A review of the use of metal oxide/carbon composite materials to inhibit the shuttle effect in lithium-sulfur batteries

-

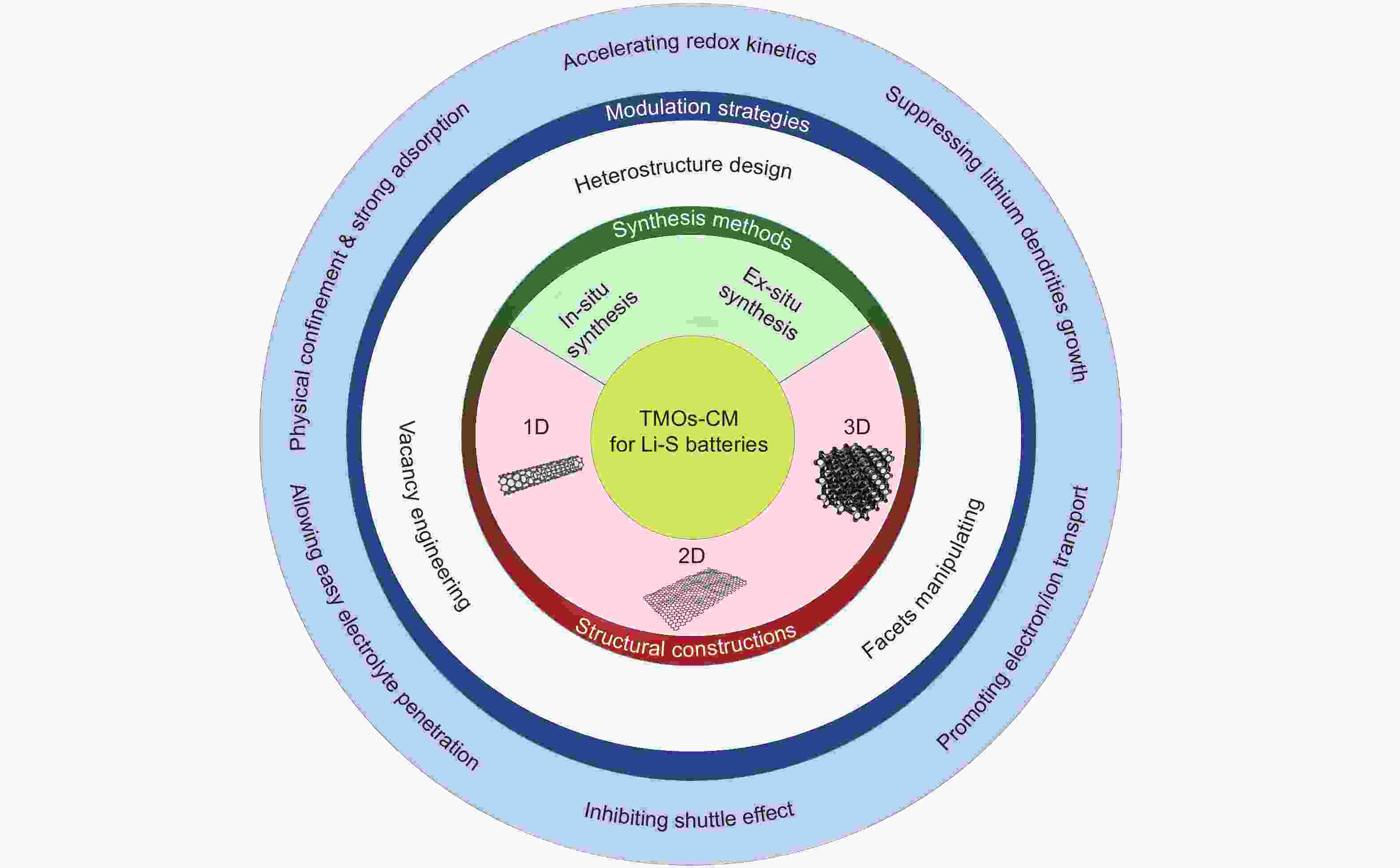

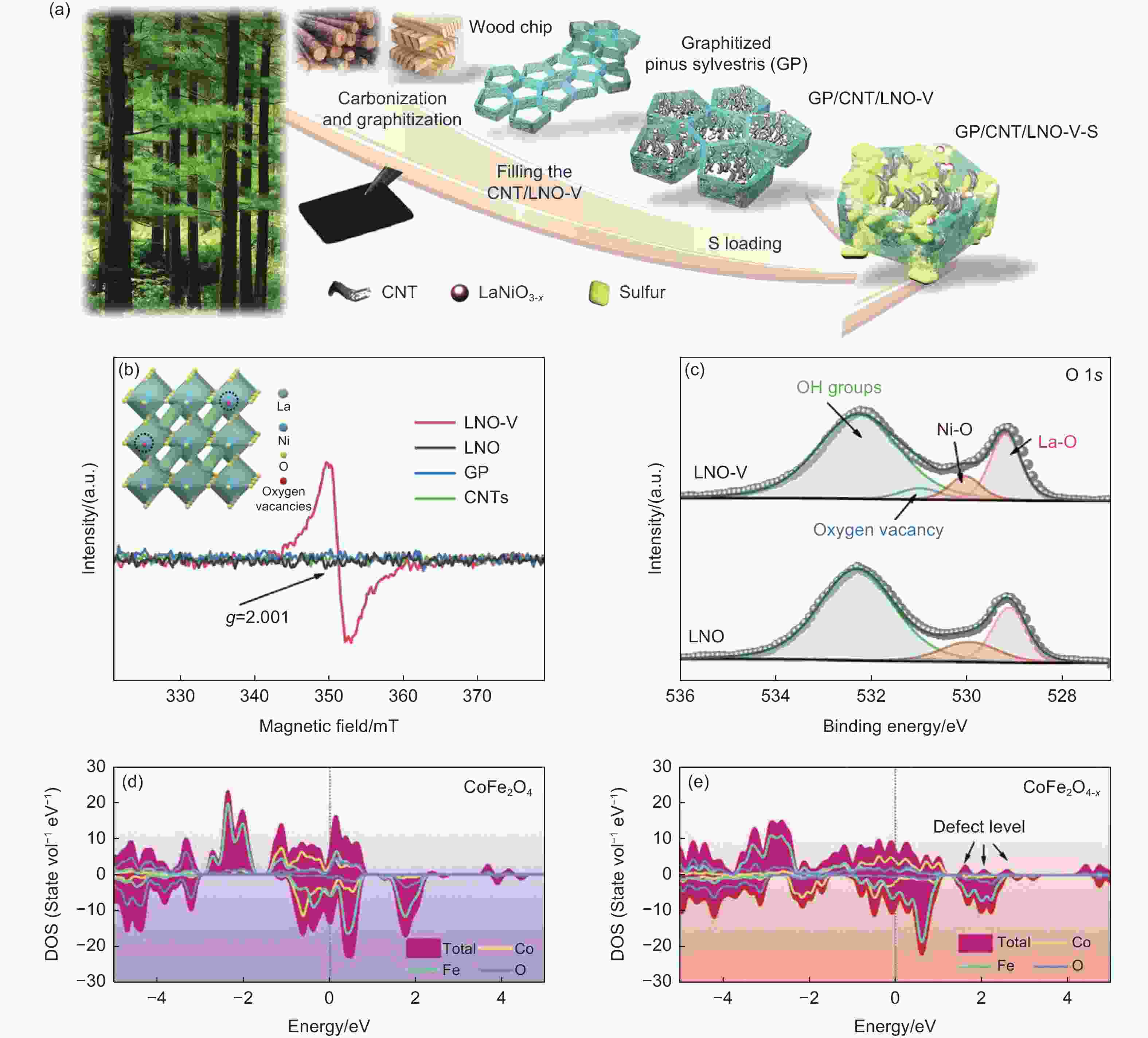

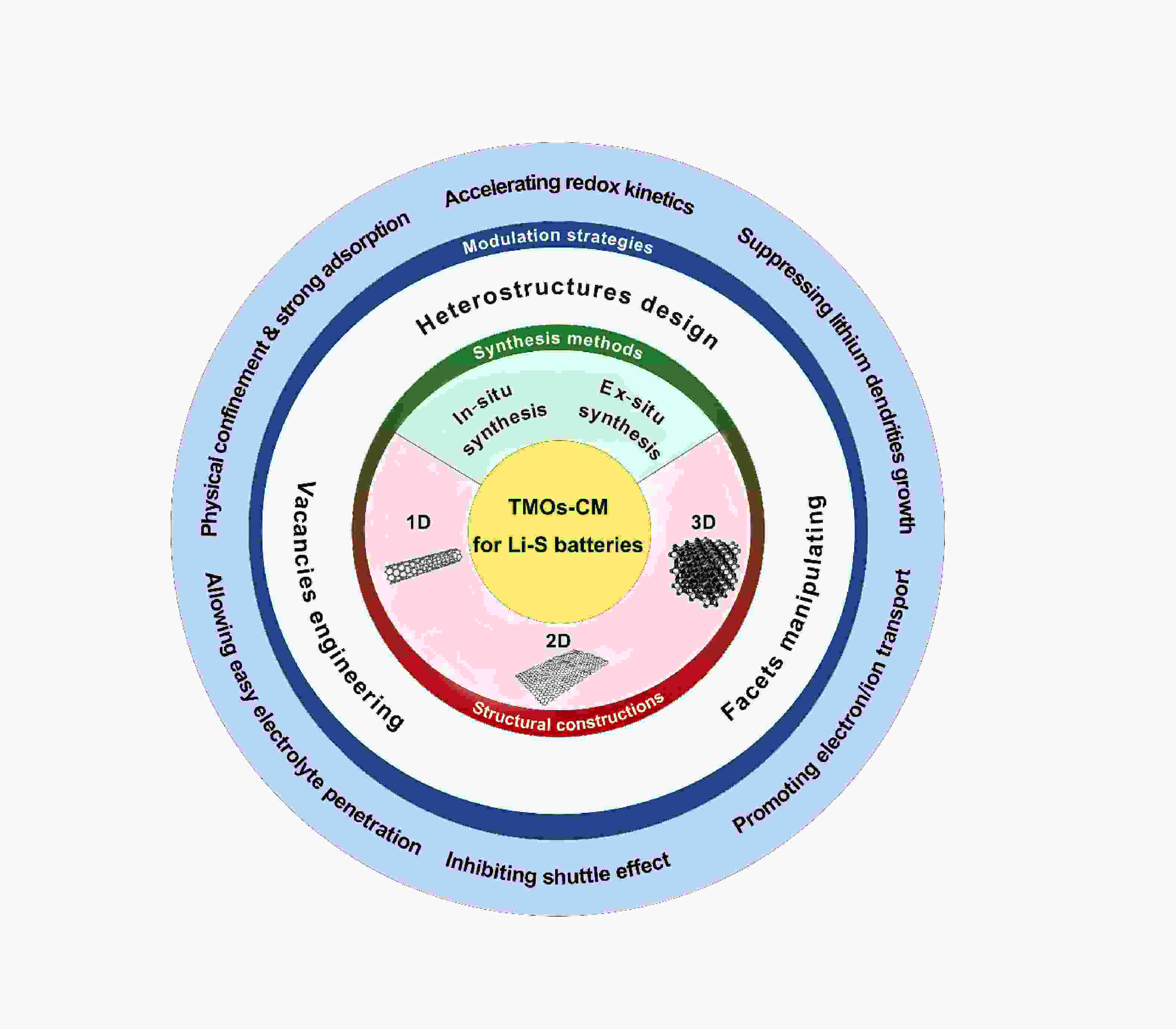

摘要: 锂硫电池因理论能量密度高、生产成本低和环境友好等优点被认为是最有前途的下一代电化学储能装置之一。然而,硫和硫化锂的低导电性、严重的穿梭效应和缓慢的反应动力学等问题阻碍了锂硫电池的大规模商业化应用。炭材料因高比表面积,良好导电性与结构多样性而备受关注,然而非极性炭材料难以与极性多硫化物紧密结合,导致活性材料大量损失和严重的穿梭效应。金属氧化物具有极性强和丰富吸附位点的优点,将过渡金属氧化物与炭材料结合,有助于增强对多硫化物的化学吸附和电化学反应活性。本文首先介绍了锂硫电池的基本原理和存在的主要问题,然后讨论了近年来过渡金属氧化物/炭复合材料在合成方法和结构设计(1D,2D,3D)方面的研究进展。此外,详细介绍了异质结构设计、空位工程和晶面调控策略的代表性工作并讨论了其机理。最后,对过渡金属氧化物/炭复合材料用于锂硫电池中的发展进行了总结和展望。Abstract: Lithium-sulfur (Li-S) batteries are among the most promising next-generation electrochemical energy-storage systems due to their exceptional theoretical specific capacity, inexpensive production cost and environmental friendliness. However, the poor conductivity of S and Li2S, severe lithium polysulfide (LiPS) shuttling and the sluggish redox kinetics of the phase transformation greatly hinder their commercialization. Carbonaceous materials could be potentially useful in Li-S batteries to tackle these problems with their high specific surface area to host LiPSs and sulfur and excellent electrical conductivity to increase electron transfer rate. However, non-polar carbon materials are unable to interact closely with the highly polar polysulfides, resulting in a low sulfur utilization and a serious shuttle effect. Because of their advantages of strong polarity and a large number of adsorption sites, integrating transition metal oxides (TMOs) with carbon-based materials (CMs) increases the chemical adsorption of LiPSs and electrochemical reaction activity for LiPSs. The working principles and main challenges of Li-S batteries are discussed followed by a review of recent research on the ex-situ and in-situ synthesis of TMO/CM composites. The formation of TMO/CMs with the dimensionalities of CMs from 1D to 3D are then reviewed together with ways of changing their structure, including heterostructure design, vacancy engineering and facet manipulation. Finally, the outlook for using TMO/CMs in Li-S batteries is considered.

-

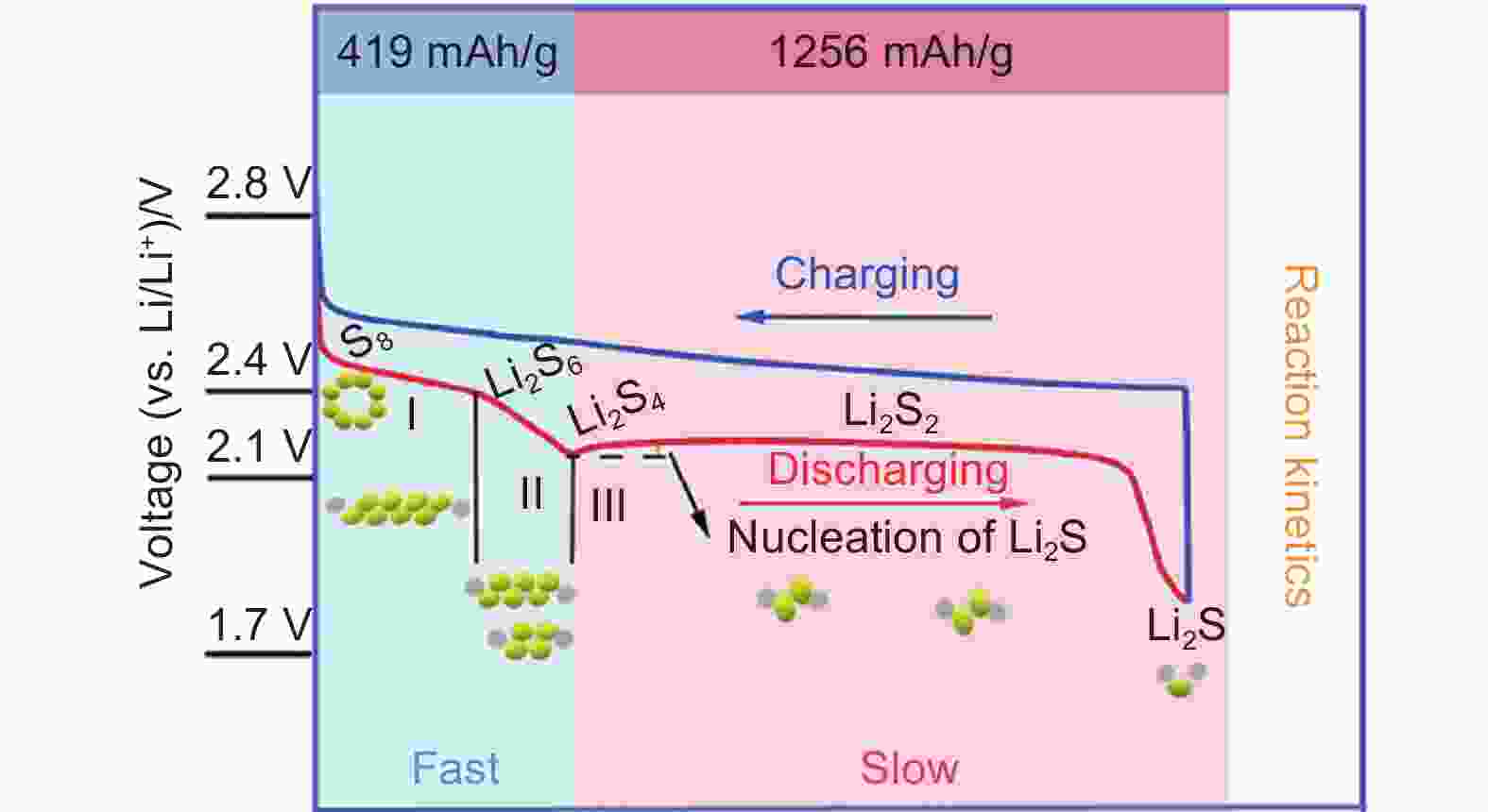

Figure 2. Typical charge/discharge curve and multi-phase evolution of LiPSs in Li-S batteries[8]. Reproduced with permission

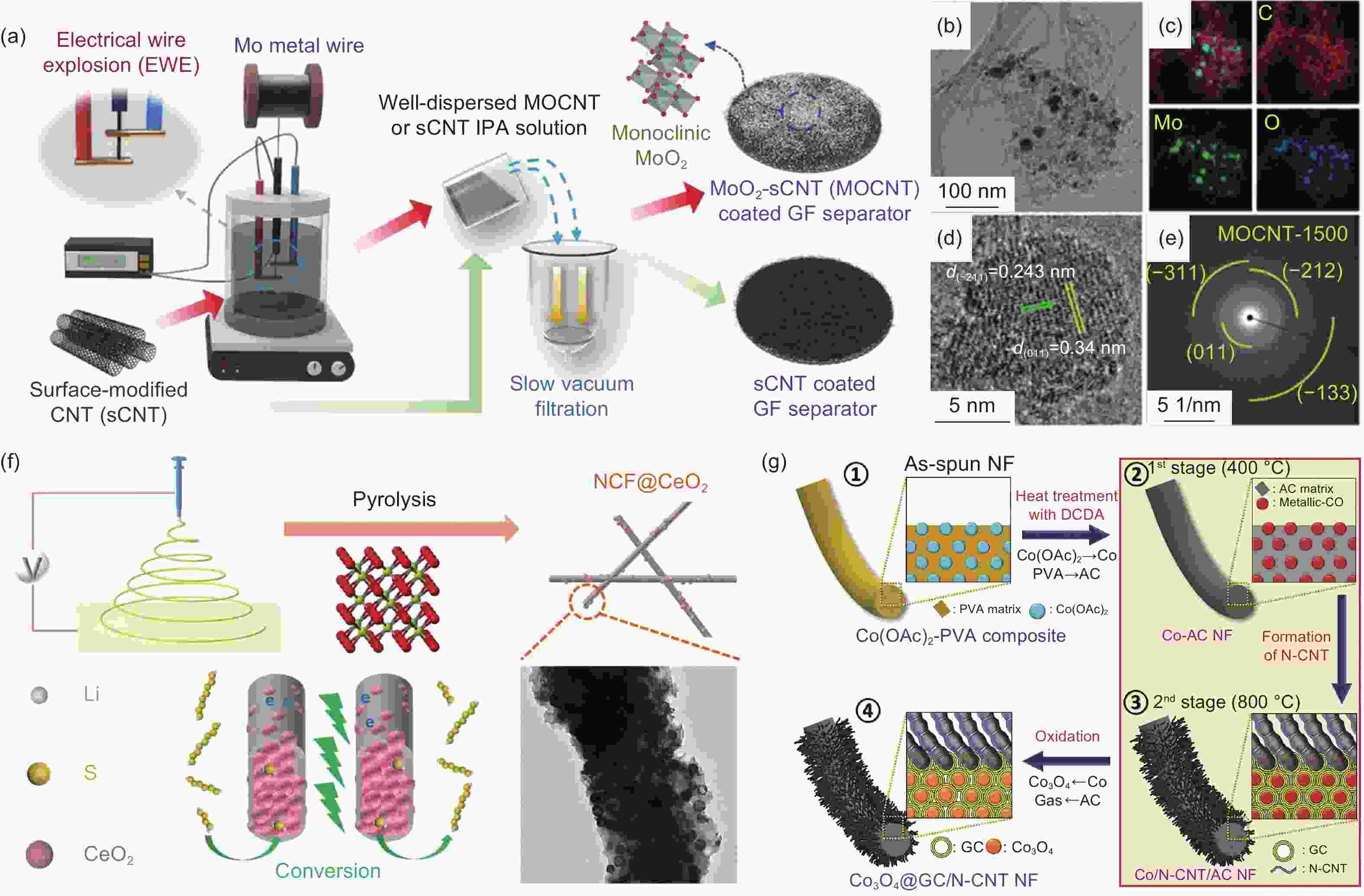

Figure 4. (a) Schematic illustration of preparation process of CoTiO3@rGO and synergistic functions in Li-S batteries[50]. (b) Schematic electrode configuration of Li-S batteries with S/rGO@mC-MnO-800 cathode material[51]. (c) SEM image of S/rGO@mC-MnO-800 cathode material[51]. (d, e) TEM images of S/rGO@mC-MnO-800 cathode material[51]. (f) Diagram of configuration of Li-S batteries with CeO2−x@C-rGO/CNTs separator[52]. (g) Cycling behavior at 1 C, 2 C, 0.5 C respectively[52]. Reproduced with permission

Figure 5. (a) Schematic illustration of synthesis process and the corresponding function of Co@NCNTs/Co-TiO2[62]. (b) Schematic diagram of polysulfides conversion process on ZCO-QDs surface[64]. (c) Schematic illustration of synergistic advantages of yolk-shell MnO2@HCS-S and the corresponding cycling performance at 1 C[66]. (d) Synthesis route of VOx@C yolk-shell nanospheres under high-frequency ultrasonic excitation[68]. (e) Diagram of the preparation process of the CC@Co3O4[71]. (f) Schematic illustration of the synthesis process of ZnO NAs assembled on NCFNs-MWCNTs scaffold[73]. Reproduced with permission

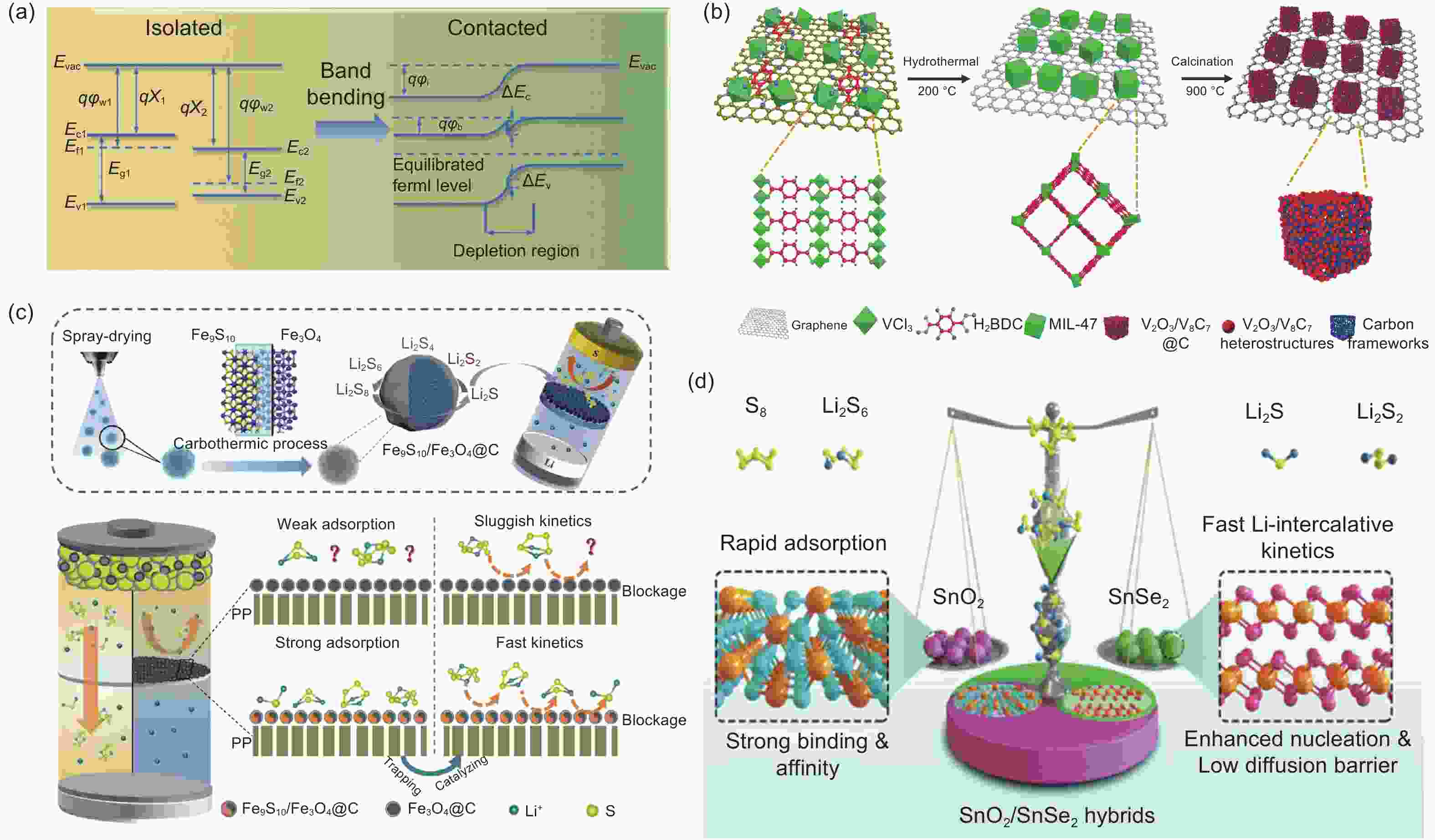

Figure 6. (a) Diagram of formation mechanisms of heterostructures[78]. (b) Schematic illustration of the synthesis route of V2O3/V8C7@C@G heterostructure[81]. (c) Schematic illustration of the preparation process and synergistic function of Fe9S10/Fe3O4@C heterostructure[82]. (d) Illustration of the multifunctional interlayer on modified separator constructed by SnO2/SnSe2 heterostructure[84]

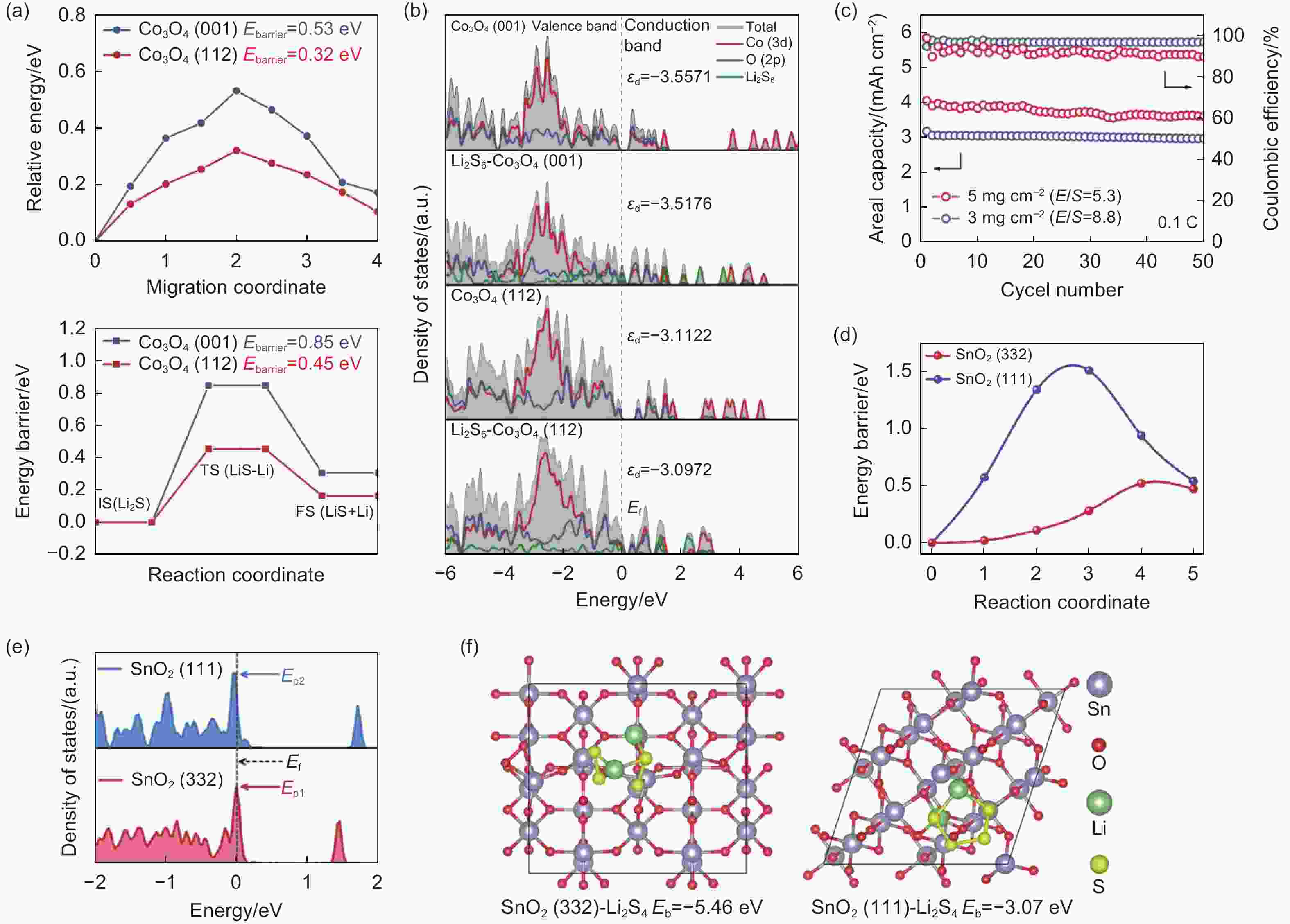

Figure 8. (a) Li+ Diffusion profiles and Li2S decomposition energy profiles on different Co3O4 crystal surfaces[94]. (b) Density of status of Co3O4 and Li2S6-Co3O4 with different crystal facets[94]. (c) Cycling performance of S@Co3O4-NP/N-rGO at 0.1 C under a high sulfur loading and a low E/S ratio[94]. (d) Li2S decomposition energy barriers on surfaces of SnO2(332) and SnO2(111)[95]. (e) DOS of Sn atoms on different SnO2 crystal facets[95]. (f) Binding energy between Li2S and different SnO2 crystal facets[95]. Reproduced with permission

Table 1. Summary of electrochemical performance of various TMOs-CM electrocatalysts in Li-S batteries

Electrocatalyst S loading/

(mg cm−2) & contentCapacity at low current/

(mAh g−1)Rate capability/

(mAh g−1)Capacity at high current/

(mAh g−1)Ref. MoO2@CNT 1.4-1.7&75% 1067 (100th, 0.2 C) 369@5 C 540 (700th, 1 C) [44] Co-SnO2@CNT 3.0&79% 767 (400th, 0.2 C) 808@2 C 710 (600th, 1 C) [45] NCF@CeO2 1.4&70% − 506@4 C 315 (1000th, 1 C) [47] Co3O4@GC/N-CNT NF 2.0&70% 712 (250th, 0.1 C) 329@2 C 319 (900th, 1 C) [48] CoTiO3@rGO 1.2&49% 1075 (500th, 0.2 C) 754@2 C 836 (500th, 1 C) [50] OV-TnQDs@PCN 2.2&79% 878 (100th, 0.1 C) 672@2 C 660 (1000th, 2 C) [56] Co@NCNTs/Co-TiO2 2.0&60% 1129 (100th, 0.2 C) 624@5 C 874 (500th, 1 C) [62] ZCO-QDs@HCS 1.3&70% − 596@5 C 675 (400th, 1 C) [64] MnO2@HCS 1.5&63% 744 (100th, 0.1 C) 765@1 C 705 (500th, 1 C) [66] MnO2-H C 1.8&60% 663 (200th, 0.2 C) 423 (1000th, 0.5 C) 621@3 C − [67] VOx@C 4.3&70% 860 (100th, 0.2 C) 540@5 C 600 (200th, 1 C) [68] GA-VOx/CB 1.0&80% 708 (200th, 0.2 C) 442@2 C 441 (600th, 1 C) [69] CC@Co3O4 4.1&— 987(200th, 0.5 C) 610@2 C 476 (500th, 2 C) [71] V2O3/V8C7@C@G 1.2-1.5&64% 1028 (200th, 0.2 C) 588@5 C 745 (1000, 1 C) [81] Fe9S10/Fe3O4@C 1.0&56% − 660@5 C 587 (500th, 1 C) [82] TiO2@MoS2 1.0-1.2&75% 902 (300th, 0.5 C) 601@5 C 578 (500th, 2 C) [83] G-mSnO2/SnSe2 1.8&64% 1341 (300th, 0.2 C) 794@8 C 1016 (1000th, 1 C) [84] GP/CNT/LNO-V 4.4&60% 962 (100th, 0.2 C) 844@1 C 571 (400th, 1 C) [88] NFBCoFe2O4-x@MWCNTs 2.0&63% 1156 (300th, 0.2 C) 746@5 C 870 (1000th, 1 C) [90] Co3O4-NP/N-rGO 1.0&60% 914 (100th, 0.2 C) 569@3 C 608 (500th, 1 C) [94] SnO2 {332}-G 1.2&68% 687 (500th, 0.5 C) 616@4 C 432 (2000th, 2 C) [95] -

[1] Geng H Y, Peng Y, Qu L T, et al. Structure design and composition engineering of carbon-based nanomaterials for lithium energy storage[J]. Advanced Energy Materials,2020,10(10):1903030. doi: 10.1002/aenm.201903030 [2] Zhao M, Li B Q, Peng H J, et al. Lithium-sulfur batteries under lean electrolyte conditions: challenges and opportunities[J]. Angew Chemie-International Edition,2020,59(31):12636-12652. doi: 10.1002/anie.201909339 [3] Yu X L, Yin Y, Ma C, et al. N-doped porous carbon@CNT nanowire as effective polysulfides adsorption-catalysis interlayer for high-performance lithium-sulfur batteries[J]. Chemical Engineering Science,2023,268:118400. doi: 10.1016/j.ces.2022.118400 [4] Tan S Y, Wu Y F, Kan S T, et al. A combination of MnO2- decorated graphene aerogel modified separator and I/N codoped graphene aerogel sulfur host to synergistically promote Li-S battery performance[J]. Electrochimica Acta,2020,348:136173. doi: 10.1016/j.electacta.2020.136173 [5] Fang R P, Chen K, Yin L C, et al. The regulating role of carbon nanotubes and graphene in lithium-ion and lithium-sulfur batteries[J]. Advanced Materials,2019,31(9):1800863. doi: 10.1002/adma.201800863 [6] Yuan C, Yang X F, Zeng P, et al. Recent progress of functional separators with catalytic effects for high-performance lithium- sulfur batteries[J]. Nano Energy,2021,84:105928. doi: 10.1016/j.nanoen.2021.105928 [7] Wang T, He J R, Cheng X B, et al. Strategies toward high-loading lithium-sulfur batteries[J]. ACS Energy Letters,2022,8(1):116-150. [8] Wu J, Ye T, Wang Y C, et al. Understanding the catalytic kinetics of polysulfide redox reactions on transition metal compounds in Li-S batteries[J]. ACS Nano,2022,16(10):15734-15759. doi: 10.1021/acsnano.2c08581 [9] Lim W G, Kim S, Jo C, et al. A comprehensive review of materials with catalytic effects in Li-S batteries: Enhanced redox kinetics[J]. Angewandte Chemie International Edition,2019,58(52):18746-18757. doi: 10.1002/anie.201902413 [10] Yao W Q, Xu J, Ma L B, et al. Recent progress for concurrent realization of shuttle-inhibition and dendrite-free lithium-sulfur batteries[J]. Advanced Materials,2023,35:2212116. doi: 10.1002/adma.202212116 [11] Chung S H, Manthiram A. Current status and future prospects of metal-sulfur batteries[J]. Advanced Materials,2019,31(27):1901125. doi: 10.1002/adma.201901125 [12] Zeng P, Su B, Wang X L, et al. In situ reconstruction of electrocatalysts for lithium-sulfur batteries: Progress and prospects[J]. Advanced Functional Materials,2023,33:2301743. doi: 10.1002/adfm.202301743 [13] Song Y Z, Cai W L, Kong L, et al. Rationalizing electrocatalysis of Li-S chemistry by mediator design: Progress and prospects[J]. Advanced Energy Materials,2019,10(11):1901075. [14] Ng S F, Lau M Y L, Ong W J. Lithium-sulfur battery cathode design: tailoring metal-based nanostructures for robust polysulfide adsorption and catalytic conversion[J]. Advanced Materials,2021,33(50):2008654. doi: 10.1002/adma.202008654 [15] Liu Y T, Liu S, Li G R, et al. Strategy of enhancing the volumetric energy eensity for lithium-sulfur batteries[J]. Advanced Materials,2021,33(8):2003955. doi: 10.1002/adma.202003955 [16] Li S L, Zhang W F, Zheng J F, et al. Inhibition of polysulfide shuttles in Li-S batteries: Modified separators and solid-state electrolytes[J]. Advanced Energy Materials,2020,11(2):2000779. [17] Huang Y Z, Lin L, Zhang C K, et al. Recent advances and strategies toward polysulfides shuttle inhibition for high- performance Li-S batteries[J]. Advanced Science,2022,9(12):2106004. doi: 10.1002/advs.202106004 [18] David L, Bhandavat R, Gurpreet Singh. MoS2/graphene composite paper for sodium-ion battery electrodes[J]. ACS Nano,2014,8(2):1759-1770. doi: 10.1021/nn406156b [19] Yu L Q, Zhao S X, Wu Q L, et al. Strengthening the interface between flower-like VS4 and porous carbon for improving its lithium storage performance[J]. Advanced Functional Materials,2020,30(16):2000427. doi: 10.1002/adfm.202000427 [20] Song Z R, Zhang G Y, Deng X L, et al. Strongly coupled interfacial engineering inspired by robotic arms enable high-performance sodium-ion capacitors[J]. Advanced Functional Materials,2022,32(38):2205453. doi: 10.1002/adfm.202205453 [21] Wang J M, Wang B B, Liu X J, et al. Prussian blue analogs (PBA) derived porous bimetal (Mn, Fe) selenide with carbon nanotubes as anode materials for sodium and potassium ion batteries[J]. Chemical Engineering Journal,2020,382:123050. doi: 10.1016/j.cej.2019.123050 [22] Ruan S J, Luo D, Li M, et al. Synthesis and functionalization of 2D nanomaterials for application in lithium-based energy storage systems[J]. Energy Storage Materials,2021,38:200-230. doi: 10.1016/j.ensm.2021.03.001 [23] Li S, Cen Y, Xiang Q, et al. Vanadium dioxide-reduced graphene oxide binary host as an efficient polysulfide plague for high- performance lithium-sulfur batteries[J]. Journal of Materials Chemistry A,2019,7(4):1658-1668. doi: 10.1039/C8TA10422K [24] Ding M, Huang S Z, Wang Y, et al. Promoting polysulfide conversion by catalytic ternary Fe3O4/carbon/graphene composites with ordered microchannels for ultrahigh-rate lithium-sulfur batteries[J]. Journal of Materials Chemistry A,2019,7(43):25078-25087. doi: 10.1039/C9TA06489C [25] Li Z, Zhang F, Cao T, et al. Highly stable lithium-sulfur batteries achieved by a SnS/porous carbon nanosheet architecture modified Celgard separator[J]. Advanced Functional Materials,2020,30(48):2006297. doi: 10.1002/adfm.202006297 [26] Liu L, Li Y K, Zhang Y G, et al. CoP@C with chemisorption-catalysis effect toward lithium polysulfides as multifunctional interlayer for high-performance lithium-sulfur batteries[J]. Electrochimica Acta,2022,419:140391. doi: 10.1016/j.electacta.2022.140391 [27] Qiao S M, Wang Q, Zhang Q, et al. Sacrificial template method to synthesize atomically dispersed Mn atoms on S, N-codoped carbon as a separator modifier for advanced Li-S batteries[J]. ACS Applied Materials & Interfaces,2022,14(37):42123-42133. [28] Salhabi E H M, Zhao J L, Wang J Y, et al. Hollow multi-shelled structural TiO2−x with multiple spatial confinement for long-life lithium-sulfur batteries[J]. Angewandte Chemie-International Edition,2019,58(27):9078-9082. doi: 10.1002/anie.201903295 [29] Lin Y, Li J C, Xie W J, et al. FeCoNi ternary nano-alloys embedded in a nitrogen-doped porous carbon matrix with enhanced electrocatalysis for stable lithium-sulfur batteries[J]. ACS Applied Materials & Interfaces,2022,14(45):51001-51009. [30] Han X G, Xu Y H, Chen X Y, et al. Reactivation of dissolved polysulfides in Li-S batteries based on atomic layer deposition of Al2O3 in nanoporous carbon cloth[J]. Nano Energy,2013,2(6):1197-1206. doi: 10.1016/j.nanoen.2013.05.003 [31] Yi R W, Liu C G, Zhao Y C, et al. A light-weight free-standing graphene foam-based interlayer towards improved Li-S cells[J]. Electrochimica Acta,2019,299:479-488. doi: 10.1016/j.electacta.2019.01.015 [32] Wang B, Ruan T T, Chen Y, et al. Graphene-based composites for electrochemical energy storage[J]. Energy Storage Materials,2020,24:22-51. doi: 10.1016/j.ensm.2019.08.004 [33] Kong Z K, Li Y, Wang Y L, et al. Monodispersed MnOx-CeO2 solid solution as superior electrocatalyst for Li2S precipitation and conversion[J]. Chemical Engineering Journal,2020,392:123697. doi: 10.1016/j.cej.2019.123697 [34] Ni L B, Duan S Q, Zhang H Y, et al. A 3D Graphene/WO3 nanowire composite with enhanced capture and polysulfides conversion catalysis for high-performance Li-S batteries[J]. Carbon,2021,182:335-347. doi: 10.1016/j.carbon.2021.05.056 [35] Chen M H, Li T Y, Li Y, et al. Rational design of a MnO nanoparticle-embedded carbon nanofiber interlayer for advanced lithium-sulfur batteries[J]. ACS Applied Energy Materials,2020,3(11):10793-10801. doi: 10.1021/acsaem.0c01855 [36] Yang R L, Du H W, Lin Z Q, et al. ZnO nanoparticles filled tetrapod-shaped carbon shell for lithium-sulfur batteries[J]. Carbon,2019,141:258-265. doi: 10.1016/j.carbon.2018.09.060 [37] Luo Y H, Ouyang Z Y, Lin Y, et al. Revealing the synergistic mechanism of multiply nanostructured V2O3 hollow nanospheres integrated with doped N, Ni heteroatoms, in-situ grown carbon nanotubes and coated carbon nanolayers for the enhancement of lithium-sulfur batteries[J]. Journal of Colloid and Interface Science,2022,612:760-771. doi: 10.1016/j.jcis.2021.12.193 [38] Sun Q, Cheng X M, Ma C, et al. NiSe nanoparticles decorated corn stalk derived 2D carbon nanosheet as separator modifier for high-performance lithium-sulfur batteries[J]. Journal of Power Sources,2023,585:233645. doi: 10.1016/j.jpowsour.2023.233645 [39] Yao W Q, Tian C X, Yang C, et al. P-doped NiTe2 with Te-vacancies in lithium-sulfur batteries prevents shuttling and promotes polysulfide conversion[J]. Advanced Materials,2022,34(11):2106370. doi: 10.1002/adma.202106370 [40] Sun R, Bai Y, Bai Z, et al. Phosphorus vacancies as effective polysulfide promoter for high-energy-density lithium-sulfur batteries[J]. Advanced Energy Materials,2022,12(12):2102739. doi: 10.1002/aenm.202102739 [41] Ruan S J, Huang Z C, Cai W D, et al. Enabling rapid polysulfide conversion kinetics by using functionalized carbon nanosheets as metal-free electrocatalysts in durable lithium-sulfur batteries[J]. Chemical Engineering Journal,2020,385:123840. doi: 10.1016/j.cej.2019.123840 [42] Ma C, Zheng Z F, Jia X F, et al. Promoting the synergistic effect of sulfur immobilization and polysulfides trapping by nitrogen functionalized interconnected hollow carbon nanocages for high-performance lithium-sulfur batteries[J]. Journal of Power Sources,2021,486:229358. doi: 10.1016/j.jpowsour.2020.229358 [43] Fu C Y, Oviedo M B, Zhu Y H, et al. Confined lithium-sulfur reactions in narrow-diameter carbon nanotubes reveal enhanced electrochemical reactivity[J]. ACS Nano,2018,12(10):9775-9784. doi: 10.1021/acsnano.7b08778 [44] Choi C, Lee D Y, Park J B, et al. Separators modified using MoO2@carbon nanotube nanocomposites as dual-mode Li-polysulfide anchoring materials for high-performance anti-self-discharge lithium-sulfur batteries[J]. ACS Sustainable Chemistry & Engineering,2020,8(40):15134-15148. [45] Yao Y, Chang C Y, Li R R, et al. Intrinsic catalytic sites-rich co-doped SnO2 nanoparticles enabling enhanced conversion and capture of polysulfides[J]. Chemical Engineering Journal,2022,431:134033. doi: 10.1016/j.cej.2021.134033 [46] Qiu W L, Li J, Zhang Y G, et al. Carbon nanotubes assembled on porous TiO2 matrix doped with Co3O4 as sulfur host for lithium-sulfur batteries[J]. Nanotechnology,2021,32(7):075403. doi: 10.1088/1361-6528/abc451 [47] Wen G Y, Zhang X P, Shi Z H, et al. Sphere-in-fiber hybrid of N-doped carbon/cerium dioxide as an interlayer material with superior electrocatalytic performance for lithium sulfide precipitation and conversion[J]. Journal of Colloid and Interface Science,2022,619:106-115. doi: 10.1016/j.jcis.2022.03.113 [48] Saroha R, Oh J H, Lee J S, et al. Hierarchically porous nanofibers comprising multiple core-shell Co3O4@graphitic carbon nanoparticles grafted within N-doped CNTs as functional interlayers for excellent Li-S batteries[J]. Chemical Engineering Journal,2021,426:130805. doi: 10.1016/j.cej.2021.130805 [49] Zhang H J, Liu Q Z, Ruan S J, et al. In-situ construction of g-C3N4/carbon heterostructure on graphene nanosheet: an efficient polysulfide barrier for advanced lithium-sulfur batteries[J]. Applied Surface Science,2022,578:152022. doi: 10.1016/j.apsusc.2021.152022 [50] He X M, Li B J, Lei Z H, et al. Multifunctional effects of hollow flower-like CoTiO3 microspheres wrapped by reduced graphene as sulfur host in Li-S battery[J]. Journal of Colloid and Interface Science,2022,626:963-974. doi: 10.1016/j.jcis.2022.07.015 [51] Qiu P P, Yao Y, Li W, et al. Sub-nanometric manganous oxide clusters in nitrogen doped mesoporous carbon nanosheets for high-performance lithium-sulfur batteries[J]. Nano Letters,2021,21(1):700-708. doi: 10.1021/acs.nanolett.0c04322 [52] Li Y L, Zhang X F, Zhang Q, et al. Layer-by-Layer assembly of CeO2-x@C-rGO nanocomposites and CNTs as a multifunctional separator coating for highly stable lithium-sulfur batteries[J]. ACS Applied Materials & Interfaces,2022,14(16):18634-18645. [53] Jian Z X, Zhang S C, Guan X G, et al. ZnO quantum dot-modified rGO with enhanced electrochemical performance for lithium- sulfur batteries[J]. RSC Advances,2020,10(54):32966-32975. doi: 10.1039/D0RA04986G [54] Guo R T, Li W, Huang R Q, et al. Shuttle-inhibited 3D sandwich MXene/SnO2 QDs sulfur host for high-performance lithium-sulfur batteries[J]. Journal of Alloys and Compounds,2023,937:168427. doi: 10.1016/j.jallcom.2022.168427 [55] Seon Y H, Saroha R, Cho J S. Hierarchically porous N-doped C nanofibers comprising TiO2 quantum dots and ZIF-8-derived hollow C nanocages as ultralight interlayer for stable Li-S batteries[J]. Composites Part B:Engineering,2022,237:109856. doi: 10.1016/j.compositesb.2022.109856 [56] Zhang H, Yang L, Zhang P G, et al. MXene-derived TinO2n-1 quantum dots distributed on porous carbon nanosheets for stable and long-life Li-S Batteries: Enhanced polysulfide mediation via defect engineering[J]. Advanced Materials,2021,33(21):2008447. doi: 10.1002/adma.202008447 [57] Yang L B, Wang X W, Cheng X M, et al. Regulating Fe aggregation state via unique Fe–N–V pre-coordination to optimize the adsorption-catalysis effect in high-performance lithium-sulfur batteries[J]. Advanced Functional Materials,2023,33:2303705. doi: 10.1002/adfm.202303705 [58] Li X Y, Han Z Y, Yang W H, et al. 3D ordered porous hybrid of ZnSe/N-doped carbon with anomalously high Na+ mobility and ultrathin solid electrolyte interphase for sodium-ion batteries[J]. Advanced Functional Materials,2021,31(50):2106194. doi: 10.1002/adfm.202106194 [59] Cheng H, Zhang S C, Li S Y, et al. Engineering Fe and V coordinated bimetallic oxide nanocatalyst Enables enhanced polysulfides mediation for high energy density Li-S battery[J]. Small,2022,18(28):2202557. doi: 10.1002/smll.202202557 [60] Wang J Y, Li G R, Luo D, et al. Engineering the conductive network of metal oxide-based sulfur cathode toward efficient and longevous lithium-sulfur batteries[J]. Advanced Energy Materials,2020,10(41):2002076. doi: 10.1002/aenm.202002076 [61] Zhu Z J, Yin H J, Wang Y, et al. Coexisting single-atomic Fe and Ni sites on hierarchically ordered porous carbon as a highly efficient ORR electrocatalyst[J]. Advanced Materials,2020,32(42):2004670. doi: 10.1002/adma.202004670 [62] Wei X L, Luo Y H, Du X H, et al. Porous transition metal oxide scaffold implanted with interpenetrated catalytic network enabling polysulfides restricted and dendrite free lithium-sulfur batteries[J]. Chemical Engineering Journal,2023,454:140152. doi: 10.1016/j.cej.2022.140152 [63] Xu C, Zheng S N, Guo J, et al. Cobalt-loaded three-dimensional ordered Ta/N-doped TiO2 framework as conductive multi-functional host for lithium-sulfur battery[J]. Chemical Engineering Journal,2023,463:142295. doi: 10.1016/j.cej.2023.142295 [64] Liu Y, Ma Z Y, Yang G, et al. Multifunctional ZnCo2O4 quantum dots encapsulated in carbon carrier for anchoring/catalyzing polysulfides and self-repairing lithium metal anode in lithium-Sulfur Batteries[J]. Advanced Functional Materials,2021,32(12):2109462. [65] Liang X, Hart C, Pang Q, et al. A highly efficient polysulfide mediator for lithium-sulfur batteries[J]. Nature Communications,2015,6:5682. doi: 10.1038/ncomms6682 [66] Shao Q J, Guo D C, Wang C, et al. Yolk-shell structure MnO2@Hollow carbon nanospheres as sulfur host with synergistic encapsulation of polysulfides for improved Li-S batteries[J]. Journal of Alloys and Compounds,2020,842:155790. doi: 10.1016/j.jallcom.2020.155790 [67] Zhang Y, Ma L, Tang R X, et al. Hollow carbon nanospheres coated by δ-MnO2 as S host to enhance the catalytic conversion of polysulfides in Li-S batteries[J]. Applied Surface Science,2022,585:152498. doi: 10.1016/j.apsusc.2022.152498 [68] Ji M Z, Ni J, Liang X, et al. Biomimetic synthesis of VOx@C yolk-shell nanospheres and their application in Li-S Batteries[J]. Advanced Functional Materials,2022,32(48):2206589. doi: 10.1002/adfm.202206589 [69] Zhang Y Z, Ge X, Kang Q, et al. Vanadium oxide nanorods embed in porous graphene aerogel as high-efficiency polysulfide-trapping -conversion mediator for high performance lithium-sulfur batteries[J]. Chemical Engineering Journal,2020,393:124570. doi: 10.1016/j.cej.2020.124570 [70] Wang M, Tan S Y, Kan S T, et al. In-situ assembly of TiO2 with high exposure of (001) facets on three-dimensional porous graphene aerogel for lithium-sulfur battery[J]. Journal of Energy Chemistry,2020,49:316-322. doi: 10.1016/j.jechem.2020.03.011 [71] Chang Z, Dou H, Ding B, et al. Co3O4 nanoneedle arrays as a multifunctional “super-reservoir” electrode for long cycle life Li-S batteries[J]. Journal of Materials Chemistry A,2017,5(1):250-257. doi: 10.1039/C6TA07202J [72] Chen S J, Zhang J X, Wang Z Y, et al. Electrocatalytic NiCo2O4 nanofiber arrays on carbon cloth for flexible and high-loading Lithium-Sulfur Batteries[J]. Nano Letters,2021,21(12):5285-5292. doi: 10.1021/acs.nanolett.1c01422 [73] Yao L, Dong X W, Zhang C R, et al. Metal oxide nanoprism-arrays assembled in N-doped carbon foamy nanoplates that have efficient polysulfide-retention for ultralong-cycle-life lithium-sulfur batteries[J]. Journal of Materials Chemistry A,2018,6(24):11260-11269. doi: 10.1039/C8TA03012J [74] Chu R R, Nguyen T T, Bai Y Q, et al. Uniformly controlled treble boundary using enriched adsorption sites and accelerated catalyst cathode for robust lithium-sulfur batteries[J]. Advanced Energy Materials,2022,12(9):2102805. doi: 10.1002/aenm.202102805 [75] Sun J M, Liu Y H, Bi J X, et al. Interface engineering toward expedited Li2S deposition in lithium–sulfur batteries: A critical review[J]. Advanced Materials,2023,35:2211168. doi: 10.1002/adma.202211168 [76] Deng S G, Guo T Z, Heier J, et al. Unraveling polysulfide's adsorption and electrocatalytic conversion on metal oxides for Li-S batteries[J]. Advanced Science,2023,10(5):2204930. doi: 10.1002/advs.202204930 [77] Zhao X, Liu M J, Wang Y C, et al. Designing a built-in electric field for efficient energy electrocatalysis[J]. ACS Nano,2022,16(12):19959-19979. doi: 10.1021/acsnano.2c09888 [78] Li Y, Zhang J W, Chen Q G, et al. Emerging of heterostructure materials in energy storage: A Review[J]. Advanced Materials,2021,33(27):2100855. doi: 10.1002/adma.202100855 [79] Cao Z X, Jia J Y, Chen S N, et al. Integrating polar and conductive Fe2O3-Fe3C interface with rapid polysulfide diffusion and conversion for high-performance lithium sulfur batteries[J]. ACS Applies Materials & Interfaces,2019,11(43):39772-39781. [80] Liang X, Kwok C Y, Lodi-Marzano F, et al. Tuning transition metal oxide-Sulfur interactions for long life lithium sulfur batteries: the “goldilocks” principle[J]. Advanced Energy Materials,2016,6(6):1501636. doi: 10.1002/aenm.201501636 [81] Zhang L, Liu Y C, Zhao Z D, et al. Enhanced polysulfide regulation via porous catalytic V2O3/V8C7 heterostructures derived from metal-organic frameworks toward high- performance Li-S Batteries[J]. ACS Nano,2020,14(7):8495-8507. doi: 10.1021/acsnano.0c02762 [82] Xu Z, Wang Z, Wang M R, et al. Large-scale synthesis of Fe9S10/Fe3O4@C heterostructure as integrated trapping-catalyzing interlayer for highly efficient lithium-sulfur batteries[J]. Chemical Engineering Journal,2021,422:130049. doi: 10.1016/j.cej.2021.130049 [83] Lee J, Choi C, Park J B, et al. Optimally arranged TiO2@MoS2 heterostructures with effectively induced built-in electric field for high-performance lithium-sulfur batteries[J]. Journal of Energy Chemistry,2023,10(83):496-508. [84] Yao W Q, Xu J, Cao Y J, et al. Dynamic intercalation-conversion site supported ultrathin 2D mesoporous SnO2/SnSe2 hybrid as bifunctional polysulfide immobilizer and lithium regulator for lithium-sulfur chemistry[J]. ACS Nano,2022,16(7):10783-10797. doi: 10.1021/acsnano.2c02810 [85] Zhu X R, Zhang X H, Li Y F, et al. Exploring transition metal oxide-based oxygen vacancy supercapacitors: A review[J]. Journal of Energy Storage,2024,80:110350. [86] Shi Z X, Li M T, Sun J Y, et al. Defect engineering for expediting Li-S chemistry: Strategies, mechanisms, and perspectives[J]. Advanced Energy Materials,2021,11(23):2100332. doi: 10.1002/aenm.202100332 [87] Song Y, Li H, Li J F, et al. Rationalizing the impact of oxygen vacancy on polysulfide conversion kinetics for highly efficient lithium-sulfur batteries[J]. Journal of Energy Chemistry,2023,87:51-60.). doi: 10.1016/j.jechem.2023.08.003 [88] Zou K Y, Zhou T F, Chen Y Z, et al. Defect engineering in a multiple confined geometry for robust lithium-sulfur batteries[J]. Advanced Energy Materials,2022,12(18):2103981. doi: 10.1002/aenm.202103981 [89] Hou W S, Feng P L, Guo X, et al. Catalytic mechanism of oxygen vacancies in perovskite oxides for lithium-sulfur batteries[J]. Advanced Materials,2022,34(26):2202222. doi: 10.1002/adma.202202222 [90] Hu S Y, Yi M J, Wu H, et al. Ionic-liquid-assisted synthesis of N, F, and B co-doped CoFe2O4-x on multiwalled carbon nanotubes with enriched oxygen vacancies for Li-S batteries[J]. Advanced Functional Materials,2021,32(14):2111084. [91] Jiang B, Tian D, Qiu Y, et al. High-index faceted nanocrystals as highly efficient bifunctional electrocatalysts for high-performance lithium-sulfur batteries[J]. Nano-Micro Letters,2021,14(1):40. [92] Yu Z H, Lv W, Lin Q W, et al. A (110) facet-dominated vanadium dioxide enabling bidirectional electrocatalysis for lithium-sulfur batteries[J]. ACS Nano,2021,15(10):16878-16886. doi: 10.1021/acsnano.1c07647 [93] Wang Z Y, Zhang B, Liu S, et al. Nickel-platinum alloy nanocrystallites with high-index facets as highly effective core catalyst for lithium-sulfur Batteries[J]. Advanced Functional Materials,2022,32(27):2200893. doi: 10.1002/adfm.202200893 [94] Xiao R J, Luo D, Wang J Y, et al. Oxidation states regulation of cobalt active sites through crystal surface engineering for enhanced polysulfide conversion in lithium-sulfur batteries[J]. Advanced Science,2022,9(31):2202352. doi: 10.1002/advs.202202352 [95] Jiang B, Qiu Y, Tian D, et al. Crystal facet engineering induced active tin dioxide nanocatalysts for highly stable lithium-sulfur batteries[J]. Advanced Energy Materials,2021,11(48):2102995. doi: 10.1002/aenm.202102995 -

下载:

下载: