Ablation behaviour and mechanical performance of ZrB2-ZrC-SiC modified carbon/carbon composites prepared by vacuum filtration combined with reactive melt infiltration

-

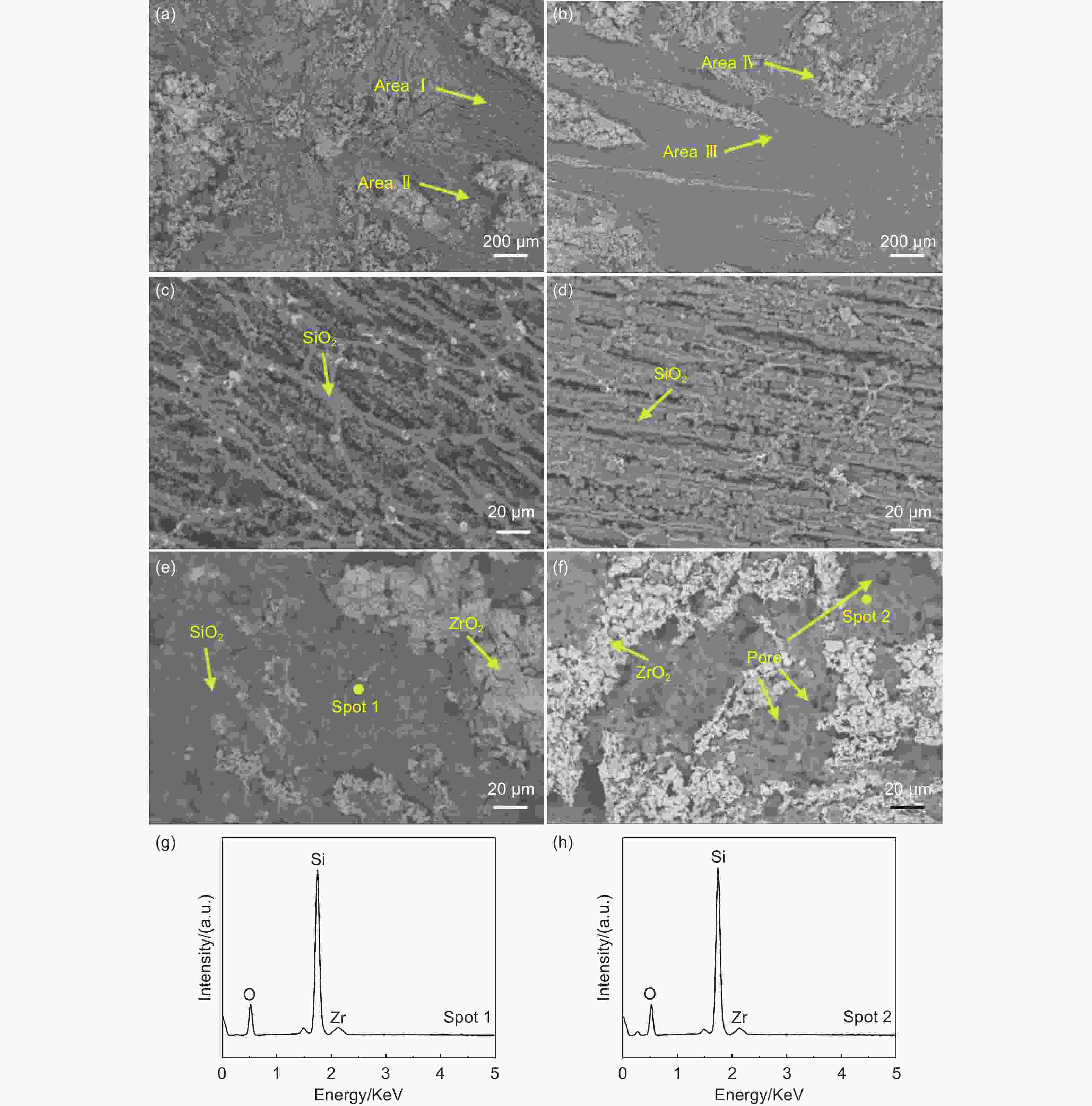

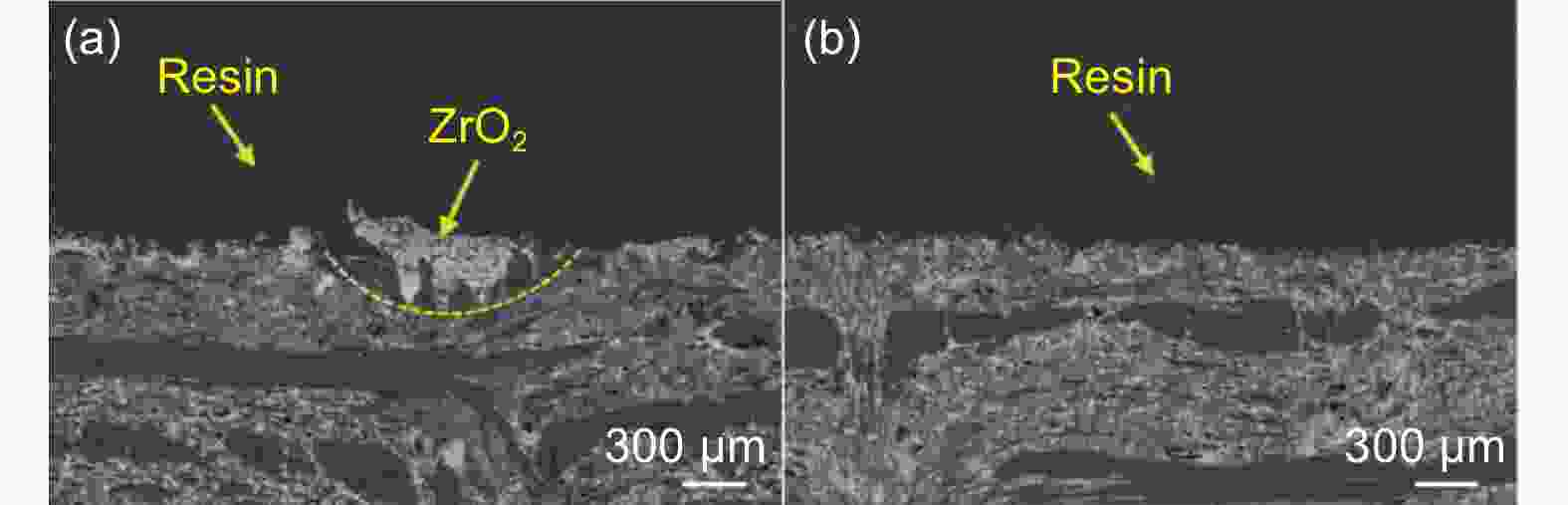

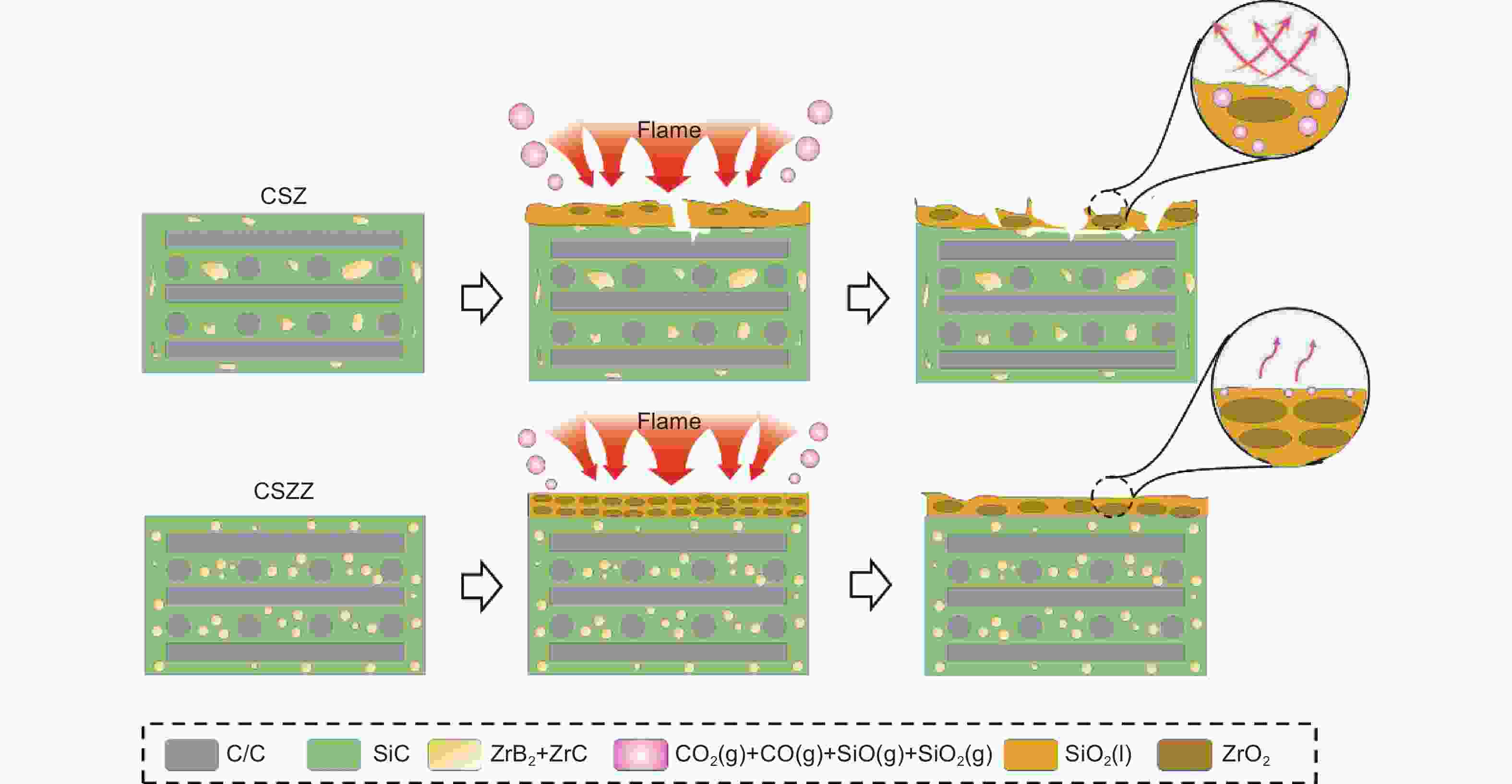

摘要: 采用真空抽滤ZrB2作为反应熔渗ZrSi2的补充,成功地将ZrB2-ZrC-SiC引入到C/C基体中,使引入的陶瓷相含量增加且分布均匀。与仅通过反应熔渗制备的C/C-ZrC-SiC相比,C/C-ZrB2-ZrC-SiC复合材料的质量烧蚀率和线性烧蚀率分别降低了68.9%和29.7%。烧蚀性能提高的原因在于B2O3的挥发带走部分热量,同时能够形成更多均匀分布的ZrO2,促进ZrO2-SiO2连续保护层的形成,从而有效地抵抗机械剥蚀,阻碍氧气的渗入。

-

关键词:

- 碳/碳复合材料 /

- ZrB2-ZrC-SiC /

- 真空抽滤 /

- 反应熔渗 /

- 烧蚀

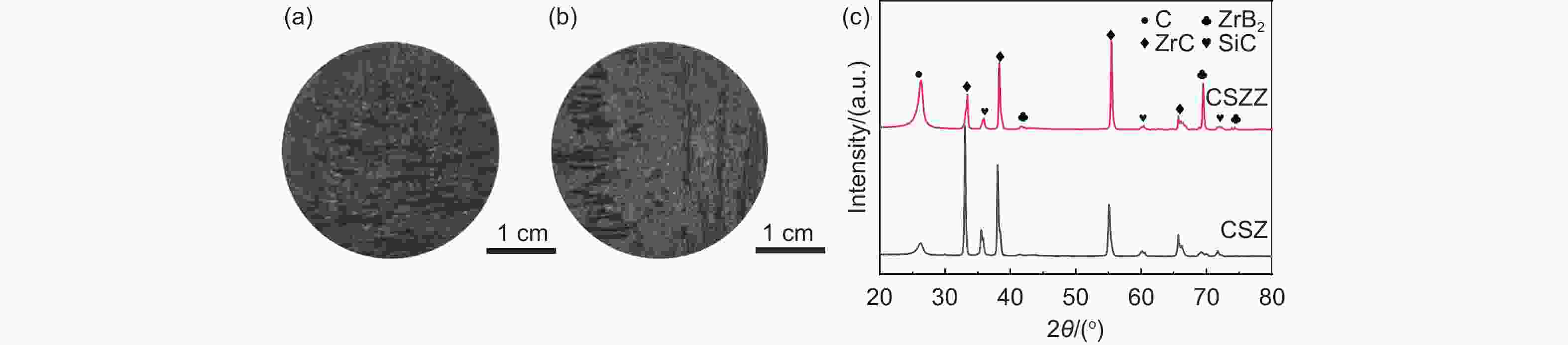

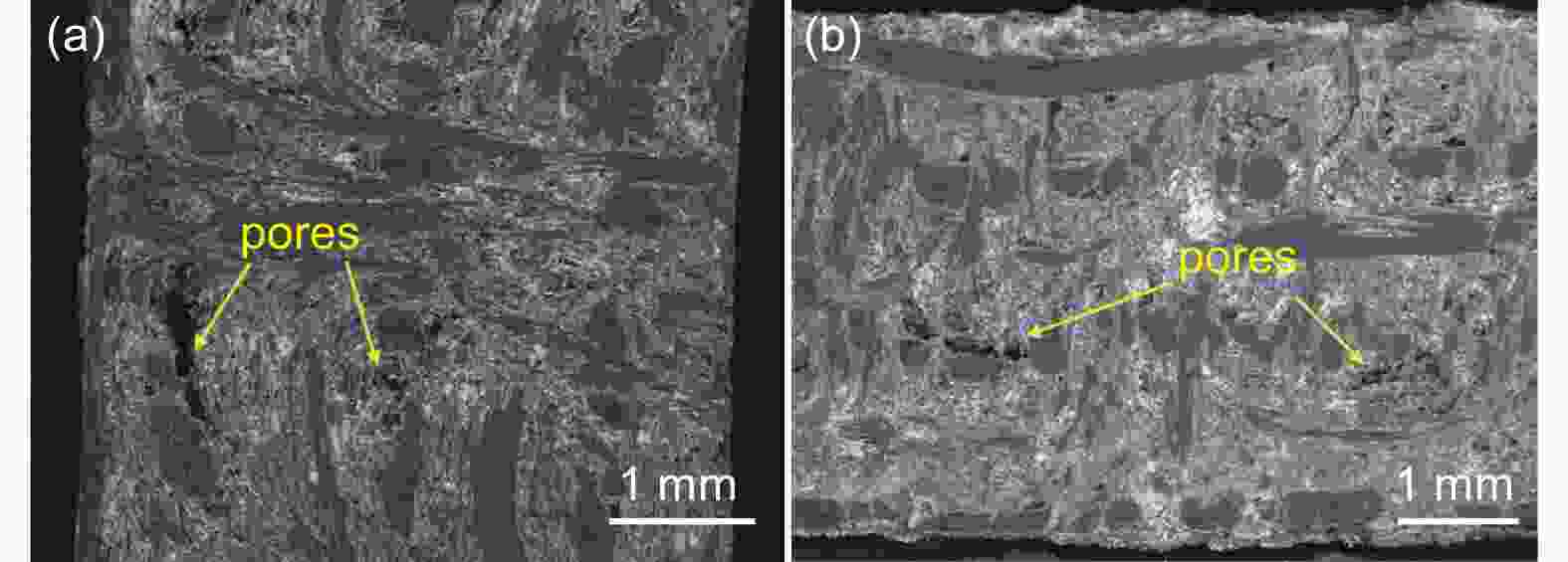

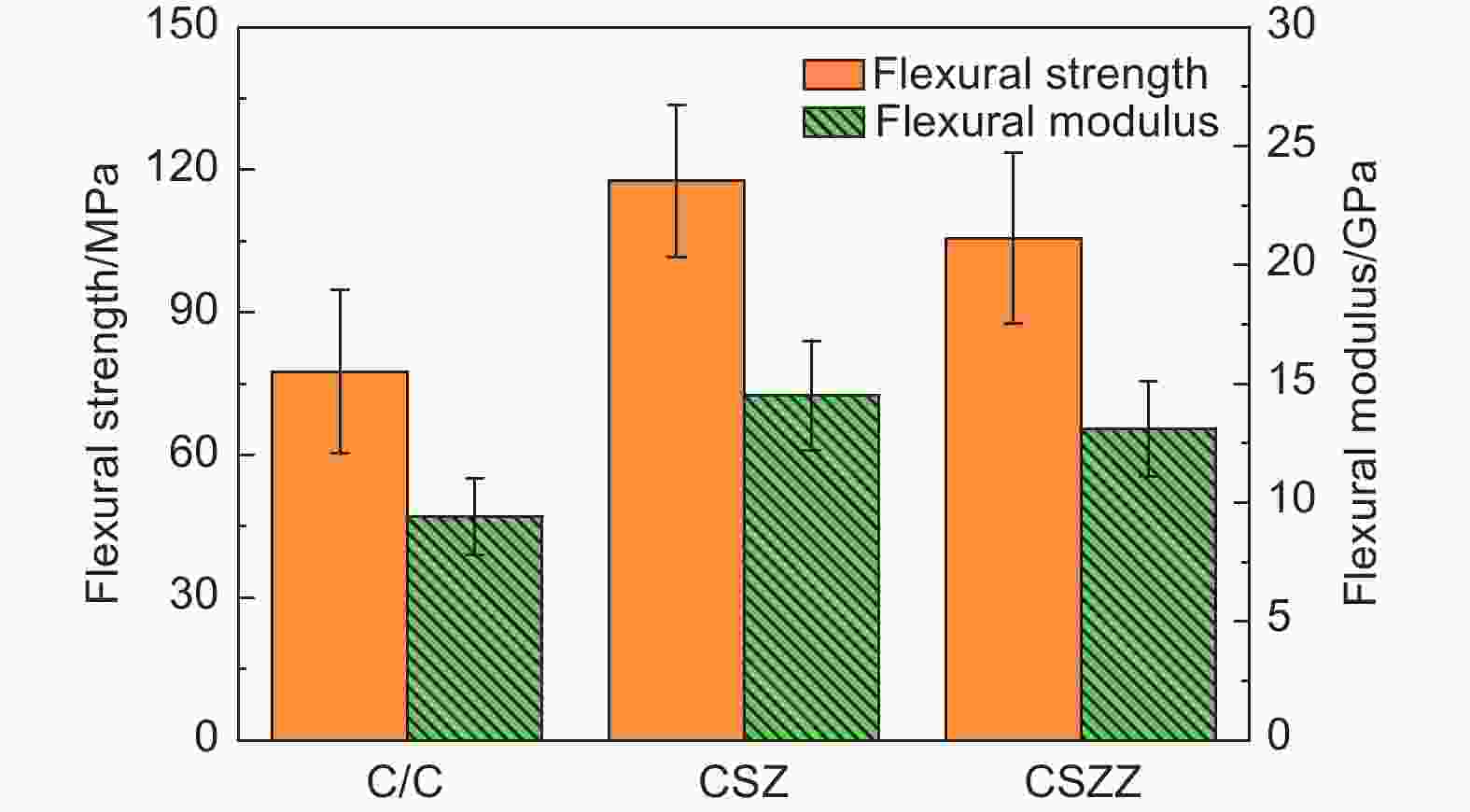

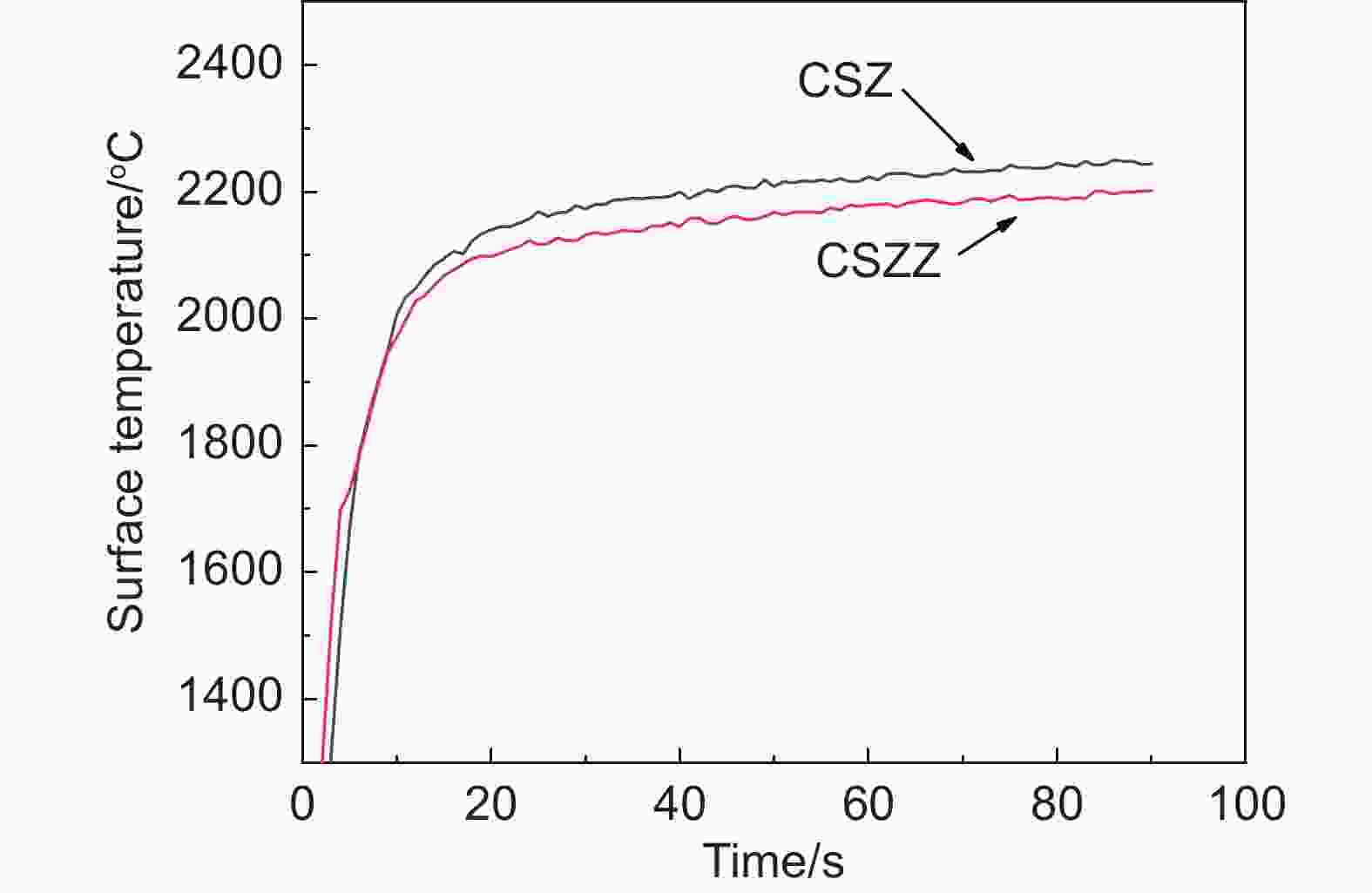

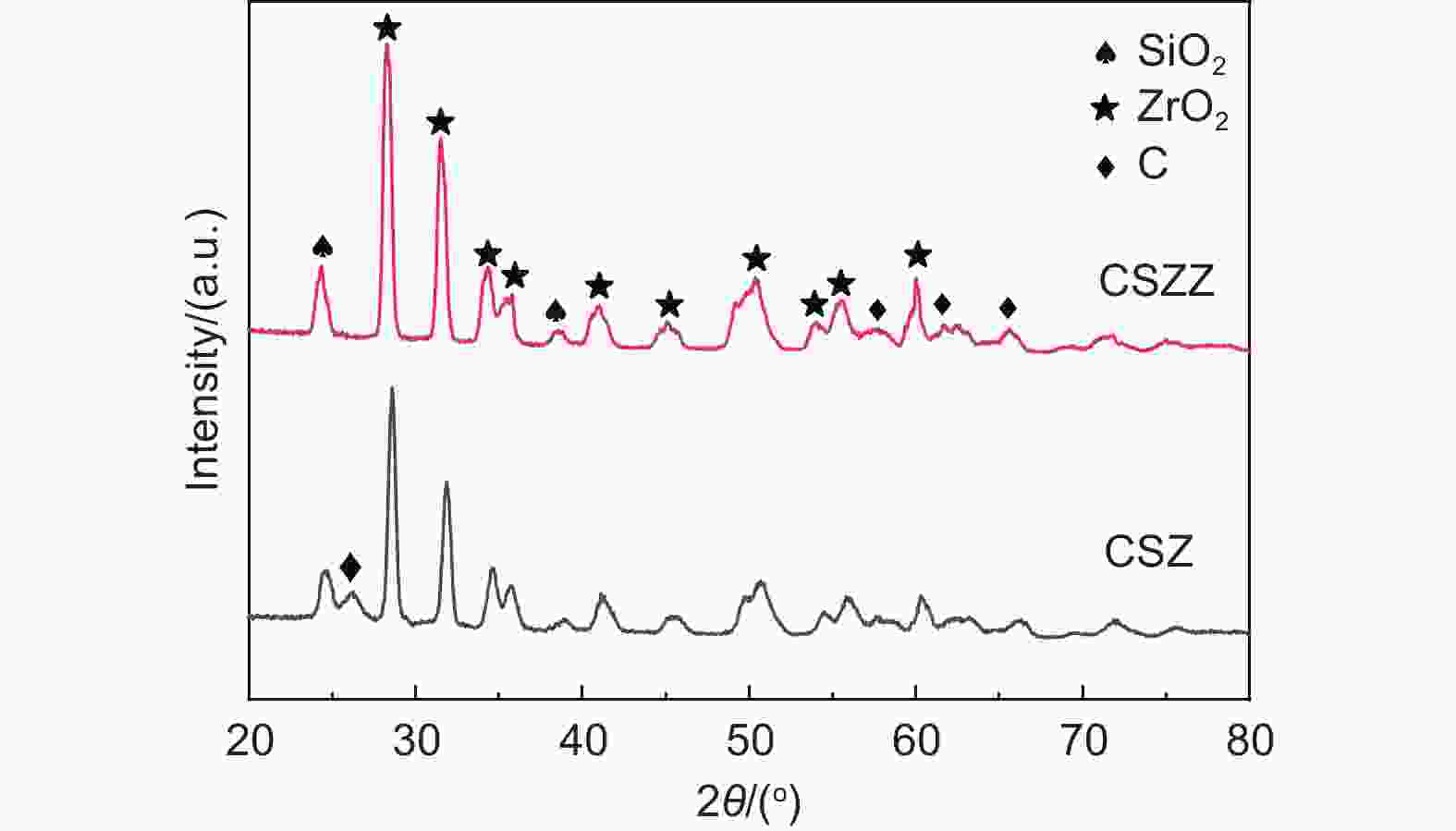

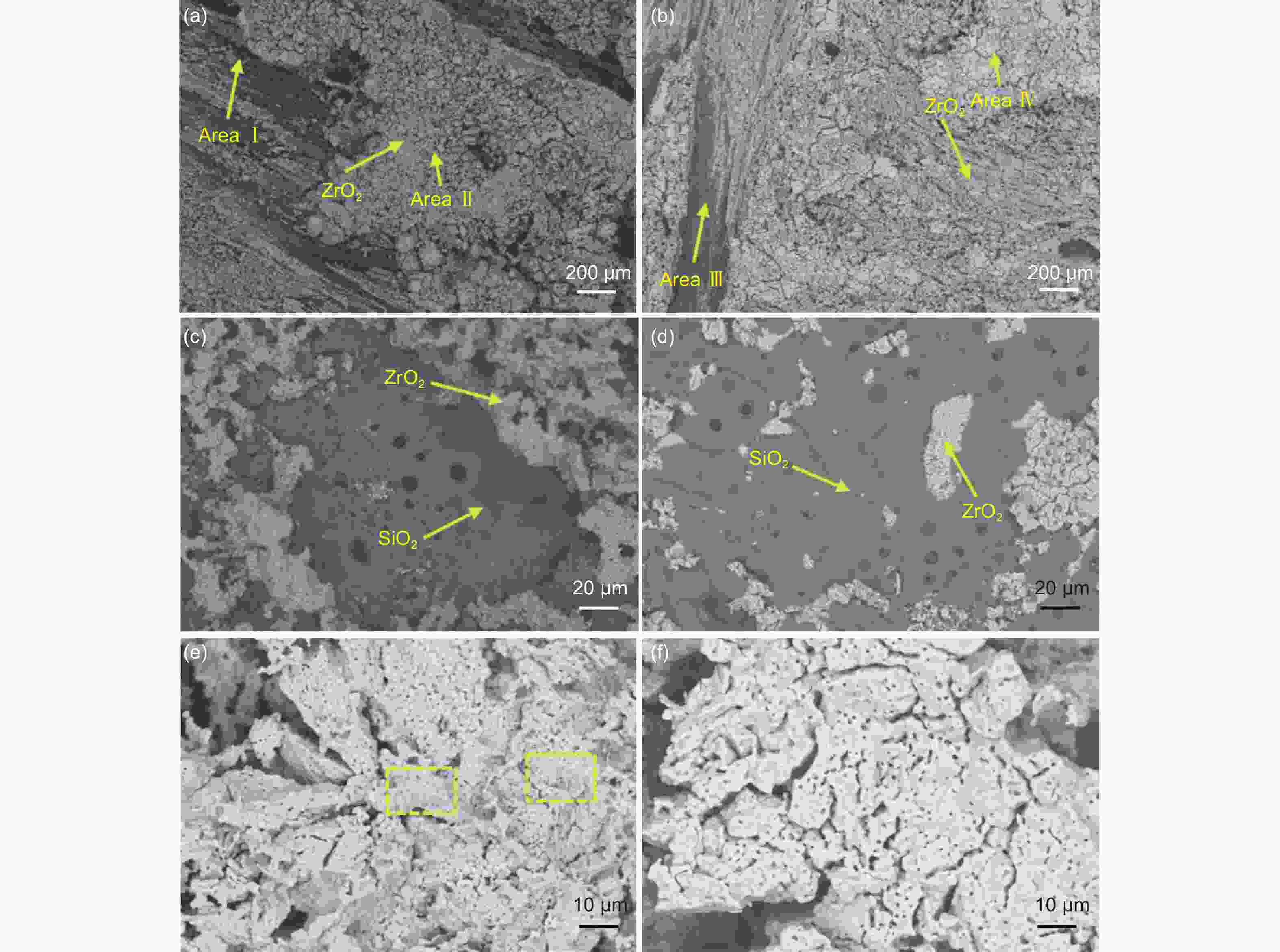

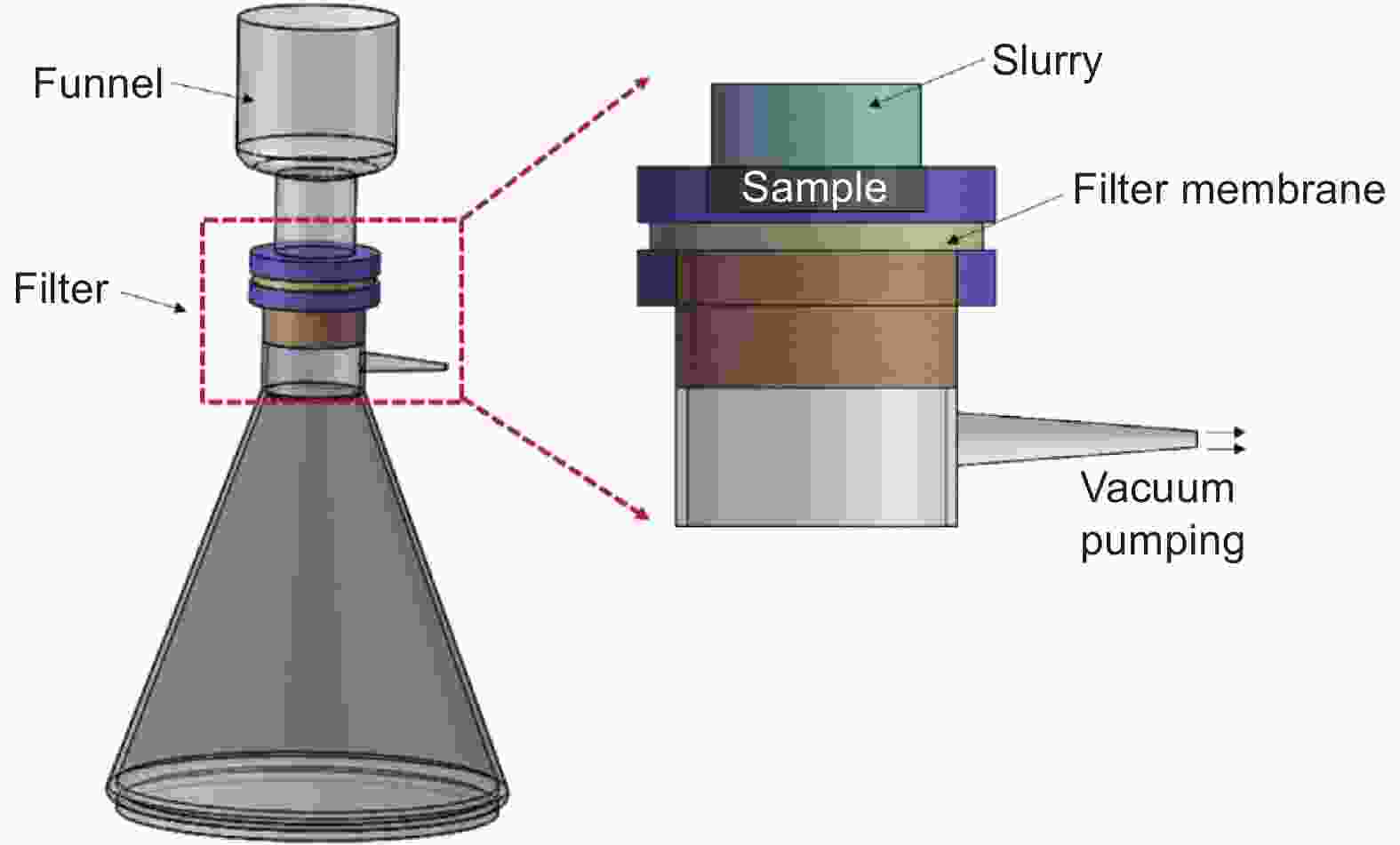

Abstract: The development of advanced aircrafts relies on high performance thermal-structural materials and composites of carbon/carbon (C/C) with ultrahigh-temperature ceramics are ideal candidates. However, traditional routes of compositing are either inefficient and expensive or lead to non-uniform distribution of ceramics in the matrix. Here, vacuum filtration of ZrB2 was successfully applied to introduce ZrB2-ZrC-SiC into C/C as a supplement for reactive melt infiltration ZrSi2, which contributed to the content increase and uniform distribution of the introduced ceramic phases. The mass and linear ablation rates of the composites were reduced by 68.9% and 29.7%, respectively, compared to those of C/C-ZrC-SiC composites prepared through reactive melt infiltration. The ablation performance was improved because of the volatilization of B2O3, taking a part of the heat away, and more uniformly distributed ZrO2 that could promote the formation of ZrO2-SiO2 continuous protective layer. This efficiently resisted the mechanical denudation and hindered the oxygen infiltration.-

Key words:

- C/C composites /

- ZrB2-ZrC-SiC /

- Vacuum filtration /

- Reactive melt infiltration /

- Ablation.

-

Table 1. Density, phase content and porosity of the composites

Sample Density/(g/cm3) Carbon content/% SiC content/% ZrC content/% ZrB2 content/% Porosity/% CSZ 2.66 35.2% 28.3% 36.5% — 10.19% CSZZ 3.06 29.4% 25.5% 32.9% 12.2% 11.68% Table 2. Ablation properties compared with other studies (Abbreviation in the table: chemical vapor infiltration (CVI)

Sample Methods Density/(g/cm3) Porosity/% Linear ablation rate/(μm/s) Mass ablation rate/(mg/s) Ref. C/C-ZrC-ZrB2-SiC CVI+PIP 1.98 13.02 0.50±0.01 2.21±0.60 [37] C/C-ZrC-ZrB2-SiC RMI+SI − − −0.65 0.69 [38] C/C-ZrC-SiC RMI 2.98 23.45 −5.30±0.50 0.70 [39] C/C-SiC-ZrC RMI 2.66 10.19 −1.72 0.61 This work C/C-SiC-ZrB2-ZrC Vacuum filtration+RMI 3.06 11.68 −1.21 0.19 This work -

[1] Fedele A, Omar S, Cantoni S, et al. Precise re-entry and landing of propellantless spacecraft[J]. Advances in Space Research,2021,68:4336-58. doi: 10.1016/j.asr.2021.09.029 [2] Savino R, Fumo M D, Paterna D, et al. Arc-jet testing of ultra-high-temperature-ceramics[J]. Aerospace Science and Technology,2010,14:178-87. doi: 10.1016/j.ast.2009.12.004 [3] Sciti D, Zoli L, Reimer T, et al. A systematic approach for horizontal and vertical scale up of sintered ultra-high temperature ceramic matrix composites for aerospace–advances and perspectives[J]. Composites Part B: Engineering, 2022, 234. [4] Fu Q G, Zhang P, Zhuang L, et al. Micro/nano multiscale reinforcing strategies toward extreme high-temperature applications: Take carbon/carbon composites and their coatings as the examples[J]. Journal of Materials Science & Technology,2022,96:31-68. [5] Li B L, Guo J G, Xun B, et al. Preparation, microstructure and properties of three-dimensional carbon/carbon composites with high thermal conductivity[J]. New Carbon Materials,2020,35:567-75. doi: 10.1016/S1872-5805(20)60510-8 [6] Li J C, Zhang Y L, Lv J S, et al. Sealing role of Ti-rich phase in HfC-ZrC-TiC coating for C/C composites during ablation above 2100°C[J]. Corrosion Science, 2022, 205. [7] Tian T, Sun W, Xiong X, et al. Novel one-step formed composite reinforcement of "Spider web like" SiCnw networks and "Z-pins like" SiC rods for ablation resistance improvement of C/C-ZrC-SiC[J]. Journal of the European Ceramic Society,2022,42:786-800. doi: 10.1016/j.jeurceramsoc.2021.10.051 [8] Yao J J, Pang S Y, Hu C L, et al. Mechanical, oxidation and ablation properties of C/(C-SiC)CVI-(ZrC-SiC)PIP composites[J]. Corrosion Science, 2020, 162. [9] Ren X R, Wang W H, Chen P, et al. Investigations of TaB2 on oxidation-inhibition property and mechanism of Si-based coatings in aerobic environment with broad temperature region for carbon materials[J]. Journal of the European Ceramic Society,2019,39:4554-64. doi: 10.1016/j.jeurceramsoc.2019.07.020 [10] Xu L, Cheng J, Li X C, et al. Preparation of carbon/carbon‐ultra high temperature ceramics composites with ultra high temperature ceramics coating[J]. Journal of American Ceramic Society,2018,101:3830-36. doi: 10.1111/jace.15565 [11] Tong M D, Fu Q G, Yao S T, et al. A novel Hf-Si-O wire drawing phenomenon after ablation of SiCnws/HfC-SiC coating on C/C composites[J]. Journal of Materiomics,2020,6:263-73. doi: 10.1016/j.jmat.2020.03.001 [12] Hui W H, Bao F T, Wei X G, et al. Ablation performance of a 4D-braided C/C composite in a parameter-variable channel of a Laval nozzle in a solid rocket motor[J]. New Carbon Materials,2017,32:365-73. doi: 10.1016/S1872-5805(17)60128-8 [13] Servadei F, Zoli L, Galizia P, et al. Preparation of UHTCMCs by hybrid processes coupling polymer infiltration and pyrolysis with hot pressing and vice versa[J]. Journal of the European Ceramic Society,2022,42:2118-26. doi: 10.1016/j.jeurceramsoc.2021.12.039 [14] Ni D, Cheng Y, Zhang J, et al. Advances in ultra-high temperature ceramics, composites and coatings[J]. Journal of Advanced Ceramics,2021,11:1-56. [15] D’Angio’ A, Zou J, Binner J, et al. Mechanical properties and grain orientation evolution of zirconium diboride-zirconium carbide ceramics[J]. Journal of the European Ceramic Society,2018,38:391-402. doi: 10.1016/j.jeurceramsoc.2017.09.013 [16] Paul A, Venugopal S, Binner J G P, et al. UHTC-carbon fibre composites: Preparation, oxyacetylene torch testing and characterisation[J]. Journal of the European Ceramic Society,2013,33:423-32. doi: 10.1016/j.jeurceramsoc.2012.08.018 [17] Zhang J P, Fu Q G, Tong M D, et al. Microstructure, ablation behavior and thermal retardant ability of C/C-HfB2 composites prepared by precursor infiltration pyrolysis combined with chemical vapor infiltration[J]. Journal of Alloys and Compounds,2018,742:123-29. doi: 10.1016/j.jallcom.2018.01.284 [18] Binner J, Porter M, Baker B, et al. Selection, processing, properties and applications of ultra-high temperature ceramic matrix composites, UHTCMCs – a review[J]. International Materials Reviews,2019,65:389-444. [19] Jin X C, Fan X L, Lu C S, et al. Advances in oxidation and ablation resistance of high and ultra-high temperature ceramics modified or coated carbon/carbon composites[J]. Journal of the European Ceramic Society,2018,38:1-28. doi: 10.1016/j.jeurceramsoc.2017.08.013 [20] Cheng Y, Lyu Y, Xie Y, et al. Starting from essence to reveal the ablation behavior and mechanism of 3D PyC Cf/ZrC-SiC composite[J]. Corrosion Science,2022,201:110261. doi: 10.1016/j.corsci.2022.110261 [21] Ren X R, Shi H L, Wang W H, et al. Influence of the ZrB2 content on the anti-oxidation ability of ZrB2-SiC coatings in aerobic environments with broad temperature range[J]. Journal of the European Ceramic Society,2020,40:203-11. doi: 10.1016/j.jeurceramsoc.2019.10.006 [22] Zhang P, Fu Q G, Liu B, et al. Development of SiC-ZrC-based ultra-high temperature ceramic coatings via composite method of polymer precursor pyrolysis plus gaseous reactive infiltration[J]. Surface and Coatings Technology, 2022, 431. [23] Ran L P, Rao F, Peng K, et al. Preparation and properties of C/C-ZrB2-SiC composites by high-solid-loading slurry impregnation and polymer infiltration and pyrolysis (PIP)[J]. Transactions of Noferrous Metals of Society of China,2019,29:2141-50. doi: 10.1016/S1003-6326(19)65120-4 [24] He L K, Sun Y H, Meng Q H, et al. Enhanced oxidation properties of ZrB2–SiC composite with short carbon fibers at 1600 °C[J]. Ceramics International,2021,47:15483-90. doi: 10.1016/j.ceramint.2021.02.114 [25] Kim K S, Lee S H, Nguyen V Q, et al. Ablation characteristics of rocket nozzle using HfC-SiC refractory ceramic composite[J]. Acta Astronautica,2020,173:31-44. doi: 10.1016/j.actaastro.2020.03.050 [26] Wang H H, Teng L, Kong J A, et al. Enhancing anti-oxidation and thermal-radiation performance of the repaired borosilicate glass coating on C/C composites by Sm-doping[J]. Journal of Materiomics,2022,8:417-26. doi: 10.1016/j.jmat.2021.07.005 [27] Ren X R, Wang W G, Sun K, et al. Preparation of MoSi2-modified HfB2-SiC ultra high temperature ceramic anti-oxidation coatings by liquid phase sintering[J]. New Carbon Materials,2022,37:603-14. doi: 10.1016/S1872-5805(21)60060-4 [28] Zhang J P, Qu J L, Fu Q G. Ablation behavior of nose-shaped HfB2-SiC modified carbon/carbon composites exposed to oxyacetylene torch[J]. Corrosion Science,2019,151:87-96. doi: 10.1016/j.corsci.2019.02.015 [29] Wang R N, Li N, Zhang J P, et al. Ablation behavior of sharp leading-edge C/C-ZrC-SiC composites using 3000°Coxyacetylene torch[J]. Corrosion Science,2022,206:110551. doi: 10.1016/j.corsci.2022.110551 [30] Chen X, Ni D, Kan Y, et al. Reaction mechanism and microstructure development of ZrSi2 melt-infiltrated Cf/SiC-ZrC-ZrB2 composites: The influence of preform pore structures[J]. Journal of Materiomics,2018,4:266-75. doi: 10.1016/j.jmat.2018.05.005 [31] Jiang J M, Wang S, Li W, et al. Preparation of 3D Cf/ZrC–SiC composites by joint processes of PIP and RMI[J]. Materials Science & Engineering A,2014,607:334-40. [32] Tang Z X, Yi M Z, Xiang Q L, et al. Mechanical and ablation properties of a C/C-HfB2-SiC composite prepared by high-solid-loading slurry impregnation combined with precursor infiltration and pyrolysis[J]. Journal of the European Ceramic Society,2021,41:6160-70. doi: 10.1016/j.jeurceramsoc.2021.06.055 [33] Wu Q, Bai H H, Yang X, et al. Significantly increasing the interfacial adhesion of carbon fiber composites via constructing a synergistic hydrogen bonding network by vacuum filtration[J]. Composites Part B: Engineering, 2021, 225. [34] Wu Q, Bai H H, Gao A J, et al. High-density grafting of carbon nanotube/carbon nanofiber hybrid on carbon fiber surface by vacuum filtration for effective interfacial reinforcement of its epoxy composites[J]. Composites Science and Technology, 2022, 225. [35] Feng W, Zhang L T, Liu Y S, et al. Fabrication of SiCf-CNTs/SiC composites with high thermal conductivity by vacuum filtration combined with CVI[J]. Materials Science & Engineering A,2016,662:506-10. [36] Liu Y, Fu Q G, Wang B B, et al. The ablation behavior and mechanical property of C/C-SiC-ZrB2 composites fabricated by reactive melt infiltration[J]. Ceramics International,2017,43:6138-47. doi: 10.1016/j.ceramint.2017.02.008 [37] Zhang M Y, Li K Z, Shi X H, et al. Effects of SiC interphase on the mechanical and ablation properties of C/C-ZrC-ZrB2-SiC composites prepared by precursor infiltration and pyrolysis[J]. Materials & design,2017,122:322-329. [38] B Z Z A, A K L, A W L, et al. Cyclic ablation behavior of C/C-ZrC-SiC-ZrB2 composites under oxyacetylene torch with two heat fluxes at the temperatures above 2000 °C[J]. Corrosion Science, 2021. [39] Wang R N, Zhang J P, Liu B, et al. Ablation of advanced C/C-ZrC-SiC leading edge composites[J]. Corrosion Science, 226(2024), 111648. [40] Wang P, Li S J, Wei C C, et al. Microstructure and ablation properties of SiC/ZrB2-SiC/ZrB2/SiC multilayer coating on graphite[J]. Journal of Alloys and Compounds,2019,781:26-36. doi: 10.1016/j.jallcom.2018.12.045 [41] Zhang D Y, Yu H Y, Wang A Z, et al. Ablation behavior and mechanisms of 3D Cf/ZrB2-SiC composite applied in long-term temperature up to 2400°C[J]. Corrosion Science,2021,190:109706. doi: 10.1016/j.corsci.2021.109706 [42] Zhuang L, Fu Q G, Liu T Y. Ablation resistance of wedge-shaped C/C-ZrB2-ZrC-SiC composites exposed to an oxyacetylene torch[J]. Corrosion Science,2016,112:462-70. doi: 10.1016/j.corsci.2016.08.010 [43] Hu C L, Pang S Y, Tang S F, et al. Ablation and mechanical behavior of a sandwich-structured composite with an inner layer of Cf/SiC between two outer layers of Cf/SiC–ZrB2–ZrC[J]. Corrosion Science,2014,80:154-63. doi: 10.1016/j.corsci.2013.11.019 [44] Wang C, Li K Z, Lu Y, et al. Effect of ablative angles on the ablation behaviors of ZrB2-SiC modified carbon/carbon composites[J]. Journal of Alloys and Compounds,2018,745:569-78. doi: 10.1016/j.jallcom.2018.02.228 [45] Zhang P, Fu Q, Cheng C, et al. Microstructure evolution of in-situ SiC-HfB2-Si ternary coating and its corrosion behaviors at ultra-high temperatures[J]. Journal of the European Ceramic Society,2021,41(13):6223-6237. doi: 10.1016/j.jeurceramsoc.2021.05.058 -

下载:

下载: