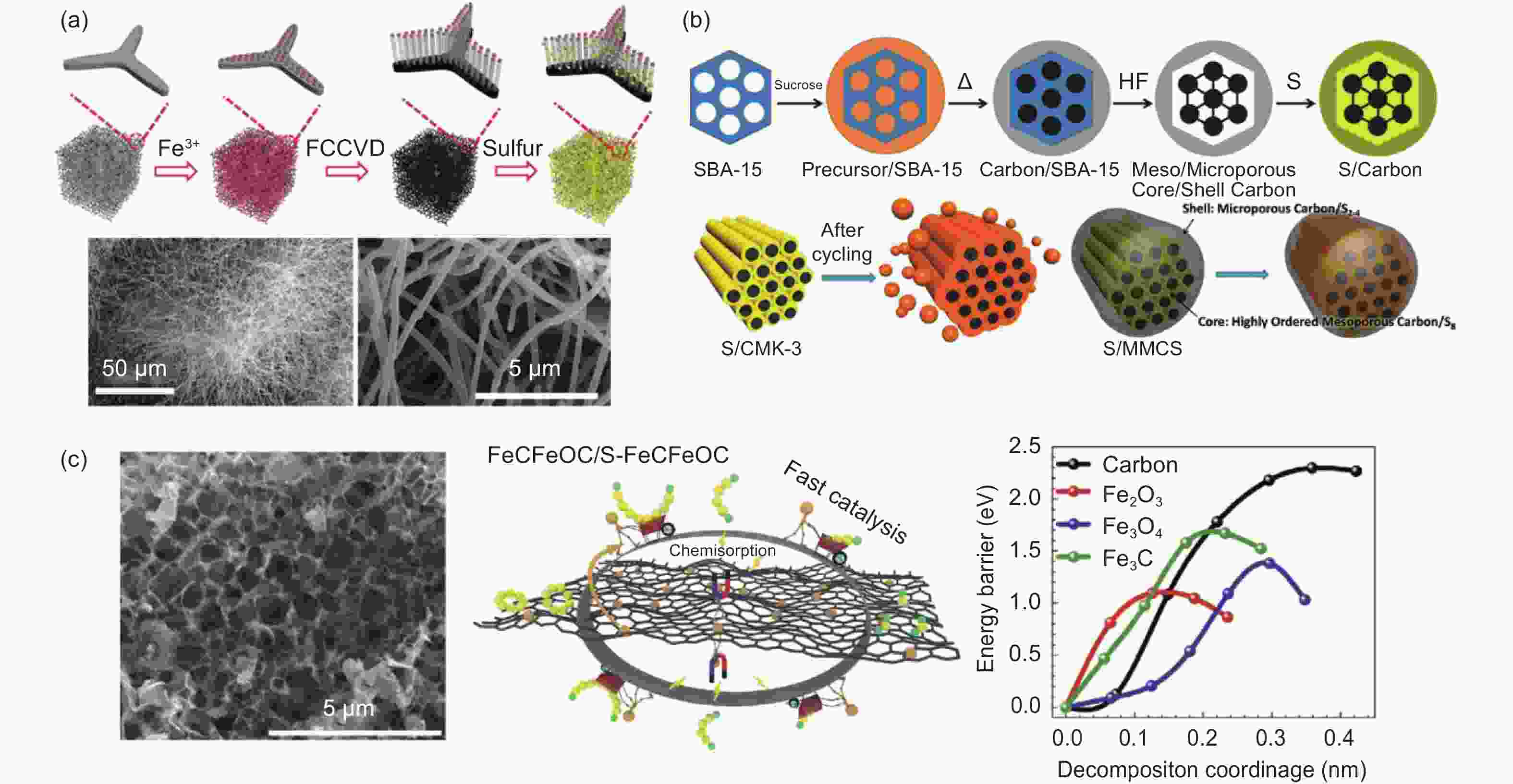

图 4 (a)Fe/Fe3C原位催化生长多孔氮掺杂碳纳米管示意图和SEM图[82];(b)有序微介孔核壳碳和硫/碳复合材料的制备原理图及核壳结构作用示意图[85];(c)Fe基化合物/碳复合材料的SEM图,多硫化物在复合材料表面的转化过程示意图以及Li2S在不同成分表面的分解的能垒[92]

Figure 4. (a) Schematic illustration of the preparation of the free-standing Fe/Fe3C@N-CNT and SEM images[82]; Reprinted with permission by John Wiley and Sons. (b) Schematic for preparation of highly ordered meso-microporous core-shell carbon and sulfur/carbon composite[85]; Reprinted with permission by American Chemical Society. (c) SEM images and the schematic illustrations of the conversion process of sulfur on the surfaces of FeCFeOC composite and the corresponding energy profiles of the composite[92]; Reprinted with permission by John Wiley and Sons

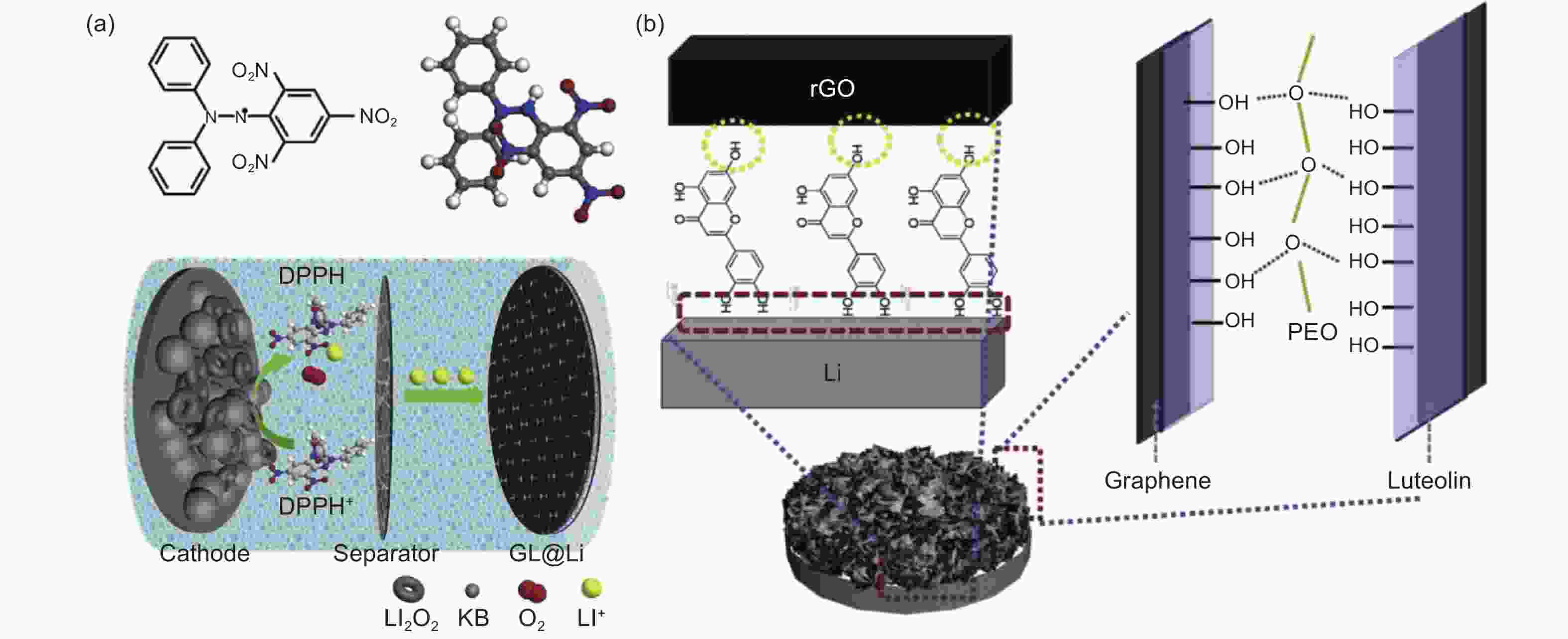

图 5 (a) 木樨草素的分子结构和对Li-O2电池的充电机理示意图,(b)锂负极表面氧化石墨烯与木樨草素复合涂层的作用原理示意图 [68]

Figure 5. (a) Molecular structure of DPPH and the charging reaction mechanism of Li-O2 cells; (b) Schematic illustration of the action principle of the composite coating of graphene oxide and lignocaine on the surface of lithium negative electrode [68]. Reprinted with permission by Elsevier

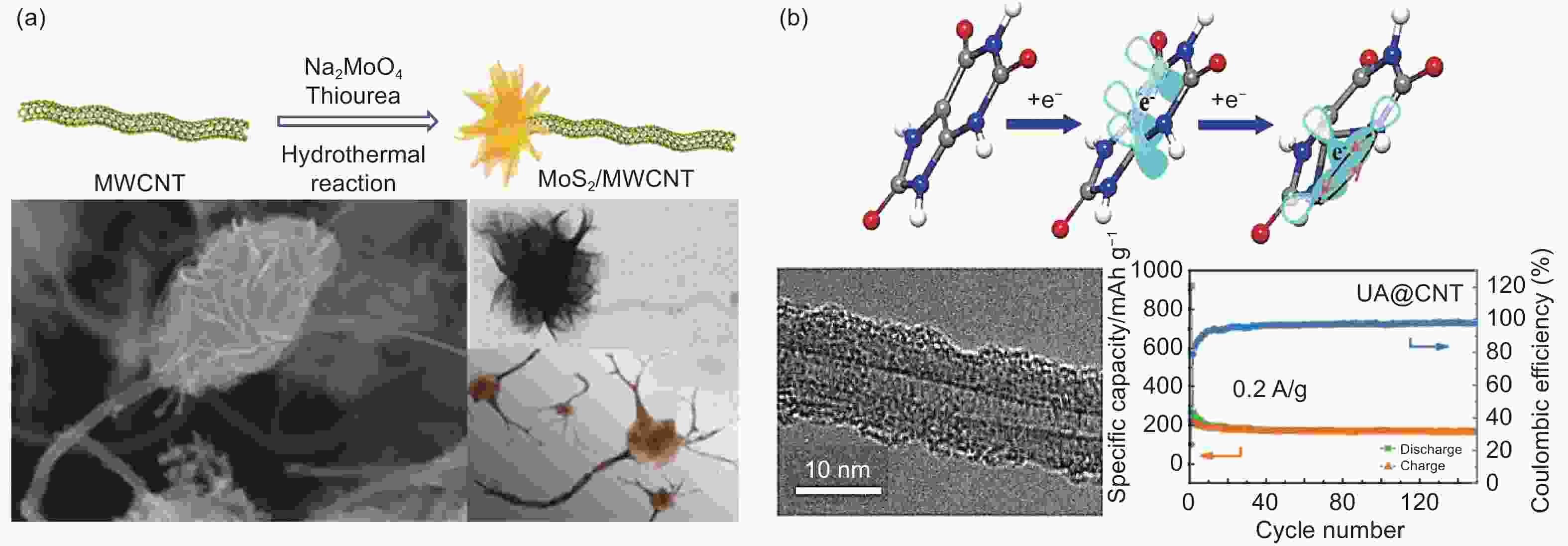

图 6 (a)MoS2/MWCNT复合物的制备过程示意图、形貌表征与类神经元结构示意图[114];(b)尿酸分子在钠离子电池中的作用原理示意图、SEM图和循环性能[115]

Figure 6. (a) Schematic illustration of the preparation and the neuron-inspired nanostructureof MoS2/MWCNT [114];Reprinted with permission by American Chemical Society. (b) Schematic illustration of UA, SEM of UA@CNT and cycling performance of the electrode [115]; Reprinted with permission by American Chemical Society

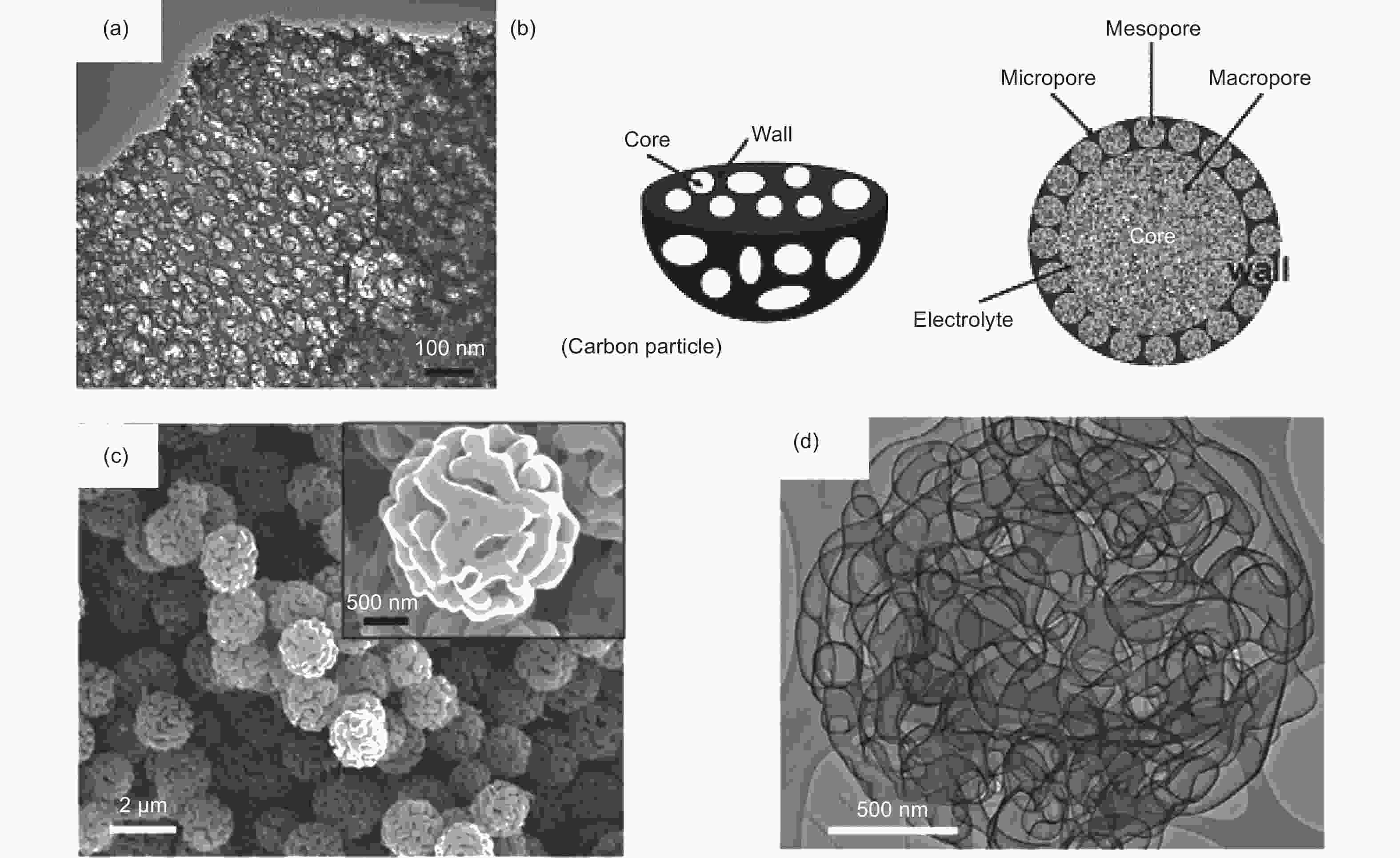

图 7 (a)三维结构周期性分层多孔石墨碳中孔壁的TEM照片,(b)三维分层多孔结构的示意图[129];(c, d)P/O-PCS材料的扫描电镜与透射电镜照片[140]

Figure 7. (a) TEM image of the mesoporous walls, (b) schematic representation of the 3D hierarchical porous texture; [128] Reprinted with permission by Elsevier. (c, d) SEM and TEM images of P/O-PCS[140]; Reprinted with permission by John Wiley and Sons

-

[1] Wei X, Li X H, Wang K X, et al. Design of functional carbon composite materials for energy conversion and storage[J]. Chemical Research in Chinese Universities,2022,38:677-687. (in Chinese) doi: 10.1007/s40242-022-2030-0 [2] Tian W, Zhang H, Duan X, et al. Porous carbons: structure‐oriented design and versatile applications[J]. Advanced Functional Materials,2020,30:1909265. doi: 10.1002/adfm.201909265 [3] Deng X, Li J, Ma L, et al. Three-dimensional porous carbon materials and their composites as electrodes for electrochemical energy storage systems[J]. Materials Chemistry Frontiers,2019,3:2221-2245. doi: 10.1039/C9QM00425D [4] Fang R, Zhao S, Pei S, et al. Toward more reliable lithium–sulfur batteries: An all-graphene cathode structure[J]. ACS Nano,2016,10:8676-8682. doi: 10.1021/acsnano.6b04019 [5] Mitchell R R, Gallant B M, Thompson C V, et al. All-carbon-nanofiber electrodes for high-energy rechargeable Li-O2 batteries[J]. Energy & Environmental Science,2011,4:2952-2958. [6] Pei F, Lin L, Fu A, et al. A two-dimensional porous carbon-modified separator for high-energy-density Li-S batteries[J]. Joule,2018,2:323-336. doi: 10.1016/j.joule.2017.12.003 [7] Wang L, Hu X L. Recent advances in porous carbon materials for electrochemical energy storage[J]. Chemistry-An Asian Journal,2018,13:1518-1529. doi: 10.1002/asia.201800553 [8] Xiao J, Mei D H, Li X L, et al. Hierarchically porous graphene as a lithium-air battery electrode[J]. Nano letters,2020,11:5071-5078. [9] Jian Z, Luo W, Ji X. Carbon electrodes for K-ion batteries[J]. Journal of the American Chemical Society,2015,137:11566-11569. doi: 10.1021/jacs.5b06809 [10] Liu T F, Hu H L, Ding X F, et al. 12 years roadmap of the sulfur cathode for lithium sulfur batteries (2009–2020)[J]. Energy Storage Materials,2020,30:346-366. doi: 10.1016/j.ensm.2020.05.023 [11] Etacheri V, Wang C, O'connell M J, et al. Porous carbon sphere anodes for enhanced lithium-ion storage[J]. Journal of Materials Chemistry A,2015,3:9861-9868. doi: 10.1039/C5TA01360G [12] Liu S, Li J, Yan X, et al. Superhierarchical cobalt-embedded nitrogen-doped porous carbon nanosheets as two-in-one hosts for high-performance lithium-sulfur batteries[J]. Advanced Materials,2018,30:1706895. doi: 10.1002/adma.201706895 [13] Lu Y H, Tang Y C, Liu R L, et al. Multifunctional templating strategy for fabrication of Fe, N-codoped hierarchical porous carbon Nanosheets[J]. Chinese Journal of Polymer Science,2021,40:2-6. [14] Zhang H J, Wang K X, Wu X Y, et al. MoO2/Mo2C heteronanotubes function as high-performance Li-ion battery electrode[J]. Advanced Functional Materials,2014,24:3399-3404. doi: 10.1002/adfm.201303856 [15] Zhou T, Lv W, Li J, et al. Twinborn TiO2-TiN heterostructures enabling smooth trapping-diffusion-conversion of polysulfides towards ultralong life lithium-sulfur batteries[J]. Energy & Environmental Science,2017,10:1694-1703. [16] Du F H, Wang K X, Fu W, et al. A graphene-wrapped silver-porous silicon composite with enhanced electrochemical performance for lithium-ion batteries[J]. Journal of Materials Chemistry A,2013,1:13648-13654. doi: 10.1039/c3ta13092d [17] Hao Q Q, Zhang Z, Mao Y, et al. Catalysts for Li-CO2 batteries: from heterogeneous to homogeneous[J]. ChemNanoMat,2022,8:e202100381. [18] Zhang Z, Bai W L, Cai Z P, et al. Enhanced electrochemical performance of aprotic Li-CO2 batteries with a ruthenium-complex-based mobile catalyst[J]. Angewandte Chemie International Edition,2021,60:16404-16408. doi: 10.1002/anie.202105892 [19] Jayaprakash N, Shen J, Moganty S S, et al. Porous hollow carbon@sulfur composites for high-power lithium-sulfur batteries[J]. Angewandte Chemie International Edition,2011,50:5904-5908. doi: 10.1002/anie.201100637 [20] Wang K, Li Z, Wang Y, et al. Carbon nanocages with nanographene shell for high-rate lithium ion batteries[J]. Journal of Materials Chemistry,2010,20:9748-9753. doi: 10.1039/c0jm01704c [21] Wang K X, Li Y, Wu X Y, et al. Carbon nanocolumn arrays prepared by pulsed laser deposition for lithium ion batteries[J]. Journal of Power Sources,2012,203:140-144. doi: 10.1016/j.jpowsour.2011.12.031 [22] Wang J G, Liu H Z, Zhang X Y, et al. Green synthesis of hierarchically porous carbon nanotubes as advanced materials for high-efficient energy storage[J]. Small,2018,14:1703950. doi: 10.1002/smll.201703950 [23] Wang Q, Chen L, Huang X. Anomalous electrochemical behavior of multiwalled carbon nanotubes as host material for lithium insertion/extraction[J]. Electrochemical and Solid-State Letters,2002,5:A188-A190. doi: 10.1149/1.1494177 [24] Zhang B, Liu Y, Huang Z, et al. Urchin-like Li4Ti5O12-carbon nanofiber composites for high rate performance anodes in Li-ion batteries[J]. Journal of Materials Chemistry,2012,22:12133-12140. doi: 10.1039/c2jm31308a [25] Li W, Li M, Wang M, et al. Electrospinning with partially carbonization in air: highly porous carbon nanofibers optimized for high-performance flexible lithium-ion batteries[J]. Nano Energy,2015,13:693-701. doi: 10.1016/j.nanoen.2015.03.027 [26] Wu Z S, Ren W C, Xu L, et al. Doped graphene sheets as anode materials with superhigh rate and large capacity for lithium ion batteries[J]. ACS Nano,2011,5:5463-5471. doi: 10.1021/nn2006249 [27] Raccichini R, Varzi A, Passerini S, et al. The role of graphene for electrochemical energy storage[J]. Nature Materials,2015,14:271-279. doi: 10.1038/nmat4170 [28] Wang G, Shen X, Yao J, et al. Graphene nanosheets for enhanced lithium storage in lithium ion batteries[J]. Carbon,2009,47:2049-2053. doi: 10.1016/j.carbon.2009.03.053 [29] Yoo E, Kim J, Hosono E, et al. Large reversible Li storage of graphene nanosheet families for use in rechargeable lithium ion batteries[J]. Nano letters,2008,8:2277-2282. doi: 10.1021/nl800957b [30] Zheng F, Yang Y, Chen Q. High lithium anodic performance of highly nitrogen-doped porous carbon prepared from a metal-organic framework[J]. Nature Communications,2014,5:5261. doi: 10.1038/ncomms6261 [31] Zhang H J, Shu J, Wang K X, et al. Lithiation mechanism of hierarchical porous MoO2 nanotubes fabricated through one-step carbothermal reduction[J]. Journal of Materials Chemistry A,2013,2:80-86. [32] Zhang F, Wang K X, Li G D, et al. Hierarchical porous carbon derived from rice straw for lithium ion batteries with high-rate performance[J]. Electrochemistry Communications,2009,11:130-133. doi: 10.1016/j.elecom.2008.10.041 [33] Du F H, Liu Y S, Long J, et al. Incorporation of heterostructured Sn/SnO nanoparticles in crumpled nitrogen-doped graphene nanosheets for application as anodes in lithium-ion batteries[J]. Chemical Communications,2014,50:9961-9964. doi: 10.1039/C4CC04187A [34] Girishkumar G, Mccloskey B, Luntz A C, et al. Lithium-air battery: promise and challenges[J]. Journal of Physical Chemistry Letters,2010,1:2193-2203. doi: 10.1021/jz1005384 [35] Peng Z, Freunberger S A, Chen Y, et al. A reversible and higher-rate Li-O2 battery[J]. Science,2012,337:563-566. doi: 10.1126/science.1223985 [36] Du F H, Li B, Fu W, et al. Surface binding of polypyrrole on porous silicon hollow nanospheres for Li-ion battery anodes with high structure stability[J]. Advanced Materials,2014,26:6145-6150. doi: 10.1002/adma.201401937 [37] Fu W, Du F H, Wang K X, et al. In situ growth of ultrafine tin oxide nanocrystals embedded in graphitized carbon nanosheets for use in high-performance lithium-ion batteries[J]. Journal of Materials Chemistry A,2014,2:6960-6965. doi: 10.1039/C4TA00021H [38] Jiang Y M, Wang K X, Guo X X, et al. Mesoporous titania rods as an anode material for high performance lithium-ion batteries[J]. Journal of Power Sources,2012,214:298-302. doi: 10.1016/j.jpowsour.2012.04.091 [39] Jiang Y M, Wang K X, Zhang H J, et al. Distinct effect of hierarchical structure on performance of anatase as an anode material for lithium-ion batteries[J]. Rsc Advances,2013,3:26052-26058. doi: 10.1039/c3ra44731f [40] Zhang H J, Shu J, Wei X, et al. Cerium vanadate nanoparticles as a new anode material for lithium ion batteries[J]. Rsc Advances,2013,3:7403-7407. doi: 10.1039/c3ra22795b [41] Zhang J P, Wu X Y, Wei X, et al. Top-down fabrication of hierarchical nanocubes on nanosheets composite for high-rate lithium storage[J]. Dalton Transactions,2018,47:16155-16163. doi: 10.1039/C8DT03596B [42] Wang Z K, Shu J, Zhu Q C, et al. Graphene-nanosheet-wrapped LiV3O8 nanocomposites as high performance cathode materials for rechargeable lithium-ion batteries[J]. Journal of Power Sources,2016,307:426-434. doi: 10.1016/j.jpowsour.2016.01.005 [43] Fu W, Du F H, Su J, et al. In situ catalytic growth of large-area multilayered graphene/MoS2 heterostructures[J]. Scientific Reports,2014,4:4673. [44] Jung H G, Hassoun J, Park J B, et al. An improved high-performance lithium–air battery[J]. Nature Chemistry,2012,4:579-585. doi: 10.1038/nchem.1376 [45] Zhang H J, Wu T H, Wang K X, et al. Uniform hierarchical MoO2/carbon spheres with high cycling performance for lithium ion batteries[J]. Journal of Materials Chemistry A,2013,1:12038-12043. doi: 10.1039/c3ta12566a [46] 白玉林, 王澄, 吴越, et al. 核壳结构MoOx/C微球的制备及储锂性能[J]. 无机化学学报,2019,35:2045-2050. doi: 10.11862/CJIC.2019.233 [47] 张豪杰, 王开学, 陈接胜. 新型球状磷酸铁锂的合成及电化学性能[J]. 高等化学学报,2011,32:641-643. [48] Gu D, Li W, Wang F, et al. Controllable synthesis of mesoporous peapod-like Co3O4@carbon nanotube arrays for high-performance lithium-ion batteries[J]. Angewandte Chemie International Edition,2015,54:7060-7064. [49] Wang K X, Zhu Q C, Chen J S. Strategies toward high-performance cathode materials for lithium-oxygen batteries[J]. Small,2018,14:1800078. doi: 10.1002/smll.201800078 [50] Liu T, Leskes M, Yu W, et al. Cycling Li-O2 batteries via LiOH formation and decomposition[J]. Science,2015,350:530-533. doi: 10.1126/science.aac7730 [51] Grande L, Paillard E, Hassoun J, et al. The lithium/air battery: Still an emerging system or a practical reality?[J]. Advanced Materials,2015,27:784-800. doi: 10.1002/adma.201403064 [52] Xu S M, Zhu Q C, Long J, et al. Low-overpotential Li-O2 batteries based on TFSI intercalated Co-Ti layered double oxides[J]. Advanced Functional Materials,2016,26:1365-1374. doi: 10.1002/adfm.201504128 [53] Bai W L, Zhang Z, Chen X, et al. Phosphazene-derived stable and robust artificial SEI for protecting lithium anodes of Li-O2 batteries[J]. Chemical Communications,2020,56:12566-12569. doi: 10.1039/D0CC05303A [54] Yoo E, Zhou H. Li-air rechargeable battery based on metal-free graphene nanosheet catalysts[J]. ACS Nano,2011,5:3020-3026. doi: 10.1021/nn200084u [55] Sun B, Huang X, Chen S, et al. Porous graphene nanoarchitectures: An efficient catalyst for low charge-overpotential, long life, and high capacity lithium-oxygen batteries[J]. Nano letters,2014,14:3145-3152. doi: 10.1021/nl500397y [56] Xiao J, Mei D, Li X, et al. Hierarchically porous graphene as a lithium–air battery electrode[J]. Nano letters,2011,11:5071-5078. doi: 10.1021/nl203332e [57] Sun B, Liu H, Munroe P, et al. Nanocomposites of CoO and a mesoporous carbon (CMK-3) as a high performance cathode catalyst for lithium-oxygen batteries[J]. Nano Research,2012,5:460-469. doi: 10.1007/s12274-012-0231-4 [58] Park J, Jeong J, Lee S, et al. Effect of mesoporous structured cathode materials on charging potentials and rate capability of lithium-oxygen batteries[J]. ChemSusChem,2015,8:3146-3152. doi: 10.1002/cssc.201500534 [59] Zhu Q C, Xu S M, Harris M M, et al. A composite of carbon-wrapped Mo2C nanoparticle and carbon nanotube formed directly on Ni foam as a high-performance binder-free cathode for Li-O2 batteries[J]. Advanced Functional Materials,2016,26:8514-8520. doi: 10.1002/adfm.201603462 [60] Zhu Q C, Xu S M, Cai Z P, et al. Towards real Li-air batteries: a binder-free cathode with high electrochemical performance in CO2 and O2[J]. Energy Storage Materials,2017,7:209-215. doi: 10.1016/j.ensm.2017.03.004 [61] Wu Z Y, Ma C, Bai Y L, et al. Rubber-based carbon electrode materials derived from dumped tires for efficient sodium-ion storage[J]. Dalton Transactions,2018,47:4885-4892. doi: 10.1039/C8DT00504D [62] Zhu Q C, Du F H, Xu S M, et al. Hydroquinone resin induced carbon nanotubes on Ni foam as binder-free cathode for Li-O2 batteries[J]. ACS Applied Materials & Interfaces,2016,8:3868-3873. [63] Xu S M, Liang X, Wu X Y, et al. Multistaged discharge constructing heterostructure with enhanced solid-solution behavior for long-life lithium-oxygen batteries[J]. Nature Communications,2019,10:5810. doi: 10.1038/s41467-019-13712-2 [64] Xu S M, Liang X, Liu X, et al. Surface engineering donor and acceptor sites with enhanced charge transport for low-overpotential lithium-xxygen batteries[J]. Energy Storage Materials,2019,25:56-61. [65] Dong J J, Ma C, Zhang Q, et al. Towards high performance lithium-oxygen batteries: Co3O4-NiO heterostructure induced preferential growth of ultrathin Li2O2 film[J]. Journal of Alloys and Compounds,2021,863:158073. doi: 10.1016/j.jallcom.2020.158073 [66] Xu S M, Zhu Q C, Du F H, et al. Co3O4-based binder-free cathodes for lithium-oxygen batteries with improved cycling stability[J]. Dalton Transactions,2015,44:8678-8684. doi: 10.1039/C5DT00498E [67] Bai W L, Xu S M, Xu C Y, et al. Free-standing N, Co-codoped TiO2 nanoparticles for LiO2-based Li-O2 batteries[J]. Journal of Materials Chemistry A, 2019, 7: 23046-23054. [68] Bai W L, Zhang Z, Chen X, et al. Boosting the electrochemical performance of Li–O2 batteries with DPPH redox mediator and graphene-luteolin-protected lithium anode[J]. Energy Storage Materials,2020,31:373-381. doi: 10.1016/j.ensm.2020.06.036 [69] Liu Q C, Xu J J, Xu D, et al. Flexible lithium-oxygen battery based on a recoverable cathode[J]. Nature Communications,2015,6:7892. doi: 10.1038/ncomms8892 [70] Lim H D, Yun Y S, Cho S Y, et al. All-carbon-based cathode for a true high-energy-density Li-O2 battery[J]. Carbon,2016,114:311-316. [71] Xu S M, Liang X, Ren Z C, et al. Free-standing air cathodes based on 3D hierarchically porous carbon membranes: kinetic overpotential of continuous macropores in Li-O2 batteries[J]. Angewandte Chemie International Edition,2018,57:6825-6829. doi: 10.1002/anie.201801399 [72] Gnana Kumar G, Chung S H, Raj Kumar T, et al. Three-dimensional graphene-carbon nanotube-Ni hierarchical architecture as a polysulfide trap for lithium-sulfur batteries[J]. ACS Applied Materials & Interfaces,2018,10:20627-20634. [73] Zhao M, Li B Q, Peng H J, et al. Lithium-sulfur batteries under lean electrolyte conditions: challenges and opportunities[J]. Angewandte Chemie International Edition,2020,59:12636-12652. doi: 10.1002/anie.201909339 [74] Liu Y, Zhao X, Li S, et al. Towards high-performance lithium-sulfur batteries: the modification of polypropylene separator by 3D porous carbon structure embedded with Fe3C/Fe nanoparticles[J]. Chemical Research in Chinese Universities,2021,38:147-154. (in Chinese) [75] Peng H J, Huang J Q, Cheng X B, et al. Review on high-loading and high-energy lithium-sulfur batteries[J]. Advanced Energy Materials,2017,7:1700260. doi: 10.1002/aenm.201700260 [76] Li W, Liu J, Zhao D. Mesoporous materials for energy conversion and storage devices[J]. Nature Reviews Materials,2016,1:16023. doi: 10.1038/natrevmats.2016.23 [77] Liu Y S, Bai Y L, Liu X, et al. , Free-standing hybrid porous membranes integrated with transition metal nitride and carbide nanoparticles for high-performance lithium-sulfur batteries[J]. Chemical Engineering Journal, 2019, 378: 122208. [78] Liu Y S, Liu X, Xu S M, et al. 3D ordered macroporous MoO2 attached on carbonized cloth for high performance free-standing binder-free lithium-sulfur electrodes[J]. Journal of Materials Chemistry A,2019,7:24524-24531. doi: 10.1039/C9TA08498C [79] Li G, Sun J, Hou W, et al. Three-dimensional porous carbon composites containing high sulfur nanoparticle content for high-performance lithium-sulfur batteries[J]. Nature Communications,2016,7:10601. doi: 10.1038/ncomms10601 [80] Peng H J, Huang J Q, Zhao M Q, et al. , Nanoarchitectured Graphene/CNT@Porous Carbon with Extraordinary Electrical Conductivity and Interconnected Micro/Mesopores for Lithium-Sulfur Batteries[J]. Advanced Functional Materials, 2014, 24: 2772-2781. [81] Wu X, Jie X, Liang X, et al. Enhanced stability of nitrogen doped porous carbon fiber on cathode materials for high performance lithium-sulfur batteries[J]. Rsc Advances,2022,12:22996-23005. doi: 10.1039/D2RA03317H [82] Liu Y S, Ma C, Bai Y L, et al. Nitrogen-doped carbon nanotube sponge with embedded Fe/Fe3C nanoparticles as binder-free cathodes for high capacity lithium-sulfur batteries[J]. Journal of Materials Chemistry A,2018,6:17473-17480. doi: 10.1039/C8TA06040A [83] Zhang C, Wu H B, Yuan C, et al. Confining sulfur in double-shelled hollow carbon spheres for lithium-sulfur batteries[J]. Angewandte Chemie International Edition,2012,51:9592-9595. doi: 10.1002/anie.201205292 [84] Sun Q, He B, Zhang X Q, et al. Engineering of hollow core-shell interlinked carbon spheres for highly stable lithium-sulfur batteries[J]. ACS Nano,2015,9:8504-8513. doi: 10.1021/acsnano.5b03488 [85] Li Z, Jiang Y, Yuan L, et al. A highly ordered meso@microporous carbon-supported sulfur@smaller sulfur core-shell structured cathode for Li-S batteries[J]. ACS Nano,2014,8:9295-9303. doi: 10.1021/nn503220h [86] Xu Z L, Huang J Q, Chong W G, et al. In situ TEM study of volume expansion in porous carbon nanofiber/sulfur cathodes with exceptional high-rate performance[J]. Advanced Energy Materials,2017,7:1602078. doi: 10.1002/aenm.201602078 [87] Hou H, Banks C E, Jing M, et al. Carbon quantum dots and their derivative 3D porous carbon frameworks for sodium-ion batteries with ultralong cycle life[J]. Advanced Materials,2015,27:7861-7866. doi: 10.1002/adma.201503816 [88] Fan X, Yuan R, Lei J, et al. Turning soluble polysulfide intermediates back into solid state by a molecule binder in Li-S batteries[J]. ACS Nano,2020,14:15884-15893. doi: 10.1021/acsnano.0c07240 [89] Du Z, Chen X, Hu W, et al. Cobalt in nitrogen-doped graphene as single-atom catalyst for high-sulfur content lithium-sulfur batteries[J]. Journal of the American Chemical Society,2019,141:3977-3985. doi: 10.1021/jacs.8b12973 [90] Gu Z H, Cheng C, Yan T R, et al. Synergistic effect of Co3Fe7 alloy and N-doped hollow carbon spheres with high activity and stability for high-performance lithium-sulfur batteries[J]. Nano Energy,2021,86:106111. doi: 10.1016/j.nanoen.2021.106111 [91] Sun F G, Wang J T, Chen H C, et al. High efficiency immobilization of sulfur on nitrogen-enriched mesoporous carbons for Li-S batteries[J]. ACS Applied Materials & Interfaces,2013,5:5630-5638. [92] Qiao Z S, Zhang Y G, Meng Z H, et al. Anchoring polysulfides and accelerating redox reaction enabled by Fe‐based compounds in lithium-sulfur Batteries[J]. Advanced Functional Materials,2021,31:2100970. doi: 10.1002/adfm.202100970 [93] Huang S Z, Wang Z H, Von Lim Y, et al. Recent advances in heterostructure engineering for lithium-sulfur batteries[J]. Advanced Energy Materials,2021,11:2003689. doi: 10.1002/aenm.202003689 [94] Zhou W, Xiao X, Cai M, et al. Polydopamine-coated, nitrogen-doped, hollow carbon-sulfur double-layered core-shell structure for improving lithium-sulfur batteries[J]. Nano letters,2014,14:5250-5256. doi: 10.1021/nl502238b [95] Cai J, Wu C, Zhu Y, et al. Sulfur impregnated N, P co-doped hierarchical porous carbon as cathode for high performance Li-S batteries[J]. Journal of Power Sources,2017,341:165-174. doi: 10.1016/j.jpowsour.2016.12.008 [96] Jiao L, Zhang C, Geng C, et al. Capture and catalytic conversion of polysulfides by in situ built TiO2‐MXene heterostructures for lithium-sulfur batteries[J]. Advanced Energy Materials,2019,9:1900219. doi: 10.1002/aenm.201900219 [97] Hu G, Xu C, Sun Z, et al. 3D graphene-foam-reduced-graphene-oxide hybrid nested hierarchical networks for high-performance Li-S batteries[J]. Advanced Materials,2016,28:1603-1609. doi: 10.1002/adma.201504765 [98] Wang J W, Yuan Y F, Zhang D, et al. Constructing metal-organic framework-derived Mn2O3 multishelled hollow nanospheres for high-performance cathode of aqueous zinc-ion batteries[J]. Nanotechnology,2021,32:435401. doi: 10.1088/1361-6528/ac15cb [99] Lei Q K, Zhang Q, Wu X Y, et al. Towards ultra-stable lithium metal batteries: interfacial ion flux regulated through LiAl LDH-modified polypropylene separator[J]. Chemical Engineering Journal,2020,395:125187. doi: 10.1016/j.cej.2020.125187 [100] Rui Z, Li N, Cheng X, et al. Advanced micro/nanostructures for lithium metal anodes[J]. Advanced Science,2017,4:1600445. doi: 10.1002/advs.201600445 [101] Matsuda S. The effect of electrical conductivity on lithium metal deposition in 3D carbon nanofiber matrices[J]. Carbon,2019,154:370-374. doi: 10.1016/j.carbon.2019.07.104 [102] Chen H, Li M, Li C, et al. Electrospun carbon nanofibers for lithium metal anodes: Progress and perspectives[J]. Chinese Chemical Letters,2021,1:141-152. [103] Zhang Q, Wei X, Liu Y S, et al. Dendrite-free lithium anode achieved under lean-electrolyte condition through the modification of separators with F-functionalized Ti3C2 nanosheets[J]. Journal of Energy Chemistry,2022,66:366-373. doi: 10.1016/j.jechem.2021.08.013 [104] Lu Z, Liu S, Li C, et al. 3D porous carbon networks with highly dispersed SiOx by molecular-scale engineering toward stable lithium metal anodes[J]. Chemical Communications,2019,55:6034-6037. doi: 10.1039/C9CC01927H [105] Zhang Q, Bai W L, Sun C Y, et al. Surface modification of Ni foam for stable and dendrite-free lithium deposition[J]. Chemical Engineering Journal,2021,405:127022. doi: 10.1016/j.cej.2020.127022 [106] Yan K, Lu Z, Lee H W, et al. Selective deposition and stable encapsulation of lithium through heterogeneous seeded growth[J]. Nature Energy,2016,1:16010. doi: 10.1038/nenergy.2016.10 [107] Pramudita J C, Sehrawat D, Goonetilleke D, et al. An initial review of the status of electrode materials for potassium‐ion batteries[J]. Advanced Energy Materials,2017,7:1602911-1602911. doi: 10.1002/aenm.201602911 [108] Lin Q, Zhang J, Lv W, et al. A functionalized carbon surface for high-performance sodium-ion storage[J]. Small,2020,16:1902603. doi: 10.1002/smll.201902603 [109] Li M, Ma C, Zhu Q C, et al. Well-ordered mesoporous Fe2O3/C composites as high performance anode materials for sodium-ion batteries[J]. Dalton Transactions,2017,46:5025-5032. doi: 10.1039/C7DT00540G [110] Bai Y L, Raxidin X, Xin X Y, et al. Core-shell anatase anode materials for sodium-ion batteries: the impact of oxygen vacancies and nitrogen-doped carbon coating[J]. Nanoscale,2019,11:17860-17868. doi: 10.1039/C9NR06245A [111] Bai Y L, Wu X Y, Liu Y S, et al. Dandelion-clock-inspired preparation of core-shell TiO2@MoS2 composites for high performance sodium ion storage[J]. Journal of Alloys and Compounds,2020:815. [112] Wang L, Lu B, Wang S, et al. Ultra-high performance of Li/Na ion batteries using N/O dual dopant porous hollow carbon nanocapsules as an anode[J]. Journal of Materials Chemistry A,2019,7:11117-11126. doi: 10.1039/C8TA12540F [113] Yang Z J, Wu X Y, Ma C, et al. Cu2SnSe3/CNTs composite as a promising anode material for sodium-ion batteries[J]. Chemical Research in Chinese Universities,2020,36:91. doi: 10.1007/s40242-020-9061-1 [114] Bai Y L, Liu Y S, Ma C, et al. Neuron-inspired design of high-performance electrode materials for sodium-ion batteries[J]. ACS Nano,2018,12:11503-11510. doi: 10.1021/acsnano.8b06585 [115] Ma C, Zhao X, Harris M M, et al. Uric acid as an electrochemically active compound for sodium-ion batteries: Stepwise Na+-storage mechanisms of π-conjugation and stabilized carbon anion[J]. ACS Applied Materials & Interfaces,2017,9:33934-33940. [116] Wang E, Chen M, Guo X, et al. Synthesis strategies and structural design of porous carbon-incorporated anodes for sodium-ion batteries[J]. Small Methods,2020,4:1900163. doi: 10.1002/smtd.201900163 [117] Li Y, Lu Y, Meng Q, et al. Regulating pore structure of hierarchical porous waste cork-derived hard carbon anode for enhanced Na storage performance[J]. Advanced Energy Materials,2019,9:1902852. doi: 10.1002/aenm.201902852 [118] Chen Y, Zou K, Dai X, et al. Polysulfide filter and dendrite inhibitor: highly graphitized wood framework inhibits polysulfide shuttle and lithium dendrites in Li-S batteries[J]. Advanced Functional Materials,2021,31:2102458. doi: 10.1002/adfm.202102458 [119] Cao B, Zhang Q, Liu H, et al. Graphitic carbon nanocage as a stable and high power anode for potassium-ion batteries[J]. Advanced Energy Materials,2018,8:1801141-1801149. [120] Jian Z, Hwang S, Li Z, et al. Hard-soft composite carbon as a long-cycling and high-rate anode for potassium-ion batteries[J]. Advanced Functional Materials,2017,27:1700324. doi: 10.1002/adfm.201700324 [121] Yang J, Ju Z, Yong J, et al. Enhanced capacity and rate capability of nitrogen/oxygen dual-doped hard carbon in capacitive potassium-ion storage[J]. Advanced Materials,2017,30:1700104. [122] Zhang W, Liu Y, Guo Z. Approaching high-performance potassium-ion batteries via advanced design strategies and engineering[J]. Science Advances,2019,5:eaav7412. doi: 10.1126/sciadv.aav7412 [123] Xu S M, Ding Y C, Liu X, et al. Boosting potassium storage capacity based on stress-induced size-dependent solid-solution behavior[J]. Advanced Energy Materials,2018,8:1802175. doi: 10.1002/aenm.201802175 [124] Tang C L, Wei X, Jiang Y M, et al. Cobalt-doped MnO2 hierarchical yolk-shell spheres with improved supercapacitive performance[J]. The Journal of Physical Chemistry C,2015,119:8465-8471. doi: 10.1021/jp512795g [125] Ji J Y, Zhang L L, Ji H X, et al. Nanoporous Ni(OH) thin film on 3D ultrathin-graphite foam for asymmetric supercapacitor[J]. ACS Nano,2013,7:6237-6243. doi: 10.1021/nn4021955 [126] Song Y, Liu T, Qian F, et al. Three-dimensional carbon architectures for electrochemical capacitors[J]. Journal of Colloid and Interface Science,2018,509:529-545. doi: 10.1016/j.jcis.2017.07.081 [127] Han L N, Wei X, Zhu Q C, et al. Nitrogen-doped carbon nets with micro/mesoporous structures as electrodes for high-performance supercapacitors[J]. Journal of Materials Chemistry A,2016,4:16698-16705. doi: 10.1039/C6TA05607E [128] Wang D W, Li F, Liu M, et al. 3D aperiodic hierarchical porous graphitic carbon material for high-rate electrochemical capacitive energy storage[J]. Angewandte Chemie International Edition,2008,47:373-376. doi: 10.1002/anie.200702721 [129] Qin Y, Xie Y, Zhao H, et al. Scalable synthesis of macroscopic porous carbon sheet anode for potassium-ion capacitor[J]. Chinese Chemical Letters,2022,33:1463-1467. doi: 10.1016/j.cclet.2021.08.101 [130] Wang K, Birjukovs P, Erts D, et al. Synthesis and characterisation of ordered arrays of mesoporous carbon nanofibres[J]. Journal of Materials Chemistry,2009,19:1331-1338. doi: 10.1039/b817156d [131] Wang K, Wang Y, Wang Y, et al. Mesoporous carbon nanofibers for supercapacitor application[J]. The Journal of Physical Chemistry C,2009,113:1093-1097. doi: 10.1021/jp807463u [132] Xu F, Tang Z, Huang S, et al. Facile synthesis of ultrahigh-surface-area hollow carbon nanospheres for enhanced adsorption and energy storage[J]. Nature Communications,2015,6:7221. doi: 10.1038/ncomms8221 [133] Li T, Zhang J, Li C, et al. Nitrogen and phosphorous co-doped hierarchical meso-microporous carbon nanospheres with extraordinary lithium storage for high-performance lithium-ion capacitors[J]. Science China Materials,2022,65:2363-2372. doi: 10.1007/s40843-021-2047-x [134] Li C, Zhang X, Wang K, et al. Nitrogen-enriched graphene framework from a large-scale magnesiothermic conversion of CO2 with synergistic kinetics for high-power lithium-ion capacitors[J]. NPG Asia Materials,2021,13:59. doi: 10.1038/s41427-021-00327-7 [135] Li T, Zhao H, Li C X, et al. Recent progress and prospects in anode materials for potassium-ion capacitors[J]. New Carbon Materials,2021,36:253-277. doi: 10.1016/S1872-5805(21)60019-7 [136] Zhang T Q, Mao Z F, Shi X J, et al. Tissue-derived carbon microbelt paper: a high-initial-coulombic-efficiency and low-discharge-platform K+-storage anode for 4.5 V hybrid capacitors[J]. Energy & Environmental Science,2022,15:158-168. [137] Liu X, Sun Y, Tong Y, et al. Exploration in materials, electrolytes and performance towards metal ion (Li, Na, K, Zn and Mg)-based hybrid capacitors: A review[J]. Nano Energy,2021,86:106070. doi: 10.1016/j.nanoen.2021.106070 [138] Shao M J, Li C X, Li T, et al. Pushing the energy output and cycling lifespan of potassium‐ion capacitor to high level through metal-organic framework derived porous carbon microsheets anode[J]. Advanced Functional Materials,2020,30:2006561. doi: 10.1002/adfm.202006561 [139] Yu X, Shao M, Yang X, et al. A high-performance potassium-ion capacitor based on a porous carbon cathode originated from the Aldol reaction product[J]. Chinese Chemical Letters,2020,31:2215-2218. doi: 10.1016/j.cclet.2019.11.012 [140] Zhao S Q, Yan K, Liang J Y, et al. Phosphorus and oxygen dual-doped porous carbon spheres with enhanced reaction kinetics as anode materials for high-performance potassium‐ion hybrid capacitors[J]. Advanced Functional Materials,2021,31:2102060. doi: 10.1002/adfm.202102060 -

下载:

下载: