Polyimide-assisted fabrication of highly oriented graphene-based all-carbon foams for increasing the thermal conductivity of polymer composites

-

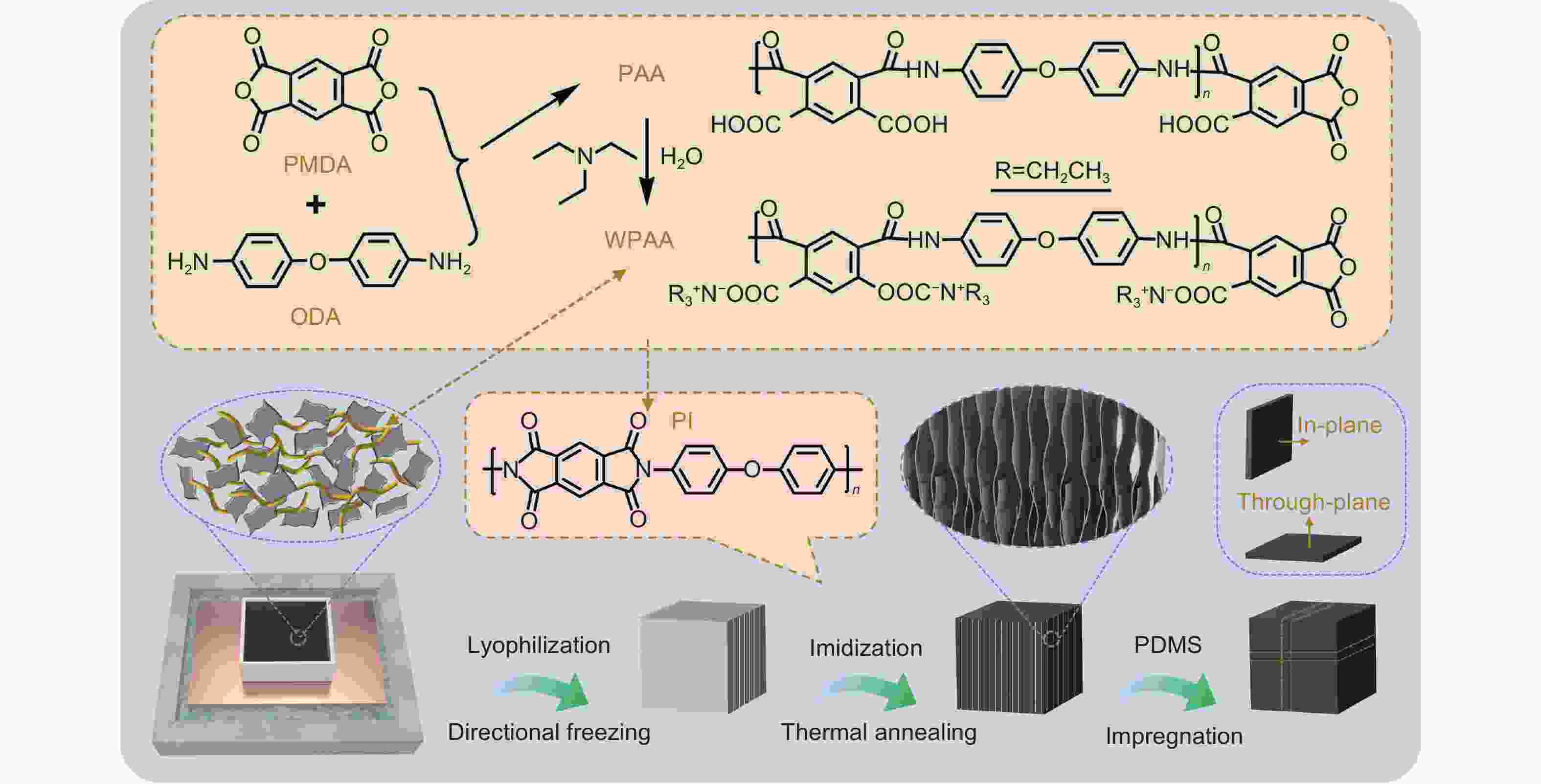

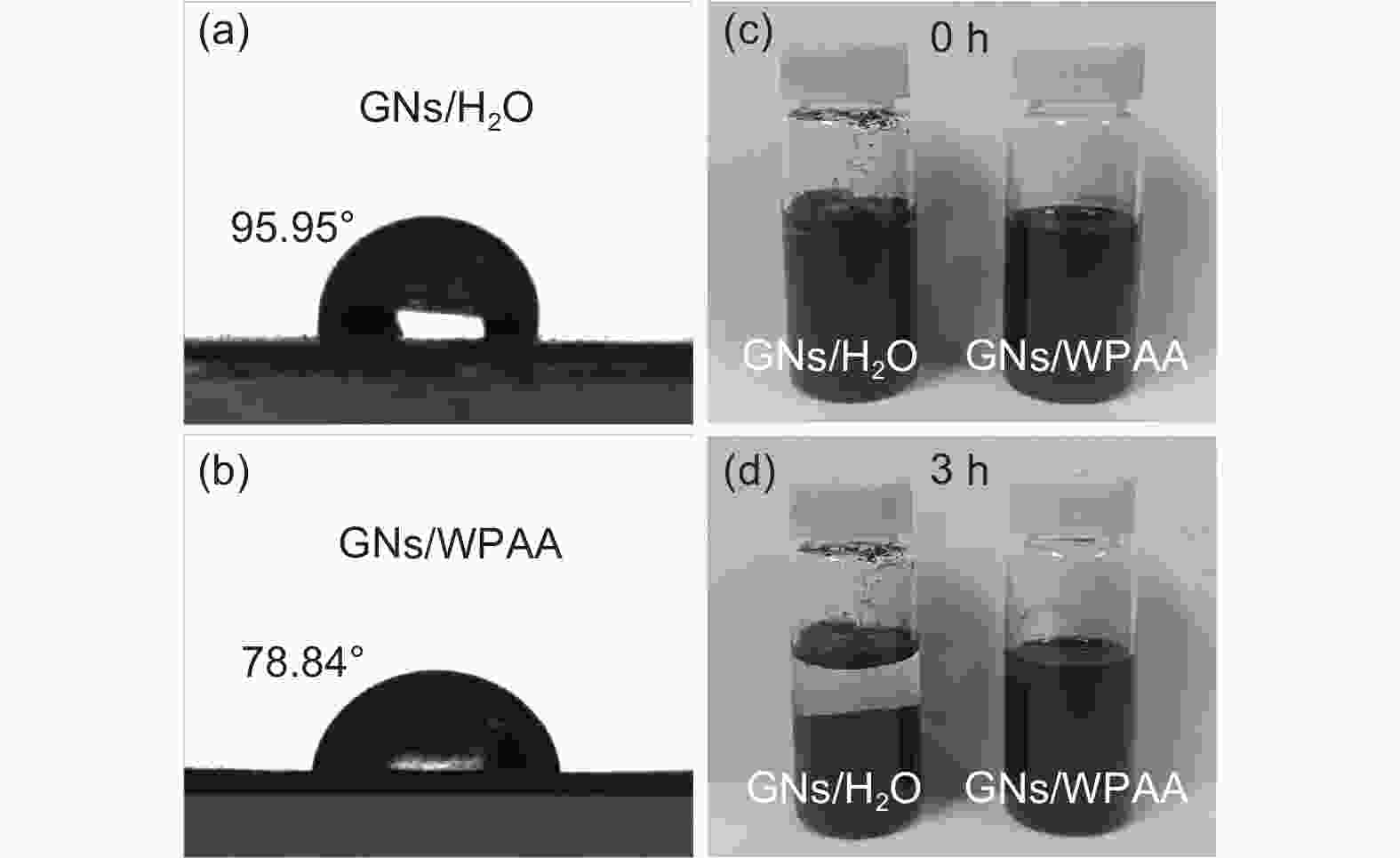

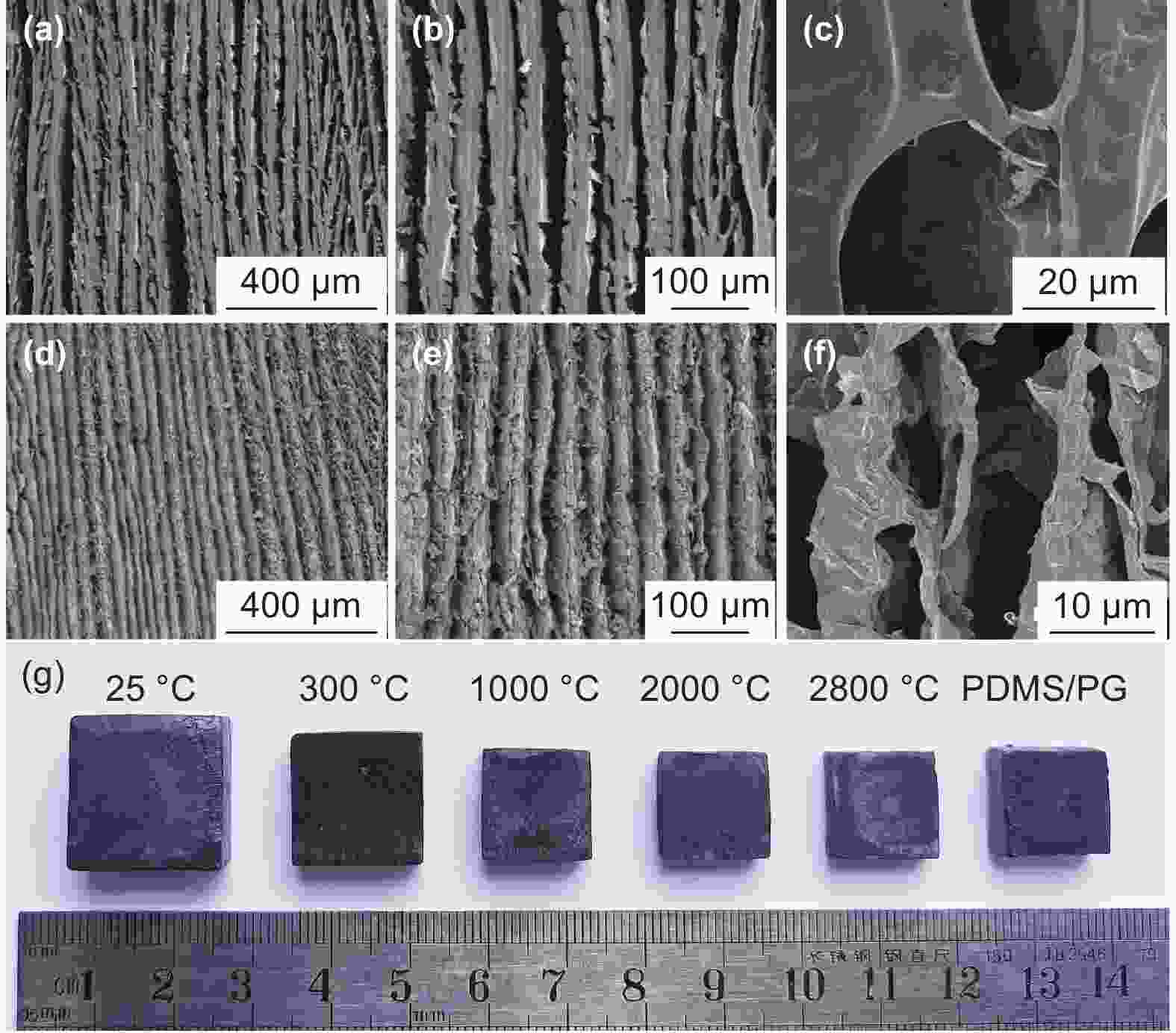

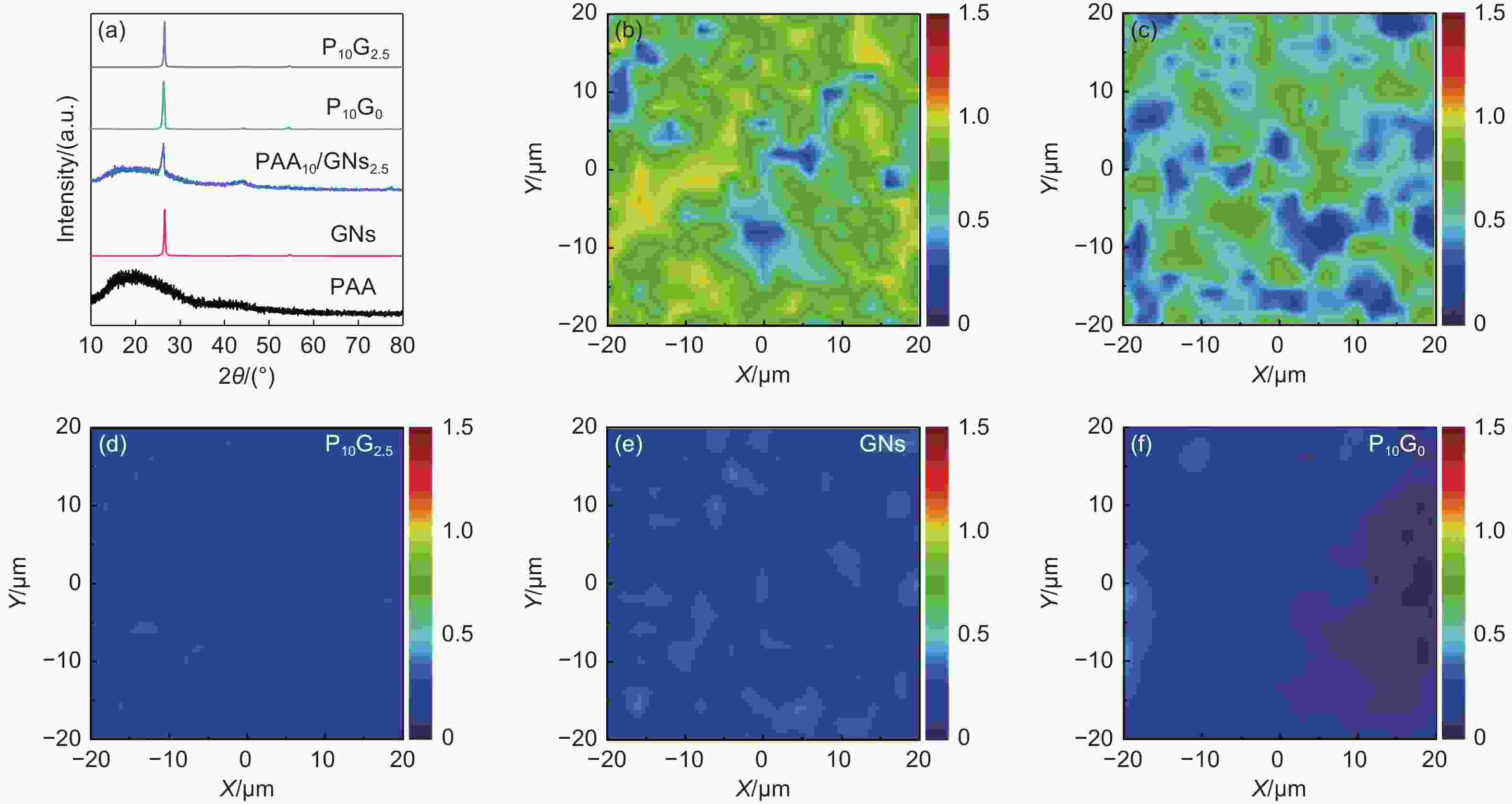

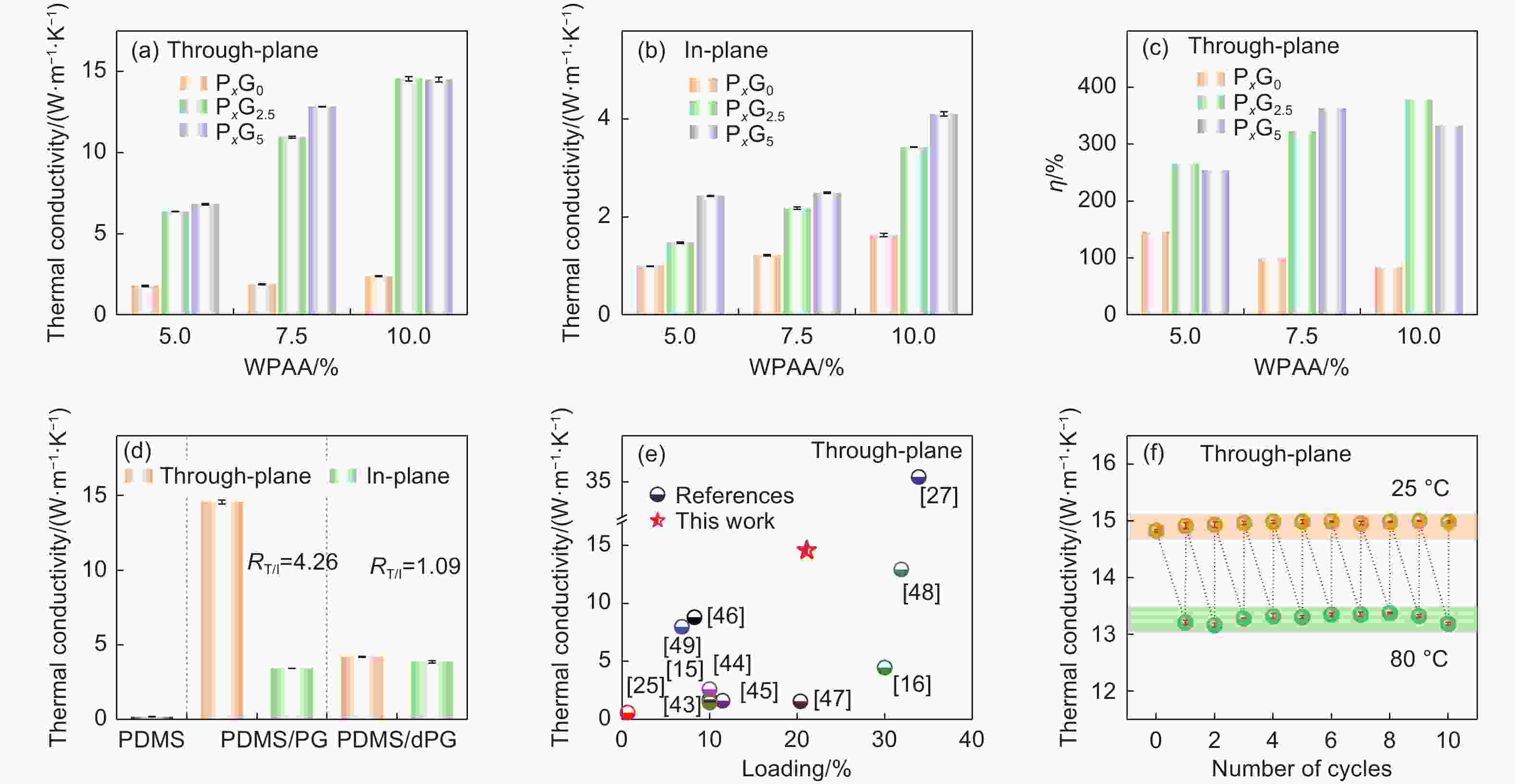

摘要: 石墨烯及其衍生物具有高纵横比的二维层状结构,在加工过程中通常倾向于水平排列。因此,石墨烯基复合热界面材料虽然具有较高的面内热导率,但其表现出的低面外热导率难以满足实际应用需求。本文通过定向冷冻策略制备了竖直排列的聚酰亚胺/石墨纳米片(PG)导热骨架以提高聚合物复合材料的面外热导率,其中石墨纳米片(GNs)为高导热石墨烯薄膜的粉体边角料。在该过程中,采用水溶性聚酰胺盐溶液直接分散疏水的GNs,热亚胺化后获得的聚酰亚胺在辅助GNs定向排列的同时经石墨化处理转变为人造石墨。同时,GNs的引入提高了PG骨架的有序度和密度,进一步提高了聚二甲基硅氧烷(PDMS)基复合材料的强度和导热性能。结果表明,所制备的PDMS/PG复合材料(PG:21.1%)的面外热导率达14.56 W·m−1·K−1,是纯PDMS的81倍。这种简便的聚酰亚胺辅助二维疏水填料定向排列的方法为各向异性热界面材料的规模制备提供了思路,同时实现了石墨烯薄膜边角料的再利用。Abstract: Graphene and its derivatives are often preferentially oriented horizontally during processing because of their two-dimensional (2D) layer structure. As a result, thermal interface materials (TIMs) composed of a polymer matrix and graphene-derived fillers often have a high in-plane (IP) thermal conductivity (K), however, the low through-plane (TP) K makes them unsuitable for practical use. We report the development of high-quality polyimide/graphite nanosheets (PG) perpendicular to the plane using a directional freezing technique that increase the TP K of polymer-based composites. Graphene-derived nanosheets (GNs) were obtained by the crushing of scraps of highly thermally conductive graphene films. A water-soluble polyamic acid salt solution was used to disperse the hydrophobic GNs filler to achieve directional freezing. The polyimide, which facilitated the directional alignment of the GNs, was then graphitized. The introduction of the GNs increases the order and density of the PG, thus improving the strength and heat transfer performance of its polydimethylsiloxane (PDMS) composite. The obtained PG/PDMS composite (21.1% PG, mass fraction) has an impressive TP K of14.56 W·m−1·K−1, 81 times that of pure PDMS. This simple polyimide-assisted 2D hydrophobic fillers alignment method provides ideas for the widespread fabrication of anisotropic TIMs and enables the reuse of scraps of graphene films.

-

Key words:

- Graphene film /

- Reutilization /

- Thermal conductivity /

- Anisotropic foam /

- Thermal interface materials

-

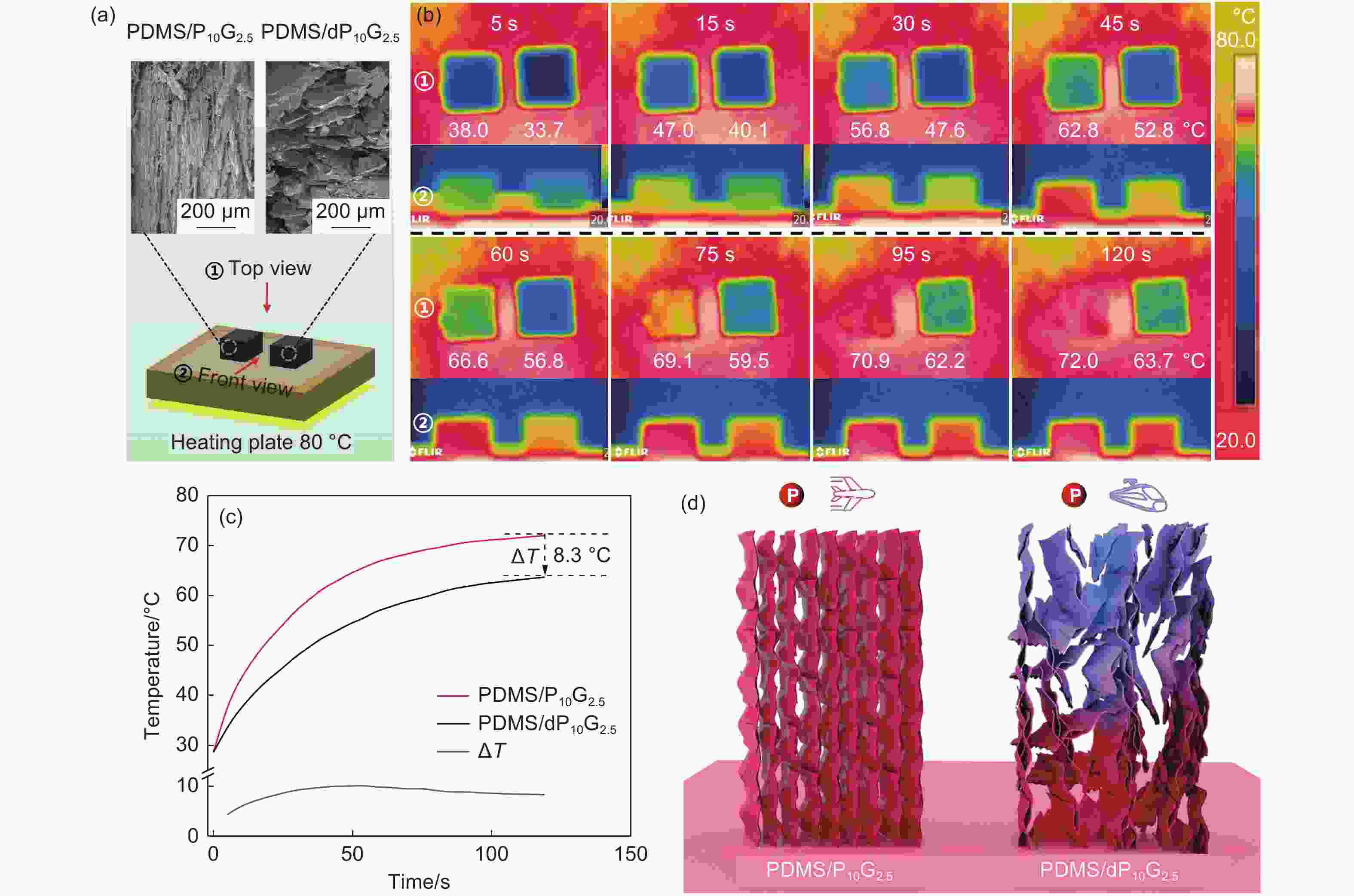

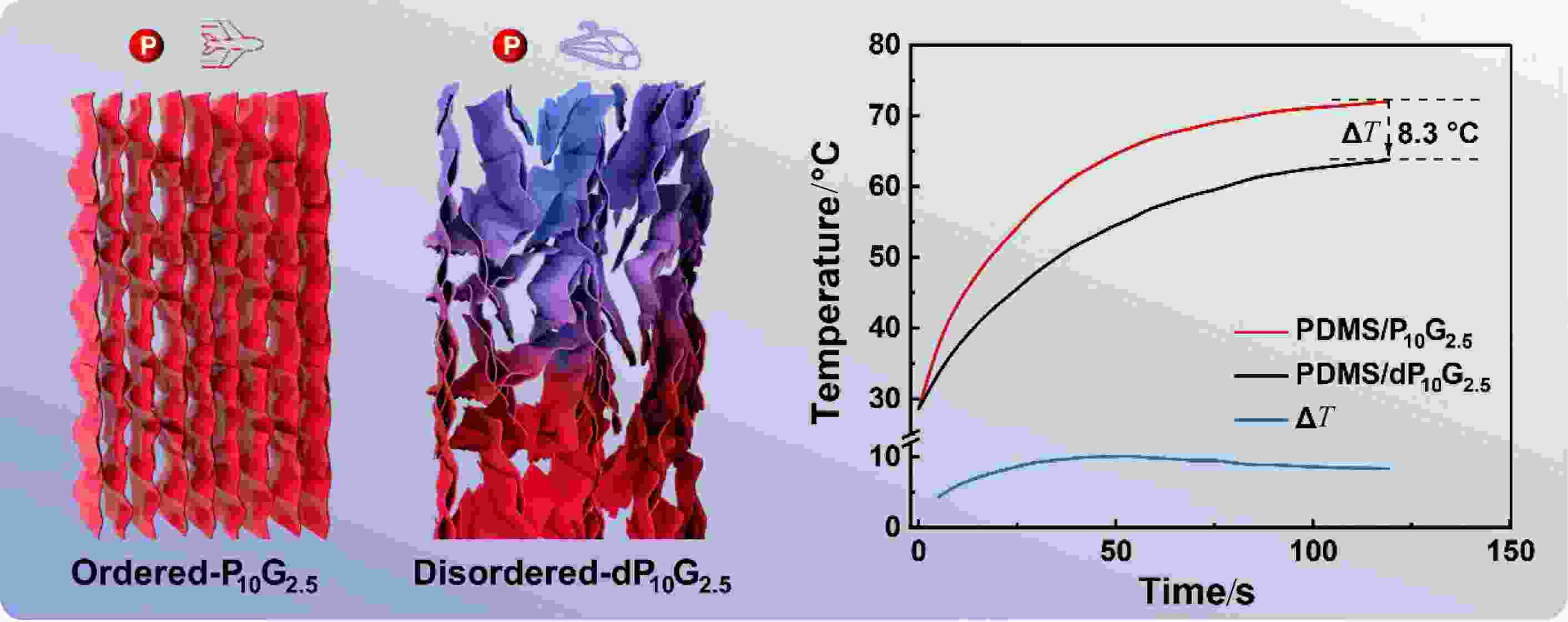

Figure 6. (a) Schematic diagram of heat transfer performance test system, and cross-sectional SEM images of PDMS/P10G2.5 and PDMS/dP10G2.5. (b) Infrared thermography images of PDMS/P10G2.5 and PDMS/dP10G2.5 during a heating process: top view (up), front view (down). (c) Surface temperature-time and temperature difference curves of PDMS/P10G2.5 and PDMS/dP10G2.5. (d) Schematic diagram of phonons transfer in PDMS/P10G2.5 and PDMS/dP10G2.5

Figure 7. (a) Thermogravimetric analysis curves of PDMS and PDMS/P10Gy composites under air atmosphere. (b) Compressive stress-strain curves of PDMS/P10Gy composites. (c) Compressive strength and (d) modulus of PDMS/PG composites. (e) Strain-stress curves and (f) TP K of PDMS/P10G2.5 compressed repeatedly for 40 times

-

[1] Xu S, Wang S, Chen Z, et al. Electric‐field‐assisted growth of vertical graphene arrays and the application in thermal interface materials[J]. Advanced Functional Materials,2020,30(34):2003302. doi: 10.1002/adfm.202003302 [2] Jing L, Cheng R, Tasoglu M, et al. High thermal conductivity of sandwich-structured flexible thermal interface materials[J]. Small,2023,19(11):2207015. doi: 10.1002/smll.202207015 [3] Dong Z J, Sun B, Zhu H, et al. A review of aligned carbon nanotube arrays and carbon/carbon composites: Fabrication, thermal conduction properties and applications in thermal management[J]. New Carbon Materials,2021,36(5):873-892. doi: 10.1016/S1872-5805(21)60090-2 [4] Liang X, Dai F. Epoxy nanocomposites with reduced graphene oxide-constructed three-dimensional networks of single wall carbon nanotube for enhanced thermal management capability with low filler loading[J]. ACS Applied Materials & Interfaces,2020,12(2):3051-3058. [5] Zhang G, Xue S, Chen F, et al. An efficient thermal interface material with anisotropy orientation and high through-plane thermal conductivity[J]. Composites Science and Technology,2023,231:109784. doi: 10.1016/j.compscitech.2022.109784 [6] Ma M, Xu L, Qiao L, et al. Nanofibrillated cellulose/MgO@rGO composite films with highly anisotropic thermal conductivity and electrical insulation[J]. Chemical Engineering Journal,2020,392:123714. doi: 10.1016/j.cej.2019.123714 [7] Feng C P, Wan S S, Wu W C, et al. Electrically insulating, layer structured SiR/GNPs/BN thermal management materials with enhanced thermal conductivity and breakdown voltage[J]. Composites Science and Technology,2018,167:456-462. doi: 10.1016/j.compscitech.2018.08.039 [8] Mehra N, Mu L W, Ji T, et al. Thermal transport in polymeric materials and across composite interfaces[J]. Applied Materials Today,2018,12:92-130. doi: 10.1016/j.apmt.2018.04.004 [9] Wang S, Feng D, Guan H, et al. Highly efficient thermal conductivity of polydimethylsiloxane composites via introducing “line-plane”-like hetero-structured fillers[J]. Composites Part A-Applied Science and Manufacturing,2022,157:106911. doi: 10.1016/j.compositesa.2022.106911 [10] Balandin A A, Ghosh S, Bao W, et al. Superior thermal conductivity of single-layer graphene[J]. Nano Letters,2008,8(3):902-907. doi: 10.1021/nl0731872 [11] Balandin A A. Thermal properties of graphene and nanostructured carbon materials[J]. Nature Materials,2011,10(8):569-581. doi: 10.1038/nmat3064 [12] Wu Z, Xu C, Ma C, et al. Synergistic effect of aligned graphene nanosheets in graphene foam for high-performance thermally conductive composites[J]. Advanced Materials,2019,31(19):e1900199. doi: 10.1002/adma.201900199 [13] Shahil K M, Balandin A A. Graphene-multilayer graphene nanocomposites as highly efficient thermal interface materials[J]. Nano Letters,2012,12(2):861-867. doi: 10.1021/nl203906r [14] Li Y K, Li W J, Wang Z X, et al. High-efficiency electromagnetic interference shielding and thermal management of high-graphene nanoplate-loaded composites enabled by polymer-infiltrated technique[J]. Carbon,2023,211:118096. doi: 10.1016/j.carbon.2023.118096 [15] Alam F E, Dai W, Yang M H, et al. In situ formation of a cellular graphene framework in thermoplastic composites leading to superior thermal conductivity[J]. Journal of Materials Chemistry A,2017,5(13):6164-6169. doi: 10.1039/C7TA00750G [16] Huang X, Lin Y, Fang G. Thermal properties of polyvinyl butyral/graphene composites as encapsulation materials for solar cells[J]. Solar Energy,2018,161:187-193. doi: 10.1016/j.solener.2017.12.051 [17] Zhang F, Feng Y Y, Feng W. Three-dimensional interconnected networks for thermally conductive polymer composites: Design, preparation, properties, and mechanisms[J]. Materials Science & Engineering R-Reports,2020,142:100580. [18] Ruan K, Shi X, Guo Y, et al. Interfacial thermal resistance in thermally conductive polymer composites: A review[J]. Composites Communications,2020,22:100518. doi: 10.1016/j.coco.2020.100518 [19] Zhao H Y, Yu M Y, Liu J, et al. Efficient preconstruction of three-dimensional graphene networks for thermally conductive polymer composites[J]. Nano-Micro Letters,2022,14:129. doi: 10.1007/s40820-022-00878-6 [20] Varshney V, Patnaik S S, Roy A K, et al. Modeling of thermal transport in pillared-graphene architectures[J]. ACS Nano,2010,4(2):1153-1161. doi: 10.1021/nn901341r [21] Liu D, Yang Z, Zhang Y, et al. Tailoring aligned and densified carbon nanotube@graphene coaxial yarn for 3D thermally conductive networks[J]. Carbon,2023,208:322-329. doi: 10.1016/j.carbon.2023.03.051 [22] Wu N, Che S, Li H W, et al. A review of three-dimensional graphene networks for use in thermally conductive polymer composites: Construction and applications[J]. New Carbon Materials,2021,36(5):911-926. doi: 10.1016/S1872-5805(21)60089-6 [23] Zhao Y H, Wu Z K, Bai S L. Study on thermal properties of graphene foam/graphene sheets filled polymer composites[J]. Composites Part A-Applied Science and Manufacturing,2015,72:200-206. doi: 10.1016/j.compositesa.2015.02.011 [24] Yan Q, Gao J, Chen D, et al. A highly orientational architecture formed by covalently bonded graphene to achieve high through-plane thermal conductivity of polymer composites[J]. Nanoscale,2022,14(31):11171-11178. doi: 10.1039/D2NR02265F [25] Zhao Y H, Zhang Y F, Bai S L. High thermal conductivity of flexible polymer composites due to synergistic effect of multilayer graphene flakes and graphene foam[J]. Composites Part A-Applied Science and Manufacturing,2016,85:148-155. doi: 10.1016/j.compositesa.2016.03.021 [26] Yang T, Jiang Z, Han H, et al. Welding dopamine modified graphene nanosheets onto graphene foam for high thermal conductive composites[J]. Composites Part B-Engineering,2021,205:108509. doi: 10.1016/j.compositesb.2020.108509 [27] An F, Li X F, Min P, et al. Vertically aligned high-quality graphene foams for anisotropically conductive polymer composites with ultrahigh through-plane thermal conductivities[J]. ACS Applied Materials & Interfaces,2018,10(20):17383-17392. [28] Cao M, Li Z, Lu J, et al. Vertical array of graphite oxide liquid crystal by microwire shearing for highly thermally conductive composites [J]. Advanced Materials, 2023: e2300077. [29] Li X H, Liu P, Li X, et al. Vertically aligned, ultralight and highly compressive all-graphitized graphene aerogels for highly thermally conductive polymer composites[J]. Carbon,2018,140:624-633. doi: 10.1016/j.carbon.2018.09.016 [30] An D, Cheng S S, Zhang Z Y, et al. A polymer-based thermal management material with enhanced thermal conductivity by introducing three-dimensional networks and covalent bond connections[J]. Carbon,2019,155:258-267. doi: 10.1016/j.carbon.2019.08.072 [31] Ma J, Shang T, Ren L, et al. Through-plane assembly of carbon fibers into 3D skeleton achieving enhanced thermal conductivity of a thermal interface material[J]. Chemical Engineering Journal,2020,380:122550. doi: 10.1016/j.cej.2019.122550 [32] Li Y, Wei W, Wang Y, et al. Construction of highly aligned graphene-based aerogels and their epoxy composites towards high thermal conductivity[J]. Journal of Materials Chemistry C,2019,7(38):11783-11789. doi: 10.1039/C9TC02937K [33] Liu J, Zhang H B, Xie X, et al. Multifunctional, superelastic, and lightweight mxene/polyimide aerogels[J]. Small,2018,14(45):e1802479. doi: 10.1002/smll.201802479 [34] Wang Y Y, Sun W J, Yan D X, et al. Ultralight carbon nanotube/graphene/polyimide foam with heterogeneous interfaces for efficient electromagnetic interference shielding and electromagnetic wave absorption[J]. Carbon,2021,176:118-125. doi: 10.1016/j.carbon.2020.12.028 [35] Li M, Liu J, Pan S, et al. Highly oriented graphite aerogel fabricated by confined liquid-phase expansion for anisotropically thermally conductive epoxy composites[J]. ACS Applied Materials & Interfaces,2020,12(24):27476-27484. [36] Liu Y, Chen B, Wu K, et al. Ultrahigh thermal conductivity of epoxy composites based on curling bioinspired functionalized graphite films for thermal management application[J]. Composites Part A-Applied Science and Manufacturing,2021,146:106413. doi: 10.1016/j.compositesa.2021.106413 [37] Liu P, Li X, Min P, et al. 3D lamellar-structured graphene aerogels for thermal interface composites with high through-plane thermal conductivity and fracture toughness[J]. Nano-Micro Letters,2021,13:22. doi: 10.1007/s40820-020-00548-5 [38] An F, Li X, Min P, et al. Highly anisotropic graphene/boron nitride hybrid aerogels with long-range ordered architecture and moderate density for highly thermally conductive composites[J]. Carbon,2018,126:119-127. doi: 10.1016/j.carbon.2017.10.011 [39] Ferrari A C, Basko D M. Raman spectroscopy as a versatile tool for studying the properties of graphene[J]. Nature Nanotechnology,2013,8(4):235-246. doi: 10.1038/nnano.2013.46 [40] Inagaki M, Ohta N, Hishiyama Y. Aromatic polyimides as carbon precursors[J]. Carbon,2013,61:1-21. doi: 10.1016/j.carbon.2013.05.035 [41] Ma L, Wang Y, Xu X, et al. Structural evolution and thermal conductivity of flexible graphite films prepared by carboxylic graphene/polyimide[J]. Ceramics International,2021,47:1076-1085. doi: 10.1016/j.ceramint.2020.08.223 [42] Konatham D, Papavassiliou D V, Striolo A. Thermal boundary resistance at the graphene-graphene interface estimated by molecular dynamics simulations[J]. Chemical Physics Letters,2012,527:47-50. doi: 10.1016/j.cplett.2012.01.007 [43] Song S H, Park K H, Kim B H, et al. Enhanced thermal conductivity of epoxy-graphene composites by using non-oxidized graphene flakes with non-covalent functionalization[J]. Advanced Materials,2013,25(5):732-737. doi: 10.1002/adma.201202736 [44] Bai Q Q, Wei X, Yang J H, et al. Dispersion and network formation of graphene platelets in polystyrene composites and the resultant conductive properties[J]. Composites Part A-Applied Science and Manufacturing,2017,96:89-98. doi: 10.1016/j.compositesa.2017.02.020 [45] Fang H, Zhao Y, Zhang Y, et al. Three-dimensional graphene foam-filled elastomer composites with high thermal and mechanical properties[J]. ACS Applied Materials & Interfaces,2017,9(31):26447-26459. [46] Shen X, Wang Z, Wu Y, et al. A three-dimensional multilayer graphene web for polymer nanocomposites with exceptional transport properties and fracture resistance[J]. Materials Horizons,2018,5(2):275-284. doi: 10.1039/C7MH00984D [47] Liang C, Qiu H, Han Y, et al. Superior electromagnetic interference shielding 3D graphene nanoplatelets/reduced graphene oxide foam/epoxy nanocomposites with high thermal conductivity[J]. Journal of Materials Chemistry C,2019,7(9):2725-2733. doi: 10.1039/C8TC05955A [48] Liu C, Wu W, Chen Q, et al. 3D expanded graphite frameworks for dual-functional polymer composites with exceptional thermal conductive and electromagnetic interference shielding capabilities[J]. ACS Applied Electronic Materials,2022,4(2):707-717. doi: 10.1021/acsaelm.1c01120 [49] Liu Z, Chen Y, Li Y, et al. Graphene foam-embedded epoxy composites with significant thermal conductivity enhancement[J]. Nanoscale,2019,11(38):17600-17606. doi: 10.1039/C9NR03968F -

20240206 Supporting+information.pdf

20240206 Supporting+information.pdf

-

下载:

下载: