-

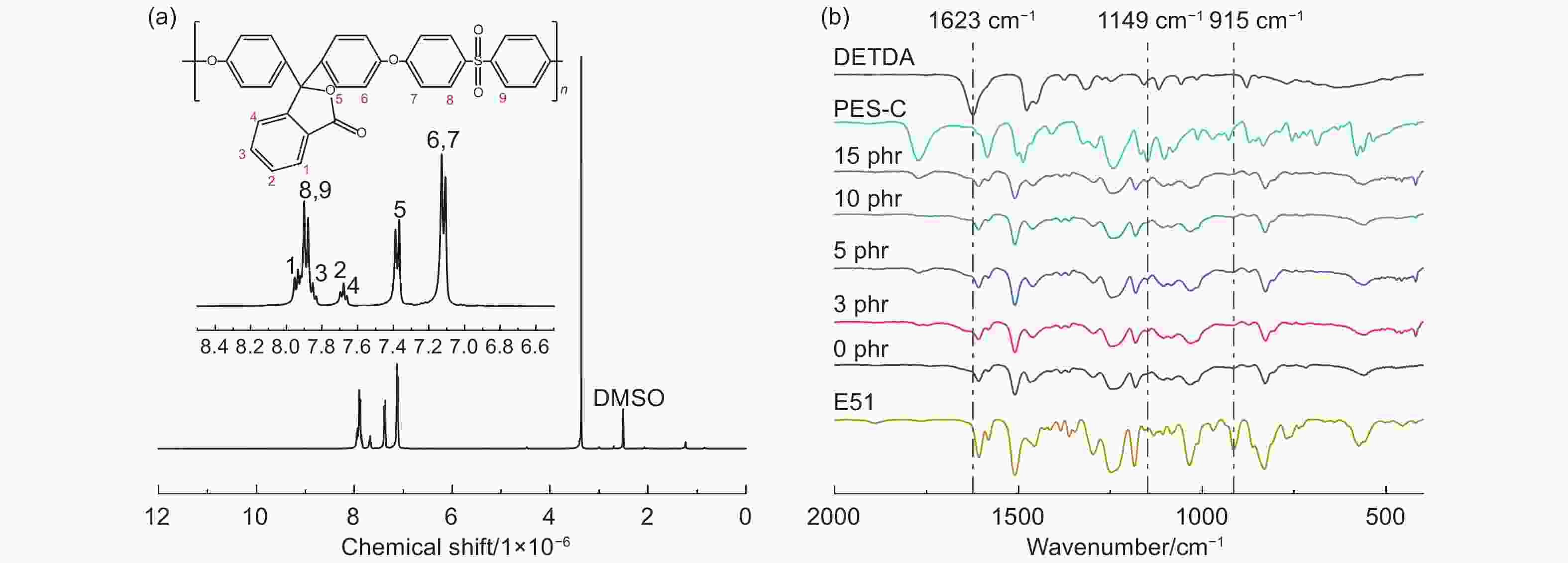

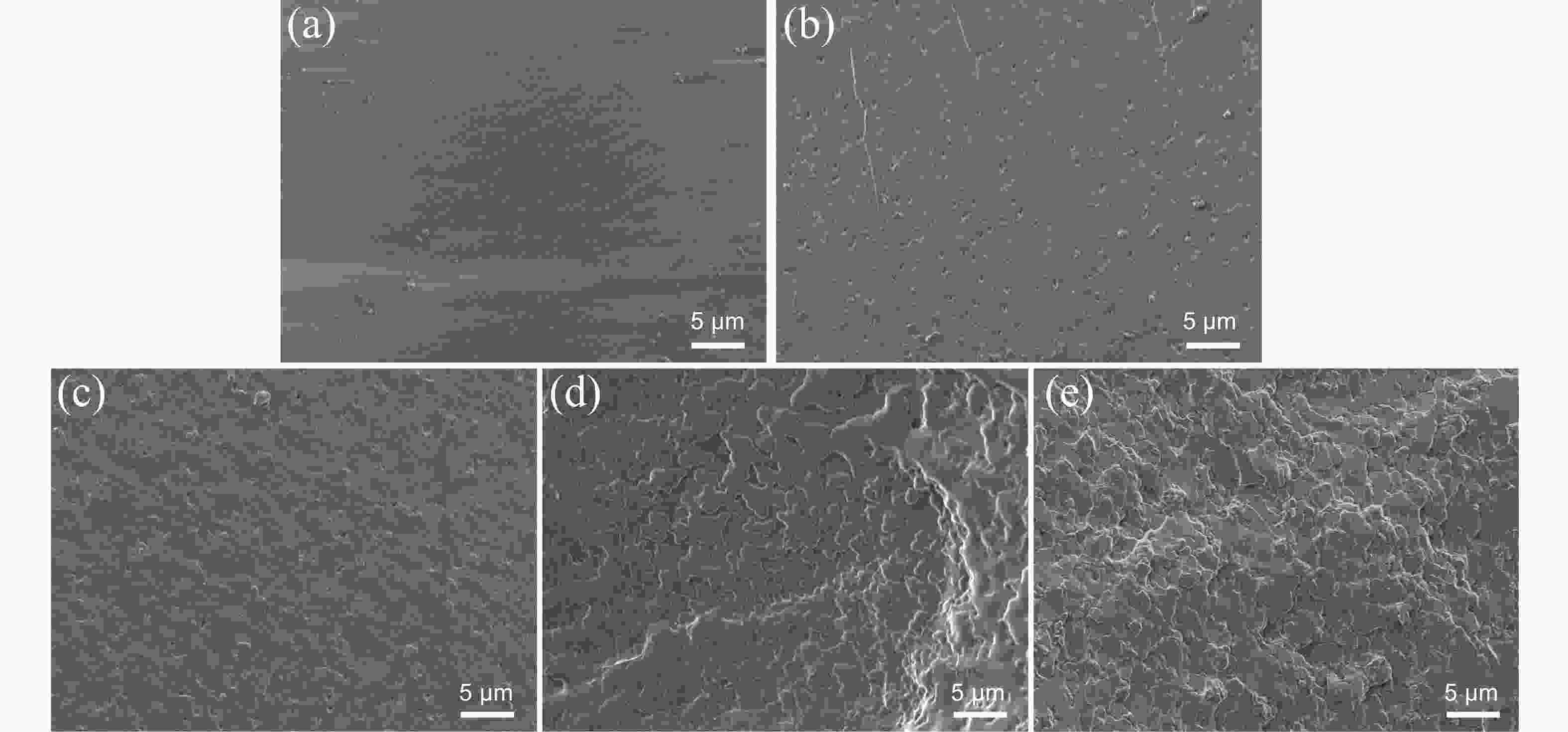

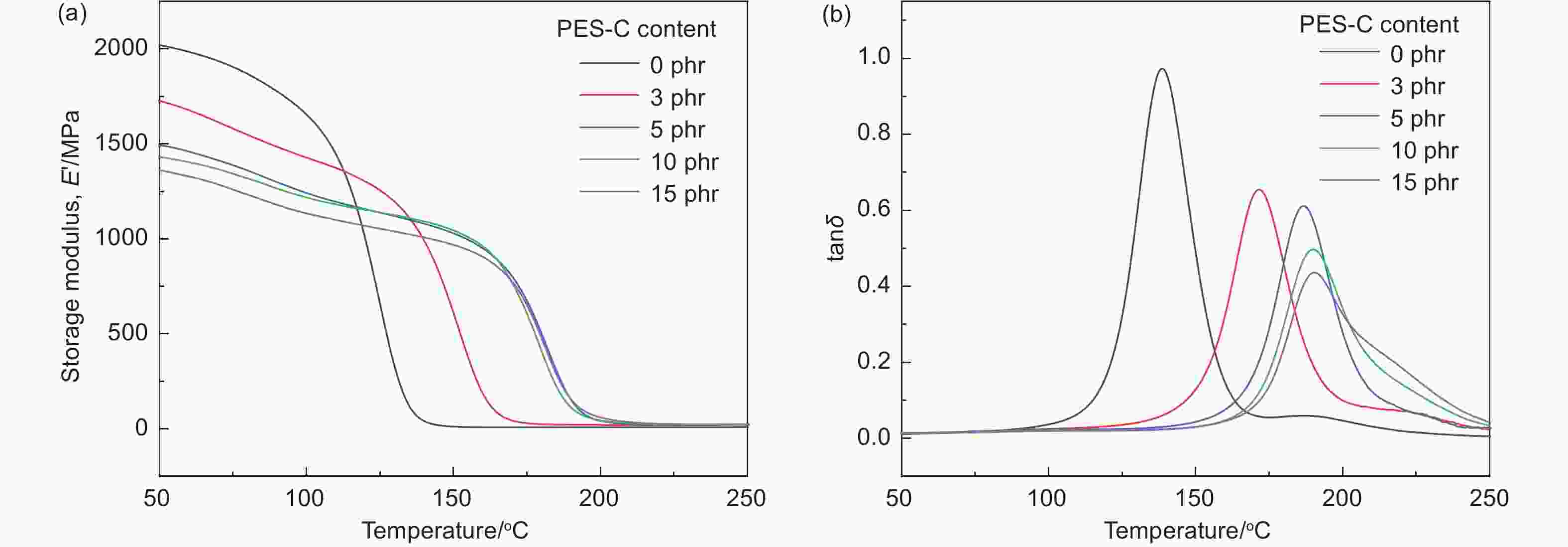

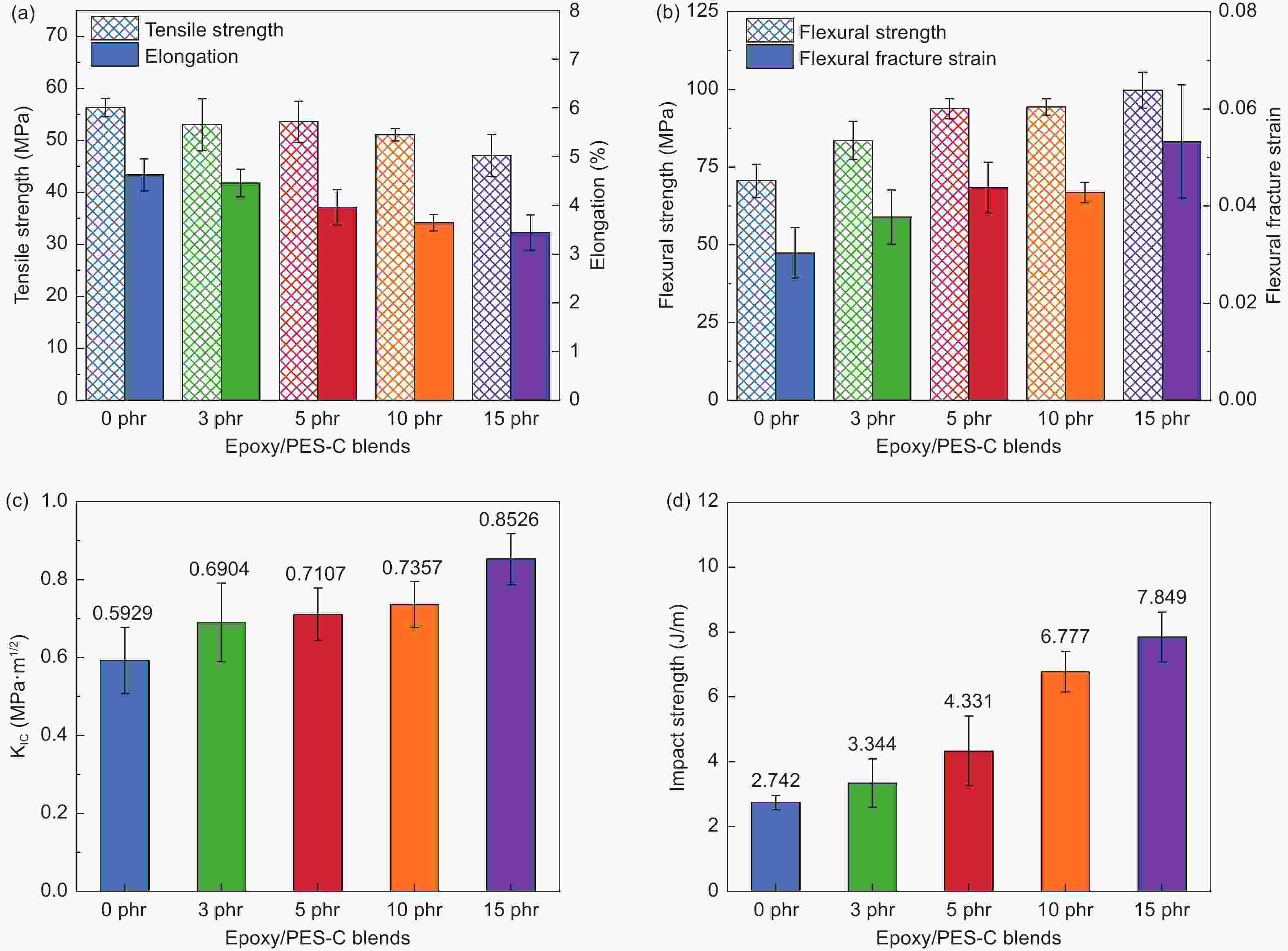

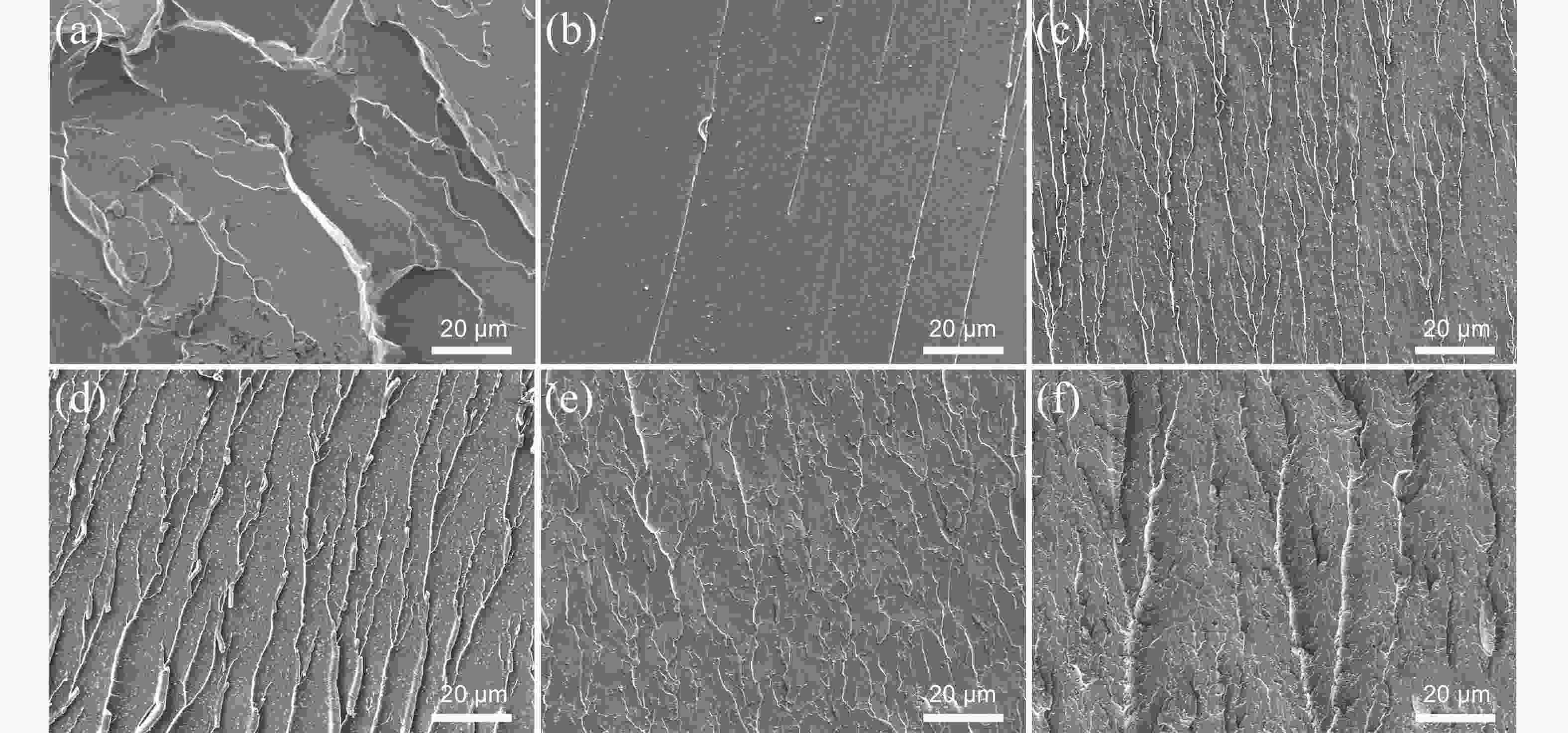

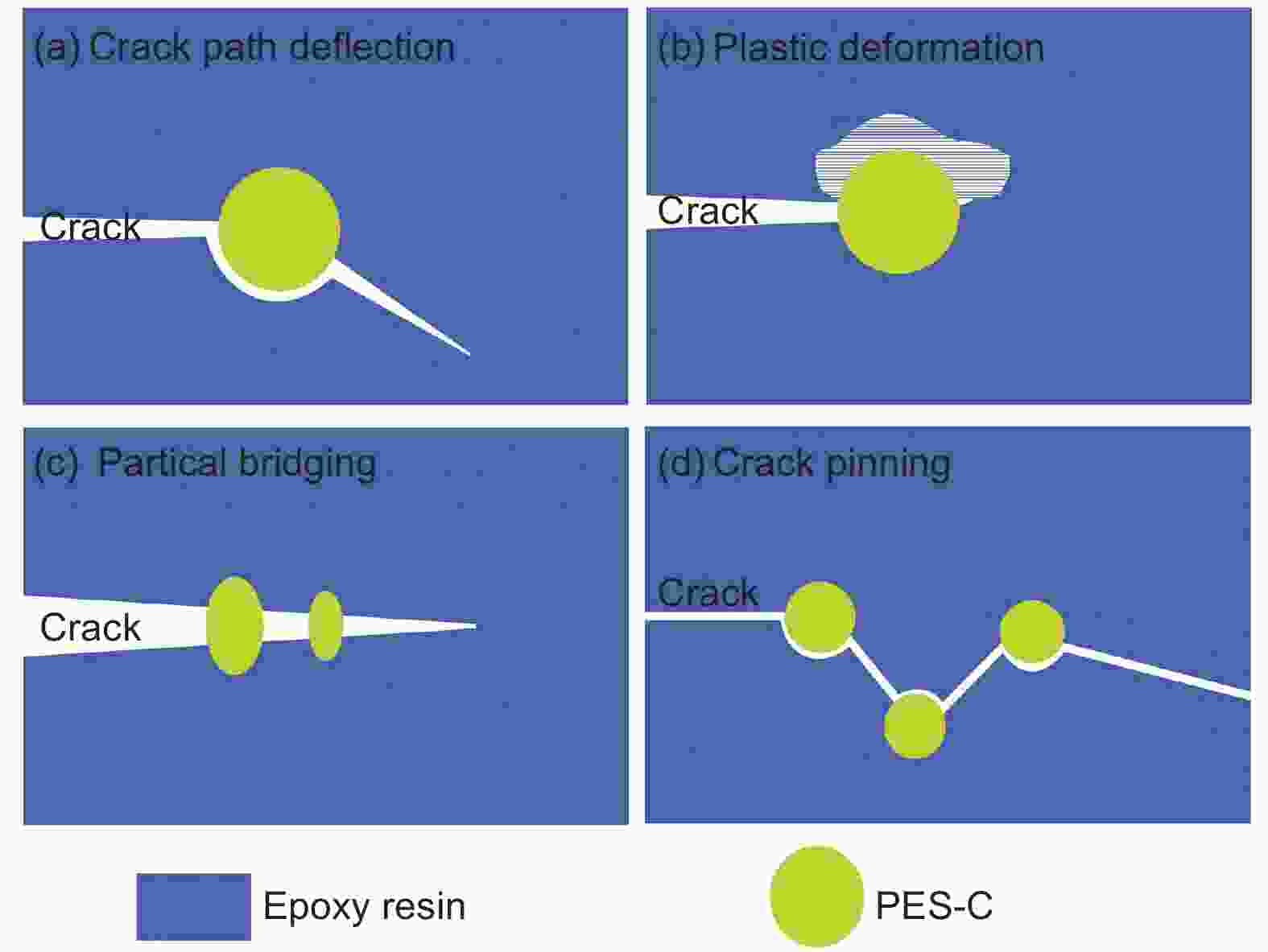

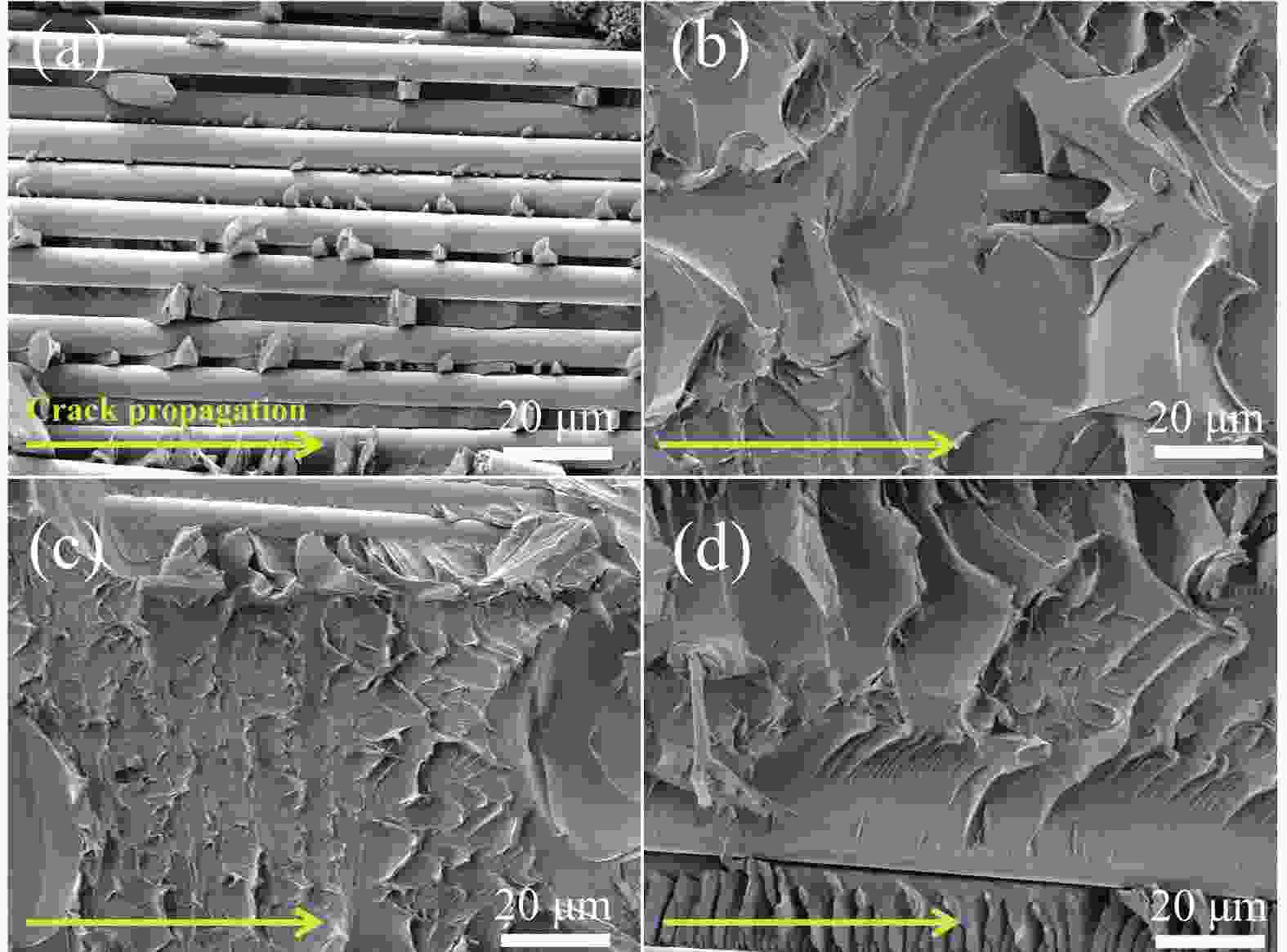

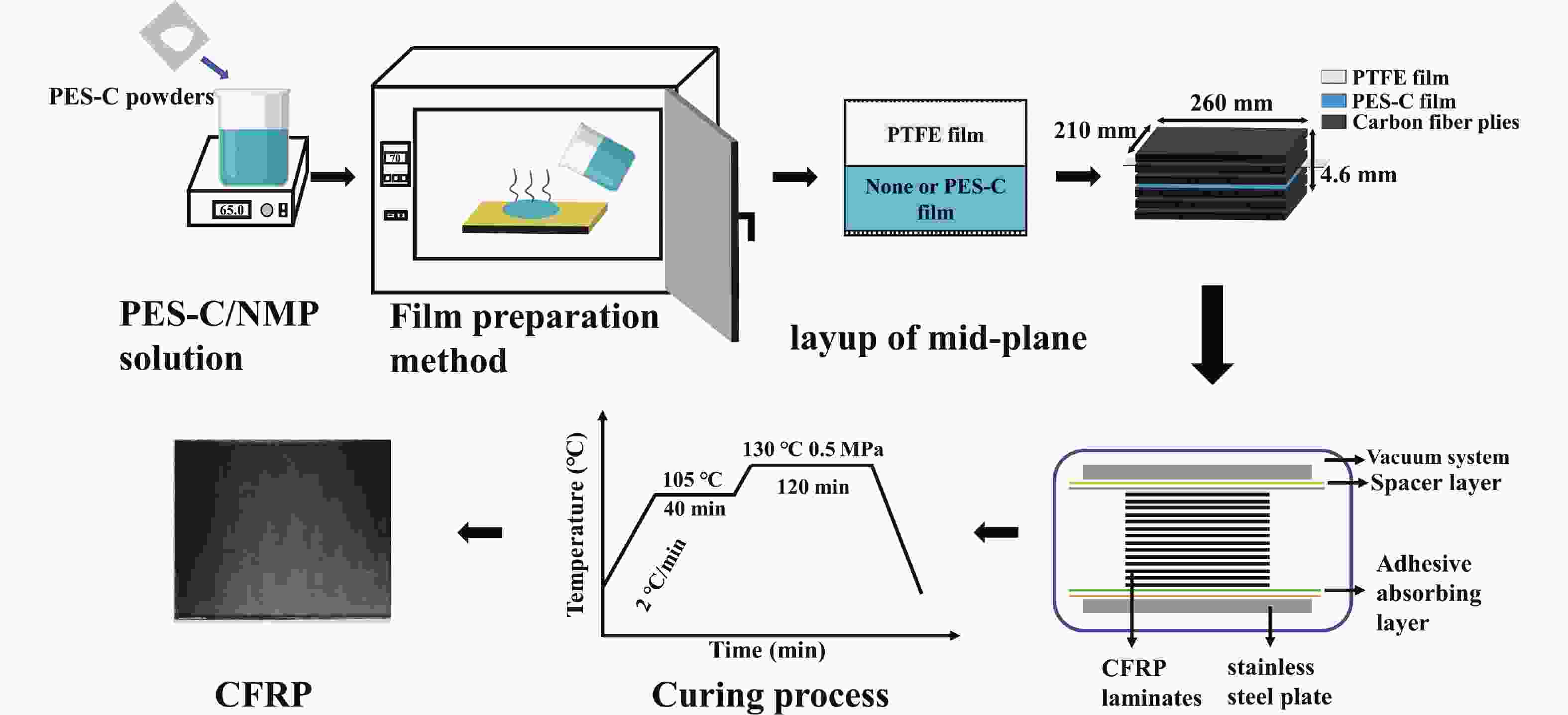

摘要: 寻找一种用量低且能够有效提高炭纤维复合材料层间韧性的增韧剂是有意义的。在本文中,研究了酚酞聚芳醚砜(PES-C)对E51/DETDA环氧树脂及其炭纤维复合材料的增韧效果。SEM结果显示,PES-C/环氧树脂混合物形成了海岛相和双连续相结构,这与反应诱导相分离有关。加入15 phr PES-C后,混合物的Tg增加了51.5 °C。同时,混合物的弯曲强度、冲击强度和断裂韧性分别提高了41.1%、186.2%和42.7%。这些提升可归因于PES-C/环氧树脂系统的相结构。此外,PES-C薄膜被用作夹层以改善炭纤维复合材料的二型断裂韧性(GIIC)。7 μm PES-C薄膜增韧层压板的GIIC值比对照层压板提高了80.3%。GIIC的显著增加可归因于插层区域的内聚破坏和塑性变形。Abstract: It is meaningful to find a toughener with a low dosage and effective improvement of interlaminar toughness in carbon fiber composites. In this paper, the toughening effect of phenolphthalein-based poly (ether sulfone) (PES-C) on E51/ DETDA epoxy and its carbon fiber composites (CFCs) was investigated. The SEM results showed that PES-C/epoxy blends formed sea-island phase and bicontinuous phase structure, which were associated with reaction-induced phase separation. After adding 15 phr PES-C, the glass transition temperature (Tg) of blends was increased by 51.5 °C. Meanwhile, the flexural strength, impact strength and fracture toughness of the blends were improved by 41.1%, 186.2% and 42.7%, respectively. These improvements could be attributed to the phase separation structure of the PES-C/epoxy system. Moreover, PES-C film was used to improve the mode-II fracture toughness (GIIC) of CFCs. GIIC value of the 7 μm PES-C film toughened laminate was improved by 80.3% than that of control laminate. The increase in GIIC could be attributed to cohesive failure and plastic deformation in the interleaving region.

-

Key words:

- epoxy resin /

- CFRP /

- PES-C /

- toughness

-

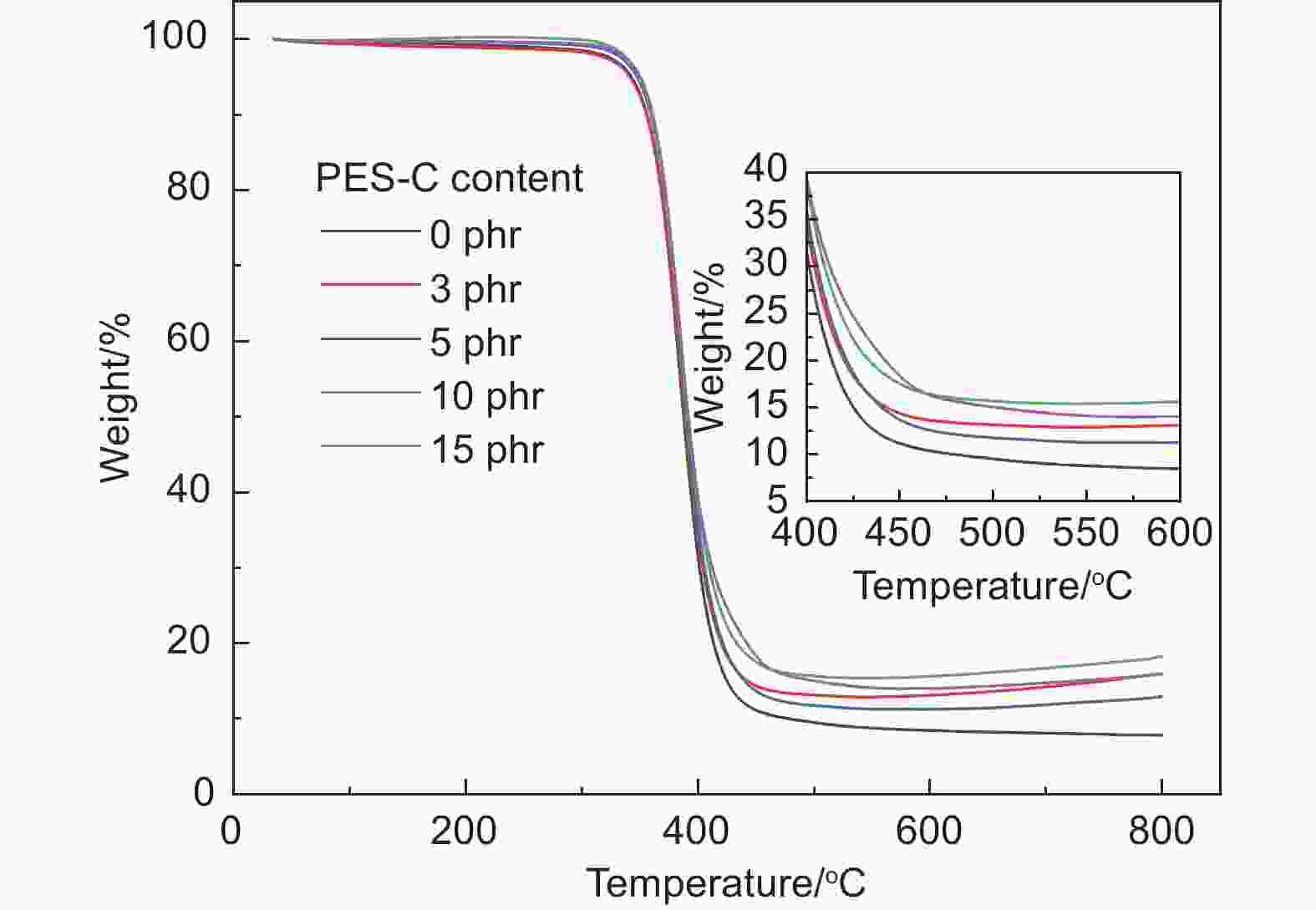

Table 1. IDT, Td10, Td50 and Tf of PES-C/EP blends

PES-C content IDT (°C) Td10 (°C) Td50 (°C) Tf (°C) 0 phr 359.5 356.1 387.7 411.4 3 phr 359.1 355.8 388.7 412.3 5 phr 360.5 359.3 390.2 413.8 10 phr 359.3 360.1 391.4 414.2 15 phr 361.1 361.1 391.7 414.1 -

[1] Yao J W, Niu K M, Niu Y F, et al. Toughening efficiency and mechanism of carbon fiber epoxy matrix composites by PEK-C[J]. Composite Structures,2019,229:111431. doi: 10.1016/j.compstruct.2019.111431 [2] Beaumont P W, Soutis C, Hodzic A. The structural integrity of carbon fiber composites: fifty years of progress and achievement of the science, development, and applications [M]. 2016. [3] Kinloch A J, Taylor A C, Techapaitoon M, et al. From matrix nano- and micro-phase tougheners to composite macro-properties[J]. Philos Trans A Math Phys Eng Sci,2016,374(2071):20150275. [4] Ning N, Wang M, Zhou G, et al. Effect of polymer nanoparticle morphology on fracture toughness enhancement of carbon fiber reinforced epoxy composites[J]. Composites Part B:Engineering,2022,234:109749. doi: 10.1016/j.compositesb.2022.109749 [5] Wei Y, Hu X Y, Jiang Q R, et al. Influence of graphene oxide with different oxidation levels on the properties of epoxy composites[J]. Composites Science and Technology,2018,161:74-84. doi: 10.1016/j.compscitech.2018.04.007 [6] Li Z Y, Wang Y, Cao J C, et al. Effects of loading rates on mode I interlaminar fracture toughness of carbon/epoxy composite toughened by carbon nanotube films[J]. Composites Part B:Engineering,2020,200:108270. doi: 10.1016/j.compositesb.2020.108270 [7] Chen Z, Luo J, Huang Z, et al. Synergistic toughen epoxy resin by incorporation of polyetherimide and amino groups grafted MWCNTs[J]. Composites Communications,2020,21:100377. doi: 10.1016/j.coco.2020.100377 [8] Sun Z, Xu L, Chen Z, et al. Enhancing the mechanical and thermal properties of epoxy resin via blending with thermoplastic polysulfone[J]. Polymers,2019,11(3):461. doi: 10.3390/polym11030461 [9] Ma H, Aravand M A, Falzon B G. Phase morphology and mechanical properties of polyetherimide modified epoxy resins: A comparative study[J]. Polymer,2019,179:121640. doi: 10.1016/j.polymer.2019.121640 [10] Yu G J, Wu P Y. Effect of chemically modified graphene oxide on the phase separation behaviour and properties of an epoxy/polyetherimide binary system[J]. Polymer Chemistry,2014,5(1):96-104. doi: 10.1039/C3PY00878A [11] Zhang J, Xie X M. Influence of addition of silica particles on reaction-induced phase separation and properties of epoxy/PEI blends[J]. Composites Part B:Engineering,2011,42(8):2163-2169. doi: 10.1016/j.compositesb.2011.05.013 [12] Rosetti Y, Alcouffe P, Pascault J P, et al. Polyether sulfone-based epoxy toughening: from micro- to nano-phase separation via PES end-chain modification and process engineering[J]. Materials (Basel),2018,11(10):1960. doi: 10.3390/ma11101960 [13] Cheng X L, Wu Q, Morgan S E, et al. Morphologies and mechanical properties of polyethersulfone modified epoxy blends through multifunctional epoxy composition[J]. Journal of Applied Polymer Science,2017,134(18):44775. [14] Lee S-E, Jeong E, Lee M Y, et al. Improvement of the mechanical and thermal properties of polyethersulfone-modified epoxy composites[J]. Journal of Industrial and Engineering Chemistry,2016,33:73-79. doi: 10.1016/j.jiec.2015.09.022 [15] Jin H, Yang B Q, Jin F L, et al. Fracture toughness and surface morphology of polysulfone-modified epoxy resin[J]. Journal of Industrial and Engineering Chemistry,2015,25:9-11. doi: 10.1016/j.jiec.2014.10.032 [16] Zheng N, Sun W F, Liu H Y, et al. Effects of carboxylated carbon nanotubes on the phase separation behaviour and fracture-mechanical properties of an epoxy/polysulfone blend[J]. Composites Science and Technology,2018,159:180-188. doi: 10.1016/j.compscitech.2018.02.039 [17] Wu Z J, Yi X S, Wilkinson A. Interlaminar fracture toughness of carbon fibre/RTM6-2 composites toughened with thermoplastic-coated fabric reinforcement[J]. Composites Part B:Engineering,2017,130:192-199. doi: 10.1016/j.compositesb.2017.08.003 [18] Zhou S, Chen Z G, Tusiime R, et al. Highly improving the mechanical and thermal properties of epoxy resin via blending with polyetherketone cardo[J]. Composites Communications,2019,13:80-84. doi: 10.1016/j.coco.2019.03.003 [19] Girard-Reydet E, Vicard V, Pascault J P, et al. Polyetherimide-modified epoxy networks: Influence of cure conditions on morphology and mechanical properties[J]. Journal of Applied Polymer Science,1997,65(12):2433-2445. doi: 10.1002/(SICI)1097-4628(19970919)65:12<2433::AID-APP15>3.0.CO;2-1 [20] Jiang M Q, Liu Y, Cheng C, et al. Enhanced mechanical and thermal properties of monocomponent high performance epoxy resin by blending with hydroxyl terminated polyethersulfone[J]. Polymer Testing,2018,69:302-309. doi: 10.1016/j.polymertesting.2018.05.039 [21] Cheng C, Zhang C Y, Zhou J L, et al. Improving the interlaminar toughness of the carbon fiber/epoxy composites via interleaved with polyethersulfone porous films[J]. Composites Science and Technology,2019,183:107827. doi: 10.1016/j.compscitech.2019.107827 [22] Li P, Liu D W, Zhu B, et al. Synchronous effects of multiscale reinforced and toughened CFRP composites by MWNTs-EP/PSF hybrid nanofibers with preferred orientation[J]. Composites Part A:Applied Science and Manufacturing,2015,68:72-80. doi: 10.1016/j.compositesa.2014.09.010 [23] Zhou J L, Zhang C Y, Cheng C, et al. Synergetic improvement of interlaminar fracture toughness in carbon fiber/epoxy composites interleaved with PES/PEK-C hybrid nanofiber veils[J]. Advanced Fiber Materials,2022,4(5):1081-1093. doi: 10.1007/s42765-022-00160-9 [24] Guo Q. Phase behaviour in epoxy resin containing phenolphthalein poly(ether ether sulphone[J]. Polymer,1993,34:70-76. doi: 10.1016/0032-3861(93)90285-I [25] Bhanuprakash L, Ali A, Mokkoth R, et al. Mode I and mode II interlaminar fracture behavior of E-glass fiber reinforced epoxy composites modified with reduced exfoliated graphite oxide[J]. Polymer Composites,2018,39(4):2506-2518. [26] Yu Y, Wang M, Gan W, et al. Polymerization-induced viscoelastic phase separation in polyethersulfone-modified epoxy systems[J]. The Journal of Physical Chemistry B,2004,108(20):6208-6215. doi: 10.1021/jp036628o [27] Li J W, Wang Y X, Zhao W Z, et al. High-performance quartz fiber/polysilazane and epoxy-modified cyanate ester microwave-transparent composites[J]. Advanced Composites and Hybrid Materials,2022,5(3):1830-1840. doi: 10.1007/s42114-022-00456-9 [28] Zhang X J, Yi X S, Xu Y Z. Cure-induced phase separation of epoxy/DDS/PEK-C composites and its temperature dependency[J]. Journal of Applied Polymer Science,2008,109(4):2195-2206. doi: 10.1002/app.28202 [29] He Y X, Li Q, Kuila T, et al. Micro-crack behavior of carbon fiber reinforced thermoplastic modified epoxy composites for cryogenic applications[J]. Composites Part B:Engineering,2013,44(1):533-539. doi: 10.1016/j.compositesb.2012.03.014 [30] Francis B, Thomas S, Jose J, et al. Hydroxyl terminated poly (ether ether ketone) with pendent methyl group toughened epoxy resin: miscibility, morphology and mechanical properties[J]. Polymer,2005,46(26):12372-12385. doi: 10.1016/j.polymer.2005.10.103 [31] Wei Y, Fu Z L, Sun Y S. Bridging toughening of epoxy resins by dispersed thermoplastics[J]. Acta Mechanica Sinica,1989,5(4):332-342. doi: 10.1007/BF02488006 [32] Beckermann G W, Pickering K L. Mode I and mode II interlaminar fracture toughness of composite laminates interleaved with electrospun nanofibre veils[J]. Composites Part A Applied Science and Manufacturing,2015,72:11-21. doi: 10.1016/j.compositesa.2015.01.028 [33] Daelemans L, Sam V, Baere I D, et al. Damage-resistant composites using electrospun nanofibers: a multiscale analysis of the toughening mechanisms[J]. Acs Appl Mater Interfaces,2016,8(18):11806-11818. doi: 10.1021/acsami.6b02247 [34] Han C L, Wang G D, Li N, et al. Study on interlaminar performance of CNTs/epoxy film enhanced GFRP under low-temperature cycle[J]. Composite Structures,2021,272:114191. doi: 10.1016/j.compstruct.2021.114191 -

下载:

下载: