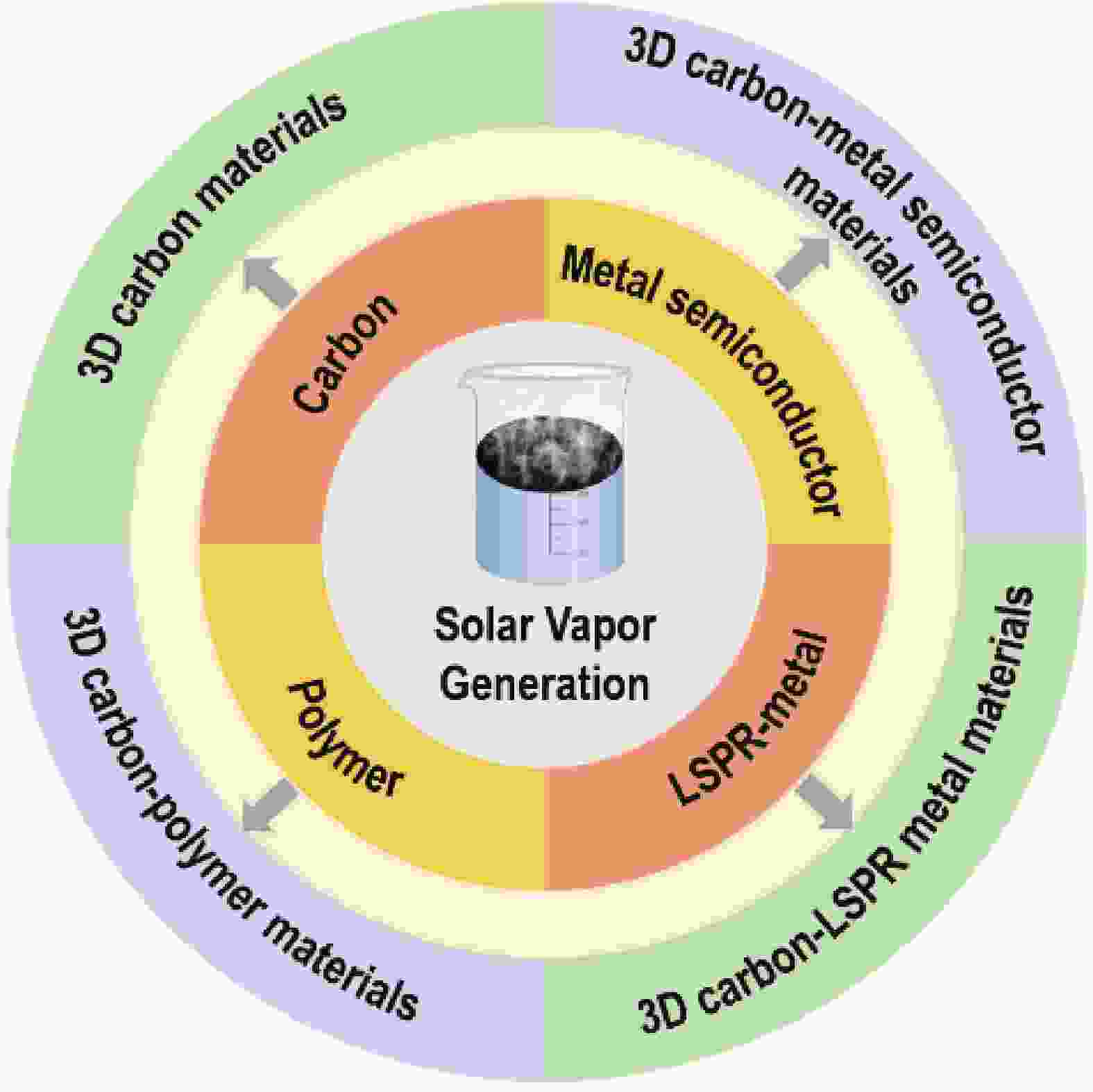

A review of 3D monolithic carbon-based materials with a high photothermal conversion efficiency used for solar water vapor generation

-

摘要:

光热驱动的海水淡化技术被认为是最具潜力的解决全球淡水资源短缺难题的方法之一。其中,太阳能界面水蒸发(SVG)是海水淡化效率的核心过程,是保证光热海水淡化技术具有能量转换效率高、设备简单、成本效益高的关键。在所有高效SVG候选材料中,三维整体式碳基光热转换材料具有成本低、吸光效率高、结构可调性好、水蒸发速率高、无二次污染等优点。本综述首先简述了SVG 的基本原理,以此为依据介绍了高效 SVG 材料的工作机制和设计原则,最后系统归纳和概述了4种不同类型的三维整体式碳基光热转换材料的研究进展。本综述为未来三维整体式碳基光热转换材料的构建及其在SVG领域的应用研究提供理论基础和研究指导。

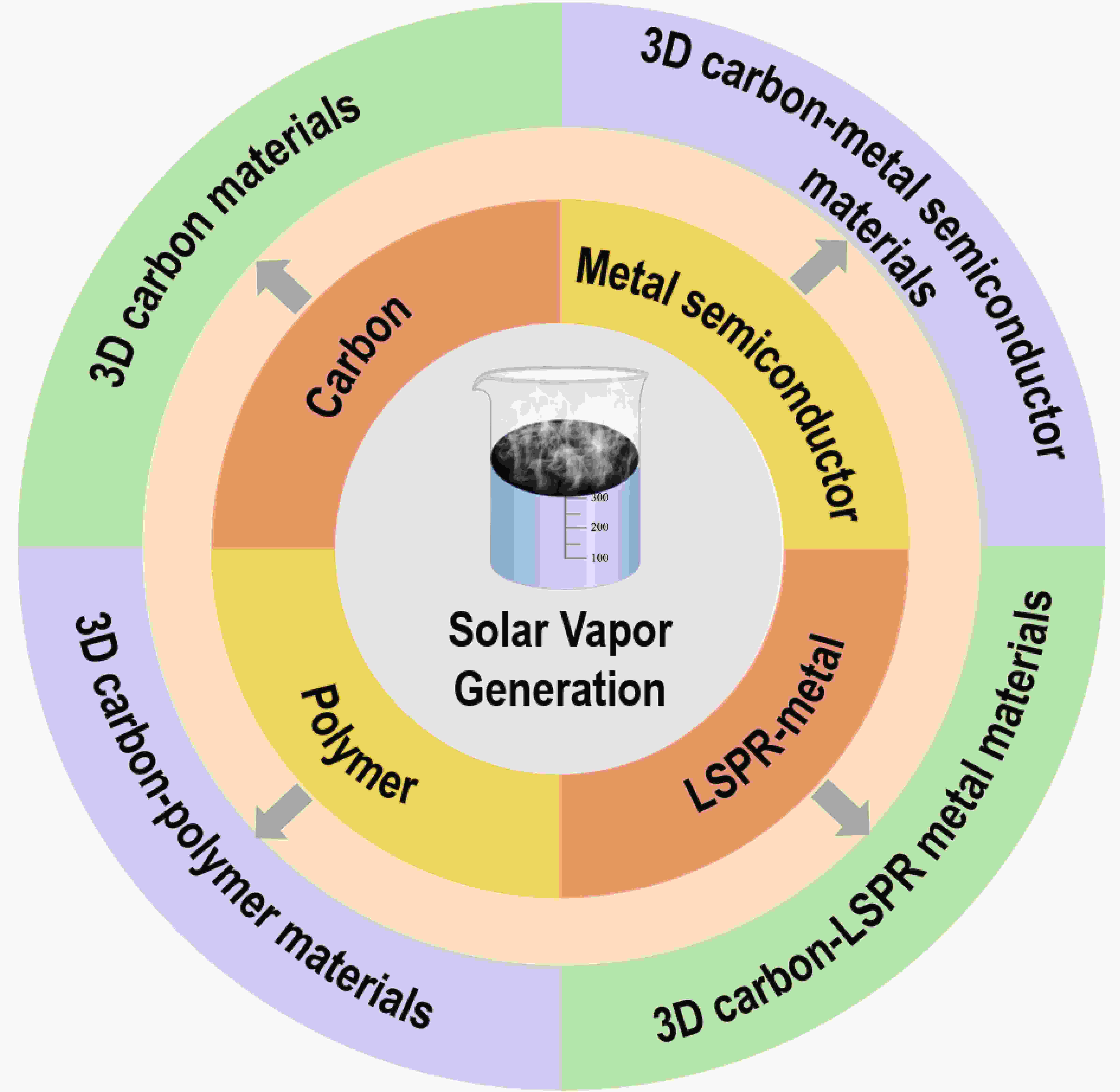

Abstract:In recent years, photothermal-driven desalination has been regarded as one of the most promising methods to solve the global crisis of freshwater scarcity. The solar generation of water vapor (SGWV) is a key process in seawater desalination which uses simple equipment and has a high cost-benefit. Among alternative photothermal conversion materials for a SGWV system, three-dimensional (3D) monolithic carbon-based materials have many advantages, including low cost, good structure control, and high light-harvesting efficiency which gives a high evaporation rate. 3D monolithic carbon-based materials with a high photothermal conversion efficiency are reviewed together with their use in interface SGWV. The working mechanism of SGWV and the classification of SGWV materials are first considered, followed by detailed consideration of 3D monolithic carbon materials, including their design, preparation and working mechanism in SGWV. Finally, both the advantages and disadvantages of 3D monolithic carbon materials with a high photothermal conversion efficiency are examined.

-

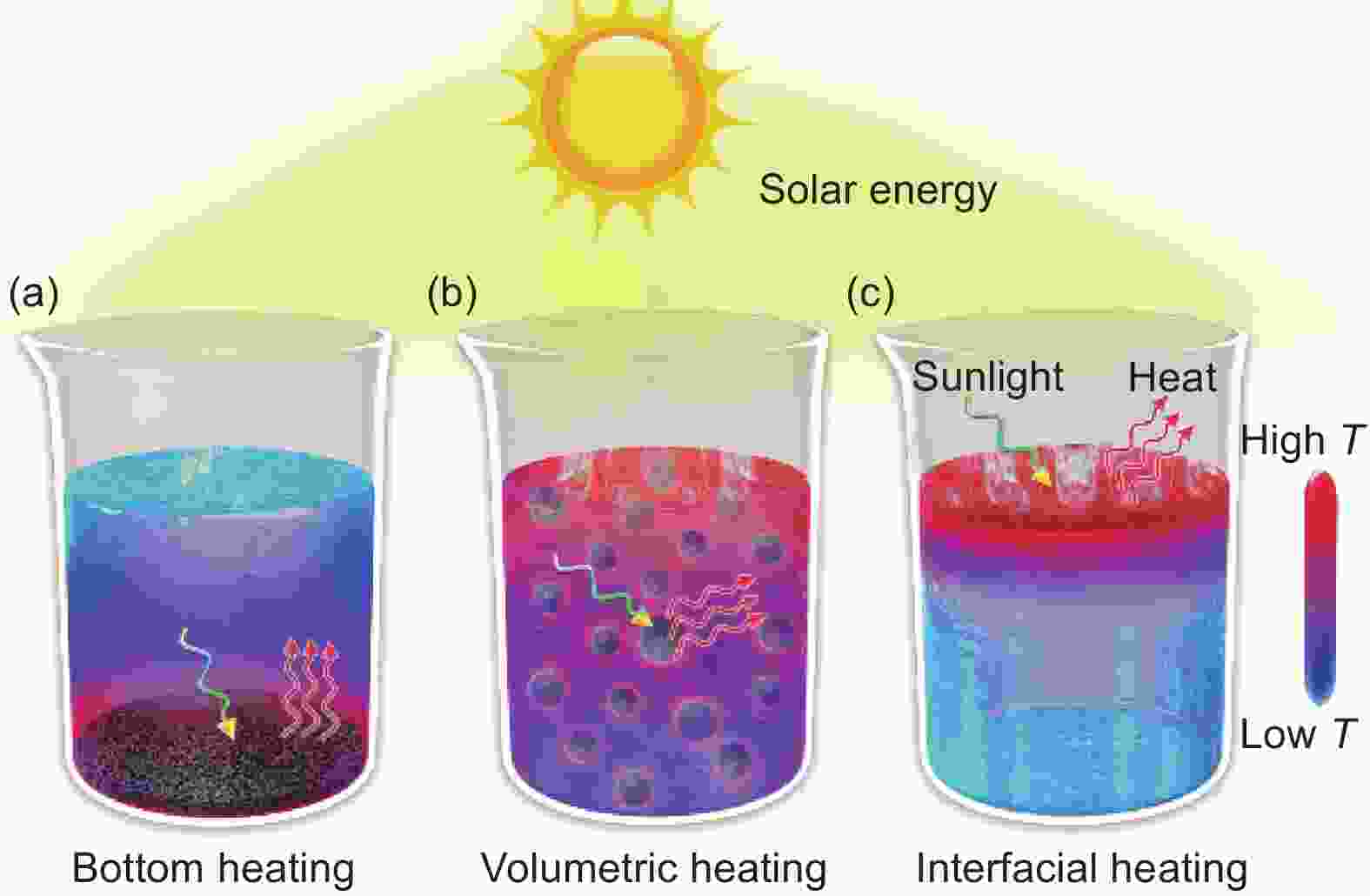

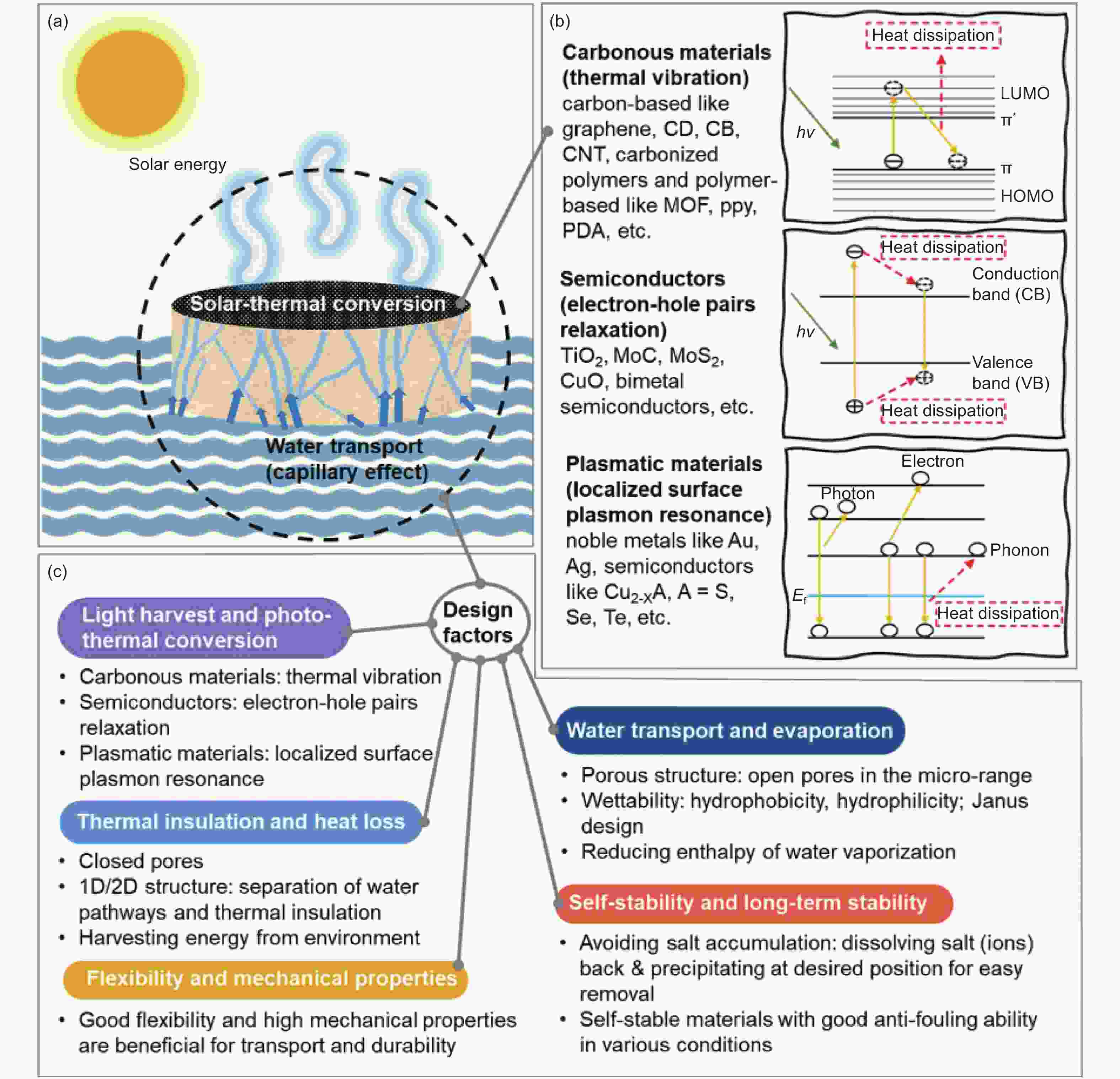

图 3 (a)典型界面太阳能蒸发器示意图;(b)不同机制的光热转换(碳质材料的热振动,半导体的电子-空穴对弛豫,等离子体材料的局部表面等离子体共振);(c)界面太阳能蒸发器设计因素[6]

Figure 3. (a) Schematic diagram of a typical interface solar evaporator. (b) Photothermal conversion of different mechanisms (thermal vibration of carbonaceous materials, electron-hole pair relaxation of semiconductors, localized surface plasmon resonance of plasma materials). (c) Interface solar evaporator design factors[6]. Reprinted with permission

图 4 炭化玉米芯基SVG的结构图。 (a)玉米穗,(b)天然玉米芯,(c)基于炭化玉米芯的太阳能蒸汽产生装置,(d)玉米芯截面,(e)炭化玉米芯侧面排列多孔片,(f)炭化玉米芯侧面的碳超细纤维阵列[33]

Figure 4. Schematic of C-corncob based solar vapor steam generator, (a) Corn ears, (b) N-corncob, (c) C-corncob based solar vapor generation device, (d) Cross-section of C-corncob, (e) Aligned porous sheet on side surface of C-corncob, (f) Carbon microfiber arrays on the side surface of C-corncob[33]. Reprinted with permission

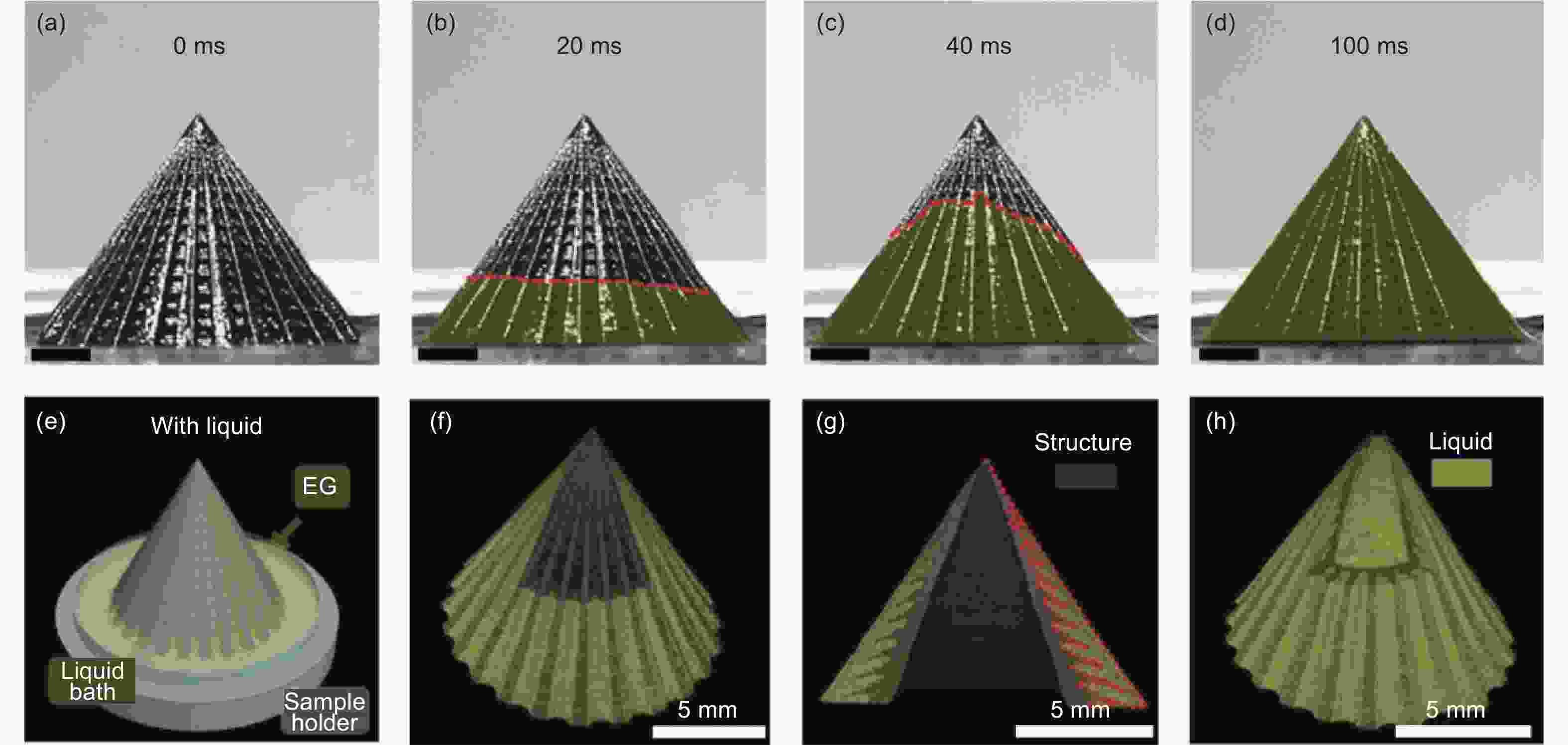

图 5 三维仿生锥形蒸发系统[77]:(a-d)水在三维仿生蒸发器表面向上扩散过程,(e-h)通过Micro-CT从不同视角观察湿态的三维仿生蒸发器

Figure 5. Three-dimensional bionic conical evaporation system[77]: (a-d) Upward diffusion process of water on the surface of the three-dimensional bionic evaporator, (e-h) Observation of a three-dimensional bionic evaporator in a wet state from different perspectives by Micro-CT. Reprinted with permission

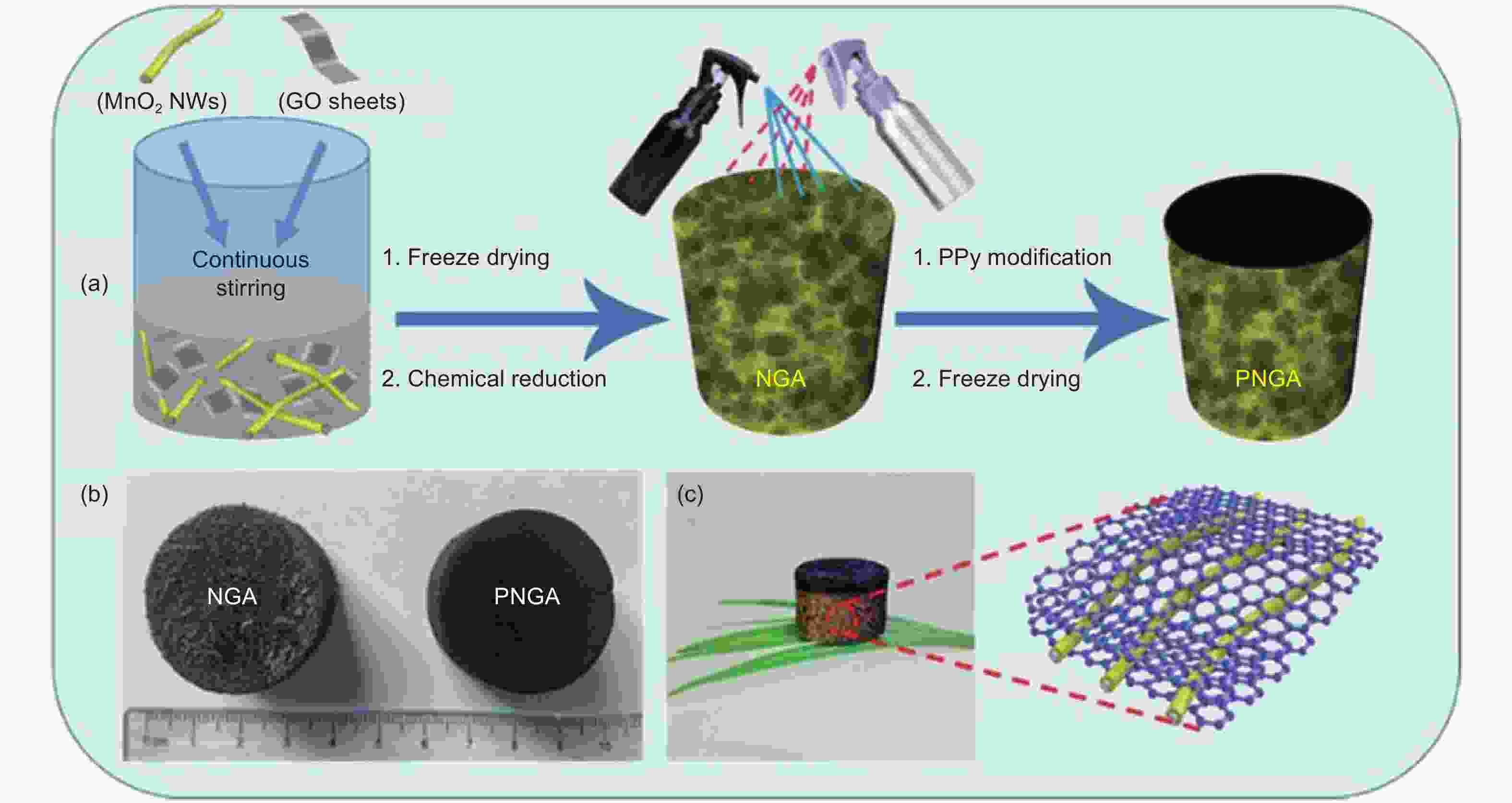

图 6 太阳能界面蒸发器的NGA和PNGA示意图[88]:(a)制备PNGA和NGA的简单工艺模拟图,(b)NGA和PNGA的相机照片,(c)放置在竹叶上的超轻PNGA样品的数码照片及内部结构模拟

Figure 6. Schematic illustration of the NGA and PNGA for solar steam generation[88]: (a) Simulation diagram of a simple process for the preparation of PNGA and NGA, (b) Camera photograph of the NGA and PNGA, (c) Digital photos of the ultralight PNGA sample put on the bamboo leaves and internal structure simulation. Reprinted with permission

图 9 太阳能蒸发用表面改性PG复合材料示意图[101]:(a)表面改性的PG复合材料:(i)原始氧化石墨烯,聚苯胺在氧化石墨烯表面,(ii)不均匀分布(iii)均匀分布;(b) GO和PG的光热分布;(c)平面GO (左)和锥形PG-10 (右)蒸汽分布的数值模拟

Figure 9. Schematic diagram of surface-modified PG composites for solar evaporation[101]: (a) Surface-modified PG composites: (i) Raw graphene oxide, (ii) inhomogeneous distribution and (iii) homogeneous distribution of polyaniline on graphene oxide surfaces; (b) Photothermal distribution of GO and PG; (c) Numerical simulation of the vapor distribution of planar GO (left) and conical PG-10 (right). Reprinted with permission

-

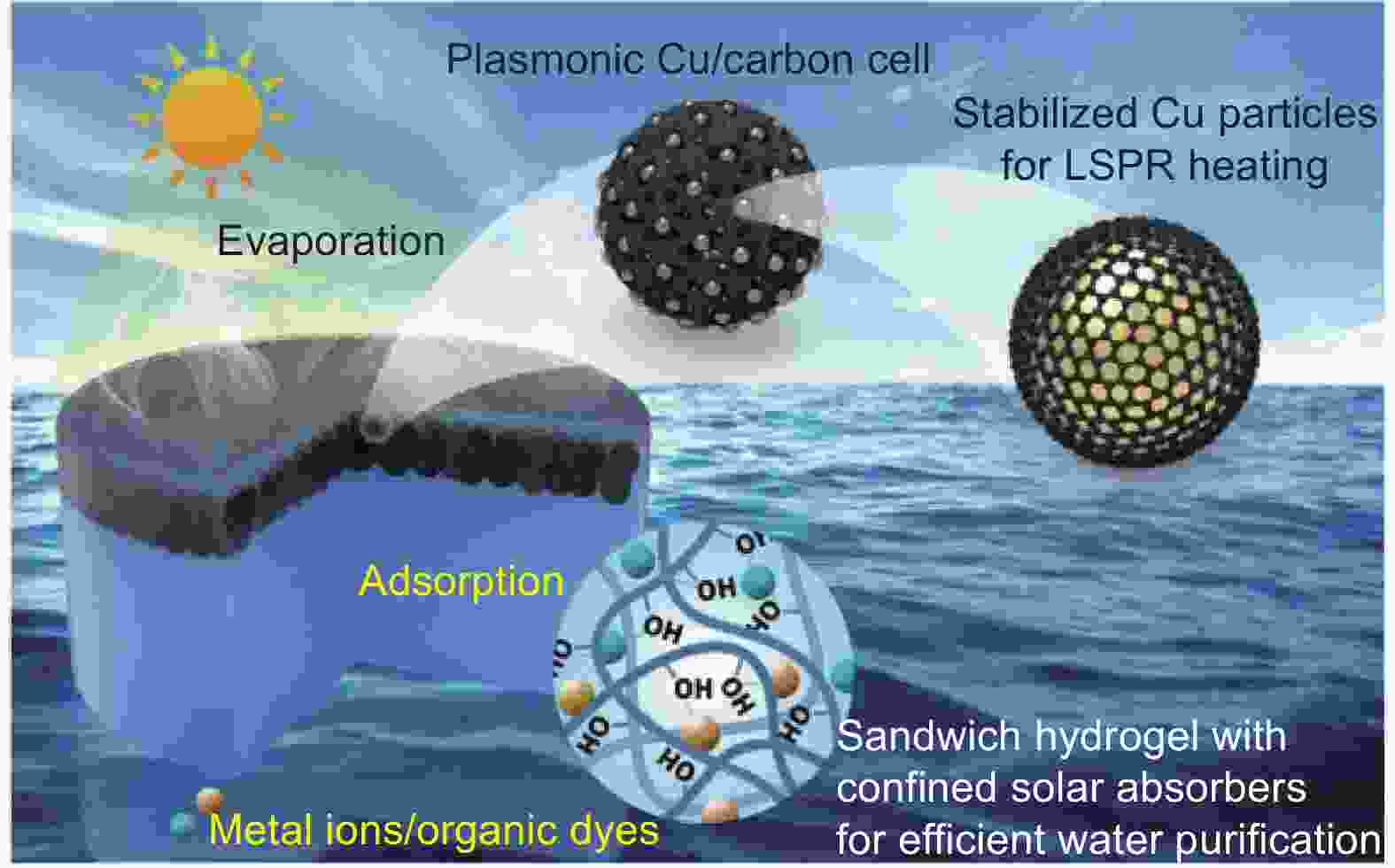

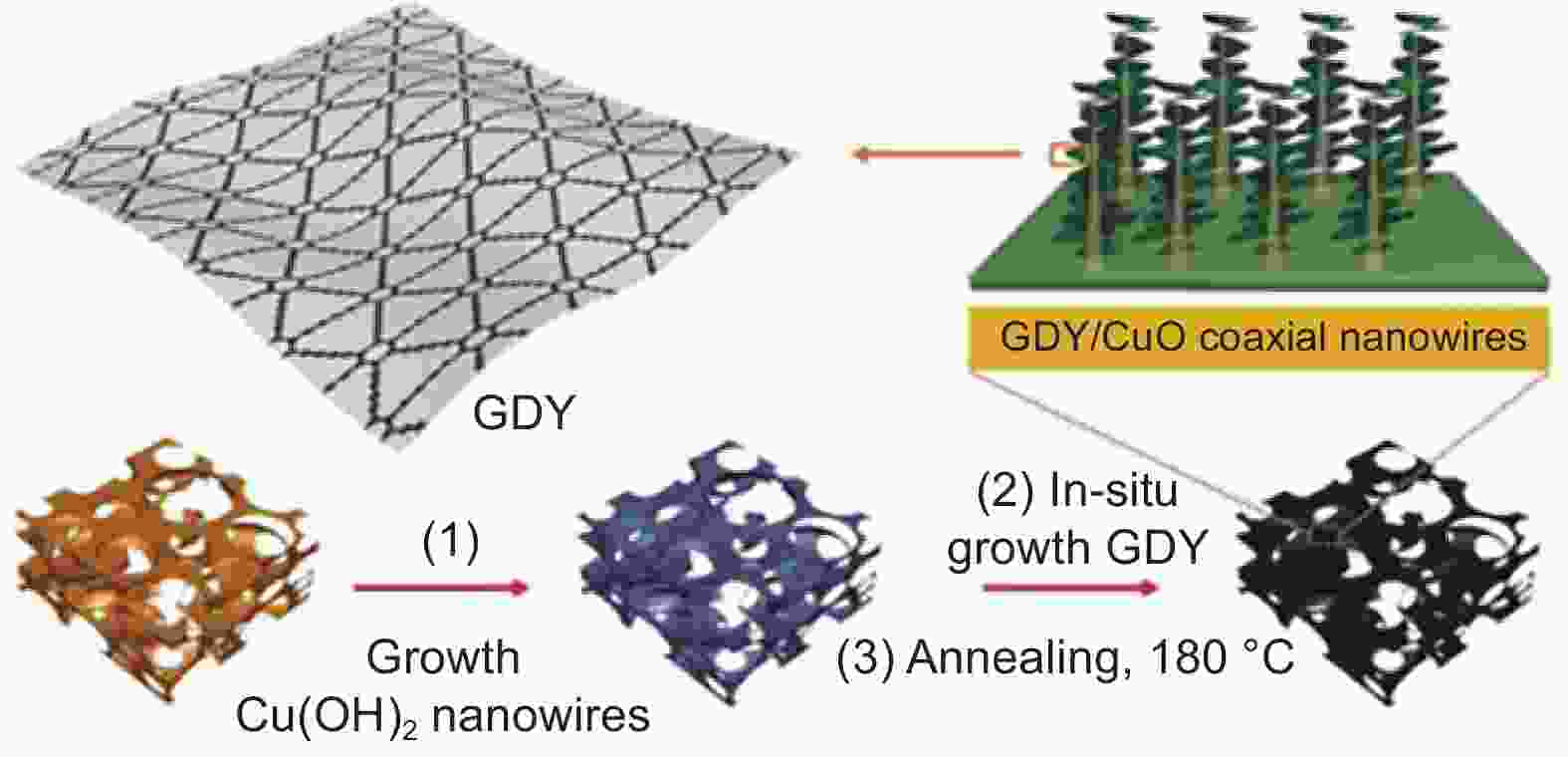

[1] Tian C, Li C, Chen D, et al. Sandwich hydrogel with confined plasmonic Cu/carbon cells for efficient solar water purification[J]. Journal of Materials Chemistry A,2021,9(27):15462-15471. doi: 10.1039/D1TA02927D [2] Alfaro-barajas A, Vega-hincapie D J, Hdz-garcia H, et al. Carbon monoliths from pet wastes for interfacial solar evaporation[J]. Materials Letters,2021,294:129796. doi: 10.1016/j.matlet.2021.129796 [3] Gao S, Dong X, Huang J, et al. Bioinspired soot-deposited janus fabrics for sustainable solar steam generation with salt-rejection[J]. Global Challenges,2019,3(8):1800117. doi: 10.1002/gch2.201800117 [4] Ni G, Li G, Boriskina S, et al. Steam generation under one sun enabled by a floating structure with thermal concentration[J]. Nature Energy,2016,1(9):16126. doi: 10.1038/nenergy.2016.126 [5] Zhao F, Zhou X, Shi Y, et al. Highly efficient solar vapour generation via hierarchically nanostructured gels[J]. Nature Nanotechnology,2018,13(6):489-495. doi: 10.1038/s41565-018-0097-z [6] Ren Y, Zhou R, Yang R, et al. Systematic review of material and structural design in interfacial solar evaporators for clean water production[J]. Solar RRL,2023,7(5):2201014. doi: 10.1002/solr.202201014 [7] Chu C, Jia Z, Yu Y, et al. 3D macroporous CuPC/g-C3N4 heterostructured composites for highly efficient multifunctional solar evaporation[J]. Nanoscale,2022,14(37):13731-13739. doi: 10.1039/D2NR03289A [8] Tarus B K, Jande Y A C, Njau K N. Electrospun carbon nanofibers for use in the capacitive desalination of water[J]. New Carbon Materials,2022,37(06):1066-1084. doi: 10.1016/S1872-5805(22)60645-0 [9] Li J, Jing Y, Xing G, et al. Solar-driven interfacial evaporation for water treatment: Advanced research progress and challenges[J]. Journal of Materials Chemistry A,2022,10(36):18470-18489. doi: 10.1039/D2TA03321F [10] Luo X, Shi J, Zhao C, et al. The energy efficiency of interfacial solar desalination[J]. Applied Energy,2021,302:117581. doi: 10.1016/j.apenergy.2021.117581 [11] Xu Y, Sun F, Wang L, et al. Double-layered phase change materials featuring high photothermal conversion for stable thermoelectric power generation[J]. Journal of Alloys and Compounds,2024,976:173285. doi: 10.1016/J.JALLCOM.2023.173285 [12] Liang L, Liu H, Yu J, et al. Plasmon-enhanced solar vapor generation[J]. Nanophotonics,2019,8(5):771-786. doi: 10.1515/nanoph-2019-0039 [13] Wang J, Li Y, Deng L, et al. High-performance photothermal conversion of narrow-bandgap Ti2O3 nanoparticles[J]. Advanced Materials,2017,29(3):1603730. doi: 10.1002/adma.201603730 [14] Sun Y, Zhao Z B, Zhao G Y, et al. Solar-driven simultaneous desalination and power generation enabled by graphene oxide nanoribbon papers[J]. Journal of Materials Chemistry A,2022,10(16):9184-9194. doi: 10.1039/D2TA00375A [15] Zhu M, Li Y, Chen F, et al. Plasmonic wood for high-efficiency solar steam generation[J]. Advanced Energy Materials,2018,8(4):1701028. doi: 10.1002/aenm.201701028 [16] Guan W, Guo Y, Yu G. Carbon materials for solar water evaporation and desalination[J]. Small,2021,17(48):e2007176. doi: 10.1002/smll.202007176 [17] Xie Z, Wang H, Deng Q, et al. Heat transfer characteristics of carbon-based photothermal superhydrophobic materials with thermal insulation micropores during anti-icing/deicing[J]. Journal of Physical Chemistry Letters,2022,13(43):10237-10244. [18] Sourav C, Jongha H, Seongji H, et al. Rational design of a high performance and robust solar evaporator via 3D-printing technology[J]. Advanced Materials, 2021, 33(38). [19] Chen Y, Zhao G, Ren L, et al. Blackbody-inspired array structural polypyrrole-sunflower disc with extremely high light absorption for efficient photothermal evaporation[J]. ACS Applied Materials & Interfaces, 2020. [20] Ahmed F E, Hashaikeh R, Hilal N. Hybrid technologies: The future of energy efficient desalination-a review[J]. Desalination,2020,495:114659. doi: 10.1016/j.desal.2020.114659 [21] Chen S, Sun Z, Xiang W, et al. Plasmonic wooden flower for highly efficient solar vapor generation[J]. Nano Energy,2020,76:104998. doi: 10.1016/j.nanoen.2020.104998 [22] Chang Q, Guo Z, Shen Z, et al. Interaction promotes the formation and photothermal conversion of carbon dots/polydopamine composite for solar-driven water evaporation[J]. Advanced Materials Interfaces,2021,8(12):2100332. doi: 10.1002/admi.202100332 [23] Luo W, Shi C, Wang S, et al. Carbon coated vermiculite aerogels by quick pyrolysis as cost-effective and scalable solar evaporators[J]. Desalination,2023,566:116886. doi: 10.1016/j.desal.2023.116886 [24] Chen Y, Zhao X, Ye Z, et al. Robust seawater desalination and sewage purification enabled by the solar-thermal conversion of the janus-type graphene oxide evaporator[J]. Desalination,2022,522:115406. doi: 10.1016/j.desal.2021.115406 [25] Ghasemi H, Ni G, Marconnet A M, et al. Solar steam generation by heat localization[J]. Nature Communications, 2014, 5. [26] Zhao X, Meng X, Zou H, et al. Nano-enabled solar driven-interfacial evaporation: Advanced design and opportunities[J]. Nano Research,2023,16(5):6015-6038. doi: 10.1007/s12274-023-5488-2 [27] Zou H, Meng X, Zhao X, et al. Hofmeister effect-enhanced hydration chemistry of hydrogel for high-efficiency solar-driven interfacial desalination[J]. Advanced Materials,2023,35(5):e2207262. doi: 10.1002/adma.202207262 [28] Shi C, Luo W, Zhang Y, et al. Scalable and flexible biomass-derived photothermal paper for efficient solar-assisted water purification[J]. Cellulose,2023,30(11):7193-7204. doi: 10.1007/s10570-023-05326-1 [29] Wang Y, Wang F, Shi C, et al. Monolithic mxene aerogels encapsulated phase change composites with superior photothermal conversion and storage capability[J]. Nanomaterials,2023,13(10):1661. doi: 10.3390/nano13101661 [30] Xu L, Wang J, Li K, et al. A systematic review of factors affecting properties of thermal-activated recycled cement[J]. Resources Conservation and Recycling, 2022, 185. [31] He W, Zhou L, Wang M, et al. Structure development of carbon-based solar-driven water evaporation systems[J]. Science Bulletin (Beijing),2021,66(14):1472-1483. doi: 10.1016/j.scib.2021.02.014 [32] Zuo S, Li D, Guan Z, et al. Utilization of sewage resources through efficient solar-water evaporation by single-atom Cu sites[J]. Carbon,2022,187:207-215. doi: 10.1016/j.carbon.2021.11.022 [33] Sun Y, Zhao Z, Zhao G, et al. High performance carbonized corncob-based 3D solar vapor steam generator enhanced by environmental energy[J]. Carbon,2021,179:337-347. doi: 10.1016/j.carbon.2021.04.037 [34] Li N, Ma Y, Chang Q, et al. Effective solar-driven interfacial water evaporation-assisted adsorption of organic pollutants by a activated porous carbon material[J]. New Carbon Materials,2023,38(5):925. doi: 10.1016/S1872-5805(23)60778-4 [35] Cen Z, Tang Y, Huang J, et al. Two-dimensional molecular brush-based ultrahigh edge-nitrogen-doped carbon nanosheets for ultrafast potassium-ion storage[J]. Batteries-Basel,2023,9(7):363. doi: 10.3390/batteries9070363 [36] Huang J, Leng K, Cen Z, et al. Cobalt-decorated carbon nanotube bottlebrushes for boosting polysulfide conversion in lithium-sulfur batteries[J]. Science China Materials,2023,66(5):1747-1756. doi: 10.1007/s40843-022-2303-0 [37] Huang J, Zuo Y, Liang M, et al. Multifunctional cationic molecular brushes-assisted fabrication of two-dimensional MoS2/carbon composites for ultrafast and long-term sodium storage[J]. Carbon,2023,202:187-193. doi: 10.1016/j.carbon.2022.10.018 [38] Shi C, Huang J, Tang Y, et al. A hierarchical porous carbon aerogel embedded with small-sized TiO2 nanoparticles for high-performance Li-S batteries[J]. Carbon,2023,202:59-65. doi: 10.1016/j.carbon.2022.09.086 [39] Tang Y, Cen Z, Ma Q, et al. A versatile sulfur-assisted pyrolysis strategy for high-atom-economy upcycling of waste plastics into high-value carbon materials[J]. Advanced Science,2023,10(15):e2206924. doi: 10.1002/advs.202206924 [40] Wang Z, Lin X, Tang Y, et al. Facile and universal defect engineering toward highly stable carbon-based polymer brushes with high grafting density[J]. Small,2023,19(20):e2207821. doi: 10.1002/smll.202207821 [41] Yang H, Huang J, Liu S, et al. Pseudocapacitive potassium-ion intercalation enabled by topologically defective soft carbon toward high-rate, large-areal-capacity, and low-temperature potassium-ion batteries[J]. Small,2023,19(39):e2302537. doi: 10.1002/smll.202302537 [42] Du R, Fu Y, Zhang L, et al. Desalination of high-salt brine via carbon materials promoted cyclopentane hydrate formation[J]. Desalination, 2022, 534. [43] Dong Z, Sun B, Zhu H, et al. A review of aligned carbon nanotube arrays and carbon/carbon composites: Fabrication, thermal conduction properties and applications in thermal management[J]. New Carbon Materials,2021,36(5):873-892. doi: 10.1016/S1872-5805(21)60090-2 [44] Hou Q, Xue C, Li N, et al. Self-assembly carbon dots for powerful solar water evaporation[J]. Carbon,2019,149:556-563. doi: 10.1016/j.carbon.2019.04.083 [45] Li J, Chang Q, Xue C, et al. Carbon dots efficiently enhance photothermal conversion and storage of organic phase change materials through interfacial interaction[J]. Carbon,2023,203:21-28. doi: 10.1016/j.carbon.2022.11.046 [46] Zhou H, Xue C, Chang Q, et al. Assembling carbon dots on vertically aligned acetate fibers as ideal salt-rejecting evaporators for solar water purification[J]. Chemical Engineering Journal, 2021, 421. [47] Du Y, Meng X, Wang Z, et al. Graphene-based catalysts for CO2 electroreduction[J]. Acta Physico-Chimica Sinica, 2022, 38(2). [48] Ma Y, Meng X, Li K, et al. Scrutinizing synergy and active site of nitrogen and selenium dual-doped porous carbon for efficient triiodide reduction[J]. Acs Catalysis, 2023: 1290-1298. [49] Zhao X, Meng X, Zou H, et al. Topographic manipulation of graphene oxide by polyaniline nanocone arrays enables high-performance solar-driven water evaporation[J]. Advanced Functional Materials,2023,33(7):2209207. doi: 10.1002/adfm.202209207 [50] Qu J, Yu Z, Zang Y, et al. A CoMn2O35-rGO hybrid as an effective fenton-like catalyst for the decomposition of various dyes[J]. New Carbon Materials,2019,34(6):539-545. doi: 10.1016/S1872-5805(19)60030-2 [51] Wu N, Che S, Li H, et al. A review of three-dimensional graphene networks for use in thermally conductive polymer composites: Construction and applications[J]. New Carbon Materials,2021,36(5):911-926. doi: 10.1016/S1872-5805(21)60089-6 [52] Liang H, Liao Q, Chen N, et al. Thermal efficiency of solar steam generation approaching 100% through capillary water transport[J]. Angewandte Chemie-International Edition,2019,58(52):19041-19046. doi: 10.1002/anie.201911457 [53] Zhou X, Guo Y, Zhao F, et al. Hydrogels as an emerging material platform for solar water purification[J]. Accounts of Chemical Research,2019,52(11):3244-3253. doi: 10.1021/acs.accounts.9b00455 [54] Li X, Ni G, Cooper T, et al. Measuring conversion efficiency of solar vapor generation[J]. Joule,2019,3(8):1798-1803. doi: 10.1016/j.joule.2019.06.009 [55] Yu Z, Cheng S, Li C, et al. Highly efficient solar vapor generator enabled by a 3D hierarchical structure constructed with hydrophilic carbon felt for desalination and wastewater treatment[J]. ACS Applied Materials & Interfaces,2019,11(35):32038-32045. [56] Zhang Y, Ravi S K, Tan S C. Systematic study of the effects of system geometry and ambient conditions on solar steam generation for evaporation optimization[J]. Advanced Sustainable Systems,2019,3(8):1900044. doi: 10.1002/adsu.201900044 [57] Zhan H, Wu K, Hu Y, et al. Biomimetic carbon tube aerogel enables super-elasticity and thermal insulation[J]. Chem,2019,5(7):1871-1882. doi: 10.1016/j.chempr.2019.04.025 [58] Fan X, Yang Y, Shi X, et al. A mxene-based hierarchical design enabling highly efficient and stable solar-water desalination with good salt resistance[J]. Advanced Functional Materials,2020,30(52):1-11. [59] Yasuhiro S, Takahiro T, Takumi H, et al. Resorcinol-formaldehyde resins as metal-free semiconductor photocatalysts for solar-to-hydrogen peroxide energy conversion[J]. Nature Materials,2019,18(9):985-993. [60] Cao S, Jiang Q, Wu X, et al. Advances in solar evaporator materials for freshwater generation[J]. Journal of Materials Chemistry A,2019,7(42):24092-24123. doi: 10.1039/C9TA06034K [61] Gao M, Zhu L, Peh C K, et al. Solar absorber material and system designs for photothermal water vaporization towards clean water and energy production[J]. Energy & Environmental Science,2019,12(3):841-864. [62] Chen C, Kuang Y, Hu L. Challenges and opportunities for solar evaporation[J]. Joule,2019,3(3):683-718. doi: 10.1016/j.joule.2018.12.023 [63] Brongersma M L, Halas N J, Nordlander P. Plasmon-induced hot carrier science and technology[J]. Nature Nanotechnology,2015,10(1):25-34. doi: 10.1038/nnano.2014.311 [64] Long R, Li Y, Song L, et al. Coupling solar energy into reactions: Materials design for surface plasmon-mediated catalysis[J]. Small,2015,11(32):3873-3889. doi: 10.1002/smll.201403777 [65] Meng F, Ju B, Zhang S, et al. Nano/microstructured materials for solar-driven interfacial evaporators towards water purification[J]. Journal of Materials Chemistry A,2021,9(24):13746-13769. doi: 10.1039/D1TA02202D [66] Cui X, Ruan Q, Zhou X, et al. Photothermal nanomaterials: A powerful light-to-heat converter[J]. Chemical Reviews, 2023. [67] Chen Q, Zhao J, Cheng H, et al. Progress in 3D-graphene assemblies preparation for solar-thermal steam generation and water treatment[J]. Acta Physico Chimica Sinica,2021,38(1):2101020. [68] Wang H, Mi X, Li Y, et al. 3D graphene-based macrostructures for water treatment[J]. Advanced Materials,2020,32(3):e1806843. doi: 10.1002/adma.201806843 [69] Gao F, Yu Z, Zang Y, et al. Resistance matching materials nanoarchitectonics for better performances in water evaporation-driven generators[J]. Nanotechnology,2022,33(19):195402. doi: 10.1088/1361-6528/ac4d55 [70] Qu J, Tu J, Guan C, et al. Nanochannel-dependent power generation performance of NiAl-LDH/SiO2-based generators driven by natural water evaporation[J]. Sustainable Energy & Fuels,2022,6(22):5100-5110. [71] Wu L, Zhang Y, Shang P, et al. Redistributing Zn ion flux by bifunctional graphitic carbon nitride nanosheets for dendrite-free zinc metal anodes[J]. Journal of Materials Chemistry A,2021,9(48):27408-27414. doi: 10.1039/D1TA08697A [72] Wang X, Sun Y, Zhao G, et al. Preparation of carbon nanotube/cellulose hydrogel composites and their uses in interfacial solar-powered water evaporation[J]. New Carbon Materials,2023,38(1):162-172. doi: 10.1016/S1872-5805(22)60621-8 [73] Li Y, Wu L, Dong C, et al. Manipulating horizontal ZN deposition with graphene interpenetrated ZN hybrid foils for dendrite-free aqueous zinc ion batteries[J]. Energy & Environmental Materials, 2023. [74] Shang P, Liu M, Mei Y, et al. Urea-mediated monoliths made of nitrogen-enriched mesoporous carbon nanosheets for high-performance aqueous zinc ion hybrid capacitors[J]. Small,2022,18(16):2108057. doi: 10.1002/smll.202108057 [75] Zhang Z, Dong Y, Gu Y, et al. Graphene-nanoscroll-based janus bifunctional separators suppress lithium dendrites and polysulfides shuttling synchronously in high-performance lithium-sulfur batteries[J]. Journal of Materials Chemistry A,2022,10(17):9515-9523. doi: 10.1039/D2TA01515C [76] Bian Y, Du Q, Tang K, et al. Carbonized bamboos as excellent 3D solar vapor-generation devices[J]. Advanced Materials Technologies,2018,4(4):1800593. [77] Wu L, Dong Z, Cai Z, et al. Highly efficient three-dimensional solar evaporator for high salinity desalination by localized crystallization[J]. Nature Communications,2020,11(1):521. doi: 10.1038/s41467-020-14366-1 [78] Chen X, Yang N, Wang Y, et al. Highly efficient photothermal conversion and water transport during solar evaporation enabled by amorphous hollow multishelled nanocomposites[J]. Advanced Materials,2022,34(7):e2107400. doi: 10.1002/adma.202107400 [79] Yang B, Zhang Z, Liu P, et al. Flatband lambda-Ti3O5 towards extraordinary solar steam generation[J]. Nature,2023,622:499-506. [80] Yang X, Yang Y, Fu L, et al. An ultrathin flexible 2D membrane based on single-walled nanotube-MoS2 hybrid film for high-performance solar steam generation[J]. Advanced Functional Materials,2018,28(3):1704505. doi: 10.1002/adfm.201704505 [81] Ying P, Li M, Yu F, et al. Band gap engineering in an efficient solar-driven interfacial evaporation system[J]. ACS Applied Materials & Interfaces,2020,12(29):32880-32887. [82] Zou Y, Qin C, Zhai H, et al. The optical characteristics of C@Cu core-shell nanorods for solar thermal applications[J]. International Journal of Thermal Sciences, 2022, 182. [83] Xu D, Zhong H, Li M, et al. Efficient plasmonic enhanced solar evaporation achieved by laser-assisted Cu/graphene nanocomposite[J]. Carbon,2023,204:231-237. doi: 10.1016/j.carbon.2022.12.019 [84] Wu L, Mei Y, Liu Y, et al. Interfacial synthesis of strongly-coupled delta-MnO2/MXene heteronanosheets for stable zinc ion batteries with Zn2+-exclusive storage mechanism[J]. Chemical Engineering Journal, 2023, 459. [85] Cao H, Jiao S, Zhang S, et al. In situ synthesizing C-CuO composite for efficient photo-thermal conversion and its application in solar-driven interfacial evaporation[J]. International Journal of Energy Research,2021,45:7829-7839. doi: 10.1002/er.6367 [86] Kim S, Tahir Z, Rashid M U, et al. Highly efficient solar vapor generation via a simple morphological alteration of TiO2 films grown on a glassy carbon foam[J]. ACS Applied Materials & Interfaces,2021,13(43):50911-50919. [87] Li B, Guo Z, Feng Y, et al. A multi-functional photothermal-catalytic foam for cascade treatment of saline wastewater[J]. Journal of Materials Chemistry A,2021,9(30):16510-16521. doi: 10.1039/D1TA03376J [88] Zhang Z, Mu P, Han J, et al. Superwetting and mechanically robust MnO2 nanowire–reduced graphene oxide monolithic aerogels for efficient solar vapor generation[J]. Journal of Materials Chemistry A,2019,7:18092. doi: 10.1039/C9TA04509K [89] Zhang J, Zhao B, Liang W, et al. Three-phase electrolysis by gold nanoparticle on hydrophobic interface for enhanced electrochemical nitrogen reduction reaction[J]. Advanced Science,2020,7(22):2002630. doi: 10.1002/advs.202002630 [90] Wu W, Gao F, Qu J, et al. Self-assembly of graphene oxide/nanodiamond microspheres with high adsorption for Pb2+ ions[J]. Chemistryselect,2022,7(10):1-9. [91] Ito Y, Tanabe Y, Han J, et al. Multifunctional porous graphene for high-efficiency steam generation by heat localization[J]. Advanced Materials,2015,27(29):4302-4307. doi: 10.1002/adma.201501832 [92] Ren H, Tang M, Guan B, et al. Hierarchical graphene foam for efficient omnidirectional solar-thermal energy conversion[J]. Advanced Materials,2017,29(38):1702590. doi: 10.1002/adma.201702590 [93] Gao X, Ren H, Zhou J, et al. Synthesis of hierarchical graphdiyne-based architecture for efficient solar steam generation[J]. Chemistry of Materials,2017,29(14):5777-5781. doi: 10.1021/acs.chemmater.7b01838 [94] Lin K, Lin H, Yang T, et al. Structured graphene metamaterial selective absorbers for high efficiency and omnidirectional solar thermal energy conversion[J]. Nature Communications,2020,11(1):1389. doi: 10.1038/s41467-020-15116-z [95] Awad F S, Kiriarachchi H D, Abouzeid K M, et al. Plasmonic graphene polyurethane nanocomposites for efficient solar water desalination[J]. ACS Applied Energy Materials,2018,1(3):976-985. doi: 10.1021/acsaem.8b00109 [96] Xu W, Hu X, Zhuang S, et al. Flexible and salt resistant janus absorbers by electrospinning for stable and efficient solar desalination[J]. Advanced Energy Materials,2018,8(14):1. [97] Zhang Q, Yang H, Xiao X, et al. A new self-desalting solar evaporation system based on a vertically oriented porous polyacrylonitrile foam[J]. Journal of Materials Chemistry A,2019,7(24):14620-14628. doi: 10.1039/C9TA03045J [98] Zhang X, Yang G, Zong L, et al. Tough, ultralight, and water-adhesive graphene/natural rubber latex hybrid aerogel with sandwichlike cell wall and biomimetic rose-petal-like surface[J]. ACS Applied Materials & Interfaces,2020,12(1):1378-1386. [99] Li X, Li J, Lu J, et al. Enhancement of interfacial solar vapor generation by environmental energy[J]. Joule,2018,2(7):1331-1338. doi: 10.1016/j.joule.2018.04.004 [100] Xu Z, Ran X, Wang D, et al. High efficient 3D solar interfacial evaporator: Achieved by the synergy of simple material and structure[J]. Desalination, 2022, 525. [101] Zhao X, Meng X, Zou H, et al. Topographic manipulation of graphene oxide by polyaniline nanocone arrays enables high-performance solar-driven water evaporation[J]. Advanced Functional Materials,2022,33(7):2209207. [102] Qin Y, Peng Q, Ding Y, et al. Lightweight, superelastic, and mechanically flexible graphene/polyimide nanocomposite foam for strain sensor application[J]. ACS Nano,2015,9(9):8933-8941. doi: 10.1021/acsnano.5b02781 [103] Zhang X, Zhang T, Wang Z, et al. Ultralight, superelastic, and fatigue-resistant graphene aerogel templated by graphene oxide liquid crystal stabilized air bubbles[J]. ACS Applied Materials & Interfaces,2019,11(1):1303-1310. [104] Xu A, Xie B, Li C, et al. Microcrystalline graphite-coupled carbon matrix composites with three-dimensional structure for photothermal conversion and storage[J]. Journal of Energy Storage,2024,84(PB):110689. doi: 10.1016/J.EST.2024.110689 -

下载:

下载: