N, S co-doped coal-based hard carbon prepared by two-step carbonization and a molten salt template method for sodium storage

-

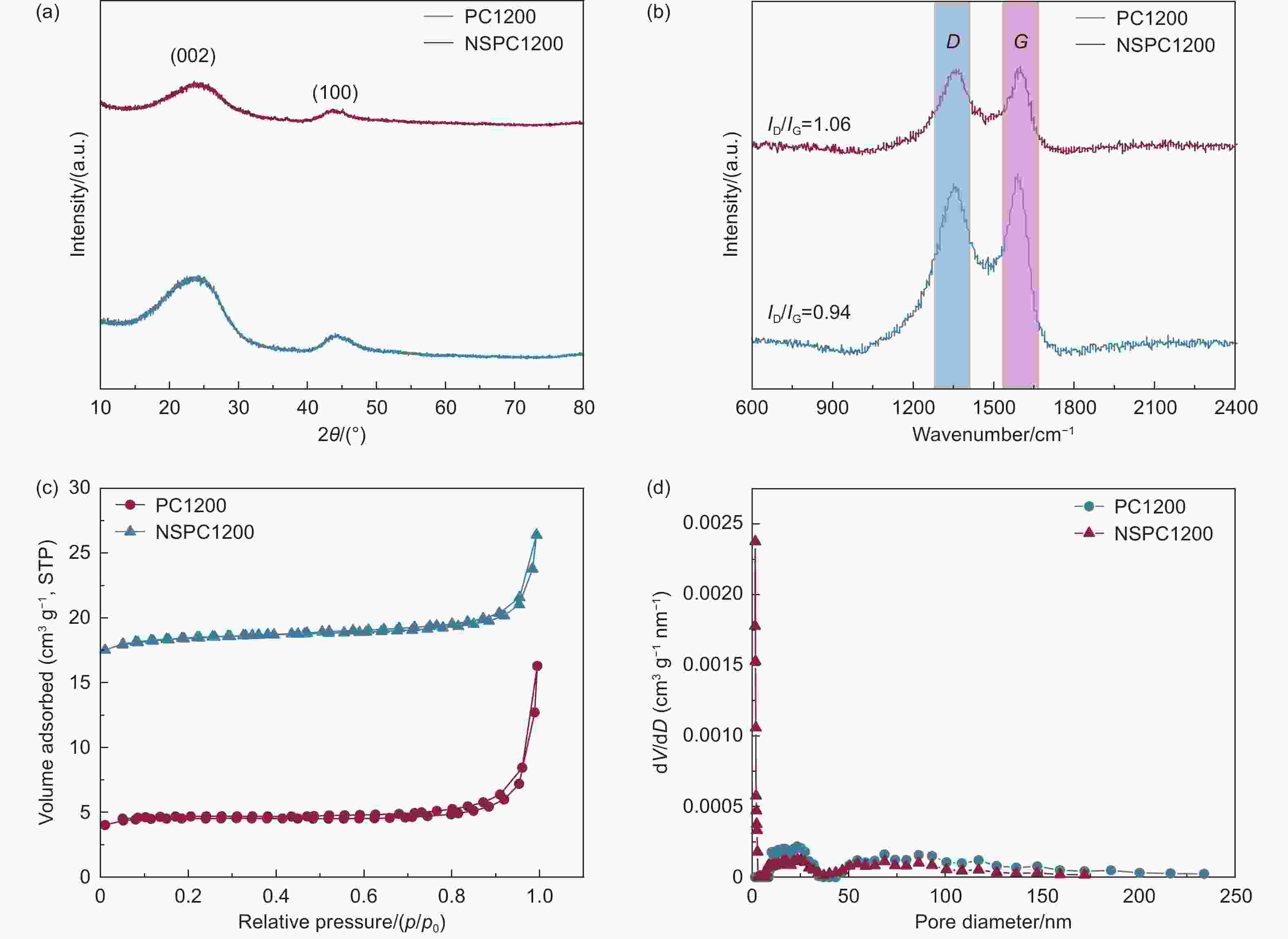

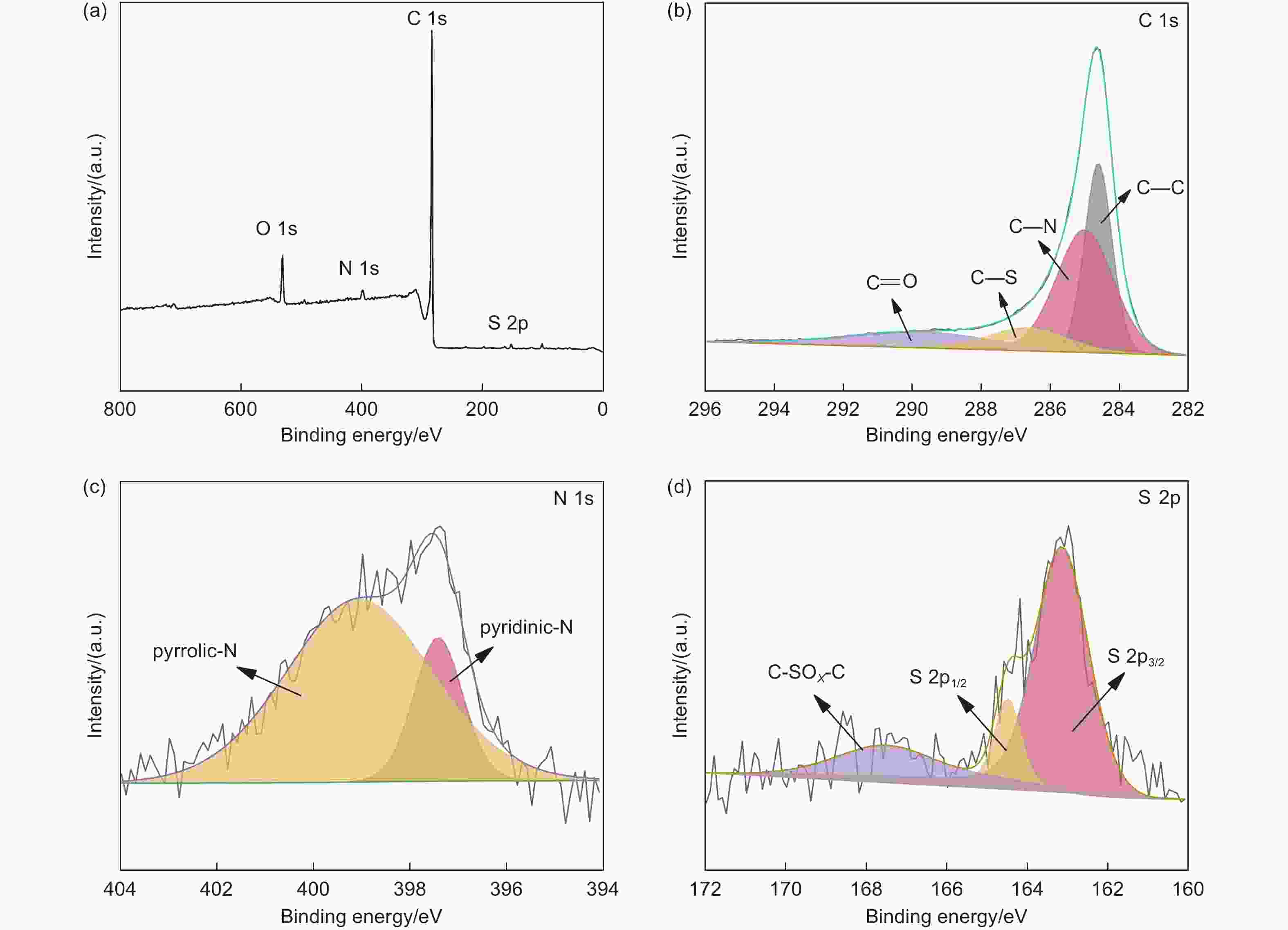

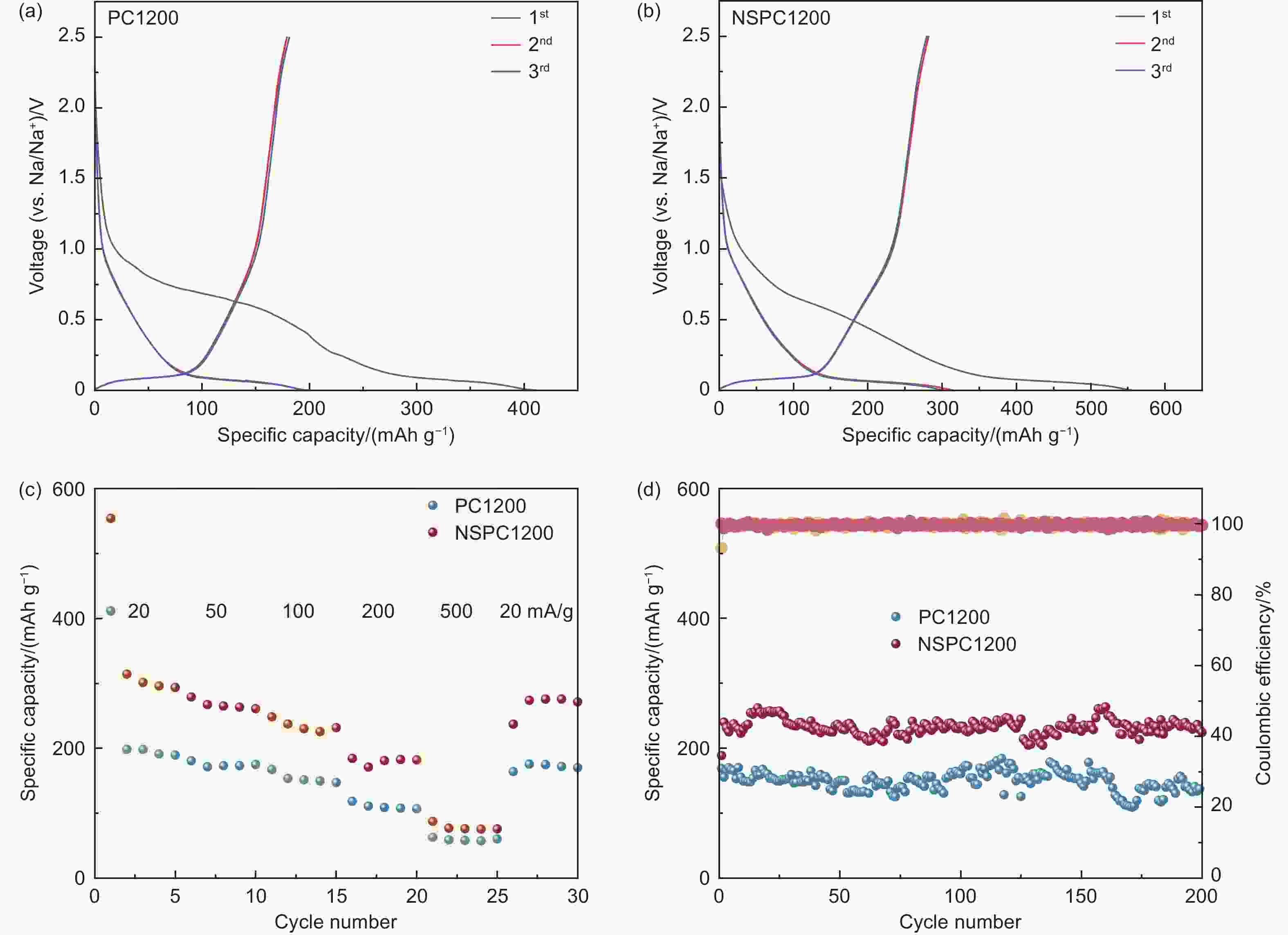

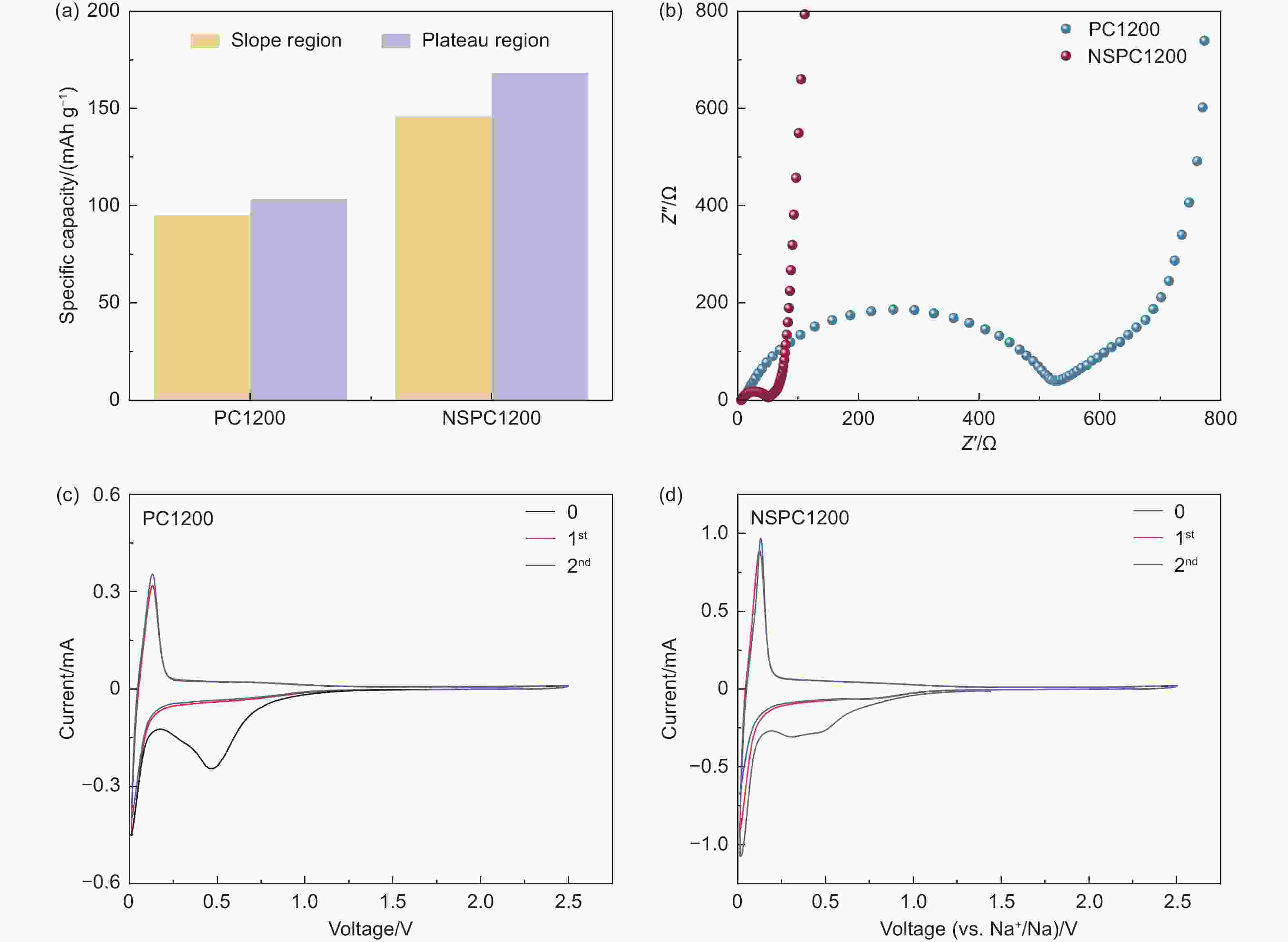

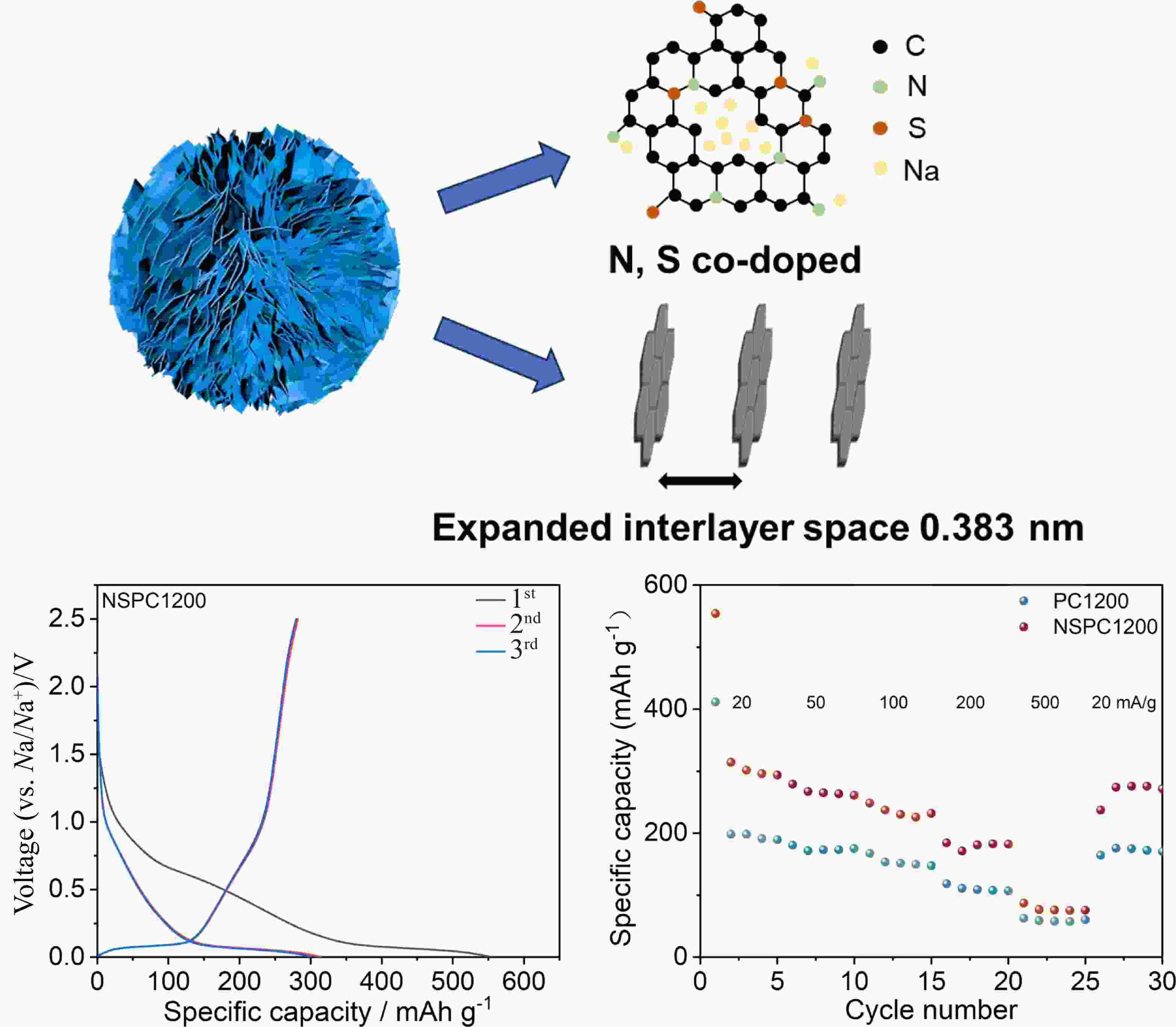

摘要: 硬炭因资源丰富、结构稳定及安全性高等优势,已成为钠离子电池常用阳极材料。其中,煤基衍生硬炭受到了广泛的关注。本工作以长焰煤为碳源,硫脲为氮硫源,NaCl为模板,通过两步炭化工艺和杂原子掺杂相结合的方法合成了N和S共掺杂的煤基硬炭(NSPC1200)。两步炭化过程在调节碳微晶结构和扩大层间距方面发挥了重要的作用。N和S的共掺杂调节了炭材料的电子结构,赋予其更多的活性位点;此外,引入NaCl作为模板有助于孔结构的构建,有利于电极和电解质之间的接触,从而实现Na+和电子的有效传输。在协同作用下,样品NSPC1200表现出优异的储钠能力,在20 mA g−1电流密度下呈现314.2 mAh g−1的可逆容量。即使在100 mA g−1下循环200次,仍保持224.4 mAh g−1的比容量。这项工作成功实现了策略性调整煤基炭材料微观结构的目标,最终获得了具有优异的电化学性能的硬炭阳极。Abstract: Hard carbon, known for its abundant resources, stable structure and high safety, has emerged as the most popular anode material for sodium-ion batteries (SIBs). Among various sources, coal-derived hard carbon has attracted extensive attention. In this work, N and S co-doped coal-based carbon material (NSPC1200) was synthesized through a combination of two-step carbonization process and heteroatom doping using long-flame coal as a carbon source, thiourea as a nitrogen and sulfur source, and NaCl as a template. The two-step carbonization process played a crucial role in adjusting the structure of carbon microcrystals and expanding the interlayer spacing. The N and S co-doping regulated the electronic structure of carbon materials, endowing more active sites. Additionally, the introduction of NaCl as a template contributed to the construction of pore structure, which facilitates better contact between electrodes and electrolytes, enabling more efficient transport of Na+ and electrons. Under the synergistic effect, NSPC1200 exhibited exceptional sodium storage capacity, reaching 314.2 mAh g−1 at 20 mA g−1. Furthermore, NSPC1200 demonstrated commendable cycling stability, maintaining a capacity of 224.4 mAh g−1 even after 200 cycles. This work successfully achieves the strategic tuning of the microstructure of coal-based carbon materials, ultimately obtaining hard carbon anode with excellent electrochemical performance.

-

Key words:

- Hard carbon /

- Sodium-ion battery /

- Coal-derived carbon /

- Two-step carbonization /

- N and S co-doped

-

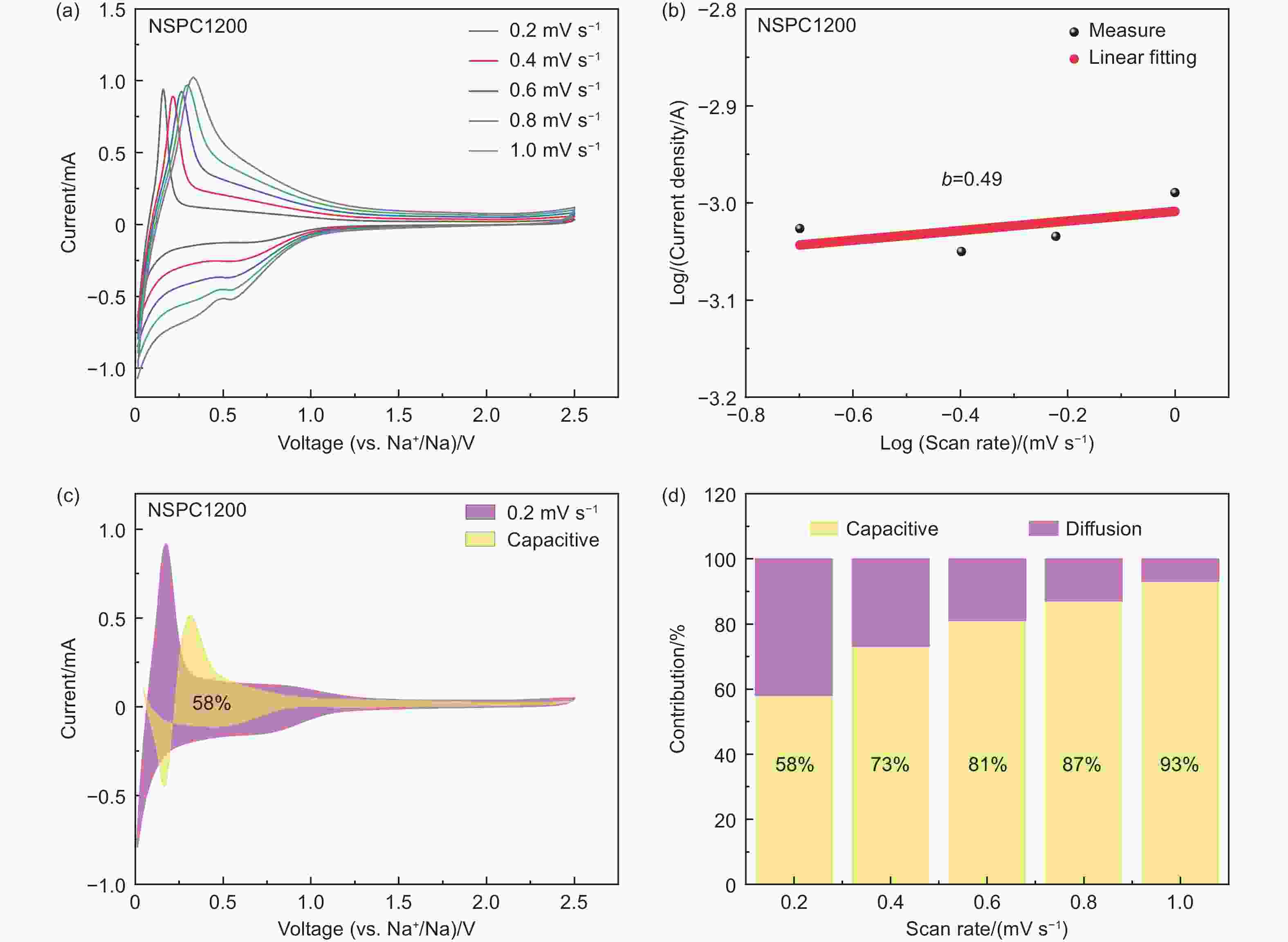

Figure 6. (a) The CV curves at various scan rates (0.1–1.0 mV s−1). (b) The relationship between the peak current and scan rate in logarithmic format. (c) The capacitive contribution to charge storage at a scan rate of 0.2 mV s−1. (d) The contribution ratio of the capacitive and intercalated charge to capacity at different scan rates

-

[1] Zhu X, Jiang Q Y, Wang T S, et al. Capacitive sodium-ion storage based on double-layered mesoporous graphene with high capacity and charging/discharging rate[J]. ChemSusChem,2019,12:4323-4331. doi: 10.1002/cssc.201900798 [2] Zhang F, Yao Y G, Wan J Y, et al. High temperature carbonized grass as a high performance sodium ion battery anode[J]. ACS Applied Materials & Interfaces,2017,9:391-397. [3] Liu Y, Dai H D, An Y K, et al. A facile and scalable synthesis of sulfur, selenium and nitrogen co-doped hard carbon anode for high performance Na- and K-ion batteries[J]. Journal of Materials Chemistry A,2020,8:14993-15001. doi: 10.1039/D0TA04513F [4] Dai Z S, Wang J H, Zhao H L, et al. Surface coupling between mechanical and electric fields empowering Ni-rich cathodes with superior cyclabilities for lithium-ion batteries[J]. Advanced Science,2022,9:2200622. doi: 10.1002/advs.202200622 [5] Xu J X, Liu Y W, Xu C W, et al. Aqueous non-metallic ion batteries: Materials, mechanisms and design strategies[J]. Coordination Chemistry Reviews,2023,474:214867. doi: 10.1016/j.ccr.2022.214867 [6] Qian J F, Wu X Y, Cao Y L, et al. High capacity and rate capability of amorphous phosphorus for sodium ion batteries[J]. Angewandte Communications,2013,52:4633-4636. [7] Gandi S, Mekprasart W, Pecharapa W, et al. Na–Ge glass anode network mixed with bismuth oxide nanocrystallites: A high capacity anode material for use in advanced sodium-ion battery design[J]. Materials Chemistry and Physics,2020,242:122568. doi: 10.1016/j.matchemphys.2019.122568 [8] Luo X Y, Tan H F, Ma T, et al. Nitrogen doped porous carbon coated antimony as high performance anode material for sodium-ion batteries[J]. Nanotechnology,2021,32:315401. doi: 10.1088/1361-6528/abf778 [9] Kim D Y, Kim D H, Kim S H, et al. Nano hardcarbon anodes for sodium-ion batteries[J]. Nanomaterials,2019,9:793. doi: 10.3390/nano9050793 [10] Yan J, Li H M, Wang K L, et al. Ultrahigh phosphorus doping of carbon for high-rate sodium ion batteries anode[J]. Advanced Energy Materials,2020,11:2003911. [11] Hoang V C, Hassan M, Gomes V G. Coal derived carbon nanomaterials-recent advances in synthesis and applications[J]. Applied Materials Today,2018,12:342-358. doi: 10.1016/j.apmt.2018.06.007 [12] Wang J, Cui Y L, Gu Y, et al. Coal-based modified carbon for high performance sodium-ion battery[J]. Solid State Ionics,2021,368:115701. doi: 10.1016/j.ssi.2021.115701 [13] Gao J T, Wang X C, Lu X Q, et al. Coal-based hierarchically porous carbon nanofibers as high-performance anode for Sodium-ion batteries[J]. ChemElectroChem,2022,9:e202200496. doi: 10.1002/celc.202200496 [14] Tang Y H, Chen J J, Mao Z Y, et al. Highly N-doped carbon with low graphitic-N content as anode material for enhanced initial coulombic efficiency of lithium-ion batteries[J]. Carbon Energy, 2022, 5. [15] Wei F, He X J, Ma L B, et al. 3D N, O-codoped egg-box-like carbons with tuned channels for high areal capacitance supercapacitors[J]. Nano-Micro Letters,2020,12:82. doi: 10.1007/s40820-020-00416-2 [16] Zhao G Y, Yu D F, Zhang H, et al. Sulphur-doped carbon nanosheets derived from biomass as high-performance anode materials for sodium-ion batteries[J]. Nano Energy,2020,67:104219. doi: 10.1016/j.nanoen.2019.104219 [17] Xue X X, Weng Y J, Jiang Z D, et al. Naturally nitrogen-doped porous carbon derived from waste crab shell as anode material for high performance sodium-ion battery[J]. Journal of Analytical and Applied Pyrolysis,2021,157:105215. doi: 10.1016/j.jaap.2021.105215 [18] Ou J K, Yang L, Zhang Z. Chrysanthemum derived hierarchically porous nitrogen-doped carbon as high performance anode material for lithium/sodium ion batteries[J]. Powder Technology,2019,344:89-95. doi: 10.1016/j.powtec.2018.11.100 [19] Chen H, Sun N, Wang Y X, et al. One stone two birds: Pitch assisted microcrystalline regulation and defect engineering in coal-based carbon anodes for sodium-ion batteries[J]. Energy Storage Materials,2023,56:532-541. doi: 10.1016/j.ensm.2023.01.042 [20] Cheng G Z, Zhang W Z, Wang W, et al. Sulfur and nitrogen codoped cyanoethyl cellulose-derived carbon with superior gravimetric and volumetric capacity for potassium ion storage[J]. Carbon Energy,2022,4:986-1001. doi: 10.1002/cey2.233 [21] Li Y M, Hu YS, Qi X G, et al. Advanced sodium-ion batteries using superior low cost pyrolyzed anthracite anode: Towards practical applications[J]. Energy Storage Materials,2016,5:191-197. doi: 10.1016/j.ensm.2016.07.006 [22] Kang M M, Zhao H Q, Ye J Q, et al. Adsorption dominant sodium storage in three-dimensional coal-based graphite microcrystal/graphene composites[J]. Journal of Materials Chemistry A,2019,7:7565-7572. doi: 10.1039/C8TA12062E [23] Qie L, Chen W M, Xiong X Q, et al. Sulfur-doped carbon with enlarged interlayer distance as a high-performance anode material for sodium-ion batteries[J]. Advanced Science,2015,2:1500195. [24] Xiao N, Wei Y B, Li H Q, et al. Boosting the sodium storage performance of coal-based carbon materials through structure modification by solvent extraction[J]. Carbon,2020,162:431-437. doi: 10.1016/j.carbon.2020.02.015 [25] Han L, Li Z M, Yang F, et al. Enhancing capacitive storage of carbonaceous anode by surface doping and structural modulation for high-performance sodium-ion battery[J]. Powder Technology,2021,382:541-549. doi: 10.1016/j.powtec.2021.01.020 [26] Li M Y, Tsai W Y, Thapaliya B P, et al. Modified coal char materials with high rate performance for battery applications[J]. Carbon,2021,172:414-421. doi: 10.1016/j.carbon.2020.10.035 [27] Huang S F, Li Z P, Wang B, et al. N-doping and defective nanographitic domain coupled hard carbon nanoshells for high performance lithium/sodium storage[J]. Advanced Functional Materials,2018,28:1706294. doi: 10.1002/adfm.201706294 [28] Li N, Wang Y, Liu L S, et al. "Self-doping" defect engineering in SnP3@gamma-irradiated hard carbon anode for rechargeable sodium storage[J]. Journal of Colloid and Interface Science,2021,592:279-290. doi: 10.1016/j.jcis.2021.02.060 [29] Pei Z X, Meng Q Q, Wei L, et al. Toward efficient and high rate sodium-ion storage: A new insight fromdopant-defect interplay in textured carbon anode materials[J]. Energy Storage Materials,2020,28:55-63. doi: 10.1016/j.ensm.2020.02.033 [30] Kim C H. J, Zhao D D, Lee G, et al. Strong, machinable carbon aerogels for high performance supercapacitors[J]. Advanced Functional Materials,2016,26:4976-4983. doi: 10.1002/adfm.201601010 [31] Song M X, Yi Z L, Xu R, et al. Towards enhanced sodium storage of hard carbon anodes: Regulating the oxygen content in precursor by low-temperature hydrogen reduction[J]. Energy Storage Materials,2022,51:620-629. doi: 10.1016/j.ensm.2022.07.005 [32] Li X, Hu X C, Zhou Li, et al. A S/N-doped high-capacity mesoporous carbon anode for Na-ion batteries[J]. Journal of Materials Chemistry A,2019,7:11976-11984. doi: 10.1039/C9TA01615E [33] Hu X D, Sun X H, Yoo S J, et al. Nitrogen-rich hierarchically porous carbon as a high-rate anode material with ultra-stable cyclability and high capacity for capacitive sodium-ion batteries[J]. Nano Energy,2019,56:828-839. doi: 10.1016/j.nanoen.2018.11.081 [34] Li Y Q, Ni B, Li X D, et al. High-performance Na-ion storage of S-doped porous carbon derived from conjugated microporous polymers[J]. Nano-Micro Letters,2019,11:1-13. doi: 10.1007/s40820-018-0235-z [35] Zhang J H, Zhang D L, Li K, et al. N, O and S co-doped hierarchical porous carbon derived from a series of samara for lithium and sodium storage: Insights into surface capacitance and inner diffusion[J]. Journal of Colloid and Interface Science,2021,598:250-259. doi: 10.1016/j.jcis.2021.04.047 [36] Li W, Zhou M, Li H M, et al. A high performance sulfur-doped disordered carbon anode for sodium ion batteries[J]. Energy & Environmental Science,2015,8:2916-2921. [37] Yang J Q, Zhou X L, Wu D H, et al. S-doped N-rich carbon nanosheets with expanded interlayer distance as anode materials for sodium-ion batteries[J]. Advanced Materials,2017,29:1604108. doi: 10.1002/adma.201604108 [38] Chen D Q, Zhang W, Luo K Y, et al. Hard carbon for sodium storage: Mechanism and optimization strategies toward commercialization[J]. Energy & Environmental Science,2021,14:2244-2262. [39] Li Q, Zhu Y Y, Zhao P Y, et al. Commercial activated carbon as a novel precursor of the amorphous carbon for high-performance sodium-ion batteries anode[J]. Carbon,2018,129:85-94. doi: 10.1016/j.carbon.2017.12.008 [40] Wu L M, Buchholz D, Vaalma C, et al. Apple-biowaste-derived hard carbon as a powerful anode material for Na-ion batteries[J]. ChemElectroChem,2016,3:292-298. doi: 10.1002/celc.201500437 [41] Chen H, Sun N, Zhu Q Z, et al. Microcrystalline hybridization enhanced coal-based carbon anode for advanced sodium-ion batteries[J]. Advanced Science,2022,9:2200023. doi: 10.1002/advs.202200023 [42] Wang Y Y, Hou B H, Lü H Y, et al. Hierarchically porous N-doped carbon nanosheets derived from grapefruit peels for high-performance supercapacitors[J]. ChemistrySelect,2016,1:1441-1447. doi: 10.1002/slct.201600133 [43] Yun Y S, Cho S Y, Shim J Y, et al. Microporous carbon nanoplates from regenerated silk proteins for supercapacitors[J]. Advanced Materials,2013,25:1993-1998. doi: 10.1002/adma.201204692 [44] Hou B-H, Wang YY, Ning QL, et al. Self-supporting, flexible, additive-free, and scalable hard carbon paper self-interwoven by 1D microbelts: Superb room/low-temperature sodium storage and working mechanism[J]. Advanced Materials,2019,31:1903125. doi: 10.1002/adma.201903125 [45] Li Q, Gao Y Z, W H Y. Investigation of pyrolysed anthracite as an anode material for sodium ion batteries[J]. New Journal Chemistry,2022,46:13575-13581. doi: 10.1039/D2NJ01258H [46] Chu Y, Zhang J, Zhang Y B, et al. Reconfiguring hard carbons with emerging sodium-ion batteries: A perspective[J]. Advanced Materials,2023,35:2212186. doi: 10.1002/adma.202212186 [47] Li Q, Liu X S, Tao Y, et al. Sieving carbons promise practical anodes with extensible low-potential plateaus for sodium batteries[J]. National Science Review,2022,9:nwac084. doi: 10.1093/nsr/nwac084 [48] Li Q, Zhang J, Zhong L X, et al. Unraveling the key atomic interactions in determining the varying Li/Na/K storage mechanism of hard carbon anodes[J]. Advanced Energy Materials,2022,12:2201734. doi: 10.1002/aenm.202201734 [49] Yu H Y, Liang H J, Gu Z Y, et al. Waste-to-wealth: Low-cost hard carbon anode derived from unburned charcoal with high capacity and long cycle life for sodium-ion/lithium-ion batteries[J]. Electrochimica Acta,2020,361:137041. doi: 10.1016/j.electacta.2020.137041 -

20240208 Supporting information.pdf

20240208 Supporting information.pdf

-

下载:

下载: